Industrial Planetary Mixers That Are Out of This World

Share

Why Industrial Planetary Mixers Are Game-Changers for Commercial Kitchens

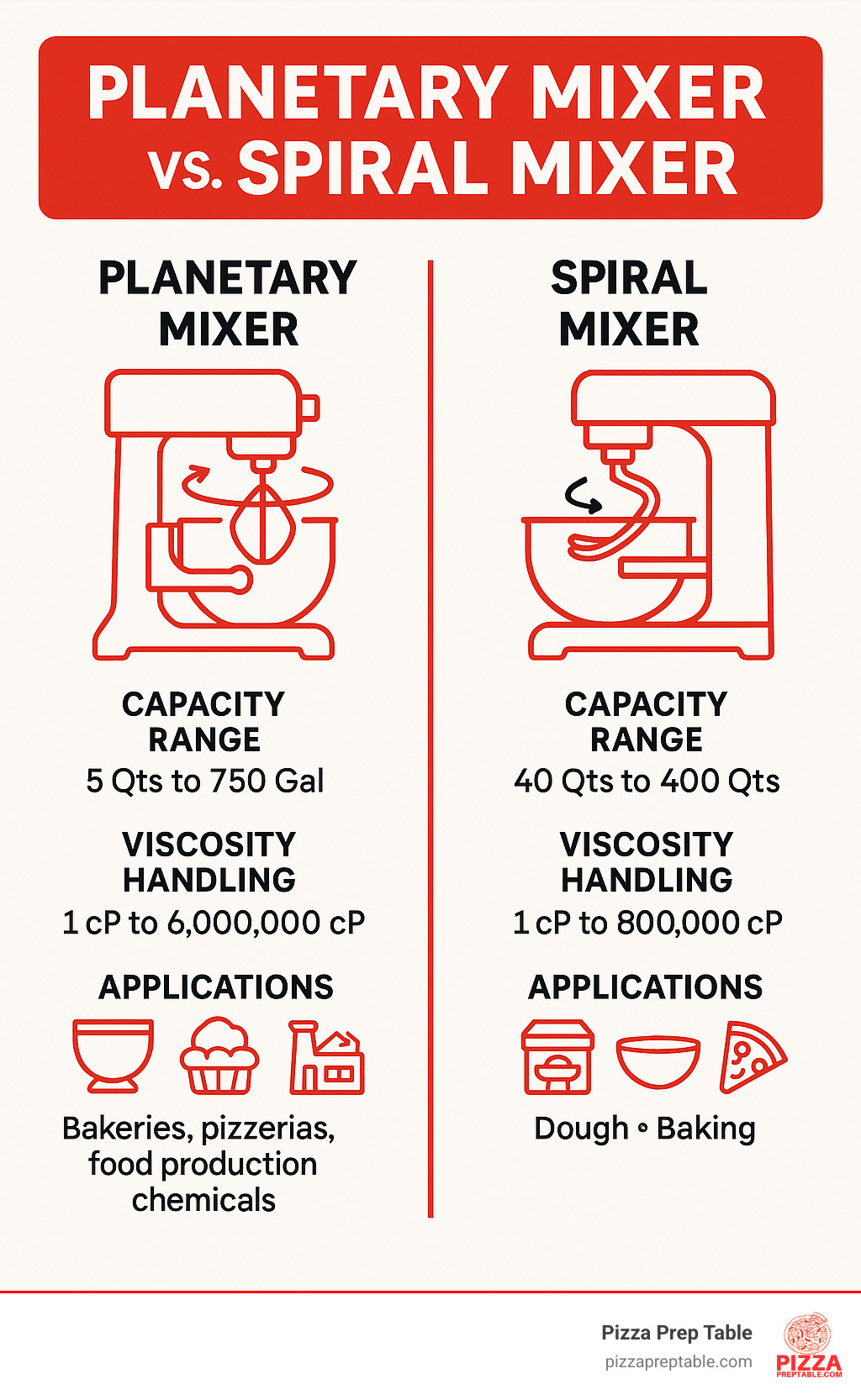

An industrial planetary mixer is a commercial mixing machine where the agitator revolves around a stationary bowl in a planetary motion, providing thorough mixing for everything from pizza dough to cake batter. Here's what you need to know:

