Fueling the Fire – Choosing Between Char Broiler Gas and Charcoal

Share

The Fire Behind Perfect Grill Marks

Char broiler a gas is a commercial cooking appliance that uses gas-powered flames beneath metal grates to cook food at high temperatures, typically above 550°F. These specialized grills are essential workhorses in restaurant kitchens, delivering consistent heat and distinctive grill marks.

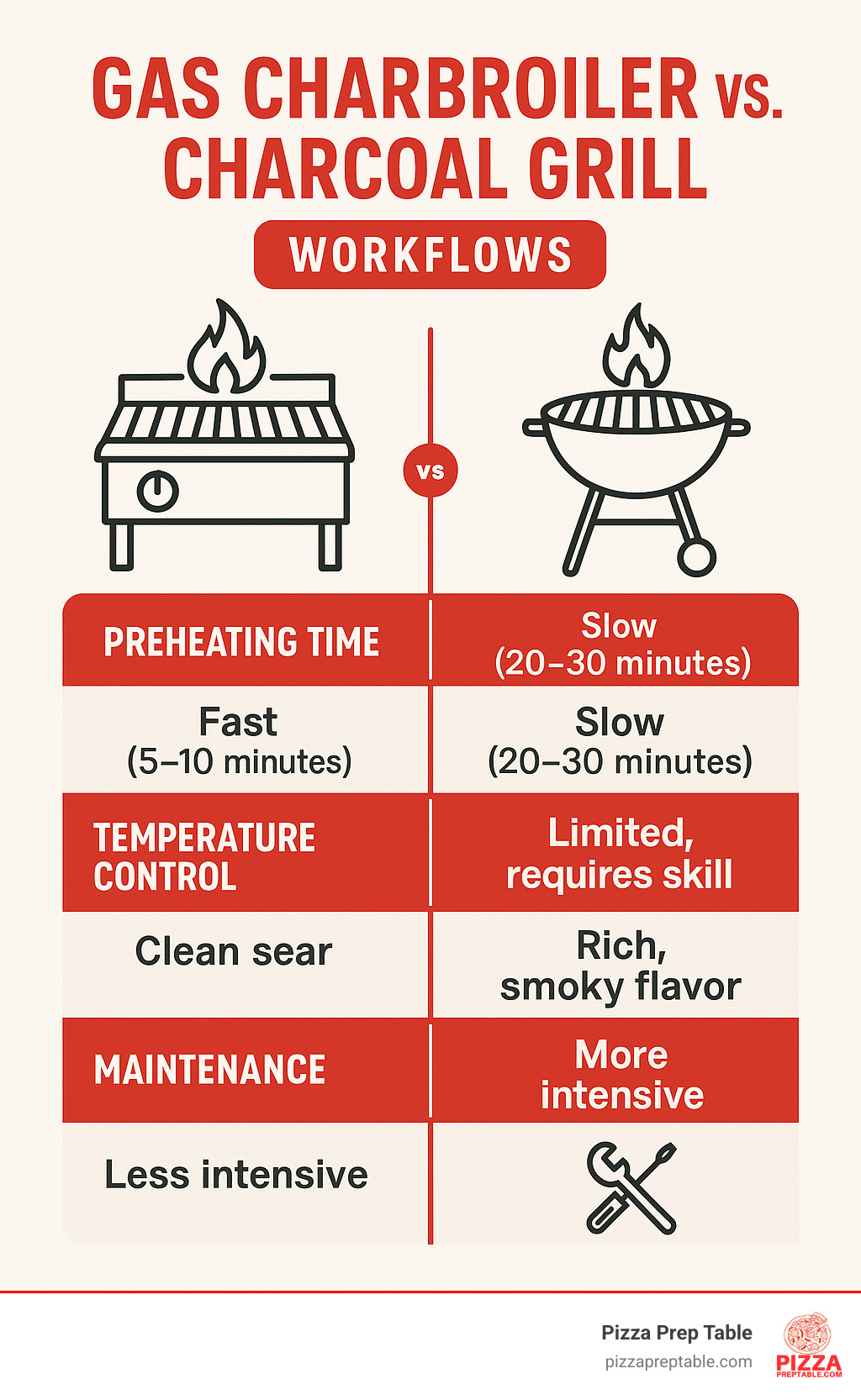

Gas Charbroiler vs. Charcoal Grill: Quick Comparison

| Feature | Gas Charbroiler | Charcoal Grill |

|---|---|---|

| Heat-up Time | Fast (5-10 minutes) | Slow (20-30 minutes) |

| Temperature Control | Precise with individual burners | Limited, requires skill |

