Elevate Your Pizzeria with the Right restaurant cleaning supplies - A Practical Guide

Share

Outfitting your pizzeria with the right restaurant cleaning supplies isn't just about passing a health inspection—it's the first line of defense in running a safe, successful kitchen. A well-stocked supply closet is your team's arsenal, ready to tackle everything from a fresh tomato sauce spill on a pizza prep table to the grease that builds up after a busy Friday night.

Think of it as your foundational toolkit for protecting your staff, your customers, and your reputation.

Your Essential Pizzeria Cleaning Supplies Checklist

Let's be honest: keeping a pizzeria clean is a unique battle. You're fighting baked-on cheese, acidic tomato sauce, a constant dusting of flour, and grease that seems to get everywhere. A generic all-purpose cleaner from the grocery store just isn't going to cut it.

That cleaner might handle a simple spill on a dining table, but it won't properly sanitize a pizza prep table where dough and toppings live, and it definitely won't touch the grease building up in your pizza ovens. It’s like trying to make a perfect pizza crust with cake flour—you need the right tool for the job.

A smart move is to create dedicated cleaning kits for different zones in your pizzeria. The chemicals you need for the front-of-house are totally different from what you'll use at the dough station or the pizza prep table. This simple separation is a game-changer for preventing cross-contamination and making the whole process more efficient.

Core Cleaning Product Categories

To build a truly effective cleaning program, you need to stock products from four critical categories. Each one plays a specific role, and having them all on hand means your team is ready for whatever mess comes their way.

- Daily Surface Cleaners: These are your everyday workhorses. Think of them for frequent wipedowns of counters, dining tables, and other non-food-contact surfaces to handle light spills and keep things looking sharp.

- Heavy-Duty Degreasers: Pizzerias are grease factories. A powerful, professional-grade degreaser is non-negotiable for cleaning oven hoods, fryers, grills, and the greasy film that builds up on backsplashes.

- Food-Contact Sanitizers: This is arguably the most important bottle in your closet. You need an NSF-certified sanitizer for any surface that touches food—your pizza prep tables, cutting boards, and utensils. This is what reduces bacteria down to legally safe levels.

- Specialized Floor Care: Flour dust, grease, and tracked-in dirt create a dangerously slippery floor. A dedicated floor cleaner that can cut through that greasy film is essential for safety. Look for a slip-resistant formula.

A well-organized supply inventory isn't just about being clean; it's about being ready. When your staff can grab the right product for the job without a second thought, cleaning becomes a smooth part of the daily workflow instead of a disruptive chore.

Here’s a quick-glance table to help you visualize your core needs.

Core Cleaning Supplies for a Pizza Restaurant

| Supply Category | Primary Use in a Pizzeria | Key Feature to Look For |

|---|---|---|

| Daily Surface Cleaners | Wiping down dining tables, counters, and windows. | Streak-free, quick-drying formula. |

| Heavy-Duty Degreasers | Cleaning oven hoods, fryers, grills, and greasy walls. | A potent, fast-acting formula that cuts through baked-on grease. |

| Food-Contact Sanitizers | Sanitizing pizza prep tables, cutting boards, and utensils. | NSF Certification; "no-rinse" is a huge time-saver. |

| Specialized Floor Care | Mopping kitchen and dining room floors. | A slip-resistant formula specifically designed to cut grease. |

This table provides a great starting point for stocking your supply closet with the essentials that will keep your pizzeria safe and sparkling.

This checklist is the foundation. For a deeper dive into specific products and protocols, you can explore our comprehensive guide on cleaning supplies for restaurants. Building this kit is the first step toward a cleaning program that’s not just effective, but rock-solid compliant.

Mastering Pizza Prep Table Sanitation

The pizza prep table is the heart of your pizzeria, the undisputed main stage where every single pie begins its journey. That makes it ground zero for food safety and quality. A quick wipe-down just doesn't cut it; true sanitation is a deliberate, multi-step process that's non-negotiable for protecting your customers and your reputation.

