Choosing Your Pizzeria's Reach In Freezer

Share

A reach in freezer is your standard upright commercial freezer, the kind you’d see in any professional kitchen, designed for grabbing frozen goods fast. For a pizza shop where speed is everything, it's the workhorse that keeps your mozzarella, pepperoni, and dough balls perfectly frozen and always within arm's reach of your pizza prep table.

The Unsung Hero of Your Pizza Prep Line

On a chaotic Friday night, your reach-in freezer is the unsung hero that keeps the pizza prep line from grinding to a halt. It’s so much more than just a cold box; it’s the core of your ingredient management, making sure every block of cheese is perfectly chilled and every dough ball is ready for action.

This appliance is built specifically for the abuse of a commercial pizzeria kitchen. Unlike that freezer in your garage at home, it’s designed to handle constant door openings while holding a steady, food-safe temperature, typically at or below 0°F (-18°C). That kind of reliability isn't just nice to have—it's non-negotiable when you're slinging pies.

Why Every Pizzeria Needs the Right Freezer

The right freezer isn't just another expense; it’s a strategic asset for your pizza shop. It has a direct impact on your kitchen's efficiency and the quality of your final product. When you place it correctly—right near your pizza prep table—it becomes a seamless part of your workflow, shaving precious seconds off every single order.

Choosing the perfect model is about more than just picking a size. It’s about understanding how every feature serves your pizzeria's specific needs. You have to think about:

- Ingredient Workflow: How quickly can your crew grab high-volume items like cheese and dough from the freezer to the pizza prep table?

- Inventory Protection: Does it hold a stable temperature to prevent freezer burn on your pepperoni and spoilage on your cheese, protecting your profits?

- Kitchen Space: Will the unit actually fit in your layout without creating a traffic jam between the oven and the prep line?

- Operational Costs: Is this thing an energy-efficient workhorse, or is it going to bleed you dry on the utility bill?

A well-chosen reach-in freezer doesn't just store ingredients—it streamlines your entire pizza-making operation. By keeping essential items organized and easy to grab, it kills downtime at the prep station, letting your team build pizzas faster and more consistently.

Ultimately, this guide is here to cut through the technical jargon and give you practical, pizzeria-focused advice. We'll dig into how picking the best reach-in freezer can smooth out your workflow, protect your inventory, and actually boost your bottom line. From storing bulk cheese to preserving delicate toppings, we'll get you set up to make a confident, informed choice for your kitchen.

Choosing Your Compressor and Door Style

Picking the right reach in freezer is about more than just its size. You’re really choosing the engine and the body style for one of your pizzeria's biggest workhorses. The compressor is that engine, and where it’s located—top or bottom—makes a huge difference, especially in a pizza-making environment.

Top Mount vs. Bottom Mount in a Pizzeria

Think of a top-mount compressor like an attic fan. It sits on the very top of the freezer cabinet, where it naturally pushes hot air up and away from the unit and your kitchen floor. This is a massive advantage in a pizzeria, where flour dust is basically part of the atmosphere. Because the compressor is up high, it's way less likely to suck in flour, grease, and other gunk from the floor that can clog its coils and make it overheat.

On the flip side, a bottom-mount compressor puts the “engine” down at the base of the freezer. The big win here is ergonomics. The bottom shelves are higher off the ground, making it much easier for your staff to grab heavy items like cases of dough or cheese without doing a deep squat every time. Maintenance is also a bit simpler, since a technician won’t need a ladder to get to the mechanical parts.

But here's the catch for a pizza shop: a bottom-mount unit acts like a floor-level vacuum cleaner. In a typical pizzeria kitchen, it will absolutely pull in flour, dust, and whatever else is on the floor. This means you have to be relentless about cleaning the condenser coils to prevent clogs that strain the compressor, spike your energy bills, and lead to a much shorter lifespan for the unit.

For most pizzerias, a top-mount reach in freezer is the smarter long-term play. Its elevated position shields the compressor from the flour-filled air, cutting down on maintenance headaches and helping the unit last longer.

Now that we’ve sorted out the engine, let’s talk about the body—the doors.

