The Right Commercial Undercounter Freezer for Your Pizzeria

Share

A commercial undercounter freezer is a compact, space-saving unit designed to slide right underneath a pizza prep table, giving you instant access to frozen ingredients. For a busy pizzeria, this means keeping essentials like dough balls, shredded cheese, and pepperoni at the perfect temperature right where you're building the pizzas. It turns your prep line into a lean, mean, pizza-making machine.

Why Your Freezer Is the Heart of Your Pizza Line

Picture the chaos of a Friday night dinner rush. The printer is spitting out orders, the phone is ringing off the hook, and your pizza makers are moving at lightning speed. Now, imagine one of them has to stop, weave through a busy kitchen, and dig through a giant walk-in freezer just to grab another tray of dough.

The entire workflow grinds to a halt.

This is exactly where a commercial undercounter freezer becomes the unsung hero of a profitable pizzeria. It’s not just a cold box; it’s a strategic tool that creates a seamless, efficient prep line integrated directly into your pizza prep table.

Creating a Point-of-Use System

By tucking your freezer directly under the pizza prep table, you create a powerful "point-of-use" system. This simple move eliminates wasted steps and keeps your team focused on what they do best: crafting perfect pizzas. Think of it as the ultimate mise en place, but for your frozen goods.

Key ingredients are always within arm's reach:

- Frozen Dough Balls: No more long treks to the back freezer. Staff can grab dough as needed, keeping a swift, continuous flow from stretching to topping.

- Shredded Cheese: Keeping bulk cheese frozen and accessible right at the prep station prevents spoilage and ensures you’re always stocked during peak hours.

- Key Toppings: High-volume items like pepperoni, sausage, and other frozen meats stay perfectly preserved and ready for action.

This strategic placement transforms your pizza prep table into a self-contained production hub. It’s the difference between a kitchen that runs like a well-oiled machine and one that’s constantly battling bottlenecks and delays.

This approach isn’t just about speed; it's also about quality and consistency. Every time someone opens a walk-in freezer door, the temperature fluctuates. An undercounter unit, built for frequent access during a pizza rush, recovers its temperature much faster, protecting the integrity of your ingredients.

Getting your cold storage organized is a game-changer, and you can dive deeper in our guide to the ultimate commercial fridge freezer combo. Viewing your commercial undercounter freezer as an investment in workflow, not just an appliance, is the first step toward a faster, more organized, and more profitable pizza kitchen.

Decoding the Features That Matter for Pizza Making

Not all freezers are created equal, especially when your kitchen is swimming in flour dust and the door is getting yanked open every few minutes. To find the right commercial undercounter freezer for your pizza prep table, you've got to look past the price tag and really get into the spec sheet. The right features directly translate into better pizza, a smoother workflow, and lower bills at the end of the month.

Think of the cooling system as the freezer's engine. A dynamic or fan-assisted cooling system is completely non-negotiable for a busy pizza prep line. Unlike the static freezers you might have at home that just passively radiate cold, these units use fans to constantly circulate frigid air.

This forced-air circulation is your secret weapon for rapid temperature recovery. Every time a cook grabs a tray of dough or a pan of pepperoni from under the pizza prep table, that blast of warm kitchen air is immediately neutralized. It’s the single best defense against temperature abuse, keeping your sensitive dough from proofing too soon and preserving the perfect texture of your cheese and toppings.

Built to Withstand the Pizzeria Gauntlet

The guts of the freezer are important, but what it's made of is just as critical. Let's be honest—pizzerias are tough on equipment. Spills from acidic tomato sauce and constant, aggressive wipe-downs are just part of a normal Tuesday.

- Stainless Steel Grade: Don't settle for just any stainless steel. You want to see 304-grade on the spec sheet. This grade offers far superior corrosion resistance compared to cheaper alternatives, which means it won't rust or pit when it inevitably comes into contact with acidic ingredients and harsh cleaning chemicals.

- Self-Closing Doors: During the dinner rush, doors get left ajar. It happens. Self-closing doors use a simple spring-loaded or magnetic mechanism to pull themselves shut, preventing all that precious cold air from escaping and saving a surprising amount of energy.

- Adjustable Shelving: A truly useful freezer needs to adapt to your inventory. Adjustable shelving lets you customize the interior to perfectly fit standard-sized dough trays and ingredient pans, making sure you can use every single inch of that valuable frozen real estate under your pizza prep table.