Think of your pizza maker cleaning the table like a surgeon scrubbing in before an operation. Each step is essential and done in a specific order for a safe outcome. If you skip a single part of that sequence, you might as well not have bothered at all—you'll just be leaving dangerous bacteria on the very surfaces your food touches.

This isn't about just looking clean. It's about a disciplined approach that actively eliminates germs instead of just pushing them around. This is one of the core practices that separates the pros from the amateurs.

The Four Pillars of Pizza Prep Table Cleaning

To properly sanitize your pizza prep table, your team needs to follow this exact four-step protocol every single time. It's not a suggestion; it’s a fundamental food safety requirement. Messing up the order or—even worse—skipping the rinse step can completely neutralize your sanitizer, wasting time, effort, and expensive chemicals.

- Scrape and Remove: This first part is all about muscle. Grab a bench scraper or spatula and clear away all the physical debris—flour, bits of cheese, stray pepperoni, and sauce splatters. You can’t clean a dirty surface, so getting the big stuff off first is always step one.

- Wash with Detergent: Now, arm yourself with a clean cloth or brush and a solution of warm water and a good detergent. Scrub the entire surface of the pizza prep table, making sure to get into the corners and along the edges where grime loves to hide. The detergent's job is to break down and lift away all that grease and food residue.

- Rinse Thoroughly: This is the step everyone wants to skip, and it's arguably the most critical. With a separate, clean cloth and fresh, clear water, wipe down the whole pizza prep table again. You have to remove every last trace of that detergent. Why? Because any soap residue left behind will kill your sanitizer on contact, making the final step completely useless.

- Apply Food-Safe Sanitizer: Finally, it's time for the sanitizer. Apply an NSF-certified, food-safe sanitizer exactly as the manufacturer’s instructions say. And here's the key: you must let it sit for the required contact time—often 30-60 seconds—to actually do its job of killing bacteria down to a safe level. Don't wipe it off. Let it air dry.

