Prep Sandwich Refrigerators That Keep Your Ingredients Fresh and Your Customers Happy

Share

The Backbone of Fast-Service Food Operations

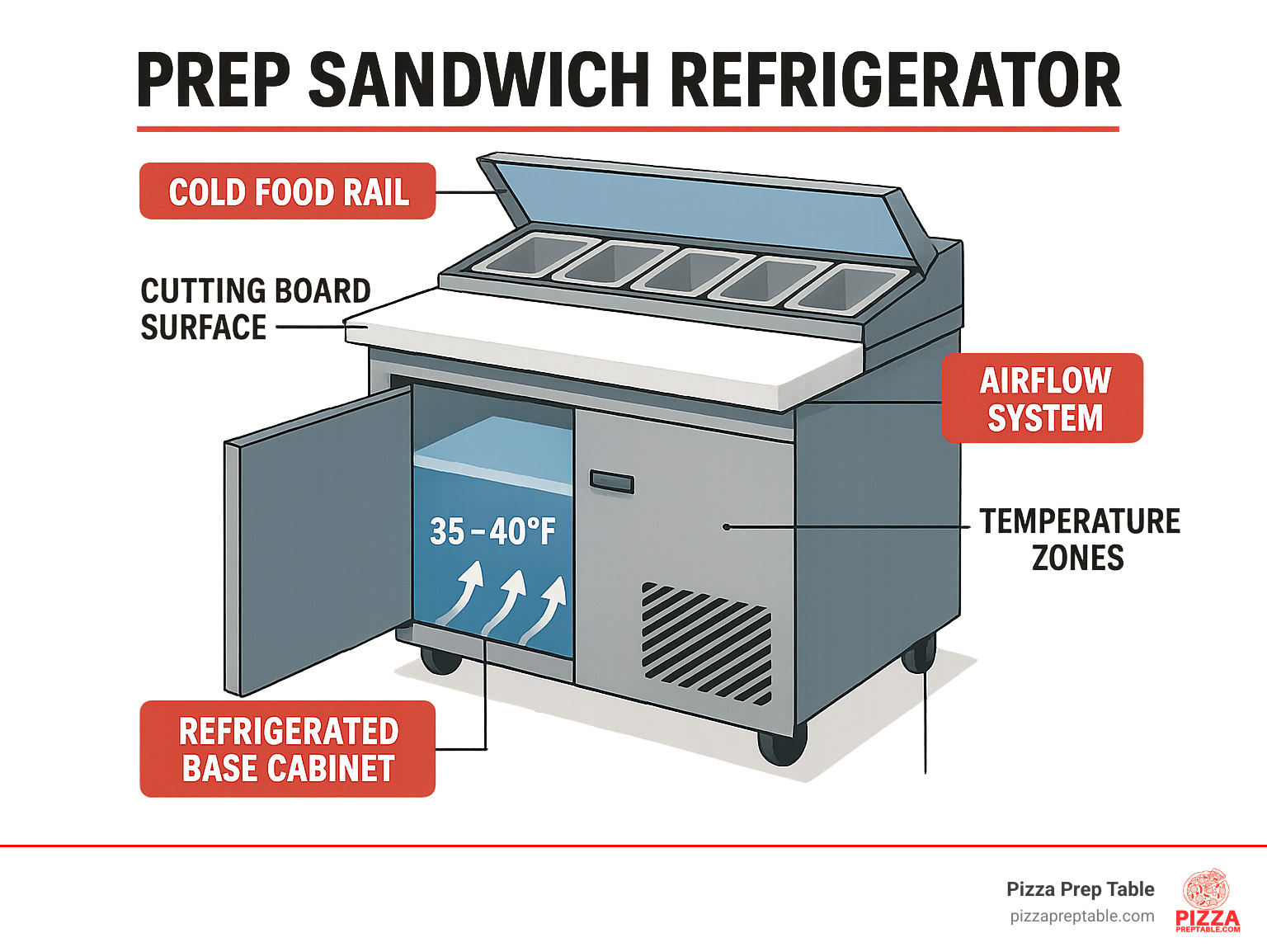

A prep sandwich refrigerator is a specialized commercial refrigeration unit designed to keep ingredients fresh while providing easy access for sandwich assembly. These units combine cold storage with a convenient workspace, making them essential for any food service operation focused on quick meal preparation.

Quick Answer: What is a prep sandwich refrigerator?

