Pizza Screen vs. Pizza Steel: Unlocking the Secrets to a Better Bake

Share

Why Choosing the Right Pizza Screen Matters for Your Pizzeria

A stainless steel pizza screen is a mesh baking surface that promotes airflow around pizza dough during cooking, resulting in a crispier, more evenly browned crust. Here's what you need to know:

Key Benefits:

- Crispier crusts - Mesh design allows heat and air to reach the dough from all angles.

- Even baking - Perforations promote smooth browning across the entire crust.

- Moisture control - Holes release excess moisture to prevent soggy bottoms.

- Durability - Stainless steel resists corrosion and warping better than aluminum.

- Easy maintenance - Most are dishwasher safe and require minimal care.

Price Range: $2.50 - $35 CAD depending on size (7" to 21")

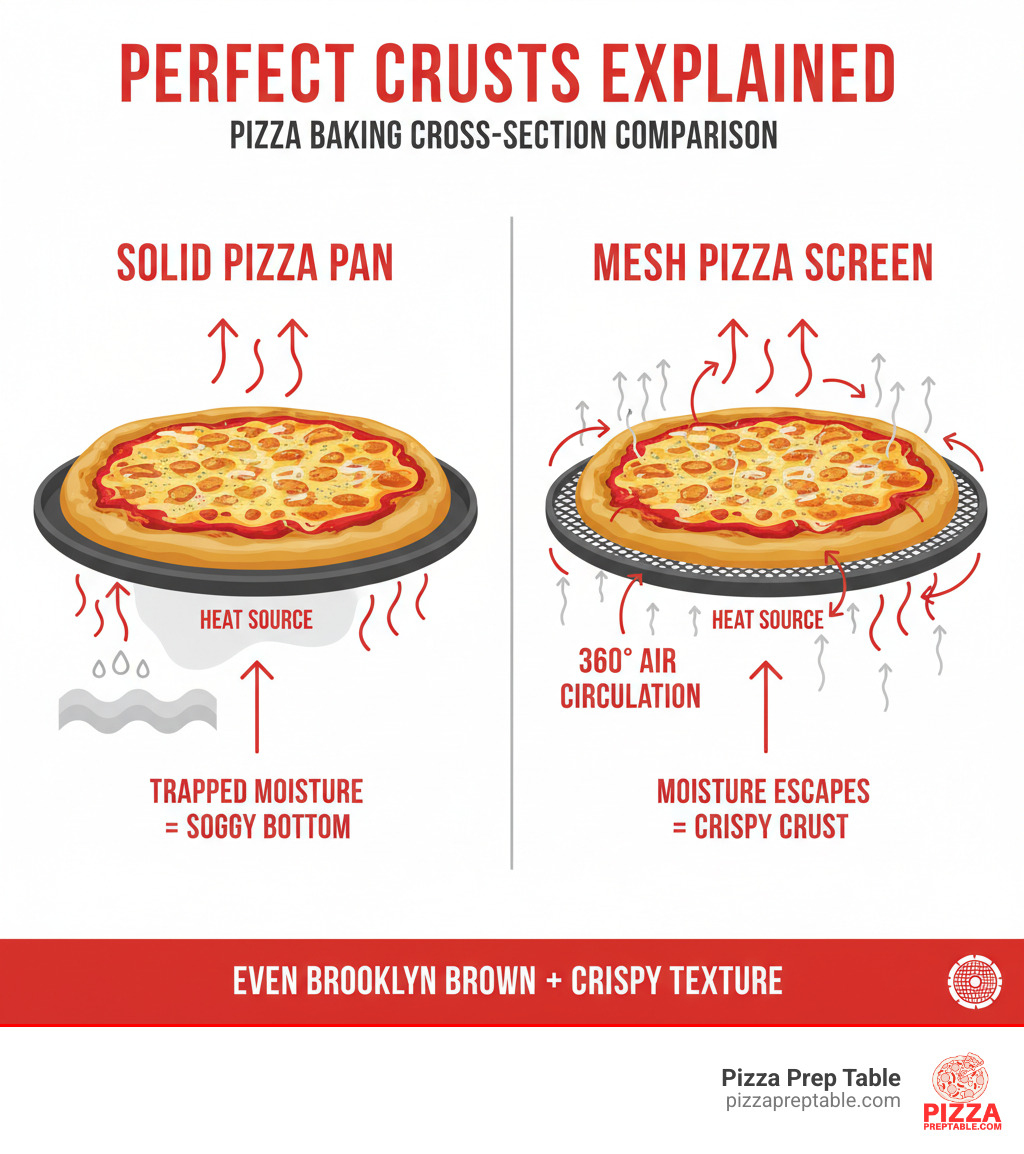

If you've ever pulled a pizza from the oven only to find a soggy, undercooked bottom, the problem likely isn't your recipe—it's the baking surface. Traditional pizza pans trap moisture, creating steam that makes crusts soft instead of crispy.

Pizza screens solve this with their mesh design. The perforations allow oven heat to transfer directly to the pizza base while letting moisture escape. This means your pizzas cook faster, brown more evenly, and develop that satisfying crunch customers expect.

While all screens help, material matters. Stainless steel offers superior durability and corrosion resistance compared to aluminum. Size and mesh pattern also affect performance, with options ranging from 10" personal-size screens to 16" large pizza screens.

For pizzerias, screens are a smart choice. They stack easily, take up minimal storage room, and cost less than pizza stones or steels. They also work in any oven type—conveyor, deck, or conventional—making them incredibly versatile.

As Sean Kearney, I've helped countless restaurant owners select equipment that maximizes efficiency. Stainless steel pizza screens consistently prove to be one of the smartest investments for achieving professional-quality results.

What is a Pizza Screen and How Does It Achieve a Crispier Crust?

Think of a pizza screen as your secret weapon against soggy crusts. It's a flat, round baking surface made from perforated metal mesh. The difference between baking on a stainless steel pizza screen and a solid pan is night and day.