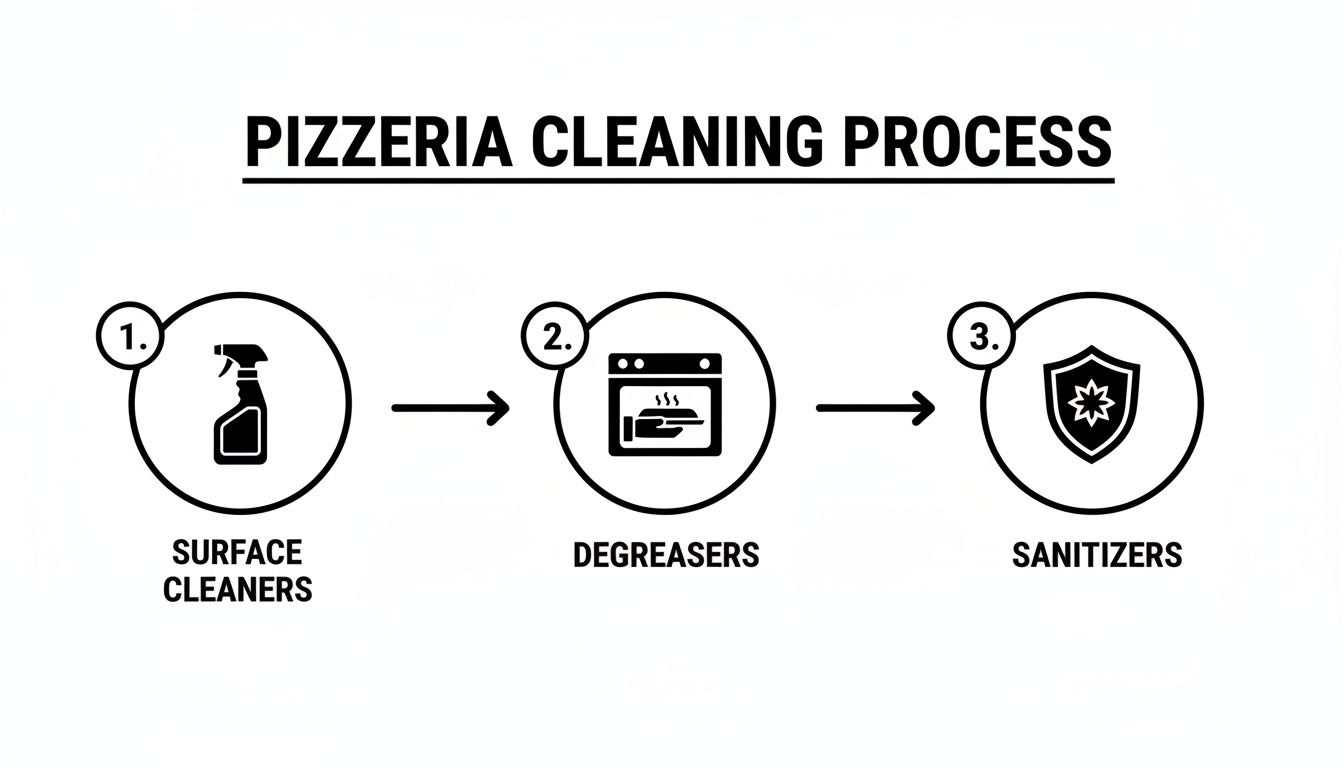

This visual guide breaks down how different products fit into this essential cleaning flow.

As you can see, the process moves logically from basic cleaning to the final, critical sanitizing step that ensures the pizza prep table is truly safe for food prep.

Beyond the Main Surface

Your job isn't done once the stainless steel top of the pizza prep table is gleaming. The refrigerated rail inserts and your cutting boards are high-risk zones for cross-contamination and bacterial growth, and they need the same level of attention.

Refrigerated Rail Inserts:

Think about it—these containers hold your fresh toppings all day, dealing with temperature changes and constant hands reaching in. They must be completely emptied, washed, rinsed, and sanitized every single day. No excuses. Skipping this is just asking for a dangerous buildup of bacteria right next to your ready-to-eat ingredients.

Cutting Boards:

Whether you use plastic or composite boards on your pizza prep table, they need special care. After running them through the same four-step cleaning and sanitizing process, give them a close look. Deep knife grooves are perfect hiding spots for bacteria. If a board is covered in deep scores, it’s time to either get it professionally resurfaced or just replace it.

"A clean pizza prep station is a direct reflection of a kitchen's discipline. It’s where food safety begins, and it’s a non-negotiable standard for any professional pizzeria."

Mastering the sanitation of your pizza prep table is fundamental. For pizzerias with large stainless steel units, knowing the ins and outs of proper care is crucial. To dive deeper, check out our guide on the best way to clean a stainless steel refrigerator; the tips there are directly applicable to your pizza prep table. When you empower your team with these protocols, you're building every pizza on a foundation of safety.

Choosing the Right Chemicals for Your Pizzeria

Walking down the cleaning aisle can feel like you need a chemistry degree. You’ve got bottles labeled "detergent," "sanitizer," and "disinfectant," but what's the real difference? More importantly, when do you use each one in a busy pizzeria? Using the wrong product isn’t just a waste of time; it can be dangerous for your customers and put you on the wrong side of the health inspector.

Think of your chemical supply cabinet as a specialist's toolkit. You wouldn't use a screwdriver to hammer a nail, right? In the same way, trying to scrub thick, baked-on grease from a pizza oven with a sanitizer is the wrong tool for the job. Sanitizer is designed to kill microscopic bacteria on an already clean pizza prep table, not power through physical grime.

When you understand the specific job of each chemical, your cleaning routine stops being a chore and becomes a precise science. This is how you ensure you're not just cleaning, but cleaning with purpose to keep your pizzeria safe, compliant, and running smoothly.

Detergents: The Grime Removers

Detergents are your frontline soldiers in the war against messes. Their mission is simple: to break down and lift away the stuff you can actually see—dirt, grease, and leftover food particles. At their core, they're soaps, and their superpower is making all that grime water-soluble so you can easily wipe or rinse it away.

