Brick by Brick, Slice by Slice – Commercial Pizza Ovens Reviewed

Share

Why Commercial Brick Pizza Ovens Are Game-Changers for Your Restaurant

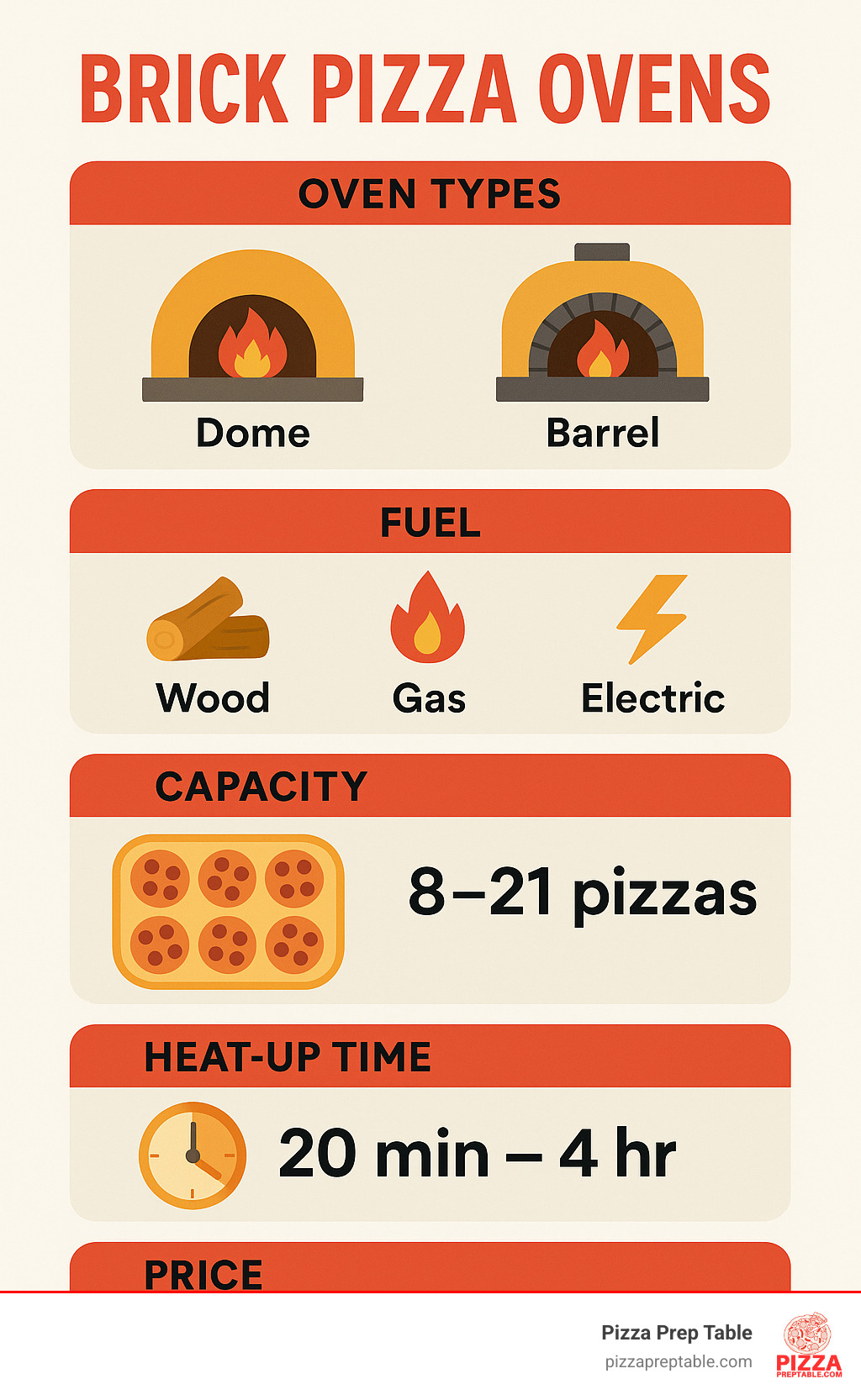

A brick pizza oven transforms your restaurant's cooking capabilities, delivering authentic Neapolitan pizzas in just 60-90 seconds at temperatures up to 950°F. Here's what you need to know about commercial brick pizza ovens:

Key Benefits:

- Speed: Cook pizzas in 60-90 seconds vs. 10-15 minutes in conventional ovens

- Temperature: Reach 850-950°F for authentic wood-fired flavor

- Versatility: Cook pizza, bread, roasts, and vegetables

- Capacity: High-end models produce up to 250 pizzas per hour

Main Types:

- Rotating deck ovens - Automated consistency for high volume

- Traditional Neapolitan - Authentic brick construction

- Modular kits - Easy transport and custom installation

- Mobile ovens - Perfect for food trucks and catering

The restaurant industry has acceptd brick ovens because they solve two critical problems: speed and authenticity. As one pizzeria owner noted after installing a Marra Forni oven: "We cooked 250 pizzas flawlessly at our first event with zero learning curve."

Whether you're opening your first pizzeria or upgrading an existing kitchen, choosing the right brick pizza oven affects everything from your menu options to your profit margins. The key is matching oven size, fuel type, and features to your specific volume needs and space constraints.

I'm Sean Kearney, and my experience in restaurant equipment sales has shown me how the right brick pizza oven can transform a struggling kitchen into a profit center. From helping small cafes choose their first wood-fired unit to assisting chains with high-volume installations, I've seen which ovens deliver on their promises.

Best Commercial Brick Pizza Ovens for 2024

Finding the right brick pizza oven for your restaurant feels overwhelming when you're staring at dozens of options. I've spent countless hours in commercial kitchens, watching these ovens perform under real pressure, and I can tell you which ones actually deliver on their promises.

The ovens I'm recommending here have proven themselves in busy kitchens from coast to coast. They're not just pretty to look at – they're workhorses that can handle the dinner rush without breaking down or burning your pizzas.

| Oven Model | Cook Time | Capacity | Heat-Up Time | Price Range |

|---|---|---|---|---|

| Marra Forni Rotator | 90-120 sec | 250 pizzas/hr | 20-30 min | $15,000-$25,000 |

| Forno Bravo Professionale | 60-90 sec | 150 pizzas/hr | 20-60 min | $8,000-$15,000 |

| Ooni Koda 2 Max | 60 sec | 120 pizzas/hr | 20 min | $800-$1,200 |

| Volta Kit | 90 sec | 100 pizzas/hr | 45 min | $2,000-$3,000 |

Marra Forni Rotator brick pizza oven

When you need to pump out 250 pizzas per hour without breaking a sweat, the Marra Forni Rotator is your answer. This isn't just a brick oven – it's a precision machine that happens to be made with brick.

The rotating deck does all the work for you. No more spinning pizzas by hand or worrying about hot spots. The oven turns your pizzas automatically, cooking them evenly every single time. I've watched brand-new employees master this oven in minutes, not months.

The automation is what makes this oven special. You slide the pizza in, the MarraSmart controls take over, and perfect pizza comes out 90 seconds later. The 84,000 BTU gas burners keep the temperature rock-steady, even during your busiest nights.

One pizzeria owner in Chicago told me: "We went from struggling to keep up with orders to having our kitchen staff actually relaxed during dinner rush." That's the kind of change a high-volume oven like this can deliver.

The Rotator comes in sizes from RT-90 to RT-150, so you can match your capacity needs perfectly. The 3-year dome warranty shows Marra Forni stands behind their engineering.

Forno Bravo Professionale brick pizza oven

The Professionale gives you authentic brick pizza oven cooking without the headaches of traditional masonry. This modular kit arrives in pieces that fit through doorways and assembles without mortar – a game-changer for restaurants with tricky access.

What impressed me most is how this oven bridges old-world craftsmanship with modern engineering. The vibratory-cast refractory dome resists cracking better than hand-laid brick, while still delivering that unmistakable wood-fired flavor.

The 20-60 minute heat-up time varies based on your fuel choice and oven size. Wood gets you there fastest, but the gas option offers convenience without sacrificing much on flavor. Many operators go with the combination setup for maximum flexibility.

This oven stays hot for over 24 hours after firing. Smart restaurateurs bake bread in the morning when the oven's cooling down, then fire it back up for pizza service. It's like having two ovens in one footprint.

The indoor/outdoor flexibility means you're not locked into one location. I've helped restaurants move these ovens during renovations – try doing that with a traditional brick installation.

Ooni Koda 2 Max "pseudo" brick pizza oven alternative

Let's be honest – the Koda 2 Max isn't technically a brick pizza oven. But when you need 60-second pies and don't have the space or budget for full brick construction, this gas-powered alternative delivers surprising results.

