Top Ice Machine Cleaners and Sanitizers for Your Pizzeria

Share

When it comes to keeping your ice machine in top shape for your pizzeria, you're dealing with two different products for two very different jobs: cleaners and sanitizers. Think of it like this: the cleaner is the deep-scrubbing power wash that gets rid of all the gunk, while the sanitizer is the final disinfectant spray that makes sure everything is truly safe. You can't skip one for the other; a solid maintenance routine needs both to keep your ice clean, safe, and tasting great alongside your signature pizzas.

Why Clean Ice Is Critical for Your Pizza Restaurant

That ice machine humming away in the back isn't just another piece of equipment—it's the unsung hero of your beverage station. Every single soda, iced tea, and drink special you serve with a slice depends on it. Clean, crystal-clear ice isn't a luxury; it's a fundamental ingredient that directly impacts how your customers experience your pizzeria.

But here’s the catch: the inside of an ice machine is a perfect storm of warm, dark, and damp conditions. It’s basically a five-star resort for contaminants. If you let it go, it quickly becomes a breeding ground for invisible threats that can tank the quality and safety of your drinks.

The Unseen Dangers in a Neglected Machine

In a busy pizzeria, the air is full of things like flour dust and airborne yeast. It’s unavoidable. Those particles love to settle inside your ice machine, fueling the growth of biofilm—that nasty pink or black slime you definitely don't want anywhere near your customers. Mix that with the mineral scale that builds up from hard water, and you've got a real problem on your hands.

This buildup can cause a cascade of issues:

- Health Risks: Slime and mold are notorious for harboring dangerous bacteria like Salmonella and Listeria. Serving contaminated ice isn't just bad for business; it's a direct health risk.

- Poor Taste and Odor: Nothing ruins a great slice of pizza faster than a drink that tastes... off. Contaminated ice gives beverages a musty, unpleasant flavor that customers will notice immediately.

- Health Code Violations: Health inspectors treat ice just like any other food product. A dirty machine is a red flag that can lead to hefty fines, a lower health grade, or even a temporary shutdown.

A clean ice machine bin is more than just a maintenance task—it’s a symbol of professionalism, safety, and care. Proper upkeep protects your customers, your equipment, and your restaurant's reputation with every drink served alongside a perfect slice.

Protecting Your Investment and Your Reputation

Using the right ice machine cleaners and sanitizers is about so much more than just acing your next health inspection. It’s a smart business move that protects your equipment. Regular cleaning stops scale from building up, which forces the machine to work harder, run up your energy bills, and eventually leads to component failure.

It’s just like making sure you have the right filters for refrigerator ice makers at home—proper maintenance is the key to longevity. A well-cared-for commercial machine runs more efficiently, produces better-quality ice, and ensures you're always delivering the top-notch experience your customers have come to expect from your pizzeria.

Cleaners vs. Sanitizers: What's the Difference?

When you're running a busy pizzeria, it's easy to lump "cleaning" and "sanitizing" into the same mental bucket. But for your ice machine, treating them as the same thing is a rookie mistake that can put your customers' health at risk.

Think of it like washing your hands after prepping dough. First, you use soap and water to get rid of the visible flour and grime. Only then would you use hand sanitizer to kill the germs you can’t see. It’s a two-step process, and one part can’t do the other’s job.

Ice machine cleaners and sanitizers work the exact same way. They are two different products with two very different jobs. To keep your machine running smoothly and your ice safe, you absolutely have to use both, in the right order.

The Role of an Ice Machine Cleaner

An ice machine cleaner is the "soap" in our hand-washing analogy. Its entire purpose is to break down and remove the physical gunk that builds up inside your machine over time. It’s a powerful first step that clears the way for the sanitizer to actually work.

Cleaners are typically acidic, specifically formulated to dissolve two main culprits lurking in your ice machine:

- Mineral Scale (Limescale): This is that hard, chalky stuff left behind by water, especially if you're in an area with hard water. It cakes onto crucial parts like the evaporator plate, making your machine work harder and produce sad, cloudy ice cubes.