You'll use detergents on just about every surface, from your pizza prep table to the kitchen floor. They are always, without exception, the first step in any proper cleaning protocol. Before you can even think about sanitizing a surface, you have to wash it with a good detergent to get rid of the physical soil where bacteria love to hide. For those really tough jobs, finding the right solutions is critical. For effective grease removal, you'll want to find the best grease cleaner built for the demands of a commercial pizzeria.

Sanitizers: The Bacteria Reducers

Once a surface looks clean, it's time for the sanitizer. This is a non-negotiable step for any surface that touches food, especially your pizza prep tables. A sanitizer’s job is to reduce the number of microorganisms, like bacteria, down to a level that public health codes consider safe.

It's a common misconception, but sanitizers don't sterilize—they don't kill 100% of germs. Instead, they knock the pathogen count down to a safe, legally acceptable level for food-contact surfaces like a pizza prep table.

Always look for an NSF-certified, food-safe sanitizer. Products based on Quaternary Ammonium (Quats), for example, are designed for commercial kitchens and often come in "no-rinse" formulas, which is a huge time-saver. To get a better handle on your options, you can learn about the three main types of sanitizer solutions in our dedicated guide.

Disinfectants: The Germ Killers

Disinfectants are the heavy hitters in your cleaning arsenal. They’re formulated to kill a much broader spectrum of microorganisms, including nasty viruses and fungi. Because they pack a bigger punch and often contain harsher chemicals, they are strictly reserved for non-food-contact surfaces.

Think about the areas where the risk of spreading illness is highest:

- Restroom fixtures like toilets and sinks

- Door handles, light switches, and railings

- Trash can lids and exteriors

You would never use a disinfectant on a pizza prep table. It's not food-safe and could leave behind harmful chemical residues. With a growing focus on hygiene, it’s no surprise the professional cleaning products market is forecasted to surge to USD 97.5 billion by 2035. Surface cleaners and disinfectants are expected to hold a 41% revenue share in 2025 because of how essential they've become.

To make this crystal clear, I've put together a simple table that breaks down the key differences.

Detergent vs. Sanitizer vs. Disinfectant in a Pizza Kitchen

This chart gives you a quick, at-a-glance reference to make sure you're always grabbing the right bottle for the job.

| Chemical Type | Primary Function | Best Used For (Pizza Kitchen Examples) |

|---|---|---|

| Detergent | Removes visible dirt, grease, and food residue. | The first step for cleaning pizza prep tables, floors, walls, and equipment. |

| Sanitizer | Reduces bacteria on surfaces to a safe level. | Food-contact surfaces like pizza prep tables, cutting boards, and pizza cutters. |

| Disinfectant | Kills a wide range of germs, including viruses. | High-touch, non-food surfaces like restroom fixtures and door handles. |

Understanding these roles isn't just about following rules—it's about building a smarter, safer cleaning system that protects your staff, your customers, and your reputation.

Essential Cleaning Tools and Safety Gear

Powerful chemicals are only half the battle. Without the right tools to put them to work and the right gear to keep your staff safe, even the best cleaning program will fall flat. Arming your team with the correct non-chemical restaurant cleaning supplies is what makes sure your expensive chemicals actually do their job and your crew can work without risk.

Think of it like this: a great pizza chef can have the best ingredients, but without sharp pizza cutters and quality pans, the food just won't be right. In the same way, the world's best degreaser is useless if you don't have a stiff brush to get into the grime. These tools are the hardware that brings your whole cleaning strategy to life.

Investing in quality tools and Personal Protective Equipment (PPE) isn't just about checking a box for the health inspector. It’s about building a safe, professional, and efficient pizzeria from the ground up.

The Right Tools for a Pizzeria

Pizzerias have their own unique cleaning challenges. You’re dealing with fine flour dust that gets everywhere, sticky dough, and cheese that’s been baked into oblivion. Your toolkit needs to be hand-picked to tackle these specific problems, especially around your busy pizza prep tables.

- Color-Coded Microfiber Cloths and Brushes: This is one of the simplest and most effective ways to stop cross-contamination in its tracks. You assign one color (say, green) strictly for pizza prep tables and food areas, another (red) for restrooms, and maybe blue for the front of the house. It's a dead-simple visual cue that makes sure the brush that scrubbed the bathroom floor never, ever comes near a food surface.

