Atosa Pizza Prep Table 93 Pizzeria Guide

Share

Picture this: it's a slammed Friday night. Tickets are piling up, the kitchen is a whirlwind of flour and sauce, and your team is hustling. The difference between a smooth, profitable rush and a chaotic meltdown often boils down to one thing: your pizza prep station.

This is exactly where the Atosa pizza prep table 93 steps in. It’s not just a big cooler with a cutting board on top; it's engineered to be the command center of a high-volume pizzeria, turning that potential chaos into a streamlined, money-making machine.

Why the Atosa 93 is Your Pizzeria's Workhorse

In a busy pizzeria, every second you can shave off your ticket times goes straight to your bottom line and keeps customers coming back. A clunky setup, with staff running between separate fridges and prep areas, is a recipe for disaster. The Atosa pizza prep table 93 is the antidote to that frantic energy.

Think of it as the ultimate assembly line for your pies. Every topping is chilled to perfection, perfectly organized in its own pan, and sitting just inches from the massive prep surface. It’s an integrated system designed to bring order to the entire pizza-making process.

From Chaos to Control

I’ve seen it a hundred times: kitchens without a proper high-capacity pizza prep table quickly hit a wall. Your team wastes precious seconds walking back and forth, grabbing ingredients from different spots. Not only does this murder your ticket times, but it also opens the door to cross-contamination and food spoilage.

The Atosa 93-inch model was built to eliminate these exact bottlenecks. By bringing refrigerated storage, ingredient rails, and a huge prep area together in one unit, it creates a workflow that is both powerful and efficient for any pizzeria.

This unified design is the secret to consistency. When your crew can build every single pizza in one spot, following the same organized steps, you guarantee that the first pie of the day is just as perfect as the last one during the dinner rush.

This focus on workflow isn't just a nice-to-have; it reflects where the industry is heading. The market for professional pizza prep tables is booming, driven by customers who want fresh, custom food and the explosive growth of fast-casual pizzerias that live and die by their speed. You can learn more about the growth in the pizza prep table market on verifiedmarketreports.com.

A well-designed pizza prep table delivers real, tangible benefits you'll feel immediately:

- Faster Ticket Times: It keeps your pizza-making crew in one spot and puts every ingredient within arm's reach.

- Improved Food Safety: It holds consistent, food-safe temperatures for all your valuable pizza toppings.

- Reduced Food Waste: Organized pans and efficient cooling mean less spoilage of cheese and meats, adding more to your profit.

- A Calmer Kitchen: An organized station reduces stress, even when your pizzeria is completely slammed.

At the end of the day, the Atosa 93 isn't just another piece of stainless steel. It’s a foundational part of a successful pizzeria's strategy for speed, quality, and profitability.

Taking a Closer Look at the Atosa 93's Key Specifications

Alright, we've talked about the big picture benefits. Now, let's get into the nuts and bolts of what makes the Atosa pizza prep table 93 a real workhorse in the kitchen. These specs aren't just numbers on a page; they're the DNA of your pizzeria's future efficiency. Every single detail has been engineered for the tough, fast-paced environment of a high-volume pizza joint.

First off, let's talk materials. The entire unit—inside and out—is built from heavy-duty stainless steel. This isn't just for show; it's a strategic move for survival. In a busy pizzeria, this table is going to get hit with acidic tomato sauce, water, and constant wipe-downs. Stainless steel shrugs off that daily abuse without rusting or breaking down, making sure your investment is built to last.

The Heart of the Operation: Refrigeration and Space

The soul of any pizza prep table is its refrigeration. The Atosa 93 is designed to hold a rock-solid temperature between 34°F and 40°F. This is the non-negotiable sweet spot for food safety, keeping everything from your cheese and pepperoni to fresh veggies perfectly chilled and safe for customers.

Its powerful, eco-friendly refrigeration system makes sure every topping in the rail stays cold, even when the lids are open during a chaotic dinner rush. That reliability is what prevents costly food spoilage and helps you serve a consistently great pizza. For a deeper look at how different models stack up, you can check out our complete guide to the Atosa pizza prep table.

The real magic is how all the features work together. The powerful cooling system and the smart physical design create a seamless workflow, turning a piece of equipment into the central command post for your pizza production.

Beyond the cooling, the sheer size of the Atosa 93 is a game-changer. The massive, full-length cutting board is your canvas for creating pizzas. At over seven feet long, it gives you enough room for multiple pizza makers to work side-by-side without bumping elbows—a common bottleneck that this table solves instantly.