| Flavor Profile | Clean sear with minimal smoke | Rich, smoky flavor |

| Operational Cost | Higher equipment cost, lower daily fuel cost | Lower equipment cost, higher labor cost |

| BTU Output | 15,000-30,000 BTU per burner | Varies with charcoal quantity |

| Indoor Use | Possible with proper ventilation | Rarely permitted |

| Maintenance | Regular cleaning, less ash | Ash removal, more intensive cleaning |

When choosing between gas and charcoal for your commercial kitchen, consider your menu requirements, kitchen space, ventilation capabilities, and operational workflow. Gas charbroilers offer convenience and consistency that's hard to beat in high-volume settings, while charcoal provides that distinctive smoky flavor that many customers crave.

I'm Sean Kearney, and I've spent over a decade helping restaurant owners select the right equipment for their operations, including guiding hundreds of pizzerias and steakhouses through the process of selecting the perfect char broiler a gas systems for their unique needs. My experience in both sales and foodservice gives me unique insight into balancing performance, budget, and kitchen workflow considerations.

Understanding Char Broiler a Gas Systems

Ever walked into your favorite steakhouse and heard that satisfying sizzle? That's the sound of a char broiler a gas working its magic. These powerful workhorses deliver an impressive 15,000 to 30,000 BTU per burner per hour—plenty of firepower to create that perfect sear on steaks and burgers that customers crave.

What makes commercial gas charbroilers special isn't just their industrial look—it's their thoughtful construction. Most professional models feature heavy-duty cast iron grates that hold and spread heat beautifully. I love that these grates are typically reversible: flip to the thin-bar side for delicate fish, or use the wide-bar side when you want those bold, Instagram-worthy grill marks on a ribeye.

Smart design extends to the burner layout too. Quality units position burners about every 6 inches—a critical detail that eliminates frustrating hot and cold spots. Premium models like the Precision 48" Heavy Duty Radiant Char Broiler Grill pack a whopping 160,000 BTU total output with perfectly spaced burners, giving chefs incredible control over different cooking zones.

When shopping for your char broiler a gas, you'll need to choose between three main heating technologies:

- Radiant systems use metal plates (usually cast iron) that absorb and radiate heat upward

- Lava rock systems employ volcanic rocks for even heat distribution

- Infrared systems convert gas flame to intense infrared radiation for maximum searing power

Most units come ready for natural gas connections but include propane conversion kits—perfect if you're operating in an area without natural gas lines or running a food truck operation.

One huge advantage of gas over charcoal? Speed. Your char broiler a gas will be ready to cook in just 5-10 minutes, while charcoal needs a full 20-30 minutes to reach cooking temperature. This efficiency means faster service and lower labor costs, though you will use more energy during operation.

How a Char Broiler a Gas Works

The beauty of a char broiler a gas lies in its straightforward operation:

Gas flows through pipes to burners positioned beneath the cooking surface, where it ignites via either standing pilots or electronic ignition systems. The flames then heat radiants, lava rocks, or infrared emitters that distribute heat evenly across the underside of those sturdy cooking grates. Your cast iron grates absorb this heat and transfer it directly to food, creating those distinctive grill marks that signal "perfectly cooked" to your customers.

Most commercial models include a clever water pan beneath the cooking surface. This unsung hero captures food drippings to reduce flare-ups and smoke while adding a touch of moisture to your cooking environment. As a bonus, the water prevents grease from hardening into a cleaning nightmare later.

Unlike their charcoal cousins, gas charbroilers produce significantly less smoke, making them suitable for indoor use with proper ventilation. You'll sacrifice a bit of that intense smoky flavor, but gain consistency and cleaner kitchen operations—a worthwhile trade-off for most busy restaurants.