- Organic Slime and Biofilm: In a pizzeria, flour dust and airborne yeast are everywhere. These particles become a feast for bacteria and mold, leading to that nasty pink or black slime you sometimes find. The cleaner's job is to physically scrub this hazardous biofilm away.

By getting rid of all this buildup, the cleaner sets the stage for the real health and safety step.

The Function of an Ice Machine Sanitizer

Once the cleaner has done the heavy lifting and washed away the scale and slime, it's the sanitizer's turn. This second step is non-negotiable if you want a machine that’s genuinely safe for food service. The sanitizer isn’t there to clean—it’s there to kill microscopic threats.

A sanitizer is a chemical agent designed to reduce bacteria, viruses, and other microorganisms to a safe level. Trying to spray sanitizer on a dirty, scale-covered surface is like trying to put a small bandage on a massive wound. It just won’t work.

You can't sanitize dough-covered hands, and you can't sanitize a dirty ice machine. The slime and scale act like a shield, protecting bacteria from the sanitizer. You have to clean it first.

For a deeper dive into the chemicals involved, check out our guide to the 3 types of sanitizer solutions used in commercial kitchens. It’s a big deal in the industry. The market for commercial ice equipment and its maintenance supplies is expected to hit USD 14,597.8 million by 2035, which tells you just how seriously restaurants are taking hygiene.

To really get a clear picture, let's break down exactly what each product does side-by-side.

Cleaner vs Sanitizer Key Functions

| Attribute | Ice Machine Cleaner (Descaler) | Ice Machine Sanitizer |

|---|---|---|

| Primary Role | Removes visible buildup like scale, slime, and grime. | Kills microscopic germs like bacteria and viruses. |

| Chemical Type | Acid-based (often phosphoric or citric acid). | Disinfectant-based (often quaternary ammonium or chlorine). |

| Purpose | Prepares surfaces for sanitization and improves machine efficiency. | Reduces microorganisms to a safe level for food contact. |

| When to Use | The first step in the maintenance process. | The second and final step, after cleaning. |

| The Analogy | The "soap and water" for your machine. | The "hand sanitizer" for your machine. |

Seeing them laid out like this makes it crystal clear—they are two sides of the same coin, and you need both for a complete job.

Why You Absolutely Need Both

Here's the bottom line: using only a cleaner leaves you with a machine that looks clean but is still crawling with bacteria. On the flip side, using only a sanitizer on a dirty machine is a complete waste of time and money, as it can't get past the grime to kill the germs.

For a pizzeria, where your reputation and your customers' safety are everything, taking shortcuts isn't an option. The full two-step process is the only way to guarantee clean, safe, and great-tasting ice with every single scoop.

Choosing the Right Products for Your Pizzeria

Picking the right ice machine cleaners and sanitizers for your pizzeria is way more than just another line item on your supply order. It’s a critical decision that directly impacts how long your equipment lasts, the safety of your ice, and whether you’re staying on the right side of health codes.

Let's face it, a pizza kitchen is a unique environment. You've got airborne flour and yeast floating around constantly, which means you can't just grab a generic cleaner from the big box store and call it a day. Using the wrong product can cause permanent damage or just not work, leaving your business wide open to some serious risks.

Material Compatibility and Equipment Safety

Before you do anything else, grab the manual for your ice machine. I know, I know—but this document is your single source of truth for what chemicals are safe to use. Ignoring it can lead to corrosion, pitting, and a massive repair bill that was completely avoidable. It’s like using the wrong cleaning solution on your stainless steel pizza prep table; eventually, it’s going to cause damage.

The big one to watch out for is nickel. Many commercial ice machines, especially the higher-end models, use nickel-plated evaporators to pump out ice efficiently. A standard, harsh descaler is a recipe for disaster on these surfaces. The acids in non-approved cleaners can literally strip the nickel plating right off, destroying the component and almost certainly voiding your warranty.