A prep sandwich refrigerator is a commercial refrigeration unit that: * Features a refrigerated base cabinet for storage * Includes a cold food rail with slots for ingredient pans * Has a built-in cutting board/work surface * Maintains food-safe temperatures (below 40°F) even in hot kitchens * Costs between $1,270-$2,650 depending on size (27"-72") * Comes in various configurations (6-30 ingredient pans)

For busy food service operations, having the right equipment can make the difference between chaotic service and smooth efficiency. Prep sandwich refrigerators stand at the frontline of this battle, keeping high-turnover ingredients perfectly chilled while remaining within arm's reach. Unlike standard refrigerators, these specialized units are engineered to maintain food-safe temperatures even in ambient conditions up to 100°F—perfect for hot, busy kitchens where every second counts.

The beauty of a prep sandwich refrigerator lies in its dual functionality: while the refrigerated base provides ample storage for backup ingredients, the top rail with customizable pan configurations keeps your most-used items readily accessible during rush periods. This strategic design dramatically cuts down assembly time while ensuring consistent quality and freshness in every sandwich you serve.

I'm Sean Kearney, and with over 15 years in restaurant equipment sales, I've helped hundreds of businesses select the perfect prep sandwich refrigerator for their unique operational needs, from small cafés to large-scale commissaries that depend on these workhorses daily.

What Is a Prep Sandwich Refrigerator?

Walk into any busy deli or sandwich shop, and you'll likely spot the unsung hero of their operation: the prep sandwich refrigerator. These aren't just ordinary fridges—they're purpose-built workstations that revolutionize how sandwiches get made.

A prep sandwich refrigerator combines cold storage with a convenient workspace, creating the perfect sandwich assembly command center. The top features refrigerated sandwich rails—those recessed cold pans that hold all your fresh ingredients at perfect serving temperature. Right in front of these rails sits a durable polyethylene cutting board surface (typically 8-10" deep) that runs the entire length of the unit, giving you plenty of space to craft the perfect sandwich.

Beneath this prep area, you'll find a refrigerated base cabinet that stores backup ingredients, keeping your operation running smoothly even during the lunch rush. The entire unit is built to commercial standards, typically featuring stainless steel inside and out for easy cleaning and maximum durability.

What makes these units special is their engineering. They're designed to maintain safe temperatures (below 40°F, as recommended by the USDA food safety guidelines) even in kitchens that reach a sweltering 100°F. Most modern units use eco-friendly R290 refrigerant, significantly reducing environmental impact while maintaining efficient cooling.

Other thoughtful features include self-closing doors that prevent cold air from escaping and 2" CFC-free, foamed-in-place polyurethane insulation that keeps energy consumption surprisingly reasonable—typically just 4-5 kWh per day.

How does a prep sandwich refrigerator differ from a standard fridge?

"It's like comparing a smartphone to a landline," says one of our customers who upgraded from a standard reach-in. The differences are substantial and directly impact how efficiently your kitchen runs.

First, the integrated work surface eliminates the back-and-forth between storage and prep areas. Everything happens in one spot. The specialized pan rail circulation directs cold air specifically to the ingredient containers on top, rather than cooling the entire interior equally like a standard fridge.

The front airflow design is another game-changer. Most prep sandwich refrigerators pull and exhaust air from the front, allowing you to install them flush against walls or other equipment—crucial for tight kitchen spaces. Many models also feature stay-open door functionality during peak prep times, so your team can work continuously without repeatedly opening and closing doors.

Perhaps most importantly, these units offer strategic temperature zoning—keeping the cabinet below slightly colder for storage while maintaining optimal serving temperature in the ingredient rail. And instead of bending down and searching for ingredients, everything is presented at eye level in clearly visible pans.

A Seattle deli owner shared with us: "Switching to a dedicated prep sandwich refrigerator cut our assembly time nearly in half while keeping ingredients fresher throughout the day. It's like upgrading from cooking on a camp stove to using a professional range."

Core benefits for commercial & home kitchens

The advantages of a prep sandwich refrigerator extend beyond just keeping ingredients cold. In commercial settings, the speed of assembly improvements are dramatic—many of our customers report 30-40% increases in production after upgrading. The organized layout significantly reduces cross-contamination risks, a critical food safety consideration.

The specialized cooling system prolongs ingredient freshness, extending shelf life and reducing waste. There are real labor savings too; the ergonomic design minimizes employee movement and strain, leading to greater efficiency and potentially lower labor costs. And because every sandwich maker has access to the same ingredients in the same arrangement, you'll achieve better consistency in your final product.

While primarily designed for commercial use, smaller prep sandwich refrigerators occasionally find their way into high-end home kitchens. They add entertainment value when hosting events with made-to-order food options, simplify family meal prep by allowing efficient preparation of multiple lunches simultaneously, and help families with members on specialized diets to prepare meals with clearly separated ingredients.