The hundreds of tiny holes create air circulation that solid pans can't match. Heat flows through the mesh and surrounds the dough from every angle, giving the bottom of the pizza direct exposure to the oven's heat.

The result is even baking across the entire crust, with consistent, golden browning from edge to center. This superior heat distribution is especially important for thin crust pizzas, which need rapid, direct heat to develop their signature crunch.

The real magic, however, is how the screen handles moisture. As dough bakes, it releases steam. On a solid pan, that steam gets trapped, creating a soft, gummy bottom. The mesh design of a pizza screen allows this moisture to escape freely through the perforations. This built-in ventilation prevents sogginess and leaves only crisp, perfectly baked dough behind.

The beauty of pizza screens is their simplicity. They offer better airflow, better moisture escape, and consistently crispier crusts every time, without complicated techniques or special oven requirements.

Stainless Steel vs. Aluminum: Which Pizza Screen Material Reigns Supreme?

When shopping for a pizza screen, the material is a key decision. Both stainless steel and aluminum can produce great results, but the best choice depends on your priorities, whether you're running a busy commercial kitchen in Chicago or perfecting pizzas at home in Houston.

Let's compare these materials on durability, heat transfer, maintenance, and cost.

| Feature | Stainless Steel Pizza Screen | Aluminum Pizza Screen |

|---|---|---|

| Durability | Superior corrosion resistance, won't rust or warp, non-reactive with acidic toppings. | Lightweight but can bend, may develop pitting over time. |

| Heat Transfer | Good heat distribution, slower to heat but maintains temperature well. | Exceptional heat conductivity, heats up faster for quicker cooking. |

| Maintenance | Dishwasher safe, easy to clean, no seasoning needed. | Requires seasoning, hand-wash only to preserve coating. |

| Cost | Higher initial investment ($10-$35). | Budget-friendly option ($5-$15). |

The Best Durability of a Stainless Steel Pizza Screen

For longevity, stainless steel pizza screens are best. They are built to last, resisting corrosion and rust even with heavy daily use in commercial kitchens. Unlike aluminum, stainless steel is non-reactive, so it won't affect your pizza's flavor when it comes in contact with acidic tomato sauce.

