Keep Calm and Store On – Food Truck Fryer Oil Storage Tips

Share

Why Food Truck Fryer Oil Storage Can Make or Break Your Mobile Kitchen

Food truck fryer oil storage is critical for safety, efficiency, and profits in your mobile kitchen. The wrong approach can lead to burns, spills, and wasted money - while the right system keeps your oil lasting up to 50% longer.

Essential Food Truck Fryer Oil Storage Solutions:

• Hot Oil Transfer: Heat-resistant containers like MirOil pots or Bayou Classic stainless steel cans (up to 350°F)

• Used Oil Storage: Mobile units like Shortening Shuttle® or DAR PRO systems with secure lids and wheels

• Capacity: 4-7 gallon containers work best for most food trucks

• Safety Features: Splash-proof covers, ergonomic handles, and one-way valves

• Materials: Food-grade stainless steel or high-temp plastics only

The stakes are high. Used cooking oil causes 25% of kitchen injuries according to industry data, and improper storage can lead to fires, health code violations, and oil that breaks down twice as fast.

But here's the good news: food trucks using proper oil storage report 30% less waste and 20% faster workflow. The right containers also extend oil life through better sealing and contamination control.

I'm Sean Kearney, and my background in restaurant equipment sales has shown me how proper food truck fryer oil storage transforms operations from chaotic to smooth. After helping countless mobile kitchen owners solve their oil handling challenges, I've seen the difference the right storage system makes.

Why Proper Fryer Oil Storage Matters in Food Trucks

Picture this: you're working the lunch rush in your food truck when a poorly secured container of hot oil tips over. In seconds, your tiny kitchen becomes a dangerous mess, your day is ruined, and you're facing potential injury claims. This nightmare scenario happens more often than you'd think - kitchen injuries account for 25% of all workplace accidents in mobile food service.

The truth is, food truck fryer oil storage isn't just about convenience - it's about protecting your business, your employees, and your bottom line. When you're working in a space smaller than most home kitchens, every safety decision gets magnified.

Proper storage systems do more than prevent accidents. They're actually money-makers in disguise. Quality storage containers with airtight seals and contamination protection can extend your oil's life by up to 50%. For a busy food truck burning through 20 gallons of oil weekly, that's hundreds of dollars saved every month.

Your customers taste the difference too. Oil stored correctly maintains better flavor profiles and cooking performance. Nobody's coming back for soggy fries or off-tasting fried chicken from degraded oil. Quality control starts with storage.

Key Risks & Challenges Inside a Tiny Kitchen

Food truck kitchens turn every oil handling task into a potential hazard. Heat burns top the danger list when you're maneuvering hot oil containers in cramped quarters with limited ventilation. One wrong move and you're dealing with serious injuries.

Slip-and-fall accidents cause the most oil-related injuries. Spilled oil on a food truck's small floor space creates an instant skating rink. The good news? Mobile fryer oil containers with secure lids and wheels reduce spill incidents by over 80% compared to traditional open buckets.

Limited space makes storage a daily puzzle. That restaurant-grade oil container won't fit through your service window or in your designated storage area. You need solutions designed for tight spaces.

Then there's odor control. Used oil smells can quickly overwhelm a small space and drift right into your customer area. Nothing kills appetite like the smell of rancid oil wafting from your kitchen.

Mobility issues add another layer of complexity. Your truck hits bumps, takes corners, and parks on uneven surfaces. Improperly secured containers shift, leak, and create hazards that stationary restaurants never face.

Business Benefits of Getting Storage Right

Smart food truck owners who invest in proper oil storage see impressive returns. That 30% reduction in oil waste isn't just a nice statistic - it's real money in your pocket. A typical truck spending $200 weekly on oil saves $60 per week, adding up to over $3,000 annually.

Workflow efficiency improves by 20% when you can safely move hot oil without drama. Heavy-duty transporters handle up to 50 pounds of oil in under 60 seconds, minimizing downtime during busy periods. Faster oil changes mean faster service.

Customer satisfaction soars when your oil quality stays consistent. Fresh-tasting food builds the repeat business that keeps food trucks profitable. Proper storage prevents the off-flavors and poor texture that send customers to your competition.

The fire risk reduction alone justifies the investment. Used oil stored improperly becomes a fire hazard that can destroy your truck and your livelihood. Quality storage systems with proper sealing and temperature control dramatically reduce this risk.

Sustainability matters too. Properly stored oil lasts longer, reducing waste and environmental impact. Many storage systems also connect directly to recycling programs, turning your used oil into biodiesel revenue.