As one Washington catering company owner told us: "Our prep sandwich refrigerator paid for itself within six months through reduced food waste alone. Ingredients stay fresher longer, and we can prep more efficiently, which means we're throwing away less at the end of the day."

Buying & Usage Guide: Choosing, Organizing, Maintaining Your Prep Sandwich Refrigerator

Finding your perfect prep sandwich refrigerator doesn't have to be overwhelming. I've helped hundreds of restaurant owners make this decision, and the right unit can transform your kitchen operations. Let's walk through everything you need to know to make a smart choice.

Size and Capacity Considerations

When it comes to prep sandwich refrigerators, size really does matter. The smallest 27" models offer about 7 cubic feet of storage, while the largest 72" behemoths provide a generous 18 cubic feet. Think about how many ingredients you'll need at your fingertips - smaller units hold around 6 pans in the rail, while larger ones can accommodate up to 30 pans for extensive menu offerings.

Footprint is crucial too, especially in tight kitchen spaces. Standard widths range from 27" to 72", but don't forget to account for door clearance! When open, these doors typically add another 20-25" to your needed space. The cutting board work surface generally extends 8-10" from the front, giving your team enough room to build those perfect sandwiches without feeling cramped.

"We initially bought a 60-inch model for our deli, but our kitchen layout made it impossible to fully open one of the doors," shares Mike, a café owner from Portland. "We downsized to a 48-inch unit, and it actually improved our workflow because everything was more accessible."

Technical Specifications

Most prep sandwich refrigerators run on standard 115V/60Hz power, making them easy to install in almost any commercial kitchen. The programmable thermostat lets you dial in the perfect temperature between 32-52°F, though for food safety, you'll want to stay in the 33-40°F range.

Mobility matters too - quality units come with four casters (usually with two that lock), making cleaning behind and under your unit much easier. You'll also need to decide between traditional doors or drawers for the lower cabinet storage. Drawers offer better organization but typically come with a higher price tag.

Speaking of price, budget anywhere from $1,270 for a basic 27" model to around $2,650 for a premium 72" unit. Looking for an Energy Star rated model might increase your upfront cost slightly but will save you money on your utility bills month after month.

Warranty Considerations

Quality manufacturers stand behind their prep sandwich refrigerators with impressive warranty coverage. Most reputable brands offer 5 years on labor, 6 years on parts, and a full 7 years on the compressor. These extended warranties reflect the durability of these workhorses - they're built to withstand the daily punishment of busy commercial kitchens.

I always tell my customers to keep their warranty information handy and register their unit immediately. Those few minutes of paperwork can save thousands of dollars down the road if something goes wrong.

Daily Maintenance Requirements

Taking care of your prep sandwich refrigerator isn't complicated, but consistency is key. Daily wipe-downs and pan sanitizing should become second nature to your team. Weekly gasket checks prevent cold air leaks, and monthly condenser coil brushing keeps the unit running efficiently.

Smart operators use the FIFO (First In, First Out) method for ingredient management. This simple practice ensures fresher products and less waste. For sandwich assembly, using barrier layering techniques (like placing cheese between bread and tomatoes) prevents the dreaded soggy sandwich syndrome that customers hate.

The pizza industry understands the value of these units - with over 75,000 pizzerias across the United States, many rely on prep sandwich refrigerators not just for sandwiches but for organizing pizza toppings and ingredients too. For those technical minds who want to dig deeper, manufacturer parts manuals and spec sheets provide detailed information about specific models.

Recommended temperature & food-safety settings for a prep sandwich refrigerator

Food safety isn't just about regulations – it's about protecting your customers and your reputation. Your prep sandwich refrigerator should maintain the prep rail between 36-40°F, which balances food safety with ingredient workability. The cabinet below typically runs slightly colder at 33-38°F, perfect for storing backup ingredients.

Modern units are engineering marvels, designed to perform even in sweltering kitchens with ambient temperatures up to 100°F. Quality refrigerators should bounce back to safe temperatures within 15 minutes after doors are closed, even during busy service periods.

"We check our temperatures religiously," says Jen, a sandwich shop owner in Miami. "Every morning during setup and again mid-service. It takes 30 seconds but gives us peace of mind that our prep sandwich refrigerator is doing its job."

For larger operations, implementing a HACCP logging system isn't just smart – it might be required by your health department. Use calibrated thermometers for accuracy, and consider automated monitoring systems if you manage multiple units or locations.

Cleaning hacks that boost performance & hygiene

A clean prep sandwich refrigerator is a happy, efficient one. Beyond the obvious food safety benefits, proper cleaning extends the life of your equipment and improves its performance.