That’s why finding a "nickel-safe" cleaner isn’t just a good idea—it’s mandatory for protecting your investment. A nickel-safe formula is engineered to be tough on mineral scale but gentle on those sensitive metal parts. For a full rundown on what to look for when you're buying a machine, check out our essential guide to choosing the best ice maker for your restaurant.

Verifying Certifications NSF and EPA

Once you've confirmed a product is safe for your machine's materials, the next step is to check for official certifications. These aren't just fancy logos on the bottle; they're your guarantee that the product meets strict public health and safety standards. Two of the most important ones are NSF and EPA.

- NSF (National Sanitation Foundation) Certification: An NSF-certified product has been rigorously tested to be safe for a food service environment. It means that when you use it as directed, it won't leave behind any harmful gunk that could contaminate your ice.

- EPA (Environmental Protection Agency) Registration: This one applies specifically to sanitizers. An EPA registration number is proof that the product is an effective antimicrobial pesticide that’s been proven to kill the specific germs it claims to on the label.

Choosing products without these certifications is a gamble with your customers' health and your pizzeria's reputation. They are the absolute baseline for running a responsible and legally compliant kitchen.

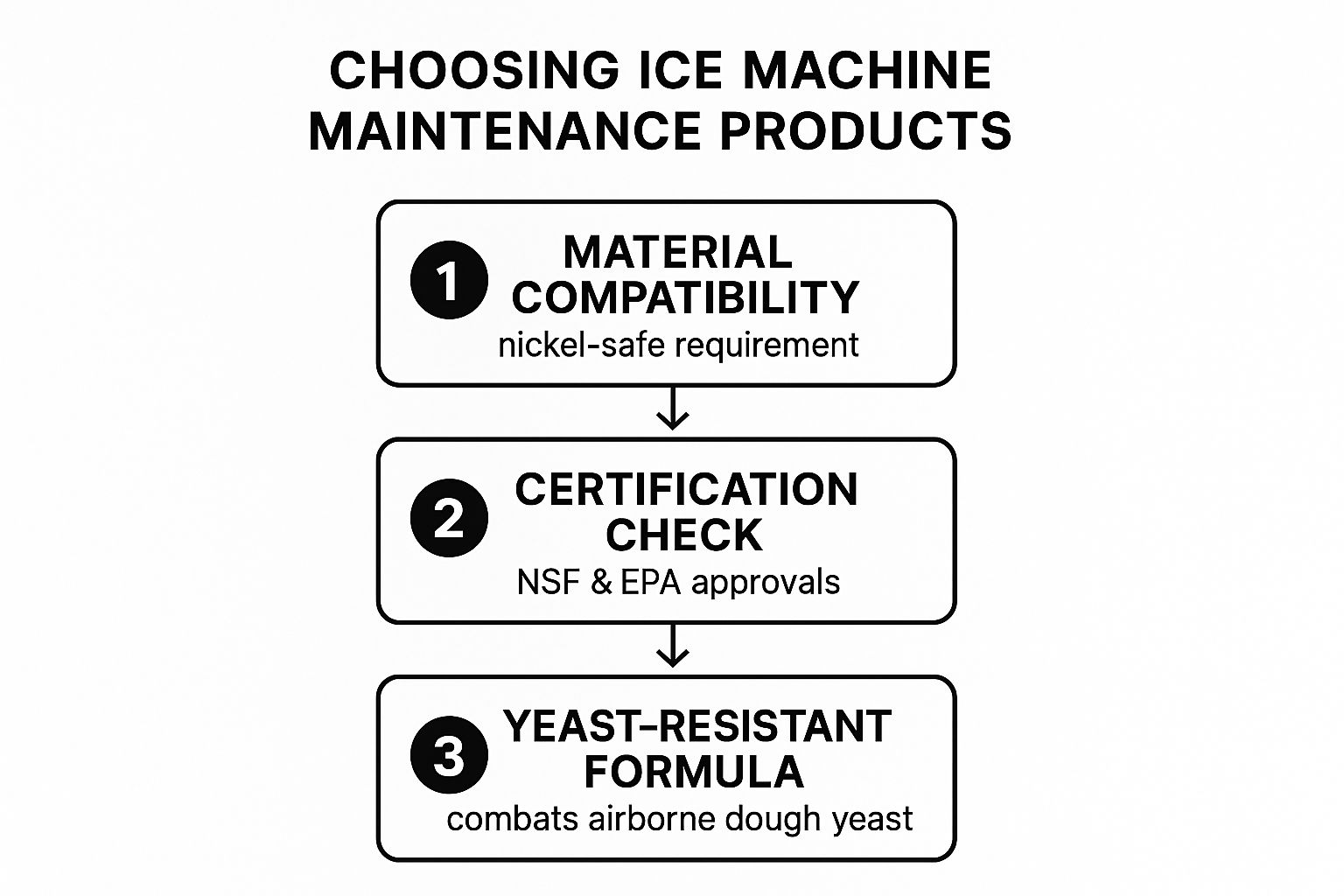

This infographic breaks down the essential decision-making process into three simple steps.

This simple flow shows that every step—from ensuring nickel safety to specifically targeting yeast—is crucial for keeping your machine in top shape in a pizzeria setting.

Tackling the Unique Pizzeria Challenge Airborne Yeast

Here’s where a pizzeria’s needs really differ from a standard restaurant. The air in your kitchen is full of fine particles of flour and, more importantly, airborne yeast from all that proofing dough. To bacteria and mold, this stuff is like a superfood, which speeds up the formation of that nasty pink and black slime inside your ice machine.

This means a standard cleaner and sanitizer probably won't cut it. You need formulas specifically built to fight this rapid biofilm growth. Look for products that specifically mention their effectiveness against organic buildup and yeast-fueled slime.