The 24-inch deck handles two 12-inch pizzas at once, making it viable for smaller restaurants that still want authentic high-temperature cooking. It reaches 950°F in just 20 minutes – faster than most brick ovens heat up.

I've seen food trucks and cafes build their entire pizza program around this oven. The portable design means you can move it for cleaning, events, or even outdoor service in good weather.

The stone baking surface gives you that crispy-bottom, chewy-crust texture that customers expect from real pizza. While it won't fool a Neapolitan purist, it'll satisfy 99% of your customers at a fraction of the investment.

Volta Kit: DIY commercial brick pizza oven on trailers

The Volta Kit solves a problem I see constantly: restaurants that want authentic brick pizza oven cooking but can't commit to permanent installation. This mortar-free system assembles in 30 minutes and reaches 1000°F in about 45 minutes.

The Italian engineering shows in the details. The interlocking refractory pieces create a perfect seal without mortar, and the spherical dome eliminates cold spots that plague many traditional ovens.

I've installed these on trailers, in pop-up locations, and inside restaurants where building codes made traditional masonry impossible. The mobile-friendly design means you're not married to one location forever.

The Volta stays hot for over 24 hours, just like much more expensive brick ovens. The three available sizes let you match your volume needs without over-buying capacity you'll never use.

What makes this oven special is its versatility. Need to move locations? Thirty minutes and it's ready to transport. Want to add a brick oven to your existing kitchen without major construction? The Volta fits through standard doorways and doesn't require special foundations.

How to Choose Your Brick Pizza Oven – Fuel, Design & Cost

Choosing the perfect brick pizza oven for your restaurant feels overwhelming at first, but it doesn't have to be. After helping hundreds of pizzeria owners make this decision, I've learned that three key factors determine success: fuel type, oven design, and understanding the real costs involved.

The fuel you choose shapes everything about your operation. Wood-fired ovens create that authentic smoky flavor customers crave, but they require skilled operators who understand fire management. Gas offers foolproof consistency and quick training, while combination systems give you the best of both worlds—though at a higher price.

Your oven's shape affects how evenly it cooks and how long it holds heat. The classic dome design has dominated for centuries because it works so well, but modern barrel shapes offer some interesting advantages for certain operations.

The cost picture extends far beyond the sticker price. That $15,000 oven might actually cost less to operate than a $5,000 model when you factor in labor, fuel, and the premium pricing that authentic brick pizza ovens command.

For operators serious about mastering wood-fired techniques, the 3-day “Mastering the Fire” class provides hands-on training that transforms beginners into confident fire masters.

Fuel Options for a Brick Pizza Oven

The fuel powering your brick pizza oven determines your pizza's flavor, your operating costs, and how much training your staff needs. Each option has passionate advocates, and for good reason.

Wood creates magic. Those dancing flames that reach 950°F produce the burst of intense heat that bakes perfect Neapolitan pizza in 60-90 seconds. Hardwoods like cherry, apple, and oak burn clean while adding subtle flavors that gas simply can't match.

But wood demands respect and skill. Your pizza makers need to understand fire management, and fuel costs vary wildly by location. In our Northeast locations, quality hardwood runs $200-300 per cord. Our Southwest customers pay $150-200 for the same wood. The key is sourcing well-seasoned hardwood with less than 20% moisture content.

Gas delivers consistency. Modern gas burners pump out 84,000 BTUs for rapid heat recovery, and your staff can master the controls in hours instead of months. Operating costs stay predictable, and you'll never run out of fuel during your dinner rush.

The trade-off? You lose some of that smoky complexity that makes customers choose brick oven pizza over regular pizza. Gas works brilliantly for high-volume operations where consistency matters more than artisanal character.

Combination systems cost 20-30% more upfront but offer incredible flexibility. Use wood for your signature pizzas and switch to gas during busy periods. It's like having two ovens in one.

Pellets and charcoal might seem appealing, but they produce steady infrared heat better suited for slow cooking. They work great for smoking after your pizza service, but they won't give you those burst flames needed for 60-second pies.

Dome vs Barrel: Which Brick Pizza Oven Bakes Faster?

The shape of your brick pizza oven affects everything from heat distribution to how long you can cook without adding fuel. Both dome and barrel designs have their champions, and the choice often comes down to what you're cooking and how you work.