Matching Door Styles to Your Pizza Prep Workflow

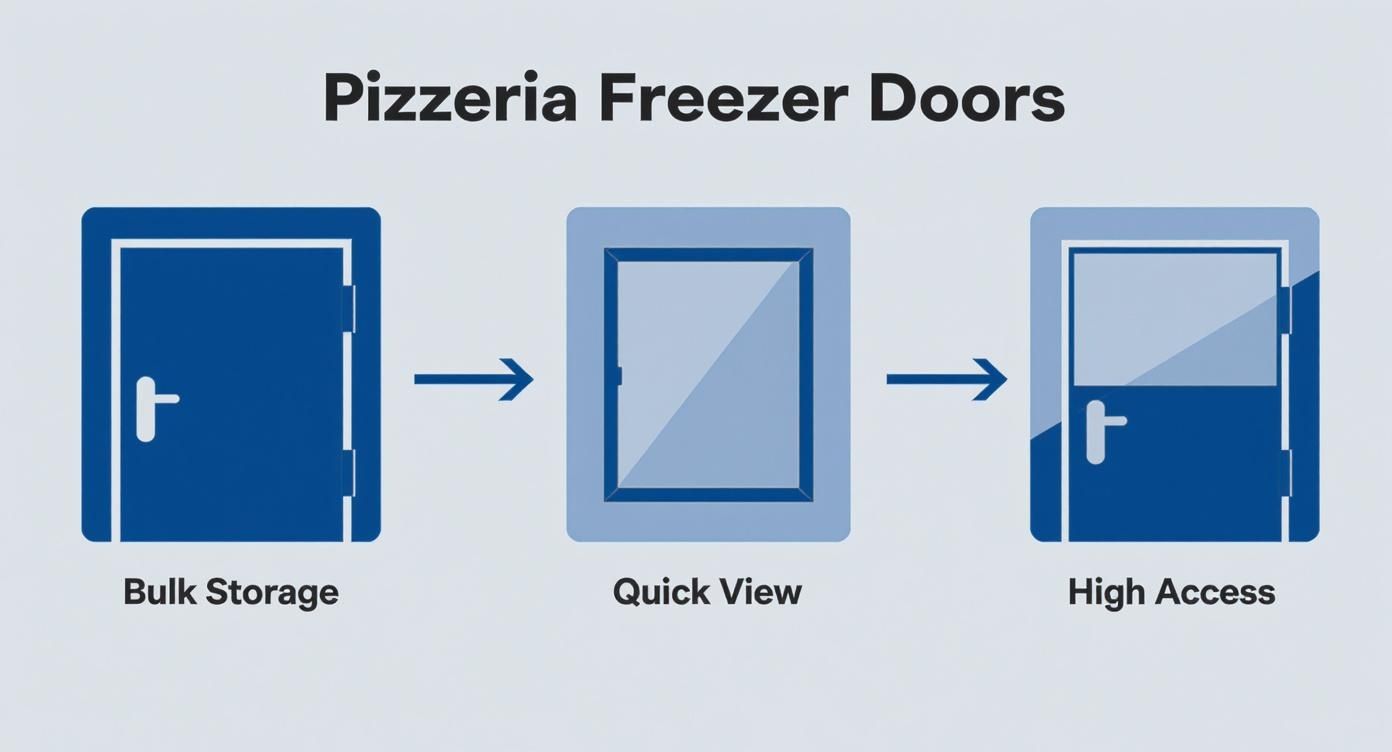

The doors on your freezer are the gateways to your pizza ingredients. The right setup can shave precious seconds off your prep time during a dinner rush, while the wrong one creates bottlenecks near the pizza prep table and wastes energy. Each style really has its own job to do in a pizzeria.

-

Solid Doors: These are the undisputed champions of insulation. With no glass to interfere with temperature stability, solid doors are the go-to for your back-of-house bulk storage. This is where you keep your main supply of cheese, meats, and backup dough—the ingredients you don't need to see every five minutes. They are, by far, the most energy-efficient option.

-

Glass Doors: Perfect for positioning near your pizza prep table, glass doors let you do a quick inventory check at a glance. Your team can see instantly if they're running low on pepperoni or pre-portioned dough balls without opening the door and letting all that cold air spill out. To learn more about this style, check out our guide on commercial glass door freezers.