To give you a clearer picture, let's break down the key technical details in a simple table. These are the numbers that really matter when you're planning your pizzeria's layout and workflow.

Atosa Pizza Prep Table 93 Key Specifications at a Glance

| Feature | Specification | Benefit for Pizzerias |

|---|---|---|

| Overall Dimensions | Approximately 93 inches wide | Provides a massive workspace for multiple staff to build pizzas simultaneously, boosting output. |

| Refrigeration System | Maintains a temperature range of 34°F to 40°F | Ensures strict food safety compliance and keeps sensitive pizza toppings fresh and safe. |

| Construction | Stainless steel interior and exterior | Offers exceptional durability, resists rust from acidic sauces, and is easy to clean. |

| Storage Capacity | Generous refrigerated cabinet base | Allows for bulk storage of backup ingredients, dough trays, and sauces right where you need them. |

| Pan Capacity | Designed to hold numerous NSF-certified stainless steel pans | Enables a diverse and well-organized topping selection for maximum assembly-line speed. |

| Workspace | Full-length, deep cutting board | Creates a large, dedicated canvas for pizza assembly, reducing kitchen congestion. |

This table highlights how each specification is purpose-built to solve a real-world pizzeria problem, from maintaining food safety to maximizing your team's efficiency during the busiest rushes.

Built for Volume and Versatility

The Atosa pizza prep table 93 is clearly designed to handle serious pizza volume. The refrigerated rail comes standard with NSF-certified stainless steel pans, giving you immediate, organized access to all your core ingredients. This is the kind of layout that enables the assembly-line speed you need to keep up with a constant stream of pizza orders.

It's this blend of rugged construction, precise temperature control, and sheer capacity that truly defines the Atosa 93. It’s not just a table; it's a complete, purpose-built system designed to meet the high-stakes demands of a modern pizzeria head-on.

How Smart Features Boost Pizzeria Workflow

A great pizza prep table isn't just another piece of stainless steel. It’s the command center of your pizzeria, especially when that Friday night rush hits and the tickets start flying.

The smart, integrated design of the Atosa pizza prep table 93 is engineered to turn that potential chaos into a smooth, profitable rhythm. It tackles the common bottlenecks that can grind a pizzeria to a halt before they even start.

Picture the scene: orders are flooding in, and the demand for fresh, hot pizza feels relentless. This is the moment a well-designed station proves its worth. With the Atosa 93, every crucial element is brought together into one high-performance system. No more frantic dashes to a separate fridge for dough, another cooler for toppings, and back to a cramped prep area.

Everything is right there, right where you need it. This unified approach is all about eliminating wasted motion. Every step a pizza maker saves shaves another second off the ticket time—and those seconds add up to happier customers and more money in your pocket.

Eliminating Pizzeria Bottlenecks

The real genius of the Atosa 93 is how its features work together to create a seamless pizza production line. The refrigerated base keeps backup ingredients and dough trays perfectly chilled, directly below the main workspace. Your staff can restock on the fly without ever leaving the station.

Up top, the ingredient rail keeps a huge array of toppings organized and consistently cooled, ready for action. This immediate access is critical. Think about it: industry data shows that 36% of all pizza orders include pepperoni, which tells you just how vital it is to have popular ingredients constantly within reach.

Finally, the oversized cutting board provides a massive canvas for pizza assembly. You’re not fighting for space; you’re in control.

This ergonomic triangle—storage below, ingredients above, and workspace in front—is the key. It solves several of the most painful pizzeria problems:

- Reduces Employee Travel Time: Staff stay planted in one spot, which drastically cuts down on the physical effort and time burned assembling each pizza.

- Keeps Ingredients Organized: Designated pans mean no more hunting for toppings. This speeds up assembly and slashes the chance of order errors.

- Minimizes Cross-Contamination Risk: Keeping everything in one clean, contained, and properly refrigerated area is a huge win for your food safety protocols.

Think of the Atosa 93 not as a table, but as a "pit stop" for your pizza production. Like a Formula 1 team, your staff has every tool and component they need within arm's length to perform their job with maximum speed and precision.

Translating Design Into Pizzeria Profit

This optimized workflow has a direct and measurable impact on your pizzeria's bottom line. By streamlining the prep process, the Atosa pizza prep table 93 contributes to profitability in very real ways.

Faster ticket times mean you can serve more customers during your peak hours, which directly increases your total sales volume. It's that simple.