A robust build isn't a luxury; it's a necessity. It ensures your investment can handle the brutal reality of a high-volume pizzeria, from accidental bumps to corrosive spills, year after year.

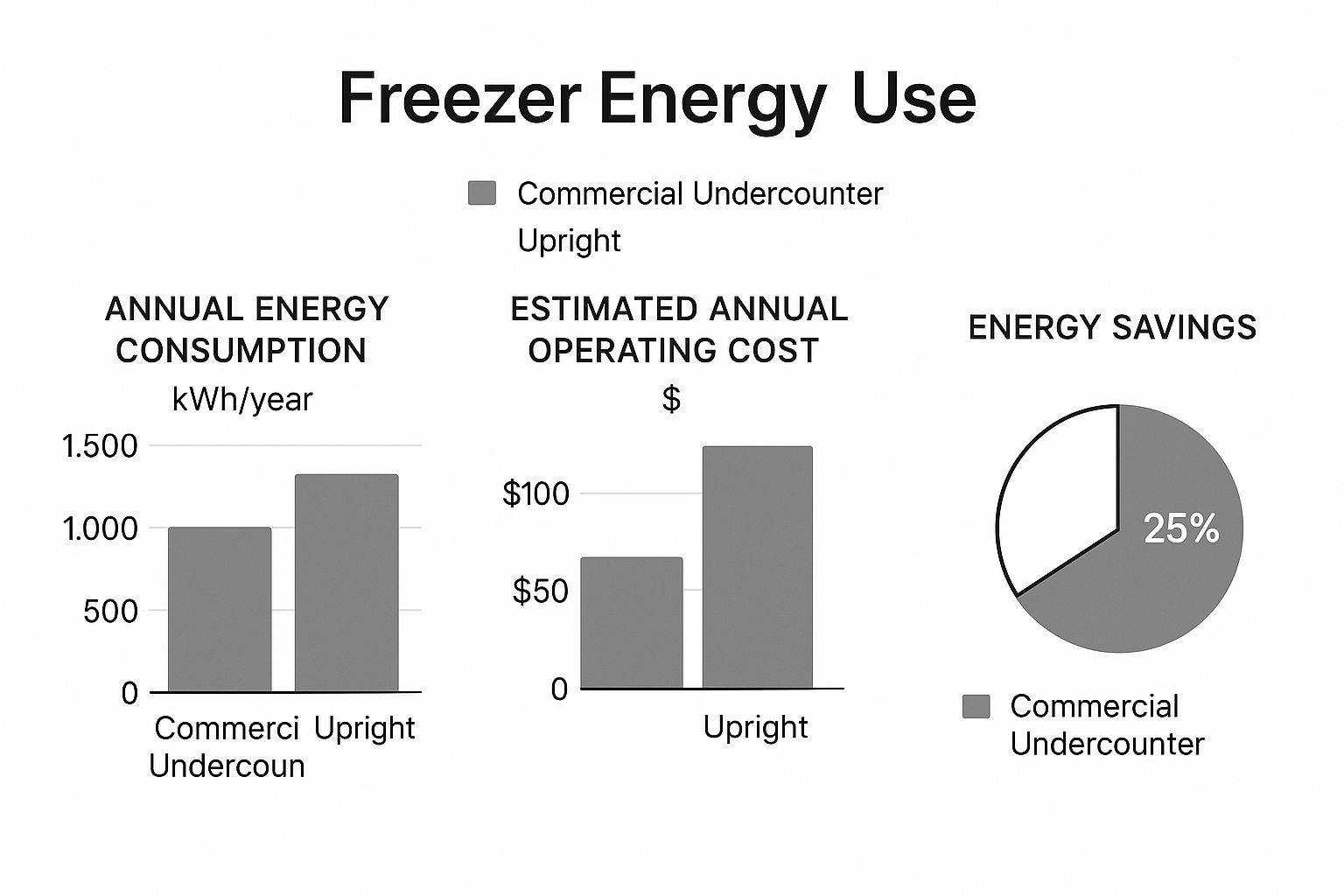

Here’s a quick look at how the energy use and costs of undercounter models stack up against their bigger, upright cousins.

As you can see, the compact, efficient design of a commercial undercounter freezer can lead to some serious energy savings over time.

To help you cut through the noise, here's a quick-glance table of the features that really move the needle in a pizzeria setting.