Dome ovens follow the ancient Neapolitan tradition for excellent reasons. That curved ceiling creates natural convection currents that circulate hot gases evenly across your cooking surface. No cold spots, no surprises—just consistent heat that reflects perfectly off the dome.

Dome shapes also win the heat retention game. They hold temperatures 15-20% longer than barrel designs because the thermal mass distributes optimally. During busy dinner rushes, this means fewer fuel additions and more consistent cooking.

Barrel ovens like the popular Mattone Barile design offer easier access for larger items and may actually heat up 10-15% faster due to lower thermal mass. The tunnel shape makes loading and unloading simpler, which reduces operator fatigue during long shifts.

Barrel designs excel when you're cooking more than just pizza. Bread, roasts, and other items requiring extended cooking times work beautifully in the tunnel shape. Plus, DIY builders often prefer barrels because they're simpler to construct correctly.

In our testing, dome ovens maintained target temperatures longer and showed more even heat distribution. Barrel ovens heated faster but needed more frequent fuel additions for extended cooking sessions. Both shapes can produce excellent pizza—it's really about matching the design to your specific needs.

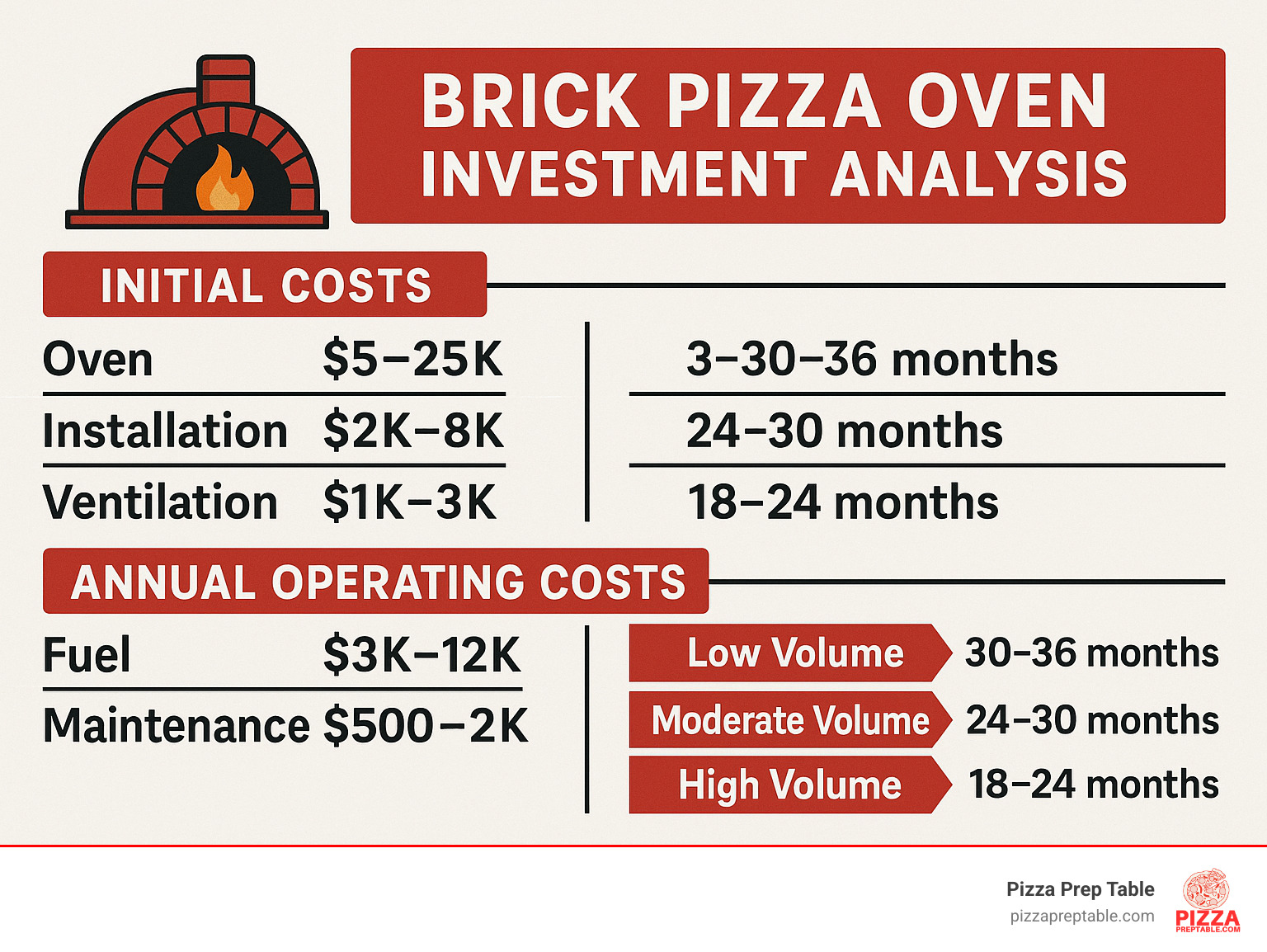

Brick Pizza Oven Cost Breakdown & ROI

Understanding the real cost of owning a brick pizza oven helps you make smart decisions and plan for profitable operations. After analyzing installations across 21 major markets, we've identified the key cost factors that affect your bottom line.

Your initial investment includes the oven itself ($5,000-$25,000), plus installation and ventilation ($2,000-$8,000), site preparation ($1,000-$5,000), and proper training ($500-$2,000). High-end markets like Manhattan require more complex installations, while smaller cities often see lower labor costs.

Operating costs stay fairly predictable once you're running. Fuel runs $3,000-$12,000 annually depending on your volume and fuel choice. Maintenance typically costs $500-$2,000 per year for routine cleaning, chimney maintenance, and minor repairs. Your insurance may increase $200-$500 annually due to the open flame equipment.

The revenue impact makes the investment worthwhile. Brick pizza ovens command premium pricing—our customers typically charge $2-4 more per pizza compared to conventional oven operations. A busy pizzeria serving 200 pizzas daily can generate an additional $146,000-$292,000 annually from the price premium alone.

Payback periods usually run 18-36 months when you factor in increased pricing, faster service, and expanded menu options. High-rent districts often see faster returns because customers expect and pay for premium experiences.

At Pizza Prep Table, we offer financing options that spread your initial investment across manageable monthly payments. This makes high-quality brick pizza ovens accessible whether you're opening your first location or upgrading an existing operation.

Build, Buy, or Kit?