Daily, make sure your team removes and sanitizes all pans properly – either in a three-compartment sink or commercial dishwasher. Wipe down that cutting board surface with food-safe sanitizer, and clean all stainless steel with appropriate cleaners. Pro tip: avoid chlorine-based products on stainless steel, as they can cause pitting and damage over time.

Weekly, remove the cutting board for a thorough sanitizing. Those board crevices can harbor bacteria if not properly cleaned. It's also the perfect time to check and clean door gaskets with a mild soap solution. Dirty gaskets don't seal properly, making your unit work harder and driving up your electric bill.

Monthly maintenance should include brushing those condenser coils. "This simple 15-minute task can improve efficiency by up to 25%," our service technician Mark always reminds customers. "It's the single most neglected maintenance item I see, and it causes the most preventable breakdowns."

Quarterly, schedule a complete defrost cycle, check refrigerant levels, and give all removable parts a deep clean. Your prep sandwich refrigerator will thank you with years of reliable service.

Smart ingredient organization to prevent soggy sandwiches

The way you organize your prep sandwich refrigerator directly impacts both your operational efficiency and final product quality. Smart operators position high-turnover items in the center of the rail where they're easiest to reach. Keep complementary ingredients next to each other – meats beside cheeses, for instance – to reduce hand movement during assembly.

Moisture management is crucial for sandwich quality. Use perforated pan inserts for freshly washed produce to allow drainage. Nobody wants a soggy sandwich, so place lettuce between bread and wet ingredients as a natural barrier. Sliced cheese works wonderfully as a "shield" between bread and moist fillings like tomatoes.

Think vertically too. The lower cabinet should store backup ingredients in logical groupings, while the top rail holds prepared, ready-to-use items. During slower periods, use rail covers to maintain temperature and freshness. Some high-volume operations even opt for dual-sided rails that allow access from both prep and service sides.

"We organize our prep sandwich refrigerator like an assembly line," explains Carlos, a deli manager in Chicago. "Ingredients flow from left to right in the exact order we build our most popular sandwiches. New employees can get up to speed in hours instead of days because the setup is so intuitive."

With these guidelines, your prep sandwich refrigerator will become the cornerstone of an efficient, food-safe operation that delivers consistent quality with every order.

27" Compact Prep Sandwich Refrigerator

Meet the mighty mini of the sandwich prep world - the 27" prep sandwich refrigerator. Don't let its compact size fool you! This space-saving wonder delivers impressive functionality for kitchens where every square inch matters.

Think of it as the studio apartment of refrigeration: efficiently designed to maximize every bit of space while still providing all the essentials. At just over two feet wide, these units slide perfectly into tight corners of food trucks, kiosks, and small cafés.

"I was skeptical about going with such a small unit," admits Carlos, a Seattle food truck owner. "But this little workhorse handles our entire lunch rush without breaking a sweat. Best equipment investment we've made."

The specs tell the story: 27 inches wide, 30 inches deep, and 44.25 inches tall, with room for 6-8 standard pans in the rail and approximately 7 cubic feet of storage below. With a single door configuration and modest 4-amp power draw on a standard 115V circuit, these units won't strain your electrical system. Pricing typically ranges from $1,270-$1,500 depending on features – making them an accessible entry point for small operations looking to upgrade their prep game.

Key features of this prep sandwich refrigerator

What makes these compact units stand out is how they pack professional features into a smaller footprint. The durable polyethylene cutting board spans the full width, giving you a proper workspace despite the unit's modest size.

One feature small-space operators particularly love is the field-reversible door that can be configured to open from either side. This flexibility is invaluable when fitting equipment into tight corners or awkward spaces.

The front-breathing compressor system is another space-saver, allowing you to push the unit flush against walls without compromising cooling performance. Inside, you'll find adjustable shelving that can be reconfigured in half-inch increments to accommodate various storage needs.

Temperature management is a breeze with the digital control panel, while heavy-duty casters make moving the unit for cleaning a one-person job. The standard configuration accepts 1/6-size pans – the industry standard for sandwich ingredients – so you won't need special-sized containers.

"In a food truck, multi-purpose equipment is everything," explains Jen, who runs a popular sandwich truck in Portland. "Our 27" prep sandwich refrigerator gives us cold storage, ingredient organization, and a dedicated prep surface all in one compact footprint."

Who should buy it?

The 27" prep sandwich refrigerator shines in specific settings where space constraints meet food prep needs:

Food trucks and mobile kitchens benefit most from these compact units. The small footprint leaves room for staff movement, while the casters allow secure positioning during transit. Many food truck operators tell us this single piece of equipment replaced both a standard undercounter refrigerator and a separate prep table, effectively paying for itself in space savings alone.