Key Features: - Capacity Range: 5 quarts to 750 gallons - Viscosity Handling: 1 cP to 6,000,000 cP - Motion: Agitator orbits bowl while rotating on its own axis - Applications: Bakeries, pizzerias, food production, chemicals

Popular Models: - Hobart Legacy+ (30-140 qt) - Pizza dough specialist - ROSS Double Planetary (½ pint-750 gal) - High viscosity champion - Avantco MX20 (20 qt) - Budget-friendly option

Whether you're kneading 90 pounds of pizza dough or whipping delicate creams, these mixers handle it all with precision. The planetary motion ensures every ingredient gets mixed - no dead spots, no inconsistent batches.

For pizzeria owners and small restaurant managers, choosing the right mixer means faster prep times, consistent quality, and the flexibility to expand your menu.

I'm Sean Kearney, and my experience in restaurant equipment sales has shown me how the right industrial planetary mixer can transform a kitchen's efficiency and product quality. Having helped countless foodservice businesses choose mixers that match their needs and budgets, I'll guide you through the best options available today.

Important industrial planetary mixer terms: - large mixer - professional mixers

What Is an Industrial Planetary Mixer?

Think of the solar system for a moment – planets orbiting the sun while spinning on their own axis. That's exactly how an industrial planetary mixer works, and it's this brilliant design that makes these machines so incredibly effective.

The mixing attachment doesn't just spin in place like a basic mixer. Instead, it travels around the entire bowl while rotating, creating what we call planetary motion. This dual movement means every single spot in your bowl gets thoroughly mixed – no dead zones, no unmixed pockets of flour hiding in corners.

What makes planetary mixers special is their fixed bowl design. While spiral mixers rotate the bowl itself, planetary mixers keep the bowl perfectly still and let the agitator do all the work. You can easily swap between different agitator attachments – paddles for cookie dough, hooks for pizza dough, whisks for whipped cream.

The size range is impressive. You've got compact 5-quart countertop models perfect for small cafes making fresh muffins, all the way up to massive 750-gallon industrial beasts that could probably mix enough pizza dough to feed half your city. And the viscosity range? These machines handle everything from thin batters at 1 centipoise to thick, putty-like materials at an incredible 6 million centipoise.