Choosing between building from scratch, buying a kit, or purchasing a fully assembled brick pizza oven can feel overwhelming. But here's the good news: there's no wrong choice, just different paths that work better for different situations.

Your decision really comes down to three things: how much time you have, what your space looks like, and whether you enjoy getting your hands dirty. I've watched restaurant owners go every route imaginable, and each approach has its sweet spots.

If you're in a tight urban space like downtown Boston where getting equipment through the door requires a miracle and two strong guys, modular kits often save the day. But if you're building a new location with loading dock access, a fully assembled oven might be your fastest path to serving customers.

The timeline matters too. Building from scratch means weeks of work, while assembled ovens can have you cooking pizzas within days. Kits split the difference—you get engineered performance without the marathon construction project.

For operators looking to maximize their brick pizza oven investment, mastering your dough technique is just as important as choosing the right oven. Our guide on mastering pizza dough kneading shows you how to get consistent results every time.

DIY Scratch Brick Pizza Oven

Building a brick pizza oven from scratch appeals to the craftsperson in all of us. There's something deeply satisfying about creating your own cooking centerpiece brick by brick. But let me be honest—it's not for everyone.

The material list reads like a masonry textbook: fire bricks for the cooking surface, refractory mortar mixed just right, vermiculite for insulation, and all the structural components to hold everything together. Getting the mortar recipe perfect—three parts sand, one part cement, one part fire clay, one part hydrated lime—requires precision that would make a chemist proud.

Time commitment is where many DIY dreams meet reality. We're talking 2-4 weeks of skilled labor, not weekend hobby time. Each layer needs to cure properly, which means patience isn't just helpful—it's mandatory.

Here's what really matters: performance consistency. Scratch-built ovens often take 2-4 hours to reach cooking temperature compared to 20-60 minutes for engineered kits. That's not just inconvenient—it affects your entire daily operation and energy costs.

The cost reality surprises most people. Materials might cost less upfront, but when you factor in weeks of labor and potential performance issues, scratch builds rarely deliver the savings they promise. Plus, if something goes wrong, you're troubleshooting your own engineering.

Modular Brick Pizza Oven Kits

Modular kits hit the sweet spot for most commercial operations. You get engineered performance without needing a masonry degree, and assembly happens in days rather than weeks.

The Mattone Barile series has become incredibly popular, especially for operations serving larger groups. Its barrel shape makes loading and unloading easier during busy periods, and the construction process is straightforward enough that most operators can handle it with basic tools and a couple helpers.