Food Truck Fryer Oil Storage Containers: Picking the Perfect Fit

Finding the right food truck fryer oil storage containers is like solving a puzzle where every piece has to fit perfectly in your tiny kitchen. You need something that's tough enough to handle hot oil, small enough to maneuver through tight spaces, and smart enough to keep your operation running smoothly.

The material choice comes down to two main options: food-grade stainless steel for maximum durability and heat resistance, or high-temperature plastics when you need something lighter to handle. Stainless steel wins for longevity, but quality plastics can be easier on your back during those long service days.

Here's where most food truck owners get it right: 4-7 gallon containers hit that sweet spot between usefulness and manageability. Go bigger and you'll struggle to lift them safely. Go smaller and you'll be running back and forth like you're training for a marathon.

The features that actually matter include splash-proof covers with gaskets (trust me, you'll thank yourself later), ergonomic handles that won't slip when your hands are greasy, and heavy-duty wheels for containers that need to move. Quick-lock clips and airtight sealing aren't just nice-to-haves - they're what keep your oil fresh and your storage area from smelling like yesterday's fish and chips.

| Container | Capacity | Material | Key Features | Best For |

|---|---|---|---|---|

| MirOil Filter Pots | 5-7 gallons | Stainless Steel | Mobile base, splash-proof covers | Hot oil transfer |

| Shortening Shuttle® | 6 gallons | High-temp plastic | Wheeled, pump system | Used oil transport |

| Frymaster PSDU50 | 50 lbs | Steel/Plastic | Manual pump, low profile | High-volume disposal |

| DAR PRO Fat4Fuel | 168.5 gallons | Steel | Indoor/outdoor, automated | Large operations |

Food Truck Fryer Oil Storage Options for Hot Oil Transfer

When you're dealing with oil straight from the fryer, heat resistance isn't negotiable - it's survival. MirOil pots have earned their reputation by handling oil at 350°F without breaking a sweat. Their ergonomic design means you won't throw out your back, and those tight-sealing lids with built-in gaskets create an airtight environment that keeps contamination out.

The Bayou Classic 4-gallon stainless steel storage can takes a different approach. Built like those old military jerry cans but designed for food service, this 304 stainless steel container lets you store hot oil immediately after cooking. The vented design prevents dangerous pressure buildup, while the airtight seal keeps your oil fresh for the next service.

High-temperature plastics offer a lighter alternative when your arms are already tired from a busy lunch rush. Just make sure you're getting containers specifically rated for hot oil temperatures - the cheap stuff will warp faster than you can say "workers' comp claim."

Food Truck Fryer Oil Storage Solutions for Used Oil

The Shortening Shuttle® has become the go-to choice for used oil handling, and there's a good reason why. Priced between $821-$865, these wheeled units reduce spill risk so dramatically that many operators say they pay for themselves in prevented accidents alone. The Economy and Simplicity series offer different pump configurations, so you can match the system to how your kitchen actually works.

DAR PRO's Space Saver units solve two problems at once by combining oil storage with shelving space. In a food truck where every square inch counts, this dual-purpose approach makes perfect sense. These containers are built to last 15+ years and come with UL certification for safety compliance - important when the health inspector comes knocking.

For high-volume operations with adequate space, airtight tanks like the Fat4Fuel system can store up to 2,500 pounds of used oil. While they're mainly designed for stationary installations, smaller versions work well for busy food trucks that go through oil like it's going out of style.

Safe Handling, Filtering & Disposal Workflow

Creating a solid workflow for handling your food truck fryer oil storage isn't just about staying organized - it's about keeping your team safe and your oil lasting longer. Think of it as your daily safety dance that saves money and prevents accidents.

Filter frequency makes all the difference in oil life. During busy seasons, daily filtering becomes your best friend. It might seem like extra work, but those few minutes each day can double your oil's lifespan. Mobile transporters with built-in pumps turn this chore into a quick, clean process that even your newest team member can handle safely.

Grease caddies are game-changers for food truck operations. These clever devices let you suction oil directly from fryers without any manual pouring. No more awkward lifting of heavy, hot containers over your head. The compact models designed to fit beneath fryers are perfect for tight food truck spaces.

Even with the best equipment, employee PPE remains non-negotiable. Heat-resistant gloves, non-slip shoes, and protective aprons should be as standard as your uniforms. Training your staff on proper procedures prevents most oil-related accidents - and trust me, that's training time well spent.