Essential Freezer Features for Pizzerias

| Feature | Why It Matters for a Pizzeria | Look For |

|---|---|---|

| Dynamic Cooling | Recovers temperature instantly after door openings, protecting dough and toppings. | Fan-assisted, forced-air circulation |

| 304-Grade Steel | Resists rust and corrosion from acidic tomato sauce and harsh cleaners. | High-grade stainless steel construction |

| Self-Closing Doors | Prevents energy waste and temperature fluctuations during chaotic rushes. | Spring-loaded or magnetic door mechanisms |

| Digital Thermostat | Ensures ingredients are held at a precise, safe temperature for peak quality. | Electronic controls with clear LED display |

| Adjustable Shelving | Maximizes storage space by accommodating your specific dough trays and pans. | Movable, coated wire shelves |

Focusing on these core elements ensures you're buying a workhorse, not just a cold box.

Precision Control and Why It's a Big Deal

Finally, don't overlook the thermostat. Precise temperature control is absolutely critical for consistency. A digital thermostat offers accuracy that old-school manual dials simply can't touch. It lets you set and monitor the temperature with surgical precision, guaranteeing your ingredients are held at the optimal 0°F (-18°C) for peak quality and food safety.

The demand for specialized gear like this is only growing. The commercial undercounter freezer market, currently valued at around USD 1.2 billion, is set to expand in a big way, driven by the need for space-saving, efficient solutions in busy pizzerias everywhere.

Getting a handle on these features is the key to picking a unit that actually supports your kitchen's rhythm. To dive even deeper, you can explore more about what makes undercounter freezers a cool choice in our detailed guide.

Choosing the Right Size Freezer for Your Volume

Picking the right commercial undercounter freezer for your pizza prep table is a classic balancing act. Go too small, and your team is stuck restocking in the middle of a dinner rush. Go too big, and you're just paying to cool empty space while wasting precious kitchen real estate.

The trick is to stop thinking in generic terms like cubic feet and start thinking like a pizzeria owner. The real question isn't "how big is it?" but rather, "how many full-size dough trays can it hold?" That simple mental shift connects the freezer directly to your workflow. The right unit holds enough key ingredients to get you through the busiest service without constant trips to the walk-in.

Calculating Your Ingredient Capacity

Finding your ideal freezer size isn't about guesswork; it's about doing some simple math based on your kitchen's reality.

To get a clear picture, you need to look at three things:

- Average Daily Pizza Sales: How many pies are you slinging on a busy Friday night? That number tells you exactly how much dough, cheese, and toppings you need to have chilled and ready on the line.

- Delivery Frequency: Are you getting frozen goods delivered once a week or three times a week? A shop with less frequent deliveries obviously needs more on-hand storage.

- Menu Complexity: A classic pepperoni and cheese menu requires a lot less frozen storage than a gourmet menu with a dozen specialty meats and ingredients.

These freezers are the unsung heroes of food safety and kitchen efficiency. It's no surprise the global market for commercial undercounter units is expected to rocket past USD 5.8 billion by 2032. That's a testament to how essential they are in professional kitchens everywhere.

Matching Door Models to Your Kitchen Layout

The number of doors on your freezer isn't just about looks; it directly shapes how your team moves and works at the pizza prep table. Different layouts demand different configurations.

The goal is to match the freezer's footprint and access points to the natural flow of your prep line, minimizing movement and maximizing output. Choosing the right door configuration is as important as choosing the right internal capacity.

A single-door unit is the perfect soldier for a small topping station or a low-volume sandwich prep area. It tucks into tight spaces while keeping the essentials right where you need them. For most high-traffic pizza prep lines, a double-door commercial undercounter freezer is the sweet spot. It offers plenty of storage and lets two pizza makers work shoulder-to-shoulder without tripping over each other.

For the high-volume powerhouses with long prep lines, a triple-door model creates a massive, uninterrupted cold zone under a long pizza prep table. This setup allows you to create dedicated sections—dough here, cheese in the middle, meats over there—keeping everything organized and within reach during the most chaotic rushes.

Before pulling the trigger, grab a tape measure and map out your space. Don't forget to account for the mandatory ventilation gaps—usually a few inches on the sides and back—so the compressor can breathe. It's also smart to think about where your pizzeria will be in a year. A freezer that feels perfect today might be bursting at the seams after a few months of growth. For a more detailed breakdown, you can learn more about how to find the right undercounter freezer capacity in our complete guide.