Choosing a heavy-duty formula ensures your cleaning efforts last longer and give you better protection against the unique contaminants floating around in your pizzeria's air. The reality is that improperly formulated or contaminated products do hit the market. Between 2017 and 2022, there were at least 15 recalls of ice machine descalers and cleaners in the U.S. and Europe due to safety issues like unsafe chemical levels. This just reinforces why sticking to certified, proven products is so critical.

Your Step-By-Step Ice Machine Cleaning Process

Running a clean machine isn't a suggestion; it's your best defense in the unique environment of a pizzeria. With airborne flour and yeast working against you 24/7, you simply can't afford to guess or cut corners. This guide lays out a clear, actionable checklist, removing the ambiguity so your team gets it right every single time.

Think of this process like perfecting a pizza recipe—every step has to be followed in the right order for a safe and delicious result. We're going on a two-phase mission: first, we remove the visible gunk, then we eliminate the invisible threats. This means you'll need both ice machine cleaners and sanitizers.

Phase 1: The Cleaning Cycle

This first phase is all about the deep clean. This is where we physically remove the mineral scale and slimy biofilm that airborne yeast and flour feed on. Sanitizing an already dirty machine is a waste of time; that slime acts like a shield, protecting germs from the very chemicals meant to kill them.

1. Prepare for a Safe Clean

Safety is always the first ingredient. Before a single drop of cleaner is used, the machine needs to be completely powered down and isolated.

- Disconnect Power: Flip the ice machine's switch to the "OFF" position, then unplug it from the wall outlet. No exceptions.

- Shut Off Water: Find the main water supply line going to the machine and turn it off. The last thing you need is an accidental flood.

- Gather Your Gear: Equip your staff with personal protective equipment (PPE). This means chemical-resistant gloves and safety goggles at a minimum.

2. Empty and Discard All Ice

Next, you need a completely empty canvas to work with. Scoop out every last cube of ice from the storage bin and get rid of it. I know it's tempting to save it, but if the machine is dirty, the ice is dirty. It could be contaminated with mold spores or bacteria from the machine's surfaces.

A common mistake I see in busy pizza kitchens is trying to "save" the ice. Always remember: if the machine is dirty, the ice is dirty. There are no exceptions.