But it goes deeper. The efficient refrigeration and organized layout lead to a significant drop in food waste. When ingredients like cheese, meats, and fresh vegetables are kept at their ideal temperatures and are clearly visible, spoilage and accidental over-portioning plummet.

This isn't just about saving a few bucks on ingredients; it's about maximizing the value of every single item you purchase. The table doesn't just hold your pizza toppings—it protects your investment in them.

Integrating the Atosa 93 into Your Kitchen Layout

Bringing a beast like the Atosa pizza prep table 93 into your kitchen is a big move. I've seen too many pizzeria owners just try to "find a spot" for a new piece of equipment. With a 93-inch table, that’s a recipe for disaster. This isn't just another table; it's the new heart of your pizza-making operation, and where you put it will make or break your kitchen's flow.

Think about it like this: your pizzeria kitchen needs a clear path from raw dough to a boxed, ready-to-go pizza. A smart layout cuts down on wasted steps and keeps your crew from bumping into each other during a chaotic Friday night rush. That’s how you turn this table into a real profit-driver.

Designing Your Pizzeria Workflow

Over the years, I've seen two layouts work exceptionally well with a big pizza prep table like this one.

The most common setup is the linear assembly line. It’s simple, intuitive, and highly effective for pizzerias. You place the Atosa 93 right between your dough station (where the mixer and sheeter live) and the pizza oven. This creates a straight shot: dough gets prepped, slides over to the table for sauce and toppings, and then goes directly into the oven. No zig-zagging, no wasted motion.

For kitchens with a bit more elbow room, a central island configuration can be a game-changer. In this layout, the Atosa 93 becomes the command center. Your team can work from multiple sides, making it a natural hub for building pies, boxing them up, and getting orders out the door. This works wonders for pizzerias that juggle a heavy stream of both dine-in and takeout orders.

No matter which layout you choose, the goal is always the same: create a workspace where every single ingredient and tool is within arm's reach. This isn't just about comfort; it's about building an ergonomic kitchen that reduces strain on your staff and lets them work at top speed.