-

Half-Doors (Split Doors): This design is the best of both worlds for a high-traffic freezer located near the prep line. By opening just a small section at a time—either the top or bottom half—you seriously minimize cold air loss. This is ideal for a freezer packed with frequently accessed toppings, as it helps maintain a steady temperature and reduces how hard the compressor has to work during your busiest hours.

Making these smart choices isn't just about convenience; it's about being part of a larger industry trend toward efficiency. The commercial refrigeration market is set to see its fastest growth between 2025-2032, driven by the essential need for reliable, low-temperature storage in restaurants and food retail. Picking the right door style is a small decision that helps ensure your pizzeria is running as efficiently as possible.

Calculating Freezer Size for Your Pizzeria

Getting the size of your reach in freezer right is one of those gut-check decisions that can haunt you for years. Go too small, and you’re stuck making emergency supply runs in the middle of a Friday night pizza rush. Go too big, and you’re basically paying to air-condition empty space, which is like throwing cash directly onto your utility bill every month.

This isn’t about guesswork. It’s a straightforward calculation based on the reality of your pizzeria’s rhythm. The goal is to perfectly match your freezer’s capacity to how much product you actually move, ensuring you have what you need without wasting a dime on energy or space.

From Pizza Ingredients To Cubic Feet

First things first, you need to do a quick inventory audit. For one full week, track exactly what you use of your core frozen pizza ingredients. You’re not just counting pizza boxes here; you’re thinking in terms of the bulk cases they arrive in.

Focus on your biggest movers:

- Bulk Cheese: How many cases of mozzarella blocks or shredded cheese are you burning through?

- Pizza Dough: Using pre-made dough balls? Get an accurate count of the cases you use weekly.

- Proteins: Track your pepperoni, sausage, and chicken wing usage by the case.

- Sides & Toppings: Don’t forget about those boxes of frozen veggies, french fries, or jalapeño poppers for your appetizer menu.

Once you have these numbers, you can translate them into the cubic footage you’ll need. As a solid rule of thumb, you can store roughly 28-35 lbs of food per cubic foot in a reach-in freezer. So, if your weekly frozen goods weigh in around 600 lbs, you should be looking at freezers with at least 20 cubic feet of capacity to hold everything comfortably.

To make this even easier, here’s a quick planning table to help you visualize your pizzeria's needs.

Reach In Freezer Capacity Planning for Pizzerias

This table helps you estimate the cubic footage you need based on the real-world ingredients you use every week. Just plug in your own numbers to get a clearer picture.

| Ingredient Type | Typical Storage Form | Estimated Space per Case/Unit | Weekly Usage Example (Medium Pizzeria) |

|---|---|---|---|

| Block Mozzarella | 40 lb case | ~1.25 cubic feet | 5 cases (200 lbs) |

| Pizza Dough Balls | 50-count case | ~1.0 cubic foot | 8 cases (400 balls) |

| Pepperoni | 25 lb case | ~0.75 cubic feet | 2 cases (50 lbs) |

| Frozen Fries | 30 lb case | ~1.0 cubic foot | 3 cases (90 lbs) |

By adding up the space required for your specific inventory, you can move from a rough guess to a data-backed decision, ensuring you buy the right size freezer the first time.

After figuring out your capacity, the next step is thinking about how your team will use the freezer, especially in relation to the pizza prep table. This is where door types come into play.

As you can see, solid doors are perfect for long-term bulk storage where you aren't opening them constantly. Glass and half doors, on the other hand, are designed for quick access right near the prep line where speed is everything.

Planning Your Physical Footprint

Beyond the internal capacity, you have to think about the unit’s external dimensions—its actual physical footprint. The single most common mistake pizzeria owners make is forgetting to measure the path the freezer needs to take just to get into the kitchen.

Before you even think about hitting "buy," grab a tape measure. Measure every single doorway, hallway, and tight corner on the delivery path. A brand-new freezer that doesn't fit through your back door is one of the most frustrating and costly headaches you can imagine.

Understanding the fundamental principles of correctly sizing cooling appliances is critical for performance and efficiency in any commercial setting, and this applies directly to choosing the right freezer for your pizzeria.

Once you know it can get inside, map out its final home. You have to leave enough clearance—usually a few inches on all sides and the top—for proper ventilation. If you shove a freezer right up against a wall or another hot piece of equipment like a pizza oven, you're essentially choking the compressor. It will be forced to work overtime, driving up your energy bills and dramatically increasing the risk of burning out.