- Heavy-Duty Squeegees: The floors in a pizzeria are a constant warzone of grease, flour, and water. A high-quality floor squeegee is your secret weapon, letting you pull all that dirty water and cleaning solution toward the drains. This slashes drying time and dramatically reduces the risk of slips and falls.

- Specialized Deck Brushes: For the stubborn, baked-on gunk that lives in the grout of quarry tile floors, a regular mop just won't cut it. You need a deck brush with stiff, tough bristles to really scrub out the embedded grease and food bits, leaving your floors truly clean and non-slippery.

A well-stocked tool caddy is as important as a well-stocked pantry. When your team has immediate access to the right brush, cloth, or squeegee, cleaning tasks are completed faster, more effectively, and with less frustration.

Protecting Your Team with Proper PPE

Personal Protective Equipment isn't a suggestion—it's a non-negotiable requirement from the Occupational Safety and Health Administration (OSHA). Providing and, just as importantly, enforcing the use of PPE protects your single most valuable asset: your people. It shields them from chemical splashes, burns, and other common pizzeria injuries.

Proper PPE also makes your team better at their jobs. When a crew member feels safe and protected, they can work more confidently and get the job done right, without hesitation. It's a core part of building a true safety culture in your pizzeria.

Essential Safety Gear for Every Pizzeria

Stocking the right safety gear is a direct investment in your team's health and a shield for your business's liability.

- Chemical-Resistant Gloves: Don't even think about using standard latex or vinyl gloves for cleaning. When your staff is handling commercial-grade degreasers or sanitizers, they need nitrile or rubber gloves designed to stand up to harsh chemicals. This is what prevents nasty skin irritation and chemical burns.

- Safety Goggles or Glasses: Splashes are going to happen. It's inevitable. Whether someone is mixing a concentrated solution or scrubbing a tough spot on a pizza oven, safety goggles are the only thing standing between their eyes and a caustic chemical that could cause permanent damage.

- Slip-Resistant Shoes: While this is often seen as part of the uniform, you should mandate certified slip-resistant footwear as a critical safety rule. It is the absolute first line of defense against the slick, greasy floors common in any pizzeria.

By arming your staff with both the right tools for the job and the essential PPE to keep them safe, you create a robust system where cleanliness and safety go hand-in-hand. This foundation is key to running a compliant and successful pizzeria.

Building Your Pizzeria Cleaning Schedule

Consistency is the secret weapon for a pizzeria that’s always clean. You can have a fully stocked supply closet, but those restaurant cleaning supplies are only doing their job when they're part of a structured, repeatable schedule. This isn’t about just wiping things down when they look dirty; it's about building a predictable routine that keeps your pizzeria spotless, makes health inspectors smile, and becomes second nature for your team.

Think of it like preventative maintenance for your pizza oven. You don't wait for the heating element to fail before servicing it. In the same way, you shouldn't wait for a health code violation or a pest problem to get serious about cleaning. A solid schedule stops those massive, costly breakdowns before they ever happen, saving you a world of stress and money.

This framework breaks the whole job down into daily, weekly, and monthly tasks, turning a monster of a chore into small, manageable actions.

Daily Cleaning: Your Non-Negotiables

Daily tasks are all about damage control after a busy service and hitting the reset button for the next day. These actions target the surfaces that get hit the hardest with food spills and frequent contact, stopping bacteria and grime from building up overnight. The name of the game here is speed, repetition, and food safety.

Your daily checklist is the absolute foundation of your cleaning program.

- Pizza Prep Tables: This is ground zero. After every single shift, all prep tables need the full clean, rinse, and sanitize treatment. That includes emptying, washing, and sanitizing every refrigerated rail insert.

- Pizza Ovens: While the deep clean happens less often, the outside of the oven needs a daily wipe-down. Any big spills or boil-overs inside should be scraped out once the oven has cooled down to stop that nasty carbon from building up.

- Floors: Kitchen floors get swept and mopped with a heavy-duty degreasing floor cleaner every night, without fail. This is a critical safety step to keep anyone from slipping on a dangerously slick surface.