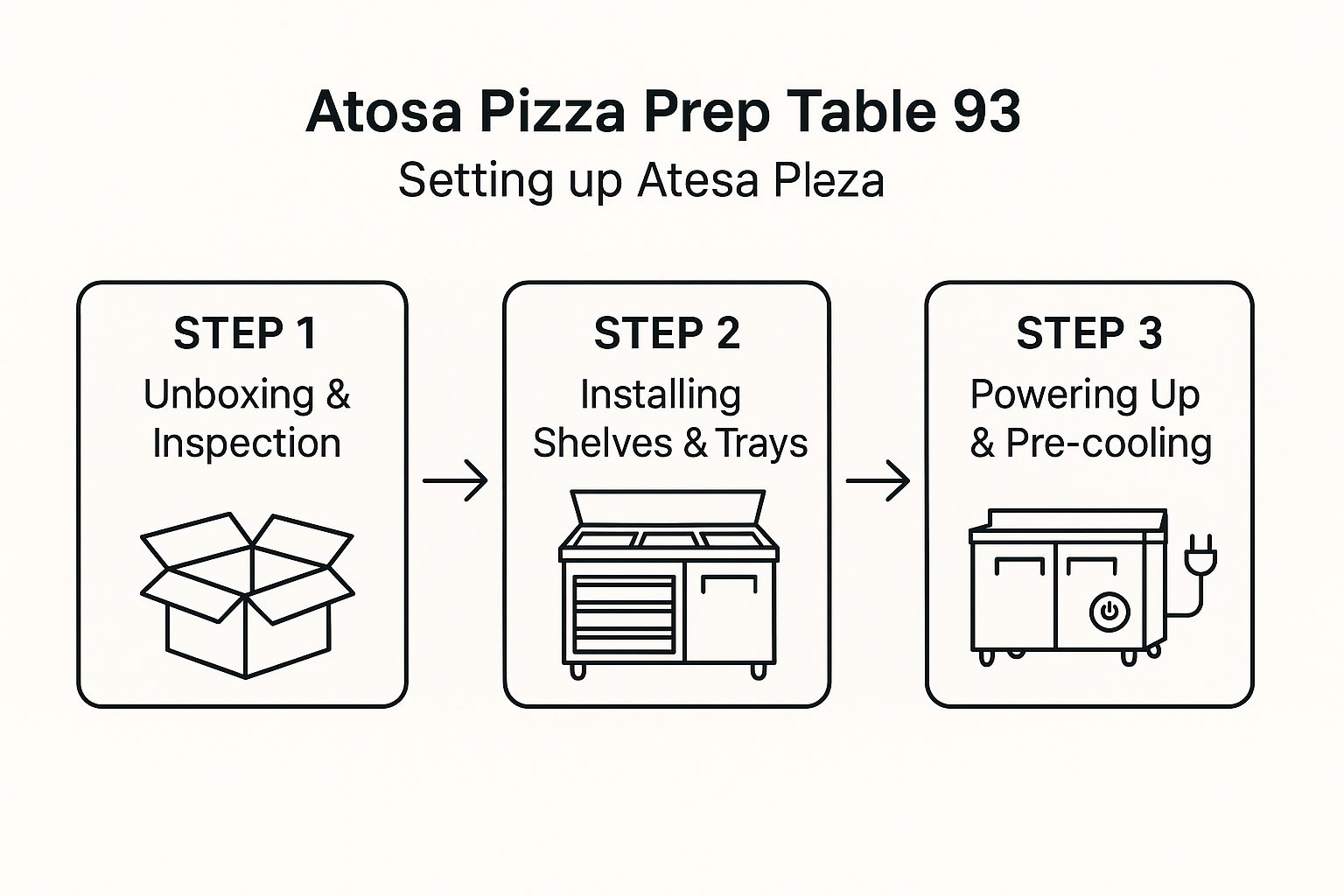

Here’s a look at the basic setup process for your new table.

As you can see, the physical setup is pretty straightforward. That frees you up to focus on the truly important part: where it lives in your pizzeria.

Critical Placement Logistics

Once you've got your workflow figured out, there are a few non-negotiable details you need to nail down for safety and performance.

- Ventilation and Clearance: That refrigeration unit needs to breathe. I've seen compressors burn out because they were shoved against a wall. Make sure there’s plenty of space around the back and sides for air to circulate freely.

- Cleaning Access: Don't wedge the unit into a tight corner. You and your crew need to get to all sides for daily wipe-downs and to access the condenser coils for maintenance. A clean machine is an efficient machine.

- Electrical Requirements: This isn't a toaster oven; it’s a powerful commercial unit. Beyond just finding an outlet, you need to ensure your kitchen is properly wired. It’s always best to invest in professional electrical installations to handle its power demands and keep your operation safe.

Thinking through these details beforehand is critical. If you're looking for more layout inspiration, our guide on choosing the right pizza prep tables for your restaurant has some great ideas. A little planning goes a long way in making sure your Atosa pizza prep table 93 is working at its best from the moment you plug it in.

Long-Term Maintenance for Peak Performance

Your Atosa pizza prep table 93 isn't just another piece of equipment; it's the engine of your pizzeria. To get years of flawless service out of that investment, you need to think about maintenance proactively. This isn't about fixing problems when they pop up—it's about making sure they never happen in the first place.

Think of it like a high-performance car. You wouldn't just drive it until the engine seizes without ever changing the oil. A little bit of consistent attention is what prevents those frantic, costly calls for emergency repairs. It’s what guarantees food safety day in and day out, and it's how you dramatically extend the life of your pizza prep table.

When you get into this rhythm, maintenance stops being a chore and becomes a strategic part of your daily workflow, protecting both your profits and your peace of mind. It all starts with a simple checklist and a consistent schedule.

Building Your Maintenance Schedule

A few minutes of attention each day and week can save you a world of hurt down the road. Creating a simple checklist for your team helps these crucial tasks become second nature, keeping your Atosa pizza prep table 93 in prime condition. After all, a well-maintained unit is an efficient one.

This is especially true for the refrigeration system. Many modern pizza prep tables use advanced tech to boost efficiency, sometimes cutting energy use by 15-20% compared to older models. But you only see those savings if the system is clean and running properly.

Here’s a practical schedule you can put into practice today:

Daily Tasks (5-10 Minutes)

- Surface Cleaning: At the end of every shift, give all stainless steel surfaces, the cutting board, and the ingredient pan rails a good wipe-down with a food-safe sanitizer.

- Clear Debris: Brush out any stray cheese, pepperoni, or other food bits from around the door seals and inside the cabinet. Buildup here can cause big problems.

Weekly Checks (10-15 Minutes)

- Gasket Inspection: Take a close look at the rubber door gaskets. Are there any rips, cracks, or hard spots? A bad seal makes the compressor work overtime, which wastes energy and puts your pizza toppings in the temperature danger zone.