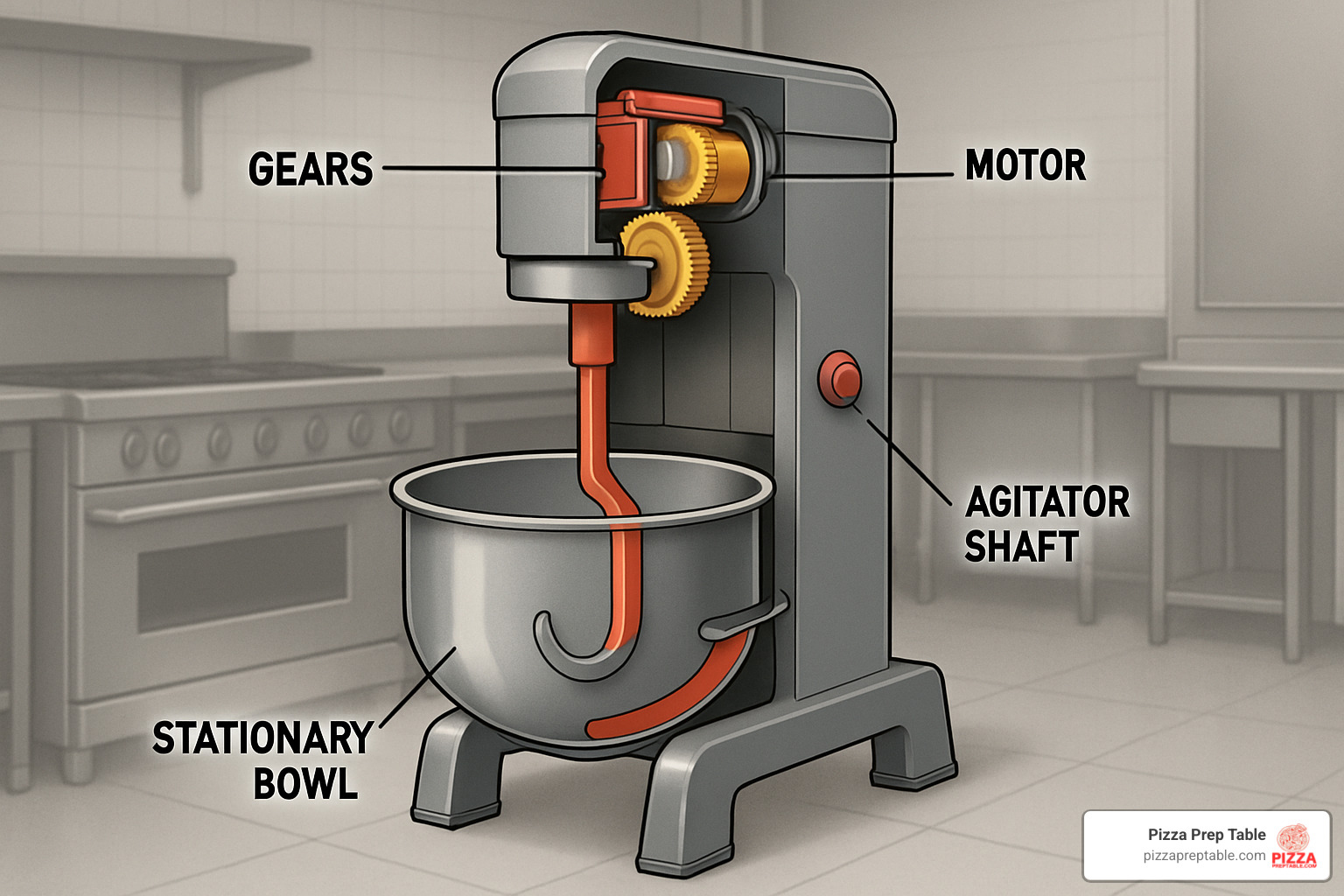

How It Works

The beauty is in the simplicity. A single motor drives the orbiting agitator through a robust transmission system. In single planetary mixers, one attachment orbits while spinning – perfect for most bakery and pizzeria needs. But double planetary mixers take things up a notch with twin blades that orbit the bowl AND interact with each other, creating incredibly thorough mixing in just 36 revolutions.

Most serious commercial units use gear-drive systems rather than belts. Why? Because when you're kneading 90 pounds of pizza dough or mixing thick adhesives, you need serious torque. Belt-driven systems just can't handle that kind of punishment day after day.

Many industrial models are vacuum-capable, pulling up to 29.5 inches of mercury. This isn't just a fancy feature. It's essential for applications where you need to remove moisture or prevent oxidation during mixing.

Key Components

Every industrial planetary mixer is built around five essential components that work together seamlessly.

The bowl is your foundation – usually heavy-duty stainless steel that can handle anything from delicate cake batter to aggressive chemical mixing. The agitator shaft is the heart of that planetary motion system, engineered to handle continuous operation without wobbling or wearing out.

Horsepower varies dramatically based on size and application. Small countertop units might run on 3/4 horsepower, while industrial giants can pack several horsepower under the hood. The control panel on modern units is where the magic happens – variable speed controls, smart timers, and safety interlocks all at your fingertips.

Finally, there's the bowl lift system. When you're dealing with a 60-quart bowl full of dough, you'll appreciate having either a manual crank or automatic lift to do the heavy lifting for you.

Types & Applications: Finding the Perfect Fit

Choosing the right industrial planetary mixer feels a bit like dating - you need to find the perfect match for your specific needs. The good news? There's a planetary mixer type for every kitchen romance, from gentle single-blade mixers that treat delicate batters with care to powerful double planetary units that can handle the toughest mixing challenges.

| Mixer Type | Capacity Range | Best For | Viscosity Range |

|---|---|---|---|

| Single Planetary | 5-140 qt | Batters, creams, light doughs | Low to medium |

| Double Planetary | ½ pint-750 gal | High-viscosity materials | Up to 6M cP |

| Hybrid/PowerMix | 1 qt-750 gal | Multi-stage mixing | Wide range |

| Vertical Batch | Custom sizes | Specialized applications | Extreme viscosity |

Single Industrial Planetary Mixer Uses

Single planetary mixers are the bread and butter of commercial kitchens (literally, in some cases). These trusty workhorses excel at mixing batters, whipping creams, and handling moderate dough loads without overworking your ingredients. Most countertop models live in the sweet spot of 5-20 quarts, making them perfect companions for bakeries, cafes, and smaller restaurants.