3. Disassemble and Hand-Wash Components

Grab the machine's manual and carefully remove all the user-serviceable parts. This usually includes the water curtain, distribution tube, ice thickness sensors, and the bin's baffle.

Take these components over to your three-compartment sink and wash them by hand, just like any other piece of food-contact equipment. Use a mild detergent, scrub every nook and cranny with a soft-bristle brush, rinse well, and let them air dry completely. Pay special attention to corners where that nasty slime loves to hide.

4. Circulate the Ice Machine Cleaner

Now it's time to tackle the machine's guts. Following the manufacturer’s instructions, start the "Clean" or "Wash" cycle. When the machine prompts you, add the correct amount of a nickel-safe ice machine cleaner.

This solution will circulate through the entire water system, breaking down and dissolving the stubborn limescale and mineral deposits that kill performance and give bacteria a place to live. Let the cycle run its full course without interruption.

5. Rinse and Scrub the Bin

While the cleaning solution is working its magic inside the machine, you can focus on the storage bin. In a separate bucket, mix up your cleaning solution and scrub the entire interior of the bin. Use a non-abrasive pad to avoid scratching the surfaces, which can create new hiding spots for germs.

After a thorough scrub, rinse the bin completely with fresh, warm water until every bit of chemical residue is gone. A spray bottle works great for getting into those tight corners.

Phase 2: The Sanitizing Cycle

With the machine now physically clean, it's time for the most critical step: sanitization. This is what eliminates the microscopic bugs that the cleaner left behind, ensuring the ice you serve is genuinely safe.

A Critical Warning: NEVER mix cleaning and sanitizing chemicals. Doing so can create toxic fumes, which is extremely dangerous in an enclosed kitchen. Make absolutely sure the machine has been thoroughly rinsed of all cleaner before you even think about starting this phase.

6. Run the Sanitizing Cycle

Put the machine back together with the clean, dry components from Step 3. Following the instructions for your specific ice machine sanitizer, start another cycle. When prompted, add the sanitizing solution to the water trough.

Let the sanitizing cycle finish completely. Most food-grade sanitizers are designed to be "no-rinse," meaning they air dry on the surfaces to provide maximum germ-killing effectiveness.

7. Final Wipe-Down and Restart

Once the sanitizing cycle is done and everything is dry, give the machine's exterior a final wipe-down. Now you can reconnect the power and turn the water supply back on.

Turn the machine back to "ICE" mode and let it run through one or two full harvests. You must discard these first batches of ice. This flushes out any residual sanitizer from the system. After that, your pizzeria's ice machine is clean, safe, and ready to serve your customers.

To make this a routine your staff can follow without fail, a clear schedule is essential. Here’s a sample schedule you can adapt for your own pizzeria.

Pizza Restaurant Ice Machine Cleaning Schedule

A posted schedule takes the guesswork out of maintenance and ensures these critical tasks actually get done. This sample outlines the daily, weekly, and monthly duties that keep your ice safe and your machine running like new.

| Frequency | Task | Recommended Product |

|---|---|---|

| Daily | Wipe down the exterior and scoop. Visually inspect the ice bin for any signs of mold or slime. | Food-grade surface sanitizer spray |

| Weekly | Sanitize the ice bin interior. Clean and sanitize the ice scoop and holder. | EPA-approved food contact surface sanitizer |

| Monthly | Perform a full cleaning and sanitizing cycle as described in the steps above. | Nickel-safe ice machine cleaner & sanitizer |

| Quarterly | Clean the air filter and condenser coils to ensure proper airflow and efficiency. | Coil cleaner spray (if needed) & brush |

By integrating these steps into your regular operations, you turn a daunting chore into a simple, repeatable process. Consistent maintenance not only guarantees food safety but also protects your investment by extending the life of your ice machine.

Common Maintenance Mistakes and How to Avoid Them

Even with the best intentions and a solid cleaning schedule, a few simple mistakes can completely undermine all your hard work. In a busy pizzeria, slip-ups are bound to happen, but they can lead to some seriously costly consequences—everything from a busted machine to a surprise visit from the health inspector.