- Utensils and Smallwares: All your cutting boards, pizza cutters, knives, and containers must be properly washed, rinsed, and sanitized.

Weekly Tasks: The Deeper Clean

Weekly jobs push past the surface to hit those areas where grime builds up more slowly but can cause huge issues if you let them go. This is your chance to reset equipment and tackle those less-visible spots, making sure your pizzeria stays in peak condition and preventing bigger, tougher cleaning jobs down the road.

A well-executed weekly plan is the difference between a kitchen that looks clean and a kitchen that is fundamentally clean, right down to the drains and corners.

- Delime Dishwashers: Hard water minerals can build up and make your dishwasher pretty useless, and can even wreck the heating element. Running a delimer through the machine once a week keeps it running like a champ.

- Scrub Floor Drains: Nobody's favorite job, but it's absolutely essential for stopping foul odors and pests. Get in there with a stiff brush and a powerful drain cleaner to scrub out any gunk.

- Clean and Organize Walk-ins: Wipe down all the shelving in your walk-in cooler and freezer. It's also the perfect time to rotate your stock and get everything properly organized.

Monthly and Periodic Deep Cleans

Monthly tasks are the big projects that maintain the bones of your pizzeria. These jobs usually demand more time and specialized restaurant cleaning supplies, but they are non-negotiable for long-term safety and compliance. Skipping these can lead to serious hazards like grease fires.

Given the scale of these deep cleans, many pizzerias find that a hybrid approach works best. To maintain the highest standards, a thorough cleaning schedule sometimes means calling in professional restaurant cleaning services for the more intense jobs or periodic deep dives.

The market for these pros is growing fast as hygiene rules get tighter. Commercial kitchen cleaning is booming, with restaurants like yours driving 47.6% of the demand. Here in North America, which holds a 38.7% market share, over 749,000 restaurants rely on professional-grade supplies like hood degreasers to fight the fire and contamination risks from grease buildup. You can learn more about this trend by reading the full report on the commercial kitchen cleaning market.

Here are the key monthly or quarterly tasks to get on the calendar:

- Deep Clean Exhaust Hoods and Filters: This is a massive fire safety task. Your filters should be cleaned more often (usually weekly), but the entire hood system needs a deep degreasing at least quarterly, if not monthly.

- Clean Behind and Under Heavy Equipment: It's time to pull out the pizza ovens and prep tables to get to the walls and floors behind them. This is where grease and food bits love to hide, basically sending an open invitation to pests.

- Empty and Sanitize Ice Machines: Follow the manufacturer’s guide to run a full clean and sanitation cycle on your ice machine. This is the only way to prevent mold and slime from building up where you least want it.

Smart Strategies for Sustainable Cleaning

Running a modern pizzeria is about more than slinging great pies. Today’s customers and staff expect you to be environmentally responsible, too. But trying to balance impeccable hygiene with sustainable practices—all while keeping an eye on the bottom line—can feel like a juggling act. It all comes down to a smarter approach to your restaurant cleaning supplies, looking past the sticker price to the total cost and impact.

Going green isn't just a feel-good move; it's a solid business decision. You protect your team from breathing in harsh chemicals, you appeal to a growing base of eco-conscious diners, and you can seriously trim your long-term supply costs.

This isn't just a niche trend. The demand for safer, greener commercial cleaning products has exploded as restaurants prioritize sustainability. The market is projected to grow from USD 20.46 billion in 2024 to USD 22.05 billion in 2025, with restaurants like yours leading the charge. In fact, over 60% of commercial buyers now choose biodegradable options to cut down on chemical runoff. You can see the full picture of this market shift in this detailed industry report.

The Power of Concentrates and Dilution Control

One of the single most effective ways to make your cleaning program sustainable and affordable is switching to concentrated chemicals. Think of it like buying tomato paste instead of pre-made sauce; you get all the flavor and power, but with way less packaging and water weight, which slashes shipping costs.