Coffee bars expanding into food service find these units perfect for introducing a small sandwich or pastry program without major kitchen renovations. The refrigerated rail keeps fillings fresh during morning and lunch rushes, while the cabinet below stores backup ingredients for quick restocking.

Salad and smoothie kiosks leverage these units to keep fresh ingredients at perfect temperatures while providing a clean workspace for assembly. The rail system keeps ingredients organized and visible, speeding up service during peak hours.

Any operation with limited counter space appreciates how these units maximize functionality per square foot. Some kitchens even use them as dedicated stations for specific menu categories – one for breakfast sandwiches and another for lunch offerings, for example.

A Washington café owner shared: "We started with one 27" unit for our basic sandwich menu. As demand grew, rather than replacing it with something bigger, we added a second compact unit. Now we have dedicated stations for cold and hot sandwiches, which actually improved our workflow more than a single larger unit would have."

For small operations looking to start or expand their sandwich program without sacrificing valuable space, the 27" prep sandwich refrigerator offers the perfect balance of professional performance and compact design.

48" Standard Prep Sandwich Refrigerator

Ask any restaurant equipment specialist about the "Goldilocks" of sandwich prep stations, and they'll point you straight to the 48" prep sandwich refrigerator. Not too big, not too small – this mid-sized workhorse hits that perfect balance that makes it our most requested model at PizzaPrepTable.com.

When I visit kitchens across Washington state, I often find this 48-incher commanding the sandwich line, and for good reason. With dimensions of 48"W × 30"D × 44.25"H, it provides generous workspace without demanding excessive floor space. The unit comfortably houses 12 standard 1/6-size pans in its rail, giving your team plenty of ingredient options while maintaining an organized workflow.

"I finally stopped playing musical chairs with my ingredients," laughed Maria, a café owner in Seattle who upgraded last year. "With 11 cubic feet of storage below and all those rail pans above, everything has its place now."

The practical two-door configuration underneath gives your team easy access to backup ingredients without disrupting the assembly process happening on top. Just remember to account for approximately 60" of clearance when doors are fully open – a consideration for tighter kitchen layouts.

At $1,300-$1,800, the 48" prep sandwich refrigerator represents an excellent value proposition. It's an investment that quickly pays dividends through improved efficiency and reduced food waste. The energy consumption hovers around a modest 3.9 kWh per day, keeping your utility bills in check while maintaining food-safe temperatures throughout service.

Why this prep sandwich refrigerator hits the sweet spot

The popularity of the 48" model comes down to thoughtful design that addresses real kitchen needs. The 2" CFC-free insulation creates a reliable cold barrier even in hot kitchens, while eco-friendly R290 refrigerant keeps your environmental footprint small and your operating costs lower.

Most operators appreciate the included 48"×10" polyethylene cutting board that comes standard – no need to source compatible workspace solutions separately. This gives your team ample room to assemble even the most complex sandwiches without feeling cramped.

"We debated going bigger, but honestly, this size is perfect," shared Tom, who runs a busy deli near Pike Place Market. "It fits perfectly between our existing equipment, the dual doors let my team access different ingredients without getting in each other's way, and we can handle our rushes without breaking a sweat."

The pan configuration offers welcome flexibility too. While the standard setup accommodates 1/6-size pans, you can easily swap in larger 1/3-size containers for high-volume ingredients like lettuce or sliced turkey. This adaptability means your prep sandwich refrigerator can evolve alongside your menu and customer preferences.

Ideal operations

The 48" prep sandwich refrigerator shines brightest in specific operational settings. Traditional delis and sandwich shops producing between 100-200 sandwiches daily find this size particularly well-matched to their needs. The rail provides ample space for diverse ingredients while the lower cabinet logically organizes backup supplies.

University and corporate cafés represent another perfect fit. These operations typically face predictable but intense lunch rushes, where the generous prep surface and ingredient capacity make all the difference between chaos and smooth service. The standardized dimensions also integrate seamlessly with institutional kitchen layouts where equipment uniformity matters.

I've also seen remarkable success when bakery operations add this unit to expand into lunchtime sandwich offerings. The dedicated space keeps sandwich ingredients separate from bakery components, allowing for menu expansion without cross-contamination concerns.

"Our 48" prep sandwich refrigerator completely transformed our lunch service," a café owner told me recently. "Before, we were constantly running back to the walk-in for ingredients. Now everything is at our fingertips, and we've actually expanded our sandwich menu while reducing prep time. Best equipment decision we've made in years."