Pump systems streamline everything by eliminating the manual handling that causes most injuries. When you can move hot oil with the flip of a switch instead of muscle power, you're already ahead of the game.

For more insights on optimizing your food truck's frying setup, check out our guide on space-saving fryers.

Step-by-Step Hot Oil Changeout

The gravity drain method is your safest bet for hot oil changes. Position your mobile container beneath the fryer's drain valve, making sure everything lines up properly. Quality transporters typically feature drain heights around 9⅝ inches when covers are open - measure yours to avoid messy surprises.

Filter powder works magic during weekly deep filtrations, but skip it for daily maintenance filtering. Add it during the filtering process to help capture those tiny particles that cloud your oil and shorten its life.

The sealed caddy approach keeps things clean and safe. Drain directly into a covered, wheeled container to minimize exposure and eliminate spill risk. Your back will thank you for not lifting heavy containers, and your floors will stay grease-free.

Set up a dedicated cooldown zone away from your main work area. Hot oil containers need time to reach safe handling temperatures without anyone accidentally bumping into them. This quiet time also lets sediment settle before final filtration, giving you cleaner oil for longer.

Disposal & Recycling Partners

Local pickup services offer the easiest solution for most food truck operators. Many areas have specialized used cooking oil collection companies that provide containers and stick to regular pickup schedules. It's like having a cleaning service, but for your used oil.

Biodiesel conversion turns your waste into someone else's fuel - literally. Many recycling companies now convert used cooking oil into renewable fuel, creating a feel-good story you can share with environmentally conscious customers.

For high-volume operations, DAR PRO Solutions Fat4Fuel systems provide automated collection through external ports. Their technicians handle everything, so you never touch the used oil. It's the ultimate hands-off approach to food truck fryer oil storage disposal.

Regulations, Costs & Space-Saving Hacks

Navigating the regulatory maze for food truck fryer oil storage doesn't have to give you a headache. Most health departments require proper containment and regular disposal schedules, but the specifics vary wildly between cities and states. I've seen food truck owners get caught off-guard by local rules they didn't know existed.

Fire marshal regulations often mandate specific storage distances from heat sources and proper ventilation around oil storage areas. These aren't suggestions - they're requirements that can shut down your operation if ignored. The good news? Most quality storage systems are designed with these regulations in mind.

UL-certified tanks provide the gold standard for regulatory compliance. Yes, they cost more upfront, but they satisfy insurance requirements and give you peace of mind during health inspections. Think of it as buying protection against costly violations and potential lawsuits.

The ROI calculation gets interesting when you factor in all the benefits. Quality storage systems typically pay for themselves within 6-12 months through extended oil life alone. Add in labor savings from easier handling and reduced injury risk, and the numbers become compelling. Many suppliers offer financing options that make these systems accessible even for startup food trucks.

Here's where it gets clever: multi-purpose prep tables that incorporate oil storage maximize your precious square footage. Some units combine stainless steel work surfaces with built-in oil storage compartments below. Space saver shelves from companies like DAR PRO integrate storage with existing equipment racks, turning dead space into functional storage.

For comprehensive cooling solutions that complement your oil storage setup, explore our commercial fridge freezer combo guide.

Extending Oil Life on a Budget

Consistent filtering represents the biggest bang for your buck when extending oil life. Daily filtering removes food particles and contaminants that accelerate oil breakdown. Even simple manual filtering with appropriate filter bags makes a significant difference - we're talking about doubling your oil's lifespan with minimal effort.

Low-temperature frying reduces oil stress when possible. Maintaining fryer temperatures at the minimum effective level slows oil degradation. This requires balancing cooking speed with oil preservation, but the savings add up quickly.

Anti-foam agents help manage oil breakdown in high-volume operations. These food-safe additives reduce foaming and extend usable oil life. Closed lids between cooking sessions prevent air exposure that accelerates oxidation - it's like putting a protective bubble around your investment.

Different oil types offer varying storage life based on their fatty acid composition. Macadamia oil can be stored up to one year thanks to its high monounsaturated fat content, while soybean oil typically lasts around six months due to its polyunsaturated fat content.