Key Types of Gas Charbroilers

Finding the right char broiler a gas for your kitchen comes down to understanding the options:

By Heating Method:

Radiant charbroilers feature metal plates that absorb and radiate heat upward. These reliable workhorses provide consistent cooking temperatures and dominate commercial kitchens. The Vulcan VCRB36 showcases this design beautifully with cast iron char-radiants delivering 14,500 BTU per 6-inch section.

Lava rock charbroilers use volcanic rocks to absorb and distribute heat. They offer more smoky flavor than standard radiant models but demand more attention—food particles love hiding in those rocks, requiring regular cleaning.

Infrared charbroilers employ special emitters that convert gas flame to infrared radiation. These high-performers reach extreme temperatures quickly while using less gas. Vulcan's exclusive IRX™ infrared burner technology represents the cutting edge of this approach.

By Installation Type:

Countertop models save precious space by sitting on existing work surfaces. They're perfect for smaller kitchens or as backup cooking stations during rush periods.

Floor models stand independently with storage space underneath. They offer more cooking area but claim more floor space—a consideration for tight kitchens.

Your operation's size will guide your width choice, with 24", 36", and 48" being the standard commercial options. Larger models not only provide more cooking area but often feature multiple independently controlled cooking zones—perfect when you're simultaneously cooking delicate fish and well-done steaks.

Charcoal Grilling Basics

There's something almost primal about cooking over charcoal. That distinctive crackling sound, the glowing embers, and that unmistakable aroma that makes everyone in the neighborhood suddenly hungry. While a char broiler a gas offers precision and convenience, charcoal grilling connects us to cooking's oldest traditions.

Charcoal grills come in two main fuel varieties. Lump charcoal is the purist's choice - actual pieces of wood burned in a low-oxygen environment until only carbon remains. It lights quickly, burns hotter, and delivers that authentic wood-fired flavor that many chefs swear by. Briquettes, on the other hand, are the reliable workhorses of charcoal cooking - compressed mixtures of charcoal dust and binders that burn longer and more consistently, though with slightly less intense flavor.

What makes charcoal special is that magical smoky aroma. When food drippings fall onto those hot coals, they vaporize and rise back up, creating that distinctive smoky flavor that's simply impossible to replicate with gas. It's chemistry and magic happening right before your eyes.

But let's be honest about the challenges charcoal presents in a commercial kitchen. That amazing flavor comes with some significant trade-offs. Your staff will need to plan ahead with a longer startup time - typically 20-30 minutes before you're ready to cook. There's also the constant dance of vent control, adjusting both bottom and top vents to maintain your desired temperature.

Ash management becomes a daily chore that can't be ignored. Without regular cleaning, ash buildup restricts airflow and compromises your cooking temperature. And speaking of temperature, expect more inconsistent heat across your cooking surface, requiring more experienced grill cooks who know how to manage these hot and cool zones.

The ventilation requirements for commercial charcoal cooking are substantial. All that wonderful smoke needs somewhere to go, meaning you'll need a robust exhaust system that can handle significantly more output than what's required for a char broiler a gas. You'll also need dry storage space for your charcoal supply, safely away from heat sources and moisture.

For restaurants where that distinctive smoky flavor is central to your brand identity - authentic barbecue joints, specialty steak houses, or heritage-focused concepts - these operational challenges might be worth embracing. The flavor payoff can be tremendous. But for high-volume operations where consistency and speed are paramount, these considerations might tip the scales toward gas options.

Gas vs Charcoal: Head-to-Head for Commercial Kitchens

Choosing between a char broiler a gas system and a traditional charcoal grill can feel like deciding between convenience and tradition. Let's break down the real differences that matter for your commercial kitchen:

| Factor | Gas Charbroiler | Charcoal Grill |

|---|---|---|

| Initial Cost | $1,500-$5,000+ | $800-$3,000 |

| Operational Speed | Rapid startup (5-10 min) | Slow startup (20-30 min) |

| Temperature Range | 300°F-700°F | 200°F-700°F+ |

| Temperature Control | Precise with individual burners | Requires skill and constant attention |

| Flavor Profile | Clean sear, minimal smoke | Rich, smoky, complex flavor |

| Indoor Usability | Yes, with proper ventilation | Rarely permitted by code |

| Fuel Cost | $0.50-$1.00 per hour per burner | $1-$3 per hour (plus labor) |

| Staff Training | Basic operation easily taught | Requires experience and skill |

| Maintenance | Regular cleaning, occasional parts | Ash removal, grate cleaning, more intensive |

| Production Capacity | High volume, consistent output | Lower volume, variable output |

| Menu Versatility | Good for most grilled items | Excellent for smoke-forward dishes |

| Safety Concerns | Gas leaks, flare-ups | Fire hazards, ember control |

Pros & Cons Breakdown

When I talk to restaurant owners about their grilling options, the conversation always comes down to what matters most for their specific operation.