For operations looking to balance capacity, workspace, and budget, the 48" model continues to prove itself as the industry's sweet spot – not just adequate, but optimal for a wide range of food service concepts.

60" Large Prep Sandwich Refrigerator

When your sandwich operation hits the big leagues, the 60" prep sandwich refrigerator becomes your MVP. This powerhouse unit bridges the gap between standard models and industrial-sized equipment, offering the perfect balance of capacity and footprint for serious sandwich makers who mean business.

"The day we upgraded to our 60-inch prep table was the day we stopped turning away catering orders," shares Maria, a deli owner from Portland. "Having all those ingredients at our fingertips completely transformed our workflow."

Standing at an impressive 60"W × 30"D × 44.25"H, these units provide a generous 14.8 cubic feet of interior storage space while accommodating 16 standard 1/6-size pans across their refrigerated rail. The dual full-size doors below give your team quick access to backup ingredients, minimizing disruptions during peak service times.

Under the hood, these units pack a punch with a 2,431 BTU/hr compressor (typically 1/3 HP) that maintains perfect temperatures without breaking a sweat. Even better, they won't break the bank on your utility bills, consuming approximately 4.05 kWh per day – remarkably efficient for their size and capability.

For kitchens in the planning stages, many manufacturers offer CAD/Revit files to help you visualize how this unit will fit into your layout before making the investment of $1,650-$2,200.

Pros & standout specs for this prep sandwich refrigerator

What makes the 60" prep sandwich refrigerator shine in busy kitchens goes beyond its size. Even when your kitchen feels like a sauna hitting 100°F during summer rush periods, these units maintain a rock-solid 36°F internal temperature, keeping ingredients fresh and food-safe hour after hour.

The thoughtful design extends to practical features that make daily operation smoother. Doors can be propped open at 110° during morning prep (perfect for restocking), then self-close with a gentle push when you're ready to start service. The epoxy-coated shelving adjusts in half-inch increments, letting you customize the interior to fit everything from bulk cheese boxes to tall dressing containers.

"What sold me was the mobility," explains Frank, who runs a hospital cafeteria. "We need to deep clean under all equipment weekly, and having those four heavy-duty casters—two with locks—means we can move it for cleaning and then lock it firmly in place during service."

Many operations appreciate the option for dual-sided rails that allow access from both prep and service sides—perfect for open kitchen concepts where sandwiches are assembled to order in front of customers. The adjustable pan dividers let you mix and match different pan sizes based on ingredient popularity, while the automatic defrost system keeps everything running smoothly without manual intervention.

Best fit kitchens

The 60" prep sandwich refrigerator finds its natural home in busy sub and sandwich shops where dozens of fresh toppings need to be readily available throughout the day. The spacious rail accommodates everything from the basics to specialty ingredients, while allowing multiple sandwich makers to work side-by-side without bumping elbows.

Hospital and institutional cafeterias particularly benefit from these units' reliability and capacity. "In healthcare food service, temperature control isn't just about quality—it's a safety requirement," notes a dietary services manager at a Seattle hospital. "Our 60-inch prep sandwich refrigerator gives us peace of mind while handling hundreds of meal preparations daily."

Catering commissaries love the extensive preparation space these units provide. When you're assembling 50 boxed lunches or building elaborate sandwich platters, having all ingredients organized and accessible in one station dramatically improves efficiency. The lower storage compartment holds enough backup ingredients to minimize interruptions during large batch preparations.

Medium-sized restaurants often choose this model for its versatility. Beyond sandwiches, these units excel as dual-purpose stations for salad prep, dessert assembly, or even as auxiliary prep areas during special events. The generous cutting board surface provides enough workspace for multiple tasks, while the organized ingredient rail keeps everything within arm's reach.

"We started as a sandwich shop but expanded into catering," shares Tom, a deli owner in Chicago. "Our 60-inch prep sandwich refrigerator adapted with us every step of the way. It's like having an extra team member who never calls in sick."

72" Mega-Top Prep Sandwich Refrigerator

When it comes to sandwich prep powerhouses, the 72" prep sandwich refrigerator sits on the throne. I've seen these impressive units transform chaotic kitchens into models of efficiency. They're not just refrigerators – they're complete production systems designed for operations where sandwich-making isn't just a menu section, it's a way of life.

At 72 inches wide, these units command attention in any kitchen while delivering best capacity for high-volume operations. The standard configuration comfortably houses 12 standard 1/6-size pans, but the mega-top versions – my personal favorite for busy operations – can accommodate a whopping 30 pans of ingredients. With 18 cubic feet of interior storage space beneath, you'll spend far less time running back to the walk-in during rush periods.