Getting a handle on these common pitfalls is the first step. This isn't just about checking boxes; it's about understanding how one small oversight can snowball into a massive problem. Let's walk through the most frequent errors we see in pizza shops and how to sidestep them for good.

Mistake 1: Using Bleach or Other Unapproved Chemicals

When you spot that first hint of slime, it’s so tempting to grab a bottle of bleach. Don't do it. This is probably the most destructive mistake you can make with an ice machine.

Bleach is incredibly corrosive, especially to the nickel-plated components and stainless steel parts that make up your machine's guts. It will literally eat away at these sensitive surfaces, causing permanent damage and almost certainly voiding your manufacturer's warranty. On top of that, bleach is a sanitizer, not a cleaner. It does nothing to break down the scale and biofilm that bacteria are hiding behind.

How to Avoid It: Stick to the script. Only use ice machine cleaners and sanitizers that are EPA-registered, NSF-certified, and specifically approved by your machine's manufacturer. Always, always use a nickel-safe cleaner to protect your investment.

Mistake 2: Sanitizing a Dirty Machine

This is a classic case of putting the cart before the horse. I’ve seen it a hundred times: a time-crunched employee skips the cleaning step and goes straight for the sanitizer. It’s like trying to wash your hands with sanitizer when they’re covered in flour and dough—it just doesn't work.

Biofilm and mineral scale act like a shield, protecting germs from whatever you throw at them. Spraying sanitizer on a dirty surface is a total waste of time, product, and effort because the chemical can't get through the grime to kill the bacteria underneath. You end up with a machine that looks clean but is still a serious health hazard.

A critical takeaway for any kitchen is that you cannot sanitize a dirty surface. Cleaning removes the physical soil, and sanitizing kills the microscopic threats. One cannot happen without the other.

Mistake 3: Forgetting the Air Filters and Condenser

In a pizzeria, the air is thick with flour dust and grease. It’s unavoidable. All those airborne particles get sucked right into your ice machine's ventilation system, where they clog the air filter and coat the condenser coils.

A clogged filter essentially chokes the machine, forcing the compressor to work overtime just to stay cool. This not only sends your energy bills through the roof but also leads to premature equipment failure. It’s one of the most overlooked yet critical maintenance tasks in any pizza shop.

- Clean the Air Filter: Most filters pop right out and can be washed with warm, soapy water. Get this done weekly, or bi-weekly at the absolute minimum.

- Inspect Condenser Coils: Every quarter, give the condenser coils a look. If you see grease and dust buildup, clean them with a soft brush or a dedicated coil cleaner.

Keeping these machines running right is more important than ever. The global ice maker market was valued at USD 3.02 billion in 2024 and is only expected to grow, which tells you just how essential this equipment has become. You can find out more about what's driving this demand. Learn more about the ice maker market's growth and trends.

By sidestepping these common errors, you’re no longer just going through the motions. You’re performing truly effective maintenance that keeps your ice safe, protects your valuable equipment, and ensures your pizzeria runs like a well-oiled machine.

Frequently Asked Questions

When you're running a busy pizzeria, questions about ice machine maintenance are bound to come up. It's a unique environment—with flour dust and airborne yeast creating extra challenges—so getting clear, straightforward answers is the key to keeping your equipment in top shape. Here, we'll tackle the most common questions pizzeria owners have about ice machine cleaners and sanitizers.

We'll cover everything from the right cleaning schedule for a high-yeast kitchen to whether the chemicals are truly safe to use near your pizza prep tables. My goal is to help you build a maintenance routine that you can stick with, one that's both effective and efficient.

How Often Should I Clean My Pizzeria's Ice Machine?

For any busy pizza restaurant, a full cleaning and sanitizing cycle every three months is the absolute minimum. But let's be realistic—the high concentration of airborne yeast and flour dust in a pizzeria is a magnet for slime and biofilm growth inside your machine.

Because of this, many local health departments and equipment manufacturers will tell you to be more aggressive. A deep clean every month is a much safer bet. It helps you get ahead of hazardous buildup before it even starts.