For traditional dome lovers, the Mattone Cupola delivers authentic Neapolitan performance with simplified assembly. These kits arrive with pre-formed components that fit together like precision puzzle pieces—no guesswork, no mixing mortar in the parking lot.

Installation flexibility is where kits really shine. Components transport through standard doorways, solving the access nightmares that plague urban restaurants. I've seen these kits carried piece by piece through narrow hallways that would never accommodate a fully assembled oven.

Custom cladding options let you match your restaurant's aesthetic perfectly. The structural components handle the thermal performance while you choose brick, stone, stucco, or tile for the exterior. It's like having a custom suit with an off-the-rack timeline.

The warranty coverage and technical support give you backup when questions arise. Instead of troubleshooting your own masonry work, you have expert help just a phone call away.

Fully Assembled Commercial Brick Pizza Oven

Fully assembled ovens represent the plug-and-play approach to brick oven cooking. If you have equipment access and want to start cooking immediately, this route eliminates construction variables entirely.

Factory quality control means every oven gets tested before it leaves the building. The dome-to-floor ratios are perfect, insulation placement is optimized, and thermal performance is guaranteed. No wondering if your mortar mix was right or if your dome shape affects heat circulation.

UL listing and code compliance come standard, which simplifies permitting and insurance requirements. When the inspector shows up, you hand them certified documentation instead of explaining your DIY engineering decisions.

The access challenge is real though. These ovens typically weigh 1,200+ pounds and require forklift or crane access. Urban locations often find that getting the oven to its final location costs more than expected. We've seen creative solutions involving roof cranes and temporary wall removal, but these add complexity and cost.

Marra Forni and Forno Bravo lead this market with comprehensive model lines covering everything from small artisan operations to high-volume commercial kitchens. Both companies offer extensive customization for finishes and branding, so your oven can reflect your restaurant's personality while delivering professional performance.

The timeline advantage is huge—you can go from empty space to serving customers in days rather than weeks. For operators facing tight opening deadlines or seasonal time pressures, this speed often justifies the higher initial investment.

Operating, Maintaining & Staying Safe

Your brick pizza oven is a powerful piece of equipment that demands respect and proper care. Think of it as a high-performance sports car—treat it right, and it'll serve you faithfully for decades. Neglect it, and you'll face expensive repairs and safety headaches.

The biggest mistake I see new operators make is rushing the curing process. I get it—you're excited to start cooking pizzas and making money. But skipping proper curing is like trying to drive a car before the engine oil has circulated. You might get away with it once, but you're setting yourself up for catastrophic failure.

Temperature control is everything in brick pizza oven operation. Too hot, and you'll char pizzas before the toppings cook. Too cool, and you'll end up with soggy, disappointing pies that customers won't order again. The sweet spot for most operations is 750-850°F for pizza, dropping to 450-500°F for bread and roasts.

Daily maintenance takes just 15-20 minutes but saves thousands in repair costs. I've seen ovens last 30+ years with proper care, while neglected units need major repairs within five years. The choice is yours, but I know which path leads to better profits.

Routine Care for a Brick Pizza Oven

Taking care of your brick pizza oven is like maintaining any relationship—consistency matters more than grand gestures. A few minutes of daily attention prevents the major headaches that come from neglect.

Start each day by removing ash and debris from the cooking surface with a long-handled brush. This isn't just about cleanliness—leftover ash creates hot spots that can burn your pizzas unevenly. Check your door seals and gaskets while you're at it. A damaged seal wastes fuel and makes temperature control nearly impossible.

Your chimney deserves weekly attention. Look for obstructions like bird nests or excessive creosote buildup. A blocked chimney doesn't just hurt performance—it's a serious fire hazard. I've seen restaurants shut down by fire marshals because they ignored chimney maintenance.

The cooking stones need deep cleaning weekly using appropriate brushes and scrapers. Grease and flour buildup doesn't just affect flavor—it can catch fire at high temperatures. For gas-fired units, check all connections and safety shutoffs. A small gas leak today becomes a major explosion risk tomorrow.

Monthly tasks include professional chimney inspection and cleaning, calibrating temperature monitoring equipment, and reviewing fuel consumption patterns. If your fuel usage suddenly spikes, something's wrong. Maybe your insulation is failing, or your door isn't sealing properly.