With high-temperature tolerance, these screens handle the heat of commercial ovens without warping, ensuring a flat surface for consistent results. Plus, most are dishwasher safe, saving valuable time and labor. This durability means a lower long-term cost, as you'll replace them far less often.

The Rapid Heat Transfer of an Aluminum Screen

Aluminum's main advantage is its exceptional heat conductivity. It transfers heat faster than stainless steel, leading to quicker cooking times—a big plus in high-volume pizzerias.

Aluminum screens are also lightweight and more cost-effective upfront, making them attractive for new businesses or home use. However, they require more care. You must season them to create a non-stick surface and they are hand-wash only. For busy operations, this extra maintenance can be a significant drawback.

The choice comes down to whether you value the durability and low maintenance of stainless steel or the speed and affordability of aluminum.

What are the benefits of using a stainless steel pizza screen compared to other materials?

When choosing a pizza screen, the material is a critical factor. Both stainless steel and aluminum are popular, but they offer different advantages. Here’s a breakdown of why one might be a better fit for your pizzeria in Phoenix or your home kitchen in Seattle.

The Best Durability of a Stainless Steel Pizza Screen

The primary benefit of a stainless steel pizza screen is its exceptional durability. It stands up to the rigors of a commercial kitchen, resisting warping, bending, and denting even at high temperatures. This warp resistance ensures a flat surface for even baking, pizza after pizza.

Another key advantage is its corrosion resistance. Stainless steel won't rust or pit when exposed to acidic sauces or cleaning chemicals, and its non-reactive surface ensures no metallic taste transfers to your food. For busy kitchens, the fact that most are dishwasher safe is a major plus, saving time and effort. This longevity makes stainless steel a smart long-term investment.

The Rapid Heat Transfer of an Aluminum Screen

Aluminum's main appeal is speed. It offers exceptional heat conductivity, heating up quickly and reducing cooking times. This can be a significant advantage during a busy dinner rush. Aluminum screens are also lightweight and more cost-effective upfront.

However, aluminum has its downsides. It requires seasoning to create a non-stick surface and is typically hand-wash only. Thinner aluminum screens are also prone to warping in high-heat environments, leading to uneven baking and the need for frequent replacement.

While aluminum offers speed and a lower initial cost, a stainless steel pizza screen provides the reliable, low-maintenance performance that is crucial for consistently crispy crusts.

Choosing the Right Stainless Steel Pizza Screen for Your Kitchen

Selecting the ideal stainless steel pizza screen can significantly impact your baking results and efficiency. It's about choosing the right tool for the job to ensure consistent quality.