Picture this: you're making a delicate vanilla cake batter or whipping up fresh cream for tomorrow's desserts. A single planetary mixer provides that gentle-but-thorough mixing action that keeps your ingredients happy. They're also fantastic for cookie dough, mashed potatoes, and whipped toppings - basically anything that needs consistent mixing without the aggressive action of high-shear equipment.

Double Industrial Planetary Mixer Advantages

When single planetary mixers meet their match, double planetary mixers step up to the plate. These powerhouses feature twin blades working in harmony, creating a mixing action so efficient it can tackle materials thick enough to stop a single-blade mixer in its tracks.

The secret sauce is in the blade-to-blade interaction. While one blade is doing its planetary dance, the other is right there working the same material from a different angle. This tag-team approach accelerates mixing efficiency dramatically - we're talking about completing thorough mixing in just 36 revolutions.

Double planetary mixers shine when you're dealing with high-viscosity materials like thick pizza sauces, dense frostings, adhesives, or specialty pastes. They're also champions of vacuum mixing, which makes them incredibly valuable for applications requiring moisture removal or preventing oxidation during processing.

Hybrid & PowerMix

ROSS PowerMix units represent the cutting edge of planetary mixer evolution. These hybrid systems are like having two mixers in one - they combine a planetary stirrer with a high-speed disperser blade, creating a mixing powerhouse that handles everything from water-thin liquids to ultra-thick materials approaching 2 million centipoise.

The genius of these systems lies in their adaptability. You can start mixing a fluid formulation and continue as it thickens during processing - something that would require multiple pieces of equipment with traditional setups.

Industry Applications

While planetary mixers feel right at home in pizza kitchens and bakeries, their talents extend far beyond the foodservice world. In bakeries, they're mixing cake batters, cookie dough, frosting, and handling light bread dough. Pizzerias rely on them for pizza sauce consistency, specialty dough for thin crusts, and creating unique toppings.

Step outside the kitchen, and you'll find planetary mixers working in chemical plants mixing adhesives and sealants, in cosmetics facilities creating perfect creams and lotions, and even in aerospace applications. The most extreme example? B&P Littleford's monster mixer - a 38-foot-high, 160,000-pound planetary mixer designed for rocket propellant mixing.