How Energy Efficiency Hits Your Bottom Line

Let’s be honest, your commercial undercounter freezer is one of the biggest workhorses in your pizzeria. It’s humming along 24 hours a day, 7 days a week, which means it’s a constant, non-stop presence on your electricity bill. This makes energy efficiency less of a "nice-to-have" feature and more of a critical factor for your long-term profitability.

It's easy to focus on the sticker price, but a smart upfront investment in an energy-efficient model pays for itself many times over. While it might cost a bit more initially, the monthly savings start adding up the day you plug it in, directly boosting your profit margin.

The Power of an ENERGY STAR Rating

When you see that blue ENERGY STAR logo on a commercial freezer, it’s more than just a sticker. It's a guarantee from the U.S. Environmental Protection Agency that the unit is, on average, 20% more energy-efficient than standard models. This certification isn't just about being green; it’s a clear sign of lower operating costs.

This efficiency comes from smarter technology working behind the scenes:

- High-Density Insulation: Modern freezers use high-density, foamed-in-place polyurethane insulation. Think of it as a premium thermos for your kitchen—it locks the cold air in and keeps the hot kitchen air out. The result? The compressor simply doesn't have to kick on as often.

- Energy-Sipping Compressors: The compressor is the heart of your freezer and its biggest energy hog. ENERGY STAR models use advanced compressors that cool more effectively while drawing significantly less power.

- Efficient LED Lighting: Those bright, cool-running LED lights do more than just illuminate the interior. Unlike old-fashioned incandescent bulbs, they don't generate heat, which reduces the overall cooling load on the system.

Choosing an energy-efficient freezer is a direct investment in your bottom line. Over its lifespan, the energy savings from an ENERGY STAR model can often exceed the initial price difference compared to a less efficient unit.

A Clear Cost-Saving Scenario

Let's break down the real-world impact. Imagine you're comparing two similar double-door commercial undercounter freezer models for your pizzeria.

| Feature Comparison | Standard Model | ENERGY STAR Model |

|---|---|---|

| Annual Energy Use | ~2,500 kWh | ~2,000 kWh |

| Est. Annual Cost (@ $0.15/kWh) | $375 | $300 |

| 5-Year Operating Cost | $1,875 | $1,500 |

| Total 5-Year Savings | - | $375 |

Over five years, the efficient model saves you $375 on a single unit. If your pizzeria has two or three of these freezers, those savings multiply fast. For a complete picture of your operational costs, it's always smart to consider broader strategies to reduce commercial utility bills, as every watt saved goes straight to your profit.

Of course, simple maintenance plays a huge role, too. Keeping the condenser coils clean and making sure the door gaskets have a tight seal are easy, no-cost ways to maintain peak efficiency. This combination of a smart purchase and routine care turns your freezer from a necessary expense into a tool for financial success.

Optimizing Placement for a Faster Pizza Prep Workflow

Here's something I've seen trip up countless pizzeria owners: where you put your commercial undercounter freezer is just as important as which model you buy. A poorly placed unit can silently sabotage your kitchen’s rhythm, adding wasted steps and precious seconds to every single pizza you make.

Think of it this way: you’re not just finding an empty spot for a new appliance; you’re designing an efficient ecosystem centered around your pizza prep table.

The real goal is to adapt the classic "kitchen work triangle" for the modern pizza line. For a pizzeria, that means creating a hyper-efficient straight line from cold storage to prep surface to oven. By tucking the freezer directly under your main pizza prep table, you eliminate all that wasted back-and-forth motion. Every frozen essential—from dough balls to pepperoni—is right there when you need it.

This integrated setup is what separates a smooth operation from a chaotic one. A few steps saved on one pizza might not seem like a big deal, but multiply that by hundreds of orders during a Friday night rush, and you’ve just reclaimed a huge chunk of production time.

Front-Breathing vs. Rear-Breathing Models

Now for a critical detail that often gets overlooked: how the freezer breathes. This isn't just a technical quirk; it determines exactly where you can install the unit without cooking its compressor.

- Front-Breathing Freezers: These models have their intake and exhaust vents right on the front grille. This design is your only real option for built-in applications. It lets you slide the unit flush under a pizza prep table and against a wall without worrying about it overheating.

- Rear-Breathing Freezers: These units need several inches of open space behind them for proper air circulation. If you box one into a tight, enclosed space, the compressor will overwork itself to death, leading to a premature failure and a very costly repair bill.

For virtually any integrated pizza prep station, a front-breathing model is non-negotiable. It’s the key to getting that seamless, built-in look without sacrificing the performance and longevity of your equipment.