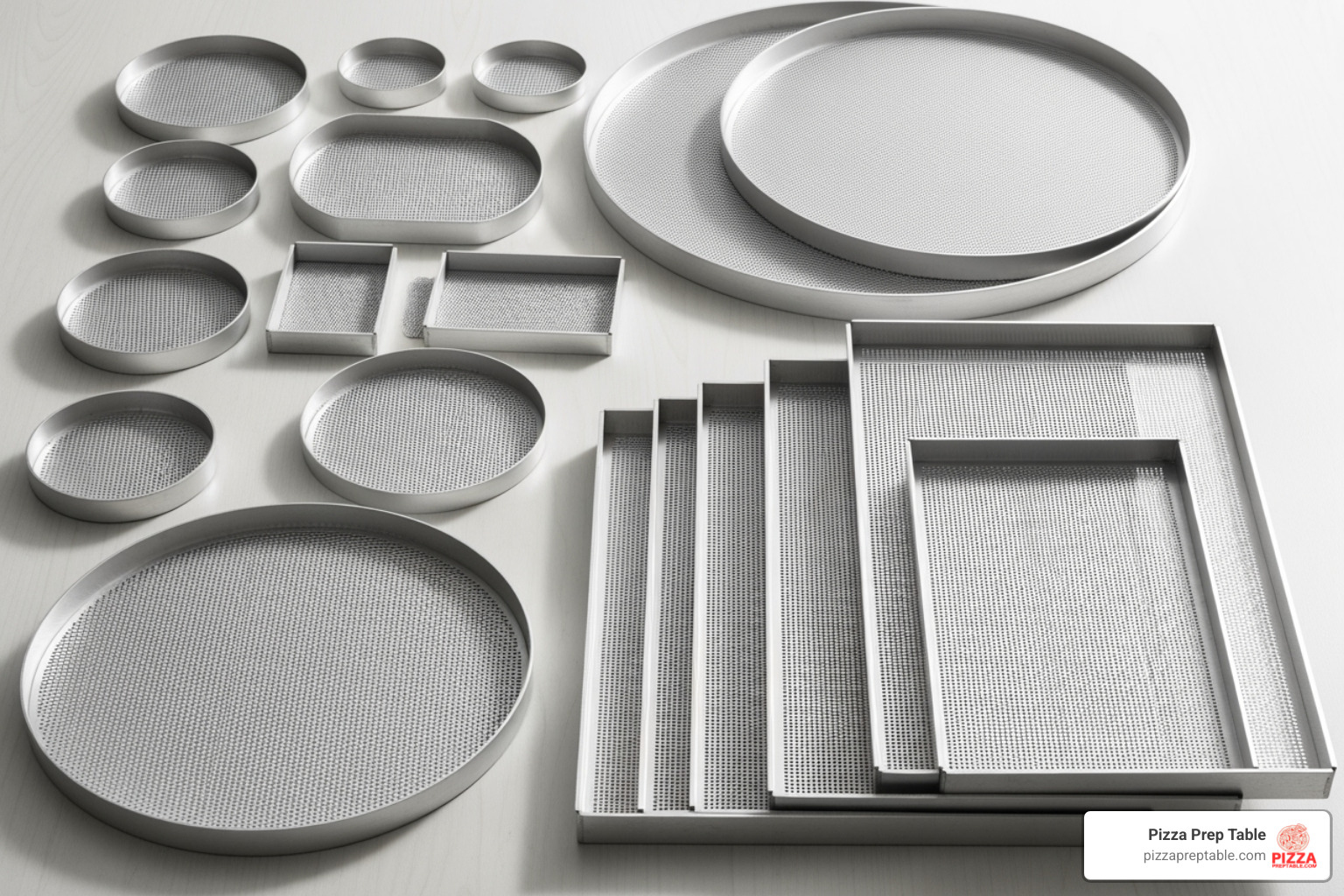

Sizes, Shapes, and Mesh Patterns

Pizza screens come in sizes from 7 inches for individual pizzas up to 21 inches or more for commercial volumes. The most popular sizes are 10", 12", 14", 16", and 18". Match your screen size to your oven capacity and menu offerings for maximum flexibility.

While round screens are classic, rectangular screens are excellent for flatbreads or maximizing oven space. The perforation pattern is also crucial, as it controls airflow. A standard mesh works for most pizzas, but a larger mesh pattern allows more air to circulate, creating an even crispier crust. Finer mesh, on the other hand, provides more support for delicate doughs.

Key Features of a High-Quality Stainless Steel Pizza Screen

For a durable, high-performing stainless steel pizza screen, look for these features:

- Gauge Thickness: A lower gauge number means thicker, more durable metal that resists warping and distributes heat evenly.

- Seamless Design: A seamless rim is safer to handle, easier to clean, and structurally stronger, with no crevices for food to get trapped.

- Reinforced Rim: This feature adds rigidity, preventing the screen from bending when loaded with a pizza. It's especially important for larger screens.

- Material Grade: Look for 304 stainless steel, the food-grade standard for kitchen equipment. It offers the best corrosion resistance and durability for commercial use.

Focusing on these key features ensures you invest in a tool that will provide years of reliable performance.

Mastering Your Pizza Screen: Best Practices and Versatility

A stainless steel pizza screen is a versatile kitchen workhorse. Understanding how to care for it and use it beyond pizza will help you get the most value from this simple but effective tool.