The char broiler a gas shines in busy kitchens where consistency is king. You'll appreciate the ability to flip a switch and have cooking heat in minutes, rather than waiting for charcoal to reach temperature. The precise control means your newer staff can produce consistent results without years of experience. And at the end of a long night, simply turning off the gas beats dealing with hot coals and ash disposal.

That said, there's something almost magical about cooking over charcoal that gas simply can't replicate. The distinctive smoky flavor that charcoal imparts has customers coming back specifically for that taste profile. For some restaurants, this flavor difference alone justifies the extra labor and attention charcoal requires.

Gas systems require a higher upfront investment but generally cost less to operate day-to-day. They're cleaner, more predictable, and far less labor-intensive. The trade-off? You'll miss out on the theater of cooking over glowing coals and that distinctive smoky flavor that many consider the hallmark of true grilled food.

Menu Applications & Flavor Impact

Your menu should ultimately drive your decision between gas and charcoal. I've seen this play out in countless kitchens across the country.

A char broiler a gas becomes your best friend when consistency and volume are paramount. High-end steakhouses serving dozens of precisely cooked steaks each hour typically rely on gas systems. The ability to maintain different temperature zones means you can simultaneously handle delicate fish on one side and sear burgers on another. The clean heat also lets the natural flavors of premium ingredients shine without being overshadowed by smoke.

Charcoal, meanwhile, creates a dining experience as much as it does a flavor profile. Restaurants built around traditional barbecue concepts or authentic ethnic cuisines often find that charcoal's distinctive flavor is non-negotiable. The visual appeal of an open charcoal grill can also become part of your restaurant's identity and atmosphere.

Many successful restaurants have found a middle ground. They use a char broiler a gas as their workhorse for high-volume items while maintaining a smaller charcoal grill for signature dishes where that smoky flavor is essential to the concept. Some modern gas charbroilers even offer wood chip drawers that provide a hint of smoke flavor while maintaining gas convenience.

The best choice comes down to your specific operation – your menu, your labor situation, your space constraints, and the expectations of your customers. Understanding these fundamental differences helps ensure you're investing in equipment that supports your culinary vision rather than working against it.

For more detailed information on specific gas grill options, check out Gas Grills to explore current models and features.

Selecting, Installing & Maintaining Your Char Broiler a Gas

Selecting the right char broiler a gas for your commercial kitchen involves careful consideration of several factors:

-

Size and Capacity: Determine your peak cooking volume and choose a unit with adequate surface area. Standard commercial widths include 24", 36", and 48".

-

BTU Requirements: Higher BTU output means faster recovery times and higher maximum temperatures. Most commercial units deliver 15,000-30,000 BTU per burner.

-

Construction Quality: Look for heavy-duty stainless steel construction with cast iron grates for durability. The Precision 48" Heavy Duty Radiant Char Broiler Grill features all-stainless construction with cast iron components for maximum longevity.

-

Grate Design: Reversible grates offer flexibility for different food types. Some models feature specialized seafood grates for delicate items.

-

Control Configuration: Individual controls for each burner section allow for creating temperature zones across the cooking surface.

-

Certification: Ensure the unit carries NSF and ETL/UL certifications for safety and sanitation compliance.

-

Warranty Coverage: Look for at least a one-year warranty on parts and labor, with extended coverage on key components like burners.

Installation of a char broiler a gas requires professional expertise to ensure safety and code compliance:

-

Gas Line Sizing: Ensure your gas supply line can deliver the required volume. A 36" charbroiler might require a 3/4" gas line to support its 87,000 BTU demand.

-

Proper Ventilation: Install under a commercial hood system rated for Type I (grease-laden) vapors with adequate CFM (cubic feet per minute) airflow.

-

Clearances: Maintain proper clearances from combustible materials as specified by the manufacturer and local codes.