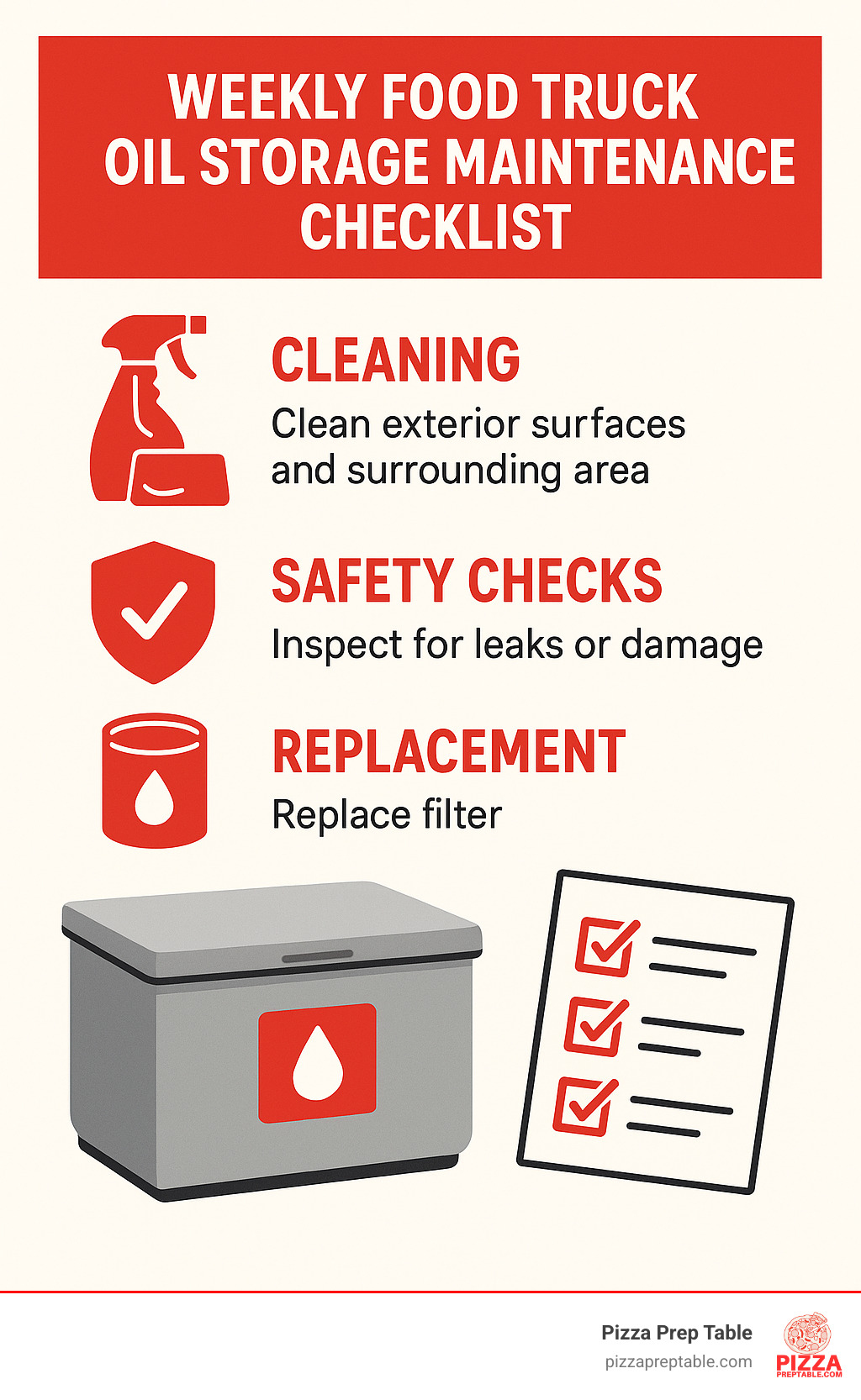

Maintenance & Cleaning Routine

Daily wipe-downs prevent oil buildup that attracts contaminants and creates slip hazards. Use food-safe degreasers and ensure all surfaces are completely dry before storing containers. It takes five minutes but prevents hours of deep cleaning later.

Weekly deep cleaning involves disassembling removable components and thorough sanitization. Pay special attention to gaskets and seals, which can harbor bacteria if not properly maintained. These small rubber components are often overlooked but critical for food safety.

Gasket checks should be part of your routine maintenance schedule. Damaged seals allow air infiltration that accelerates oil degradation. Replace gaskets at first signs of cracking or hardening - they're inexpensive insurance against oil spoilage.

Wheel lubrication keeps mobile units functioning smoothly. Use food-grade lubricants on wheel bearings and check for wear that could cause sudden failures during oil transport. Nothing ruins your day like a wheel falling off a container full of hot oil.