These kitchen workhorses typically run around 5.05 kWh per day – remarkably efficient considering their size and cooling capacity. Price-wise, expect to invest between $1,900-$2,650 depending on features and configuration. While that might seem substantial, the 7-year compressor warranty offered by most manufacturers reflects their confidence in these units' longevity.

Top-tier capacity & flexibility in a prep sandwich refrigerator

What makes these 72" giants special goes beyond their imposing size. The three self-closing doors provide thoughtfully segmented access to your backup ingredients, allowing for logical organization while minimizing cold air loss when grabbing items during service.

The expansive 60"×10" cutting board surface gives your team plenty of elbow room – I've seen three sandwich makers working comfortably side-by-side during peak periods. No more bumping elbows or waiting for workspace!

Behind the scenes, these units feature sophisticated automatic heated defrost systems that maintain peak performance without manual intervention. The enamel-coated evaporator coils might not be visible, but they significantly extend system life while improving efficiency – something your maintenance team and utility bills will appreciate.

I'm particularly fond of the dual rail configuration options. Whether you need standard capacity or the mega-top version with its liftd rail design, these units adapt to your specific ingredient requirements. One pizzeria owner told me, "We switched from two smaller units to one 72-inch mega-top, and now we can offer twice the topping variety while actually saving floor space."

Perfect for

The 72" prep sandwich refrigerator truly shines in high-volume environments. Chain sandwich operations appreciate the consistent performance and capacity to handle even the busiest lunch rushes without breaking a sweat. I've visited locations churning out 300+ sandwiches during peak periods with minimal restocking from their walk-ins.

Resort and hotel buffet services love these units for their impressive capacity and professional appearance. When guests are watching their sandwiches being assembled, these substantial units convey quality and abundance – important psychological factors in customer satisfaction.

The rise of ghost kitchen operations has created another perfect home for these units. When you're preparing food for multiple virtual restaurant concepts from one kitchen, having extensive, well-organized ingredient storage becomes critical. These mega-units provide the organizational foundation that makes multi-concept production possible in limited spaces.

Commissary kitchens preparing sandwiches for multiple locations find these units indispensable. As one commissary manager in Washington shared with me: "Our 72-inch prep sandwich refrigerator is command central. We prep for five different restaurant concepts from this single unit, and it keeps everything organized and efficient. It's probably the hardest working piece of equipment in our kitchen."

The beauty of these refrigerators isn't just their size – it's how they transform workflow. With thoughtful organization, they become the heart of a sandwich operation, minimizing movement and maximizing productivity. For high-volume operations, they're not just convenient – they're essential.

Frequently Asked Questions about Prep Sandwich Refrigerators

How do I prevent ingredients from drying out in the prep rail?

The dreaded dried-out ingredients – every sandwich maker's nemesis! I've seen countless operators struggle with this common challenge in their prep sandwich refrigerators.

The good news is that solving this problem doesn't require expensive equipment upgrades. During slower periods, simply use the rail cover that came with your unit. These hinged covers are designed specifically to maintain the perfect balance of humidity and temperature. Think of them as tucking your ingredients in for a little nap between rushes!

For delicate items like leafy greens, here's a pro tip from a Seattle deli owner I worked with: "We place just a few tablespoons of water in the bottom of the pan – not enough to make anything soggy, but just enough to create a microclimate that keeps our lettuce crisp all day long."

The depth of your pans makes a significant difference too. Those deeper 4-inch pans provide better moisture retention than the standard 2.5-inch ones. I always recommend keeping pans at least ⅔ full when possible – less product means more air exposure, which leads to faster drying.

For overnight storage, a simple layer of plastic wrap directly on the surface of items like sliced cheese works wonders. And for particularly finicky ingredients, consider investing in pans with individual lids that can be closed when that ingredient isn't actively being used.

What is the average lifespan of a commercial prep sandwich refrigerator?

"How long will this investment last me?" It's one of the most common questions I hear from operators considering a prep sandwich refrigerator purchase.

With proper care, you can expect 8-12 years of reliable service from a quality commercial unit. The compressor – typically the first major component to require replacement – generally lasts 7-10 years. However, I've worked with many restaurant owners who report 15+ years of service with diligent maintenance.

A pizzeria owner in Washington recently told me: "We have a prep sandwich refrigerator that's been in service for over 14 years. The secret has been religious monthly maintenance and addressing small issues immediately. We've replaced the compressor once, but otherwise, it's been incredibly reliable."

Your maintenance routine makes an enormous difference in longevity. Regular cleaning of condenser coils (monthly), drain lines, and door gaskets can add years to your unit's life. Environmental factors play a huge role too – units in kitchens with excessive heat, grease, or dust will naturally require more attention.