-

Gas Type Conversion: If converting between natural gas and propane, use only the manufacturer's approved conversion kit and have the work performed by a licensed professional.

-

Leveling: Use the adjustable legs to ensure the unit is perfectly level for even cooking and proper grease drainage.

At PizzaPrepTable.com, we can help coordinate professional installation in any of our service areas including New York City, Los Angeles, Chicago, and other major metropolitan areas across the United States.

Operating a Char Broiler a Gas Safely and Efficiently

Proper operation of your char broiler a gas ensures safety, efficiency, and longevity:

- Startup Procedure:

- Check that all control valves are in the OFF position

- Turn on the main gas supply

- Light pilot lights according to manufacturer instructions

-

Allow 5-10 minutes for thorough preheating before cooking

-

Temperature Management:

- Use sectional controls to create cooking zones of different temperatures

- Higher heat near the back (typically 550°F+) for searing

- Medium heat in the center for cooking through

-

Lower heat at the front (around 300°F) for holding or finishing

-

Cast Iron Grate Care:

- Season new grates before first use with high-temperature cooking oil

- Avoid cleaning with water when hot to prevent thermal shock and cracking

-

Maintain seasoning by applying a light coat of oil after cleaning

-

Shutdown Procedure:

- Turn all control valves to OFF position

- For extended shutdowns, close the main gas supply valve

-

Allow unit to cool completely before cleaning

-

Energy Efficiency:

- Turn off unused sections during slow periods

- Use lower settings when possible to conserve gas

- Keep the unit well-maintained for optimal performance

Maintenance Best Practices

Regular maintenance of your char broiler a gas is essential for performance, safety, and longevity:

Daily Maintenance: - Scrape grates with a wire brush while still warm (not hot) - Empty and clean grease collection trays - Wipe down exterior surfaces with stainless steel cleaner - Check that pilot lights are functioning properly

Weekly Maintenance: - Remove grates and soak in degreasing solution if heavily soiled - Clean radiants or lava rocks of accumulated grease - Clean burners and check for even flame pattern - Inspect gas hoses and connections for wear or damage

Monthly Maintenance: - Deep clean removable components - Check gas pressure regulator operation - Inspect burner venturi tubes for blockages - Test temperature controls for accuracy - Examine grates for cracks or excessive wear

Quarterly Service: - Schedule professional inspection by a certified technician - Have gas pressure tested and adjusted if necessary - Clean ventilation system and hood filters - Check safety systems including automatic shutoffs

Proper maintenance not only extends equipment life but also ensures energy efficiency. A well-maintained char broiler a gas will use less fuel and cook more consistently than a neglected unit.

Ventilation & Safety Requirements

Safety considerations for char broiler a gas installations are paramount:

- Ventilation Requirements:

- Type I commercial hood system required

- Minimum exhaust rate typically 150-250 CFM per linear foot of hood

- Makeup air system to replace exhausted air

- Fire suppression system integrated with hood

-

Regular cleaning of hood filters and ductwork

-

Clearance Requirements:

- Typically 6" clearance from combustible materials

- 0" clearance from non-combustible walls

- 4" minimum leg height for air circulation

-

Access space for cleaning and maintenance

-

Gas Safety:

- Automatic gas shutoff valve tied to fire suppression system

- Quick-disconnect gas line with restraining device

- Carbon monoxide detectors in kitchen area

- Gas leak detection equipment

-

Emergency shutoff valve in accessible location

-

Staff Training:

- Proper lighting and shutdown procedures

- Recognition of gas leak symptoms

- Fire safety and suppression system operation

- Emergency procedures for gas-related incidents

Compliance with local codes is essential, as requirements vary by jurisdiction. At PizzaPrepTable.com, we can help you understand the specific requirements for your location, whether you're in Phoenix, San Antonio, or any of our other service areas.

Frequently Asked Questions about Gas vs Charcoal Charbroiling

Does gas compromise the smoky flavor I get from charcoal?

Let's be honest – there's a difference in flavor between gas and charcoal. A char broiler a gas won't give you that intense smokiness that charcoal delivers, but that doesn't mean your food won't be delicious! Gas charbroilers still create beautiful caramelization and those rich Maillard reaction flavors that make grilled food so crave-worthy.