Sizing, Features & Buying Checklist

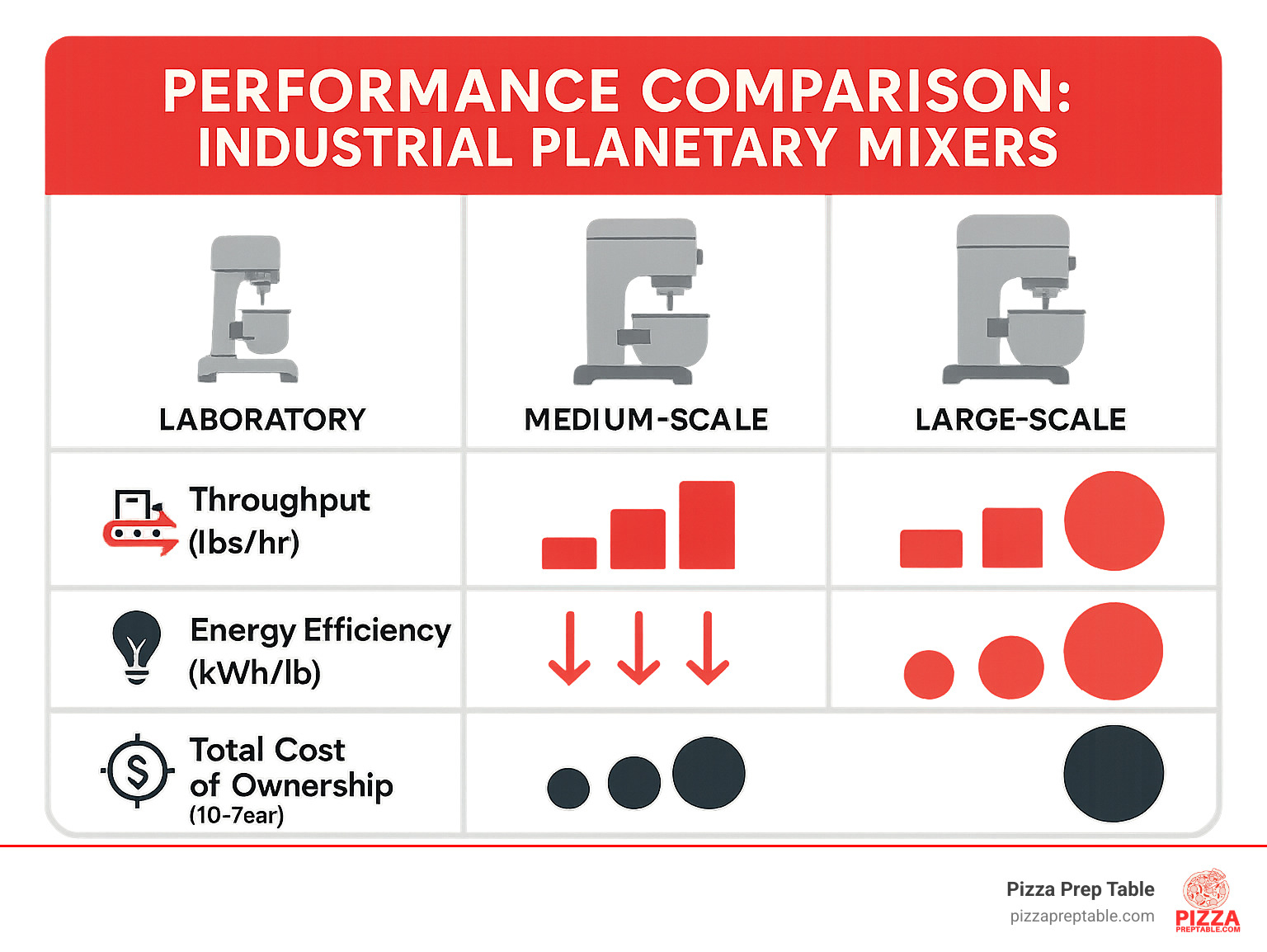

Choosing the right industrial planetary mixer feels overwhelming at first, but I've guided hundreds of pizzeria owners and restaurant managers through this decision. The secret? Focus on your actual daily production, not your biggest day of the year.

Most operators make the same mistake - they think bigger is always better. But an oversized mixer wastes energy, takes up valuable kitchen space, and actually mixes small batches poorly. On the flip side, an undersized mixer becomes your bottleneck during busy periods.

Calculate Your Batch Size

Here's the golden rule that's saved countless operators from buyer's remorse: never fill your mixer more than 75% of its rated capacity. If you regularly make 40 pounds of pizza dough, you need at least a 60-quart mixer to handle that load properly.

Pizza dough calculations get tricky because recipes vary so much. Start with your flour weight, then add your absorption ratio - the percentage of water relative to flour. A typical pizza dough uses 60% absorption, meaning 60 pounds of water per 100 pounds of flour.

The dough percentage method makes this easier. If your total recipe equals 180% (100% flour + 60% water + 20% other ingredients), and you use 50 pounds of flour, your total batch weighs 90 pounds. That 60-quart Hobart HL662 handles exactly this load - no coincidence it's so popular with pizzerias.

Must-Have Features

After selling mixers across major markets from New York to Los Angeles, certain features separate the workhorses from the headaches. Variable speed control tops the list - you'll need different speeds for incorporating dry ingredients versus developing gluten structure.

The #12 attachment hub might seem like an add-on feature, but it transforms your mixer into a multi-purpose machine. Suddenly you can run meat grinders, vegetable slicers, and pasta makers through the same motor. For small operations, this versatility is huge.

Safety bowl guards with interlocks aren't just good ideas - they're required by most health departments. The smart timer with memory ensures consistent batches even when you're training new staff. And for anything 60 quarts or larger, a power bowl lift saves your back and prevents workplace injuries.

Upstream & Downstream Equipment

Your industrial planetary mixer doesn't work in isolation. Smart operators think about the entire production flow before making their purchase.

Ingredient preparation comes first. You'll want accurate scales, ingredient bins positioned for easy loading, and potentially a flour sifter for consistent results. Moving mixed products efficiently prevents bottlenecks. Dough dividers and sheeters work best when positioned close to your mixer.