This simple planning saves a world of trouble on installation day. For smaller kitchens where every square inch is precious, consider pairing a reach-in with a freezer base on your pizza prep table. These undercounter units can be a fantastic solution when a full-size upright just won’t fit.

Boosting Profit with Energy and Safety Features

A reach-in freezer is a big-ticket item, but the day you buy it isn't the last time it affects your wallet. The real costs—and the real opportunities for savings—pop up every month on your utility bill and every time the health inspector walks through the door. Thinking about energy efficiency and safety certifications isn't just about checking boxes; it's a core strategy for making your pizzeria more profitable.

These two things are more connected than you might think. A freezer that sips energy instead of chugging it tends to run better, hold its temperature like a champ, and last longer, all of which are huge wins for food safety. On the flip side, a freezer built to strict safety standards is a breeze to clean and maintain, which helps it run more efficiently.

Decoding Energy Efficiency for Your Pizza Shop

Once you've paid for the freezer, the real test begins: the ongoing cost of keeping it running. Your electricity bill is a major player in your monthly profits, and getting smart about how to save electricity with an efficient freezer is key to your pizza shop's financial health. That ENERGY STAR sticker isn't just for decoration; it’s proof that you’re about to save some serious cash.

An ENERGY STAR certified reach-in freezer is engineered to be about 20% more energy-efficient than a standard model. For a pizzeria, where your refrigeration is one of the thirstiest appliances in the building, that 20% can easily translate into hundreds, or even thousands, of dollars back in your pocket each year.

When you're shopping, keep an eye out for these game-changing features:

- R290 Refrigerant: This is the modern, eco-friendly stuff. It’s a hydrocarbon refrigerant that's not only kinder to the planet but is also fantastic at its job—absorbing heat. That means your compressor doesn't have to kick on as often, saving power and wear-and-tear.

- High-Density Insulation: Think of this as the freezer's winter coat. High-quality polyurethane foam is injected into the walls, creating a super-insulated box. The thicker and denser it is, the less cold air leaks out, and the less your freezer has to work to stay frosty.

- Automatic Defrost Cycles: Frost buildup on the evaporator coils is like putting a wool sweater on your freezer's cooling system—it forces it to work way harder. Smart defrost cycles are a lifesaver; they run automatically only when needed, keeping the coils clear without wasting energy on pointless heating cycles.

Choosing an energy-efficient model is like pre-paying for lower utility bills for the next decade. The small premium you might pay upfront is quickly returned through month-after-month operational savings. For a deeper dive, explore our guide on energy-efficient commercial refrigeration.

Why NSF Certification Is Non-Negotiable in a Pizzeria

While energy efficiency saves you money, NSF certification saves your business. Period. The National Sanitation Foundation (NSF) sets the gold standard for how commercial kitchen equipment should be built. Seeing that NSF mark on a reach-in freezer is your best line of defense when a health inspector shows up unannounced.

Inspectors look for that mark because it’s a guarantee. It tells them the freezer was designed from the ground up for safe food handling in a high-risk environment like a pizzeria. This certification is your assurance that the unit is built with:

- Cleanability: Smooth, non-porous surfaces like stainless steel are key. They don't have tiny cracks or crevices where bacteria from raw toppings can hide. Coved corners—the rounded ones inside the freezer—make wiping down the interior faster and way more effective.

- Durable Materials: The freezer is built to survive a busy pizzeria kitchen. The materials can handle harsh cleaning chemicals and the daily grind without chipping, rusting, or falling apart.

- Food-Safe Construction: Every part that could possibly touch your pizza ingredients is non-toxic and constructed to prevent any chance of cross-contamination.

At the end of the day, buying a freezer without NSF certification is a gamble you simply can't afford to take. You're risking failed inspections, hefty fines, and the one thing you can never get back: your reputation and the trust of your customers. It’s a foundational investment in the safety and longevity of your pizzeria.

Integrating Your Freezer into the Kitchen Workflow

Buying the freezer is the easy part. Making it a seamless piece of your pizzeria puzzle is where the real work begins. A well-placed reach in freezer isn't just a cold box—it's a high-performance pit stop in your pizza production line. The right spot can shave precious seconds off every pie you make, which adds up to a massive advantage during a chaotic dinner rush.