If you're worried about missing that smoky punch, you've got options. Many restaurants add wood chips in a smoker box, or invest in specialty gas charbroilers with built-in wood chip drawers. Some chefs keep a small charcoal grill on hand just for finishing special menu items that really benefit from that smoky touch.

Here's something interesting – many customers actually prefer the cleaner flavor profile from gas grilling, especially with delicate proteins like fish or chicken. Heavy smoke can sometimes overwhelm the natural flavors of these foods, making gas a better choice for highlighting their subtle qualities.

How much will a char broiler a gas add to my utility bills?

When budgeting for your kitchen equipment, utility costs are definitely something to consider. A standard 36" char broiler a gas with 87,000 BTU capacity will use about 87 cubic feet of natural gas per hour when running full blast.

What does that mean for your wallet? At typical commercial natural gas rates ($0.80-$1.20 per therm), you're looking at roughly $0.70-$1.05 per hour of operation. For a busy restaurant open 8 hours daily, that's about $5.60-$8.40 per day, or $168-$252 monthly.

Compare this to charcoal, which typically costs $1-$3 per hour plus the extra labor needed to manage it, and gas often comes out as the more economical choice over time, despite the higher upfront investment.

The efficiency between models varies quite a bit, though. Look for efficient burner designs, good heat retention in the grates and radiants, and sectional controls that let you use only the burners you need. These features can make a significant difference in your monthly utility costs.

Can I convert my existing gas charbroiler to propane or vice-versa?

Good news! Most commercial char broiler a gas units can indeed be converted between natural gas and propane. Manufacturers typically offer conversion kits that include replacement orifices sized appropriately for the gas type, regulator adjustments, a new rating plate, and detailed instructions.

But here's the important part – this isn't a DIY project. Conversion should only be handled by licensed gas technicians who know what they're doing. Using only manufacturer-approved conversion kits is crucial for safety and performance, and unauthorized conversions might void your equipment warranty.

Many models, like the Precision Heavy Duty Radiant Char Broiler Grill, ship ready for natural gas but include propane conversion kits in the box. This flexibility is especially helpful if you're moving locations or if your gas supply options change.

That propane typically produces more BTUs than natural gas, which might affect how you control temperature after conversion. You'll also need to ensure the conversion meets local code requirements – something we at PizzaPrepTable.com can help you steer, whether you're in Phoenix, San Antonio, or any of our service areas.

Conclusion & Next Steps

Deciding between a char broiler a gas and a charcoal grill isn't always straightforward. It's a bit like choosing between convenience and tradition, between consistency and that distinctive smoky flavor that makes customers close their eyes when they take that first bite.

For most busy commercial kitchens, gas charbroilers win the day with their reliable performance and operational efficiency. They're the workhorses that keep service moving during your Friday night rush. But there's no denying that charcoal brings something special to the table—a flavor profile that some menu concepts simply can't do without.

Before you make your decision, take a moment to consider what really matters for your operation:

How many steaks, burgers, or chicken breasts will you need to push out during your busiest hour? Can your team handle the extra attention charcoal requires, or would you benefit from the set-it-and-forget-it nature of a char broiler a gas? Is that smoky flavor the cornerstone of your concept, or are your customers more focused on consistent doneness and quick service?

Your kitchen layout matters too. Do you have the ventilation system to handle either option? And let's not forget about your local health department and fire marshal—they'll have opinions about your choice as well!

Here at PizzaPrepTable.com, we've helped hundreds of restaurants work through these exact questions. Our team understands that the equipment you choose today will impact your operations (and your bottom line) for years to come. We're not just order-takers—we're partners in helping your kitchen run smoothly.

We pride ourselves on offering more than just competitive pricing on top commercial brands. Need financing to make your equipment upgrade possible? We've got options. Worried about installation? We'll coordinate with professionals in your area. And our support doesn't end when the equipment arrives—we're here for the long haul.

With our network spanning from Boston to San Diego, Seattle to Dallas, we can get your new char broiler a gas delivered promptly anywhere in the continental US. Whether you're launching a new concept or upgrading equipment that's seen better days, we've got you covered.

Ready to take the next step? Our team is just a phone call away, eager to help you find the perfect charbroiler solution that balances your culinary vision with operational realities. Let's talk about how the right equipment choice can help your kitchen shine.