Seasonal maintenance involves comprehensive inspection of refractory materials, weather protection assessment for outdoor installations, and professional service. This is when you catch the small cracks and wear patterns before they become expensive problems.

The operators who follow these routines religiously are the ones still running profitable operations decades later. The ones who skip maintenance are the ones calling us for emergency repairs at the worst possible times.

Safety Checklist Around a Brick Pizza Oven

Brick pizza oven safety isn't optional—it's the foundation of sustainable operation. I've seen too many preventable accidents that could have been avoided with proper protocols and equipment.

Fire prevention starts with proper installation. Your oven needs adequate clearances from combustible materials, appropriate fire suppression systems, and easily accessible Class K fire extinguishers. Train every staff member on emergency shutdown procedures before they touch the oven. When seconds count, you can't afford confusion.

Burn protection requires the right equipment and training. Heat-resistant gloves rated for 500°F+ temperatures aren't optional—they're essential. Safety glasses protect from sparks and debris, while non-slip footwear prevents dangerous falls on greasy kitchen floors. Long-handled tools keep your staff at safe distances from extreme heat.

Air quality management protects both staff and customers. Install carbon monoxide detectors in enclosed areas and ensure adequate ventilation per health department requirements. Train staff to recognize symptoms of poor air quality: headaches, dizziness, or nausea. These aren't just comfort issues—they're life-threatening emergencies.

Personal protective equipment saves lives and prevents lawsuits. Provide heat-resistant gloves, safety glasses, and appropriate clothing that won't ignite easily. Document training and equipment provision—your insurance company and local authorities will appreciate the paper trail.

The restaurants that take safety seriously create positive work environments where staff feel protected and confident. The ones that cut corners face worker compensation claims, regulatory fines, and the devastating costs of preventable accidents.

Your brick pizza oven is a powerful tool that demands respect. Treat it with the care it deserves, and it'll reward you with years of profitable operation and delicious food that keeps customers coming back.

Frequently Asked Questions about Commercial Brick Pizza Ovens

How long does a brick pizza oven take to heat?

The heating time for your brick pizza oven depends on several key factors, and understanding these helps you plan your daily operations effectively. From our installations across the country, we've seen consistent patterns that can help you set realistic expectations.

Modern engineered kits like the Forno Bravo Professionale reach cooking temperature in just 20-60 minutes. These ovens use advanced refractory materials that heat up much faster than traditional construction. The Volta kit hits 1000°F in about 45 minutes, making it perfect for busy lunch rushes.

Traditional brick construction takes considerably longer—typically 2-4 hours to reach optimal temperature. While this seems like a drawback, many operators actually prefer this slower heat-up because it creates incredibly stable cooking conditions once you reach temperature.

Gas-fired systems are the speed champions here. The Marra Forni Rotator reaches cooking temperature in just 20-30 minutes thanks to its powerful 84,000 BTU burners. This quick recovery time means you can start cooking almost immediately.

Wood-fired ovens generally need 45-90 minutes, but this varies dramatically based on your fire management skills and wood quality. Well-seasoned hardwood with less than 20% moisture content heats much faster than green or wet wood.

Weather affects heating time more than most people realize. Cold winter mornings can add 30-45 minutes to your heat-up time, while hot summer days might cut 15-20 minutes off. Well-insulated ovens handle these temperature swings much better than basic construction.

What fuel is best for flavor and speed?

Choosing the right fuel for your brick pizza oven is like picking the right tool for the job—each option excels in different areas, and the best choice depends on your priorities.

For pure flavor, nothing beats hardwood. Cherry, apple, and oak create those aromatic compounds that make customers say "wow" when they taste your pizza. The smoke infuses a complexity that gas simply can't match. As one of our pizzeria owners in Portland told us: "Customers can taste the difference immediately. They come back specifically for that wood-fired flavor."

For speed and consistency, gas wins hands down. Modern gas burners deliver instant, controllable heat that lets you maintain exact temperatures throughout your busiest periods. You'll never worry about running out of fuel mid-rush or training staff on fire management techniques.

For cost control, gas typically offers the most predictable operating expenses. While wood prices fluctuate with seasons and regional availability—we've seen hardwood costs range from $150 in Phoenix to $300 per cord in Boston—gas prices remain relatively stable.

For authenticity and atmosphere, wood-fired cooking creates an experience that customers remember. The visual appeal of flames dancing in the oven adds theater to your kitchen that gas can't replicate.