Think about your kitchen layout in terms of footsteps. Every extra step your cook takes between the freezer and the pizza prep table is wasted time and motion. By placing the freezer as close as possible to the prep table, you create a natural, ergonomic triangle. This setup lets your team pivot from freezer to prep station in one fluid motion, grabbing cheese, dough, and toppings without breaking their rhythm.

Proper Placement and Setup

Getting your freezer installed correctly goes way beyond just plugging it into the wall. It’s about creating the perfect environment for it to run efficiently, saving you from future headaches and repair bills. The single most important factor is giving the unit enough room to breathe, especially away from your hot pizza oven.

A reach-in freezer’s compressor is like the lungs of the appliance—it needs to breathe. Suffocating it by pushing the unit tight against a wall or next to a hot pizza oven will force it to work overtime, drastically increasing energy costs and leading to premature failure.

Always follow the manufacturer's guidelines for clearance. Most will recommend leaving at least 3-4 inches of open space around the sides, back, and top of the unit. This gap is non-negotiable; it allows air to circulate freely and pull heat away from the hard-working compressor and condenser.

Beyond airflow, your electrical setup is critical. A commercial freezer is a power-hungry beast that absolutely needs its own dedicated electrical circuit. Trying to share a circuit with your mixer or other prep table appliances is a recipe for disaster, and you’re just asking for tripped breakers right in the middle of your busiest service.

Ensuring a Perfect Seal

One of the most overlooked installation steps is simply leveling the unit. If your freezer is wobbly or leaning, the doors won't hang properly, preventing them from forming a tight seal. Even a tiny gap lets cold air escape and invites warm, moist kitchen air inside.

This constant air exchange is a silent killer for your freezer's efficiency and your bottom line:

- Sky-High Energy Bills: The compressor has to run almost constantly to make up for the cold air it's losing.

- Frost Buildup: All that moisture seeping in quickly turns into thick frost, which blocks airflow and makes the freezer even less efficient.

- Spoiled Inventory: An unstable internal temperature puts your valuable dough, cheese, and toppings at risk of freezer burn.

Take the time to adjust the leveling feet until the unit is perfectly stable and the doors swing shut and seal completely on their own. It’s a simple, one-time tweak that makes sure your freezer operates at peak performance from day one, turning it from just another appliance into a strategic asset for a faster, smoother pizzeria kitchen.

Your Pizzeria's Reach-In Freezer Buying Checklist

Alright, let's get down to brass tacks. Picking out a new reach-in freezer can feel like a huge decision, because it is. But it doesn't have to be a stressful one. We've boiled down everything we’ve talked about into a simple, no-nonsense checklist. Use this when you're comparing models to make a smart buy that’ll serve your pizzeria for years.

Think of this as your final walkthrough before you sign on the dotted line. Each point is a gut check to help you sidestep common pitfalls and make sure the freezer you bring home is the right fit for your pizza kitchen's real-world chaos.

Capacity and Space Planning

First things first: size. We're talking about the inside and the outside. Getting this wrong is a recipe for daily headaches, whether it's running out of cheese mid-rush or the pure nightmare of a unit that can’t even fit through your back door.

- Do the Math on Capacity: Tally up the total weight of your weekly frozen goods—all that dough, cheese, and pepperoni. A solid rule of thumb is that one cubic foot of freezer space holds about 28-35 lbs of product. Don't eyeball it; pull out your order sheets and get a real number.

- Measure Everything. Twice. Grab a tape measure. Get the dimensions of every single doorway, corner, and hallway on the delivery path. Then, measure the spot where it will live, making sure to leave at least 3-4 inches of breathing room on all sides for ventilation, especially away from the pizza oven.

Workflow and Performance Features

Next up, let's talk about the features that will actually affect your day-to-day grind and your electric bill. The right compressor and door setup can make your pizza prep table a model of efficiency; the wrong ones just create bottlenecks and frustration.

- Pick the Right Compressor: For 99% of pizzerias, a top-mount compressor is the only way to go. Its elevated position keeps it high and dry, away from the flour dust and floor grime that kills bottom-mount units. A bottom-mount freezer only makes sense if your kitchen is kept as clean as a surgical suite.