Frequently Asked Questions about Food Truck Fryer Oil Storage

Let's tackle the most common questions I hear from food truck owners about food truck fryer oil storage. These answers come from real-world experience helping mobile kitchen operators solve their oil handling challenges.

How often should I filter and replace fryer oil?

The honest answer? It depends on how busy you are and what you're frying. High-volume food trucks should filter daily - especially if you're cranking out hundreds of orders during lunch rushes. More moderate operations can often stretch filtering to every other day without problems.

Here's my rule of thumb: if your oil looks dark, gets foamy, or starts smelling funky, it's time to replace it. Most food trucks end up changing oil every 3-7 days depending on usage. Busy festival weekends might require daily changes, while slower periods can extend oil life.

Temperature monitoring gives you another clue about oil health. When your oil takes forever to heat up or won't reach proper cooking temperatures, it's telling you something. Degraded oil just doesn't perform like fresh oil.

The good news? Proper food truck fryer oil storage with airtight containers can extend these timeframes by preventing contamination and air exposure between uses.

What container size works best for a typical food truck?

After helping countless food truck owners, I've found that 4-7 gallon containers hit the sweet spot for most operations. They're large enough to handle your daily oil changes but won't throw out your back when you're wrestling them around a cramped kitchen.

Smaller food trucks often prefer 4-gallon units - they're easier to maneuver and store. High-volume operations can usually handle 7-gallon containers, especially if they have decent storage space and strong team members.

Here's a practical tip: think about your fryer's oil capacity when choosing containers. You'll need storage for both fresh and used oil, so plan for at least twice your fryer's capacity in total container volume. If your fryer holds 3 gallons, you'll want around 6-7 gallons of total container storage.

Don't forget about your truck's door width and storage areas when sizing containers. I've seen operators buy perfect containers that wouldn't fit through their service door!

Can I store fresh and used oil in the same unit?

Absolutely not - and this is one mistake that can cost you serious money. Mixing fresh and used oil is like putting dirty socks back in your clean laundry drawer. Cross-contamination destroys fresh oil quality faster than you'd believe and creates potential food safety headaches.

Always maintain separate, clearly labeled containers for fresh and used oil. I recommend a simple system: many operators use stainless steel containers for fresh oil and plastic units for used oil. The visual difference prevents dangerous mix-ups during busy service periods.

Color-coding or clear labeling saves you from expensive accidents. Trust me, accidentally contaminating 5 gallons of fresh oil with used oil is a costly mistake you only want to make once. Good food truck fryer oil storage practices include foolproof identification systems that work even when you're rushing during peak hours.

Some operators even position their containers in different areas of the truck to prevent confusion. Fresh oil near the prep area, used oil near the disposal zone. Simple systems work best in high-stress environments.

Conclusion & Next Steps

Getting your food truck fryer oil storage right isn't just about buying the right containers - it's about changing your entire mobile kitchen operation. When you invest in proper storage solutions, you're really investing in your crew's safety, your food quality, and your bottom line.

The numbers tell the story. Food trucks using dedicated oil storage systems see 30% less waste and 20% faster workflows. That translates to real money in your pocket and fewer headaches during busy lunch rushes. More importantly, you're protecting your team from the burns and spills that cause 25% of kitchen injuries.

Start with your biggest pain point. Maybe it's the constant worry about hot oil spills in your cramped kitchen. Or perhaps you're frustrated watching expensive oil go bad too quickly because you can't store it properly. Whatever keeps you up at night, there's a storage solution that addresses it directly.

The environmental benefits matter too, especially as more customers choose businesses that care about sustainability. Proper storage extends oil life, reduces waste, and makes recycling easier. It's a win-win that feels good and looks good to your customers.

At PizzaPrepTable.com, we've seen countless food truck operators struggle with oil storage challenges. Our experience in the commercial kitchen equipment world has taught us that the right solution isn't always the most expensive one - it's the one that fits your specific operation and space constraints.

Your next step is simple: evaluate what you're currently using and identify where it's falling short. Whether you need better hot oil transfer containers, more efficient used oil storage, or a complete workflow overhaul, the solutions we've covered give you a roadmap to success.

Ready to tackle other aspects of your mobile kitchen? Check out our complete collection of mobile kitchen articles for more practical tips that help food truck operators like you maximize efficiency and boost profits.

Proper food truck fryer oil storage is just one piece of creating a successful mobile kitchen. But it's a foundational piece that affects everything else - from crew safety to customer satisfaction to your monthly expenses. Get this right, and everything else becomes easier.