- Deep Clean Interior: Pull out all the topping pans and shelves and give the inside of the refrigerated base a thorough cleaning.

A clean pizza prep table is a safe and efficient pizza prep table. Regular maintenance is your best defense against unexpected equipment failure and the costly downtime that comes with it.

Monthly and Quarterly Deep Dives

While the daily and weekly stuff is vital, a few less frequent tasks are absolutely critical for the long-term health of your machine. These jobs focus on the heart of your prep table—the refrigeration system. To keep your Atosa 93 humming along for years, you’ll want to adopt some basic preventive maintenance tips for commercial refrigeration.

Monthly Task (15-20 Minutes)

- Condenser Coil Cleaning: Think of the condenser coils as the lungs of your refrigerator. They get dusty and greasy over time, which chokes the system. Gently use a soft brush or a vacuum to clean them off. Clogged coils are one of the top reasons compressors fail.

Quarterly Task (5 Minutes)

- Check Casters and Leveling: Make sure the table is still level and that the casters are clean and roll smoothly. A unit that isn't level can cause the doors to hang improperly, leading to bad seals.

By sticking to this simple schedule, you’re protecting one of the most valuable assets in your kitchen. For a bigger-picture look at keeping your whole operation in top shape, check out our guide to caring for all types of commercial food prep equipment.

Questions We Hear All the Time About the Atosa 93" Prep Table

When you're looking at a serious piece of equipment like the Atosa pizza prep table 93, the questions start piling up. It's a big decision, and you need to know for sure that it's not just going to fit in your kitchen, but that it'll actually make your pizzeria's life easier during a chaotic dinner rush.

We get it. We've talked to hundreds of pizzeria owners who've been in your exact shoes. They're not asking about fancy marketing specs; they're asking the real-world, "how is this going to work for my pizzeria?" questions. Let's dive into some of the most common ones.

Can I Change Up the Topping Pans?

This is probably the number one question we get. Every pizzeria's menu is different, and a rigid, one-size-fits-all setup is a recipe for frustration.

So, can you swap out the pans on the ingredient rail for different sizes? Absolutely. The Atosa pizza prep table 93 is built for this kind of on-the-fly adjustment. It ships with standard 1/3-size pans, but with a few simple adapter bars, you can create a custom layout with smaller 1/6 or 1/9-size pans. This means you can perfectly tailor the rail to your menu, whether you're a classic pepperoni-and-cheese joint or a gourmet spot with a dozen specialty toppings.

What’s It Like to Live With? (Operation & Maintenance)

Beyond the setup, pizzeria owners want to know about the day-to-day reality. A pizza prep table has to be a reliable partner in the kitchen, not another headache to manage.

Here are a few of the practical questions that always come up:

- How loud is this thing? Look, any commercial fridge is going to make some noise. But the Atosa 93 is designed to run efficiently without being the loudest thing in your pizzeria. It won't drown out the sound of tickets printing.

- Can I take the cutting board off to clean it? Yes, and you'll be glad you can. The high-density polyethylene cutting board is removable. This is a huge deal for proper deep cleaning and sanitizing, which is non-negotiable for food safety in a pizzeria.

- Is cleaning the condenser a huge pain? Atosa gets that you don't have time for complicated maintenance. The condenser slides out, making the monthly cleaning process surprisingly simple. A few minutes with a brush is all it takes to keep your unit cooling efficiently and prevent a catastrophic failure down the road.

Think of the Atosa 93 as more than just steel and refrigeration; it's a system you're relying on. The warranty is your safety net, protecting that system and giving you peace of mind when you need it most.

What's the Warranty Situation?

Every smart pizzeria owner knows that the purchase is just the beginning. What happens if something goes wrong? A good warranty isn't just a document; it's a manufacturer telling you they stand behind their product.

So, what’s the coverage? Atosa typically offers a solid two-year parts and labor warranty. That's a strong vote of confidence right there. But the real kicker is the extended five-year warranty on the compressor. The compressor is the heart of the whole system, and it's the most expensive part to fix. Having that component covered for five years is a massive value and a clear sign of long-term durability for your Atosa pizza prep table 93. Just be sure to confirm the exact terms with your dealer when you buy.

Ready to build a faster, more efficient, and more profitable pizzeria? The Atosa pizza prep table 93 is the cornerstone of a high-performance kitchen. At Pizza Prep Table, we specialize in helping independent pizzeria owners find the perfect equipment to bring their vision to life. Explore our full selection and discover how the right prep table can transform your operations by visiting us at https://pizzapreptable.com.