More info about choosing large mixer - our detailed guide covers integration planning that most operators overlook until it's too late.

Best Industrial Planetary Mixers of 2024

After testing mixers in real commercial kitchens and talking with hundreds of pizzeria owners, we've identified the industrial planetary mixers that actually deliver results. These aren't just spec sheet winners - they're the machines that keep running during your busiest dinner rush and still mix perfect dough at closing time.

External research on planetary mixers confirms what we see in the field: reliability and consistent performance matter more than flashy features.

Hobart Legacy+ HL662 (60-Qt Pizza Powerhouse)

The Hobart Legacy+ HL662 costs $27,250.30, but it's worth every penny for serious pizzerias. This 60-quart beast handles up to 90 pounds of dough with its powerful 2.7 horsepower motor. What makes it special is the Shift-On-The-Fly control system - you can change speeds while mixing without stopping the machine.

The gear-driven transmission provides consistent power that belt-driven mixers simply can't match. The swing-out design and single-point bowl installation make loading 50-pound flour bags manageable. Being NSF and UL listed means it meets all health department requirements.

Perfect for: High-volume pizzerias making 200+ pizzas daily, commercial bakeries, restaurants needing rock-solid reliability.

ROSS DPM-750 (Heavy Viscosity Champion)

When you need to mix materials thick enough to walk on, the ROSS DPM-750 steps up. This double planetary mixer handles up to 750 gallons and materials reaching 6 million centipoise - think thick pizza sauce, dense frosting, or industrial adhesives.

The twin HV-blades work together to cover every point in the vessel in just 36 revolutions. The vacuum capability up to 29.5 inches of mercury allows moisture removal during mixing.

Perfect for: Large food processing facilities, operations mixing extremely thick materials, facilities requiring vacuum processing.

Ferneto BTI 140 (Pastry Pro)

The Ferneto BTI 140 handles 100-140 liters with European precision engineering. The stainless steel frame option resists corrosion in high-moisture environments, while the IPX5 rating means it survives aggressive washdown procedures.

Perfect for: Artisan bakeries, pastry shops with high sanitation standards, operations requiring European-style precision.

Avantco MX20 (Budget-Friendly Bench Star)

At under $2,000, the Avantco MX20 proves you don't need to break the bank for quality mixing. This 20-quart countertop unit packs a 1.5 horsepower motor that outperforms many higher-priced competitors.

The gear-driven transmission provides reliability that belt-driven budget mixers can't match. Being ETL listed for both US and Canada means it meets all commercial kitchen requirements.

Perfect for: Small bakeries starting out, cafes with moderate mixing needs, pizza shops making limited dough batches.

Jaygo 3000 L Jacketed DPM (Extreme Scale)

When your operation measures ingredients by the ton, the Jaygo 3000-liter jacketed mixer handles the load. This massive double planetary mixer processes materials up to 2 million centipoise while maintaining precise temperature control from 34°F to 355°F.

Perfect for: Large food processing plants, industrial bakeries, operations requiring temperature-controlled mixing at massive scale.