- Match Doors to the Job: Think about how you’ll use it. You want heavily insulated solid doors for your back-of-house bulk storage where you’re trying to lock in the cold. For freezers near the pizza prep line, energy-saving glass or half-doors are perfect for quick inventory checks without letting all the cold air spill out.

Taking a few extra minutes to nail down these details is the single best way to avoid that sinking feeling of buyer's remorse. A freezer that fits your space, works with your flow, and meets all the safety rules will be a reliable workhorse, not a constant source of stress.

Certifications and Long-Term Value

Finally, look past the shiny stainless steel to the stickers and paperwork that actually guarantee performance and protect your wallet. These little logos are your assurance of quality, efficiency, and safety for your pizza shop.

- Look for the Right Logos: There are two non-negotiable certifications you need to see. The first is ENERGY STAR, which is proof that the unit is energy-efficient and won't inflate your utility bills. The second is NSF (National Sanitation Foundation), which means it’s built for food safety and is easy to clean—something your health inspector will definitely be looking for.

- Check the Warranty and Local Service: A solid warranty shows the manufacturer believes in their product. But here’s the pro tip: check for local certified technicians who can actually service the brand you're buying. A five-year warranty is worthless if the only person who can fix it is three states away and can't get to you for a week when your freezer full of cheese goes down.

Got Questions About Pizzeria Freezers? We've Got Answers.

Even after you’ve picked out the perfect reach in freezer, a few practical questions always pop up. It’s one thing to have the equipment; it’s another to integrate it perfectly into a busy, flour-dusted pizzeria. Let's tackle the most common questions we hear from pizza shop owners.

Think of this as your final check-in, making sure you’re getting the most out of your investment and keeping your pizza ingredients in prime condition.

What Is the Ideal Freezer Temperature for a Pizza Shop?

You absolutely need to keep your reach-in freezer at or below 0°F (-18°C). This isn't just a "nice-to-have"—it's the non-negotiable temperature for food safety and quality. Everything from your bulk mozzarella and pepperoni to your backup dough relies on this intensely cold, stable environment.

A consistent 0°F is your best weapon against two enemies: bacterial growth and freezer burn. Freezer burn is especially brutal on pizza dough and cheese, as it sucks the moisture right out, ruining their taste and texture. That leads directly to wasted product and unhappy customers.

Pro Tip: Don't just trust the built-in display. They can be off by a few degrees. Grab a separate, calibrated freezer thermometer, stick it inside, and check it every single day. It’s the only way to know the true internal temperature.

How Often Should I Clean My Freezer Coils?

In a normal commercial kitchen, you’d clean the condenser coils every 90 days. But a pizzeria is not a normal kitchen. With all that flour and grease in the air, you’ve got a magnet for grime, creating a thick, fuzzy blanket that insulates the coils.

Because of this, you should clean them monthly.

When the coils are caked with grime, the compressor has to work overtime just to push heat out. That means your energy bills skyrocket, and you’re putting massive strain on the motor. Sooner or later, that leads to a very expensive breakdown. A quick cleaning with a stiff brush and a vacuum is one of the smartest, money-saving tasks you can do.

Can I Place My Freezer Next to My Pizza Oven?

Absolutely not. Putting your freezer right next to a pizza oven, fryer, or any other hot equipment is one of the fastest ways to kill it. The constant waves of ambient heat force the freezer's compressor to run nearly non-stop just to keep up.

This creates a perfect storm of problems:

- Sky-High Energy Bills: The unit will guzzle electricity way beyond what it’s rated for.

- Compressor Burnout: The motor will wear out in a fraction of its expected lifespan, leading to a costly replacement.

- Risky Performance: The freezer will struggle to hold a safe temperature, putting all your valuable cheese, dough, and toppings on the line.

Always leave several feet of breathing room between your freezer and any heat source. Just as important, make sure there’s plenty of airflow around the entire unit, especially near the compressor. Sticking your freezer in a cooler, well-ventilated spot in the kitchen will make it run better, cheaper, and for a whole lot longer.

Ready to find the perfect workhorse for your kitchen? At Pizza Prep Table, we specialize in high-quality refrigeration that streamlines your workflow. Explore our wide selection of reach-in freezers and pizza prep tables designed for the demands of a busy pizzeria. https://pizzapreptable.com