Proper Cleaning, Seasoning, and Maintenance

Maintaining a stainless steel pizza screen is straightforward. Most are dishwasher safe, a major time-saver for busy pizzerias in Denver or Seattle. For stubborn, baked-on food, a quick soak in soapy water and a scrub with a non-abrasive brush will clear the perforations.

Unlike aluminum, stainless steel requires no seasoning. It's naturally resistant to sticking and corrosion, so you can wash it and use it right out of the box. For storage, screens stack neatly, saving space. Ensure they are dry before stacking, and consider a dedicated rack for larger operations. To optimize your prep area, see our guide on stainless steel prep tables. With proper care, a quality screen will last for years.

Best Ovens and Other Kitchen Uses

Pizza screens are highly adaptable and work well in various ovens.

- Conveyor Ovens: The screen's airflow complements the consistent heat, ensuring maximum crispiness.

- Deck Ovens: Screens prevent charring on the hot stone and make loading and unloading pizzas easier.

- Conventional Ovens: Home bakers can achieve restaurant-quality results without a specialized pizza oven.

Beyond pizza, their versatility shines. Use them for baking pastries to prevent soggy bottoms, as a cooling rack to keep baked goods crisp, or for thawing ingredients evenly. They are also great for crisping up frozen foods or reheating leftovers. For more tips on equipping your kitchen, check out our resource on commercial stainless steel tables.

Frequently Asked Questions about Pizza Screens

Here are answers to some common questions about using pizza screens.

Do I need to season a stainless steel pizza screen?

No. Stainless steel pizza screens do not need seasoning. Unlike aluminum, stainless steel is naturally non-stick and corrosion-resistant. Just wash your new screen before its first use, and you're ready to bake. This low-maintenance feature is a major advantage in a busy kitchen.

Can I cut my pizza directly on the screen?

We strongly advise against it. While stainless steel pizza screens are durable, cutting on them will dull your pizza cutter and damage the screen's mesh over time. This can trap food particles and affect the screen's longevity. Always transfer your pizza to a cutting board before slicing. This protects both your tools and your investment. For durable prep surfaces, check out our commercial stainless steel tables.

Pizza screen vs. pizza stone: which is better for a crispy crust?

Both tools create a crispy crust, but in different ways.

- A pizza stone (often called a baking stone) uses intense, retained direct heat. It requires a long preheat time and produces a rustic, slightly charred crust with a chewy interior, similar to a brick oven.

- A pizza screen uses airflow. The mesh allows hot air to circulate and moisture to escape, resulting in a uniformly crisp and evenly browned crust without charring. It heats up quickly with no preheating needed.

For the chewy, artisanal texture of a stone, you need time and patience. For consistent, even crispiness, versatility across oven types, and speed—especially in commercial kitchens—the stainless steel pizza screen is often the superior choice. It offers reliability and low maintenance for both home and professional use.

Conclusion

The journey to pizza perfection is simpler with the right tool. A stainless steel pizza screen is a game-changer for both home ovens and commercial kitchens, delivering consistently crispy crusts. By promoting 360-degree air circulation and allowing moisture to escape, it eliminates soggy bottoms and ensures an even, crunchy bake.

While aluminum is an option, stainless steel pizza screens are the clear winner for serious pizza makers due to their superior durability, corrosion resistance, and low-maintenance design. They don't warp, are non-reactive, and are often dishwasher safe, making them a smart long-term investment.

Choosing a quality screen with features like a seamless construction and reinforced rim ensures years of reliable performance. Their versatility extends beyond pizza to baking pastries, cooling goods, and more, making them invaluable in any kitchen.

At PizzaPrepTable.com, we specialize in equipment that delivers. A quality stainless steel pizza screen is one of the most impactful and affordable upgrades for any pizza operation. It’s a simple tool that works, every time.

Ready to take your pizza game to the next level? Explore our complete selection of commercial pizza equipment and learn everything you need to know to buy pizza shop supplies. From prep tables to the perfect screen, we'll help you build a kitchen that produces exceptional pizzas, every time.