Maintenance, Safety & Cleaning

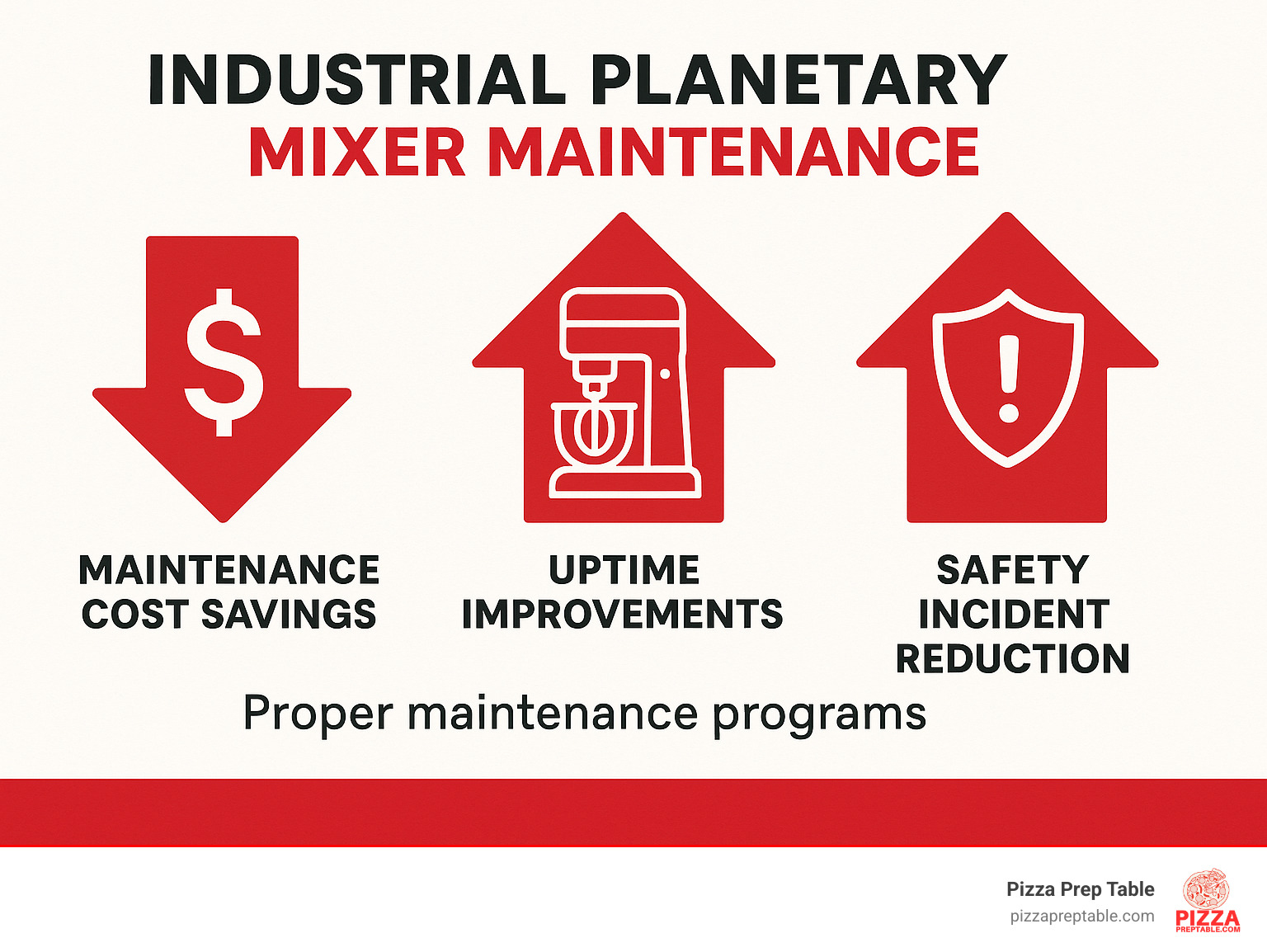

Your industrial planetary mixer is built to last decades with proper care. I've walked into pizzerias where 1980s Hobart mixers are still cranking out perfect dough batches - but they didn't get there by accident. Smart maintenance keeps these workhorses running and protects your investment.

Routine Maintenance Schedule

Think of mixer maintenance like brushing your teeth - small daily habits prevent big problems later. Daily tasks take just minutes but make all the difference. Wipe down surfaces after each shift, check that the bowl guard moves smoothly, and inspect your mixing attachments for chips or wear.

Weekly maintenance digs a bit deeper. Look for grease leaks around the gearbox - they start small but signal bigger issues brewing. Test your safety interlocks by trying to start the mixer with the guard open (it shouldn't start).

Monthly deep cleaning keeps everything running smoothly. Clean the control panel carefully with a damp cloth (never spray directly). Check that motor mounting bolts stay tight from all that vibration.

Annual professional service is non-negotiable for commercial operations. A qualified technician should service the gearbox, test the motor, and verify all safety systems. This yearly checkup typically costs $200-400 but prevents thousand-dollar repairs.

Safety Features Checklist

Modern industrial planetary mixers pack serious safety features, but older units might need upgrades. The bowl guard interlock is your first line of defense - it prevents the mixer from starting with the guard open. Never, ever bypass this system, even during cleaning.

Every mixer should have an emergency stop button within easy reach. Overload protection saves your motor from burning out when someone overloads the bowl or adds ingredients too quickly.