The demand for this kind of smart, space-saving equipment is only growing. In North America alone, the commercial refrigeration market was recently valued at over USD 13.5 billion. This boom is driven by the need for better temperature-sensitive storage and rising food safety standards. If you want to dig deeper, you can explore more about the growth of the commercial refrigeration market in recent industry reports.

Your Pre-Installation Checklist

Before your new freezer even shows up, running through a quick checklist can prevent some major headaches down the road.

- Confirm Electrical Requirements: Make sure you have the correct voltage and a dedicated outlet nearby. Whatever you do, don't use an extension cord—it’s a safety hazard and can instantly void your warranty.

- Ensure the Floor Is Level: An uneven floor can cause the freezer's doors to sag over time. This prevents them from sealing properly and leads to massive energy waste as cold air constantly leaks out.

- Plan for Cleaning Access: You need to be able to easily pull the unit out to clean the condenser coils and the floor underneath it. Don't box it in so tightly that basic maintenance becomes impossible.

Thinking through these practical details ahead of time is the difference between just furnishing a kitchen and actually designing a workflow that works.

Pizzeria Undercounter Freezer FAQs

Even when you’ve found the perfect commercial undercounter freezer for your pizza line, the day-to-day questions never stop. Knowing the right answers can be the difference between a smooth Friday night rush and a costly service call. We’ve pulled together the questions we hear most from pizzeria owners, with answers straight from years of in-the-trenches kitchen experience.

Our goal is simple: give you the practical knowledge to not only choose the right freezer but to keep it running like a champ, ensuring your pizza line never misses a beat.

How Often Should I Clean My Pizzeria Freezer Coils?

In a normal restaurant, cleaning condenser coils every 90 days is the standard advice. But let's be honest, a pizzeria kitchen is anything but normal. With a constant cloud of airborne flour, grease, and dust, you have to be way more proactive.

For any commercial undercounter freezer in a pizza shop, plan on cleaning the condenser coils every 30 to 60 days. When coils get clogged, they act like a thick wool blanket, forcing the compressor to work itself to death. This sends your energy bills through the roof and puts incredible strain on the most expensive part of your freezer, risking a total meltdown right in the middle of dinner service. A few minutes with a stiff brush can literally save you thousands.

What Is the Best Temperature for Pizza Ingredients?

The magic number for your frozen dough, cheese, and toppings is 0°F (-18°C). This isn't just a friendly suggestion—it’s the gold standard for quality and food safety.

At this temperature, your frozen dough balls stay completely dormant, preserving the yeast so you get that perfect, predictable rise every single time. It also stops large, damaging ice crystals from forming in your meats and cheeses, which is key to maintaining their original texture and flavor. Don't just trust the digital display; we always recommend putting an independent thermometer inside the unit just to be sure it's telling you the truth.

Holding your ingredients at a rock-solid 0°F is the bedrock of a fantastic pizza. It guarantees that every single item you pull from that freezer performs exactly the way you expect it to, from the dough to the last slice of pepperoni.

Can I Put Hot Food Directly into the Freezer?

No. Absolutely, positively not. Tossing hot items like a freshly made sauce or pre-cooked sausage straight into the freezer is one of the most common—and damaging—mistakes we see in commercial kitchens. It creates a dangerous domino effect.

That sudden blast of heat skyrockets the internal temperature of the entire freezer. This puts every other item inside into the temperature danger zone and kicks your compressor into overdrive trying to fix the problem. Always, always cool hot foods down completely, either in a refrigerator or an ice bath, before they ever see the inside of your freezer.

Why Is a Front-Breathing Freezer Important for a Pizza Prep Table?

A front-breathing freezer is a unit designed with its air intake and exhaust vents on the front grille, usually right below the door. This design isn't just a nice-to-have feature; it's essential for any piece of equipment you plan to build into a cabinet or slide directly under a pizza prep table.

This setup allows the freezer to breathe properly without needing any clearance on the back or sides. If you tried to install a rear-breathing unit in that same tight space, it would quickly overheat and fail. For a clean, seamless pizza prep station, a front-breathing commercial undercounter freezer is really the only way to go.

Ready to build a smarter, more profitable pizza line? At Pizza Prep Table, we live and breathe high-quality refrigerated prep tables and undercounter units built for the real world of a pizzeria. Explore our curated selection of top-tier equipment and find the perfect workhorse for your kitchen.