To do this right, you need a chemical dilution system. These are typically wall-mounted dispensers that automatically mix the perfect ratio of concentrated cleaner and water, giving you a ready-to-use solution on demand. This takes all the guesswork out of it and stops staff from "free-pouring" chemicals, which is a massive source of waste.

When you install a dilution control system, you're not just buying chemicals—you're buying consistency. Every spray bottle gets the exact same strength, guaranteeing it works perfectly while preventing your team from pouring expensive concentrate down the drain.

Strategic Purchasing and Staff Training

Beyond the chemicals you choose, how you buy and use your supplies is a huge piece of the puzzle. Smart purchasing and great training are the foundation of any cost-effective cleaning plan.

- Leverage Bulk Purchasing: Once you’ve dialed in your core products, buying them in larger quantities can drastically lower your per-unit cost. Zero in on the high-volume stuff like floor cleaner and sanitizer concentrates to see the biggest savings.

- Invest in Proper Training: Don’t just show your staff how to clean—explain why they're using specific products and dilutions. When the team understands that one precise pump from the dispenser does the job, they stop wasting product and your inventory stretches further.

- Use High-Quality Tools: Spending a little more on durable, reusable tools like quality microfiber cloths and sturdy brushes pays off big time. You'll stop burning through disposable wipes and pads, and they clean more effectively, which means less chemical and less elbow grease.

By weaving together certified green products with smart systems like dilution control and strategic buying, you create a powerful cycle. You shrink your pizzeria's environmental footprint, make the workplace safer for your crew, and boost your bottom line—all without sacrificing an ounce of clean.

Pizzeria Cleaning Supplies: Your Questions Answered

When you're running a pizzeria, questions about cleaning supplies and procedures come up all the time. Getting the right answers is crucial for keeping your team confident, your kitchen safe, and the health inspector happy.

Let's tackle some of the most common questions we hear from pizzeria owners, especially when it comes to that all-important pizza prep table.

What’s the Real Difference Between Cleaning, Sanitizing, and Disinfecting?

It’s easy to think these three words mean the same thing, but in a commercial pizzeria, they are three very distinct, non-negotiable steps. Getting them wrong is a major food safety risk.

- Cleaning is step one, always. This is the physical act of removing visible gunk—flour, sauce splatters, melted cheese—using good old soap and water. You have to clean before you can do anything else effectively.

- Sanitizing comes next. This process reduces the number of bacteria and other microorganisms on a surface to a safe level. For any surface that touches food, like your pizza prep table, this is a must-do.

- Disinfecting is the heavy hitter, designed to kill a much broader spectrum of germs, including viruses. You'll disinfect surfaces like bathroom door handles or trash can lids, but not your pizza prep areas.

For your pizza prep table, the process is simple: clean first, then sanitize.

How Often Should I Clean the Refrigerated Rail on My Pizza Prep Table?

That refrigerated rail holding all your precious toppings? It needs to be emptied, cleaned, and sanitized every single day, without fail. No exceptions. Spilled toppings and condensation create a perfect storm for bacterial growth if left overnight.

At the end of every service, your closing crew should pull all the topping inserts, wash and sanitize them, and then thoroughly wipe down the entire inside of the rail with a food-safe sanitizer. This is one of the most critical food safety checkpoints in your entire pizzeria.

Can I Just Use Bleach to Sanitize My Pizza Prep Table?

Technically, a perfectly diluted bleach solution can sanitize. But should you use it in your pizzeria? Absolutely not.

Using bleach on your expensive stainless steel equipment is a bad idea. Over time, it can be corrosive and cause pitting on surfaces like your pizza prep table. It also has a powerful odor that can linger, and if the dilution isn't exactly right, it’s no longer food-safe.

Stick with a commercial, NSF-certified, food-safe sanitizer. Products based on Quaternary Ammonium (we call them "Quats") are designed specifically for this job. They give you reliable, consistent results without putting your valuable equipment—or your food—at risk.

Ready to build a kitchen foundation that’s as solid as your pizza crust? Pizza Prep Table offers a curated selection of NSF-compliant refrigerated prep tables designed for the modern pizzeria. Find the perfect workstation to streamline your process at https://pizzapreptable.com.