Beyond the deep clean, some smaller tasks need more frequent attention:

- Daily: The ice scoop and its holder need to be cleaned and sanitized every single day, just like any other food-contact utensil. No exceptions.

- Weekly: Take a minute to check the air filter. In a pizzeria, it gets clogged with flour and grease surprisingly fast, which forces the machine to work harder and can lead to breakdowns.

Always double-check your machine's manual for its specific recommendations. And use your eyes—if you spot any slime, it's time to clean, regardless of what the calendar says.

Can I Use Vinegar or Bleach Instead of Commercial Products?

I get this question a lot, and the answer is an emphatic no. It might seem like a clever, money-saving shortcut, but using household products like vinegar or bleach in a commercial ice machine is a recipe for disaster. It can lead to expensive repairs and will almost certainly void your warranty.

Vinegar is a weak acid, plain and simple. It's just not strong enough to break down the heavy, commercial-grade mineral scale that builds up inside these machines. You'll just be wasting your time.

Using bleach is an even bigger mistake. Bleach is highly corrosive and will eat away at sensitive components, especially nickel-plated and stainless steel parts. It can cause pitting and deterioration that leads to catastrophic equipment failure.

Plus, bleach is a sanitizer, not a cleaner. It does absolutely nothing to remove the scale and slime where bacteria and mold love to hide. For both safety and effectiveness, you have to use EPA-registered and NSF-certified ice machine cleaners and sanitizers that are specifically formulated for your equipment.

What Are the Signs My Ice Machine Needs Cleaning Urgently?

Your ice machine will give you some pretty clear warning signs when it's overdue for a deep clean. If you train your staff to spot these red flags, you can prevent a minor issue from turning into a major health violation or a costly repair bill.

Keep an eye out for these telltale signs:

- Visible Growth: This is the most obvious one. If you see pink, brown, or black slime inside the machine, on the water curtain, or in the storage bin, stop what you're doing and clean it.

- Unpleasant Odor or Taste: Does the ice smell musty, stale, or just "off"? That smell is a direct result of microbial contamination, and it will transfer directly to your customers' drinks.

- Poor Ice Quality: A dirty machine struggles to do its job. If it starts producing smaller, cloudy, or hollow ice cubes, it's often because scale buildup on the evaporator plate is messing with the freezing process.

- Reduced Ice Production: If the machine just isn't keeping up or the bin isn't refilling as quickly as it used to, buildup is likely interfering with its mechanical function.

If you notice any of these signs, don't wait for the next scheduled cleaning. An urgent cleaning and sanitizing cycle is needed immediately to protect your customers and prevent further strain on the machine.

A common misconception is that the freezing process kills bacteria. In reality, it only makes them dormant. When the ice melts in a customer's drink, those microorganisms can become active again, posing a health risk.

Are These Cleaning Chemicals Safe for a Food Prep Area?

Yes, they are—but only when you use them exactly as the manufacturer directs. These products are specifically formulated for foodservice environments like your pizzeria. The key is following the safety and usage protocols to the letter. Staff must wear appropriate personal protective equipment (PPE), like gloves and eye protection, and make sure the area is well-ventilated during the cleaning process.

The most critical safety step is the final rinse cycle after cleaning and before sanitizing. Following the manufacturer’s rinsing instructions meticulously is non-negotiable. This is what ensures that no chemical residue from the cleaner is left behind.

Similarly, most NSF-certified sanitizers are "no-rinse" formulas, meaning they are designed to air dry safely on food-contact surfaces. By discarding the first one or two batches of ice produced after a full cycle, you flush out any final traces, making all subsequent ice completely safe for your customers.

Ready to streamline your kitchen operations with reliable, top-tier equipment? At Pizza Prep Table, we provide everything from high-efficiency ice machines to the perfect refrigerated prep tables for your pizzeria. Explore our full catalog and find the gear that will help your business thrive. Visit us at https://pizzapreptable.com to get started.