Look for UL or CE certification labels - they mean the electrical system meets safety standards. The forces in a planetary mixer can cause life-changing injuries, so safety systems only work if you let them.

Quick-Clean Tips

Smart cleaning design saves hours every week. Removable bowls are worth their weight in gold - you can soak them properly instead of trying to clean around a fixed bowl. Clean-in-place (CIP) systems work wonders for high-volume operations.

For multi-product facilities, dedicated bowls for different recipes prevent cross-contamination. The key to easy cleaning? Don't let things sit and harden. Clean immediately after each batch, and your mixer will reward you with years of reliable service.

Frequently Asked Questions about Industrial Planetary Mixers

Over the years, I've fielded thousands of questions about industrial planetary mixers from restaurant owners, bakery managers, and foodservice operators. Here are the ones that come up most often - along with the honest answers that help you make the right choice for your operation.

Can one industrial planetary mixer replace a spiral mixer?

This question comes up almost daily, especially from pizzeria owners trying to maximize their equipment investment. The truth is, it really depends on what you're making and how much of it.

Planetary mixers are your best bet when you need versatility above all else. They handle multiple attachments, work beautifully with small to medium batches, and shine when you're making different products throughout the day.

Spiral mixers win the day for dedicated dough production, especially when you're cranking out 200+ pounds of pizza dough daily. They develop gluten more gently, run quieter, and handle massive batches without breaking a sweat.

Here's my rule of thumb: if you're making 50-100 pounds of dough plus sauces, toppings, and other prep work, a solid industrial planetary mixer like the Hobart HL662 handles everything beautifully. But if you're a high-volume pizzeria pushing 200+ pounds of dough every day, the efficiency of a dedicated spiral mixer usually pays for itself.

How do I scale from lab to production?

Food manufacturers face this challenge constantly - your recipe works perfectly in the test kitchen, but now you need to make 50 times as much. The good news is that planetary mixers scale remarkably well.

ROSS offers the perfect example of this scalability, with models ranging from tiny ½-pint laboratory units all the way up to massive 750-gallon production beasts. The key is maintaining what engineers call "geometric similarity" - basically keeping the same proportions as you scale up.

What attachments should every buyer own?

This is where industrial planetary mixers really show their versatility. Every mixer should come with the holy trinity of attachments: flat paddle for general mixing and batters, dough hook for heavy work like pizza dough, and wire whip for anything that needs air incorporated.

The real magic happens when you find the #12 attachment hub that comes standard on most commercial mixers. This opens up a whole world of possibilities - meat grinders for fresh sausage, vegetable slicers for prep work, pasta extruders for house-made noodles, and dozens of other accessories.

Conclusion

The right industrial planetary mixer can completely transform how your kitchen operates. I've watched small cafes in Boston double their daily output after upgrading from a worn-out 20-quart unit to a proper Hobart Legacy+. Similarly, pizzerias in Las Vegas have told me their new mixers paid for themselves in just six months through improved efficiency and consistency.

Whether you're whipping up cake batter for a neighborhood bakery or cranking out 90 pounds of pizza dough for the dinner rush, there's an industrial planetary mixer that fits your needs and budget. The beauty of these machines lies in their versatility - one day you're mixing pizza sauce, the next you're preparing frosting for a special order.

At PizzaPrepTable.com, we know that buying commercial equipment feels like a big leap. That's why we offer financing options that let you spread the investment over manageable monthly payments. Our team serves major markets from New York City to Los Angeles, Chicago to Houston, and everywhere in between. When you need support, we're just a phone call away.

The mixers we've explored today represent years of real-world testing in busy commercial kitchens. The budget-friendly Avantco MX20 has launched countless bakery dreams, while industrial giants like the ROSS DPM-750 keep major food manufacturers running smoothly. Each has earned its place through reliable performance when it matters most.

Here's what I've learned after years in this business: a quality mixer isn't an expense, it's an investment. Those Hobart mixers we installed in pizzerias back in the 1990s? Many are still mixing perfect dough today. Choose thoughtfully, maintain consistently, and your planetary mixer will become the reliable backbone of your operation for decades.

Ready to find your perfect mixer? Our professional mixer buying guide walks you through every detail, from sizing calculations to financing options. Our equipment specialists understand the unique challenges of commercial kitchens - we're here to help you make the right choice for your specific operation.