The initial quality of your unit matters as well. Those higher-end models with better components generally justify their cost through extended service life and fewer repairs. When small issues do arise, addressing them promptly prevents them from cascading into major (and expensive) problems.

Can I use freezer-friendly sandwiches directly from the unit?

While your prep sandwich refrigerator is a marvel at keeping ingredients fresh for assembly, it's important to understand it's designed for refrigeration, not freezing. That said, it can play a vital role in an efficient frozen sandwich workflow.

The spacious cutting board and organized ingredients make your prep unit the perfect assembly station for freezer-friendly sandwiches. Just remember that once assembled, these sandwiches need to be transferred to a proper freezer immediately – not stored in the prep refrigerator itself.

A catering company owner shared this brilliant workflow with me: "We use our prep sandwich refrigerator for assembly of freezer-friendly sandwiches, but we have a specific system. We assemble, then immediately transfer to sheet pans in our blast freezer. Once frozen solid, we package and store them in our regular freezer. This prevents sogginess and maintains quality."

Not all ingredients freeze equally well. Peanut butter, cooked meats, and hard cheeses (especially if grated first) maintain their quality beautifully. However, mayonnaise tends to separate, and fresh vegetables like lettuce and tomatoes turn limp and watery after freezing.

When you need to use your frozen sandwiches, thaw them in a standard refrigerator rather than your prep unit. This preserves the carefully maintained temperature zone needed for your fresh ingredients in the prep rail.

With these strategies, your prep sandwich refrigerator can become the cornerstone of an efficient frozen sandwich operation, expanding your menu options while maintaining quality and food safety.

Conclusion

Choosing the right prep sandwich refrigerator isn't just about buying another piece of equipment—it's about changing how your sandwich operation functions from the ground up. These thoughtfully designed units stand at the crossroads of smart engineering and practical functionality, tackling the everyday challenges that sandwich shops face during those hectic lunch rushes.

When you invest in a quality prep sandwich refrigerator, you're getting so much more than cold storage. Modern units with energy-efficient compressors and proper insulation can significantly reduce your monthly utility bills compared to older, less efficient systems. This savings adds up month after month, year after year.

Food safety becomes less of a constant worry too. These units are specifically engineered to maintain those critical food-safe temperatures even when your kitchen feels like a sauna during summer service. Health inspectors notice this level of commitment to temperature control—and so do customers who never experience foodborne illness from your establishment.

"The day we installed our new prep sandwich refrigerator was the day our lunch service transformed," shared one Washington deli owner. "We went from scrambling to keep up with orders to a smooth, almost choreographed workflow. The unit paid for itself within months just through increased output alone."

The workflow improvements can't be overstated. Having all your ingredients organized and at your fingertips means sandwich assembly becomes quick and intuitive. Your staff spends less time hunting for ingredients and more time crafting quality sandwiches. During those peak hours when every second counts, this efficiency translates directly to happier customers and stronger sales.

At PizzaPrepTable.com, we've helped hundreds of businesses—from tiny cafés just adding sandwiches to dedicated shops making hundreds daily—find their perfect prep sandwich refrigerator match. Our equipment specialists take the time to understand your specific needs, considering your menu complexity, daily volume, available space, and budget constraints before making recommendations.

We also understand that quality equipment represents a significant investment. That's why we offer flexible financing options that make these essential units accessible to operations of all sizes. With proper maintenance, your investment can provide reliable service for 8-12 years—making the decision even more economical when viewed through a long-term lens.

For more information about our selection of prep sandwich refrigerators and other essential pizza and foodservice equipment, reach out to our team today. We're real people who understand the challenges you face because we've been there too. Your ingredients will stay fresher, your staff will work more efficiently, and ultimately, your customers will taste the difference.

About The Pizza Prep Table Blog Author

Sean Kearney has an impressive background, having previously worked at the renowned Amazon.com before embarking on his entrepreneurial journey by founding The Restaurant Warehouse. Sean has over ten years of experience in the restaurant equipment and supplies industry. He understands what restaurants need to succeed. He graduated from the well-known University of Washington in 1993. There, he earned a Bachelor of Arts degree in business and marketing. While at the university, he showed his athletic skills by playing linebacker for the Huskies football team. He demonstrated his commitment and teamwork both on and off the field. Today, Sean helps restaurants find the right equipment at fair prices. He makes sure they have the tools they need to succeed. Additionally, he offers various financing options to make the purchasing process easier for restaurant owners. If you’re interested in connecting with Sean and learning more about his expertise, you can connect with him on LinkedIn.