Many successful operators choose dual-fuel systems that let them use wood for signature pizzas and special events while relying on gas for consistent volume production. This approach costs 20-30% more initially but provides maximum flexibility for different service styles.

The reality is that both fuels can produce exceptional pizza when used properly. Your choice should align with your operation's priorities, staff skills, and customer expectations.

Can a brick pizza oven cook more than pizza?

Absolutely! A brick pizza oven is actually one of the most versatile pieces of equipment you can add to your kitchen. The high heat and exceptional thermal retention create opportunities that go far beyond pizza, potentially expanding your revenue streams throughout the day.

Bread baking becomes incredibly profitable with a brick oven. After your dinner pizza rush, the oven retains enough heat (400-500°F) to bake artisan breads overnight. Many of our customers bake fresh bread for the next day's service using yesterday's residual heat—essentially free energy.

Roasted meats develop incredible flavor in the high-heat environment. Whole chickens cook in 25-30 minutes with crispy skin and juicy interiors. Lamb shoulders and beef roasts develop caramelized crusts while staying tender inside. The radiant heat creates browning that conventional ovens struggle to match.

Vegetables transform in a brick oven. Seasonal vegetables like Brussels sprouts, carrots, and winter squash develop deep caramelization in minutes rather than the 45+ minutes required in conventional ovens. These can become signature side dishes that set your restaurant apart.

Seafood cooks beautifully at high temperatures. Whole fish, salmon fillets, and shellfish develop perfect textures in the intense heat. We've seen coastal restaurants build their entire dinner menu around brick oven seafood preparations.

Desserts work wonderfully with retained heat. Fruit cobblers, bread puddings, and rustic tarts use the oven's cooling period effectively. Some operators even offer "dessert pizza" with fruit and sweet toppings.

One chef in Seattle summed it up perfectly: "People who think these are just pizza ovens are missing the point completely. We cook everything from breakfast bread to slow-roasted dinner meats. It's become the heart of our entire kitchen operation."

The key is planning your menu to take advantage of the oven's different temperature zones throughout the day. High heat for pizza service, medium heat for roasting, and low retained heat for baking—it's like having three ovens in one.

Conclusion

Choosing the right brick pizza oven can transform your restaurant from ordinary to extraordinary. After reviewing the top commercial models and installation options, it's clear that today's market offers solutions for every operation—whether you're running a high-volume pizzeria or a cozy neighborhood spot.

The standout performers each serve different needs perfectly. The Marra Forni Rotator dominates high-volume operations with its ability to pump out 250 pizzas per hour while requiring minimal training. The Forno Bravo Professionale strikes that sweet spot between authentic brick construction and modern reliability. For mobile operations or tight spaces, the Volta kit proves you don't need a permanent installation to serve authentic brick oven pizza.

Your fuel choice shapes everything from flavor to operating costs. Wood-fired ovens deliver that smoky authenticity customers crave, while gas systems offer the consistency and speed that busy kitchens demand. Many successful operators find that dual-fuel systems give them the best of both worlds.

The numbers tell a compelling story. Most brick pizza oven installations pay for themselves within 18-36 months through premium pricing alone. When you factor in faster service times and expanded menu options, the return on investment becomes even more attractive. A quality oven isn't just equipment—it's a profit center that keeps delivering year after year.

At Pizza Prep Table, we've seen how the right oven transforms entire operations. But here's what many operators miss: the oven is just the beginning. The magic happens when you pair that beautiful brick oven with the right prep workflow. Our pizza prep tables, refrigeration units, and kitchen equipment create seamless production lines that maximize your oven's potential.

From our customers in busy markets like New York City and Los Angeles to growing operations in Columbus and Austin, we've learned that successful pizza businesses share one trait: they understand that every piece of equipment must work together. Your brick oven might be the star, but your prep tables are what keep the show running smoothly during the dinner rush.

Whether you're taking the plunge with your first brick pizza oven or upgrading to handle growing demand, financing options make even premium equipment accessible. We've helped countless operators spread their investment across manageable payments, turning dream kitchens into profitable realities.

Ready to dive deeper into optimizing your pizza operation? Our team has created comprehensive guides covering everything from dough management to equipment selection at pizzapreptable.com/blogs/pizza. Because the best pizza isn't just about the oven—it's about the entire system working in harmony.

Your customers are waiting for that perfect pizza. Let's help you build the kitchen that delivers it, one slice at a time.