Choosing Your Restaurant Pizza Prep Table

Share

Walk into any busy pizzeria, and you might think the oven is the star of the show. But look closer. The real action, the place where speed and quality collide, is the pizza prep table. This isn't just a slab of stainless steel; it's the command center for your entire pizza-making operation.

What used to be a simple workbench has evolved into a highly specialized, refrigerated powerhouse. Understanding that the right pizza prep table is a strategic investment—not just an expense—is the first step toward a smoother, more profitable pizzeria.

This single piece of equipment directly impacts your pizza workflow, your food safety standards, and ultimately, your bottom line. It's no wonder the market for these units is booming. The global food prep tables market was valued at around USD 1.18 billion in 2023 and is only expected to climb. You can explore more data on the global market to see just how essential these workhorses have become for pizzerias everywhere.

A well-organized pizza prep table acts as the central nervous system for pizza production. It’s where every order begins its journey, and its efficiency dictates the pace of the entire kitchen.

Why It's More Than Just a Table

A pizza prep table is engineered from the ground up for one specific job: making pizzas faster and safer. Unlike a standard kitchen counter or island, it integrates a few critical features that streamline the entire pizza-making process.

- Integrated Refrigeration: A refrigerated rail holds pans filled with toppings, keeping everything from pepperoni to peppers perfectly chilled and right at your fingertips. No more running to the walk-in for more cheese.

- Cold Storage Base: The cabinet underneath provides chilled storage for backup sauces, extra cheese, and boxes of dough, keeping your most-used pizza ingredients close by.

- Durable Work Surface: You get a large, often full-length cutting board that gives you tons of space for stretching dough and building pizzas without messing up the stainless steel frame.

This guide will walk you through everything you need to know about choosing, organizing, and maintaining the perfect prep table for your pizzeria. Let's turn this essential piece of equipment into a true workhorse for your business.

Anatomy of a Modern Pizza Prep Table

To really get why a dedicated pizza restaurant prep table is such a game-changer, you have to look under the hood. This isn't just a simple counter; it's a complete system where every single part has a job, all working together to make pizza production faster, safer, and way more consistent.

Think of it as a purpose-built assembly line for one thing: crafting perfect pizzas. When every component, from the chilled topping rail down to the storage base, is designed to cut out wasted steps, your pizzeria gets a serious boost. If your team can build a dozen pizzas without taking more than a step or two, you’re not just saving time—you’re crushing ticket times and improving order accuracy. Let's break down the core parts that make this possible.

The Refrigerated Topping Rail

The first thing you’ll notice is the refrigerated rail. This is the sunken well at the back of the work surface, designed to hold all your food pans. This is the heart and soul of your pizza line, keeping perishable toppings like cheese, pepperoni, and veggies chilled to a food-safe temperature, usually between 33°F and 41°F.

The system works by pushing a constant flow of cold air all around the pans, making sure every last mushroom slice stays fresh and ready to go. When you’re not using it, a hinged, insulated lid drops down to lock in the cold and protect your ingredients overnight. This instant access to every pizza topping is what truly separates a real pizza prep table from just any old work surface.

The Work Surface Showdown

The big, open workspace in front of the rail is where the magic really happens. This surface needs to be tough as nails, a breeze to clean, and perfect for handling dough. There are really two main players in the pizza space:

- Polyethylene Cutting Boards: This is what you’ll see most often in high-volume pizzerias. These synthetic boards are durable, non-porous, and you can pop them right off for easy cleaning and sanitizing. They give you a fantastic all-purpose surface for stretching dough and building pizzas.

- Marble or Granite Slabs: A favorite in artisan pizzerias, a stone surface stays naturally cool, which is a huge advantage when you're working with delicate pizza dough. It helps keep the dough from getting sticky or overworked, leading to a lighter, airier crust. The trade-off? Stone needs a bit more TLC than the synthetic options.

Honestly, the choice between them usually comes down to your dough recipe and how you work. High-volume shops often lean on the rugged reliability of polyethylene, while craft pizzerias might spring for the superior dough-handling feel of marble.

The Cold Storage Base

Right below the worktop is the refrigerated base, the unsung hero that handles all your bulk storage. This is where you’ll stash backup dough boxes, big bags of cheese, and buckets of sauce. How this base is set up can make or break your kitchen’s flow, and you generally have two choices.

Doors vs. Drawers: A Critical Decision for Pizzerias

Swing doors give you wide-open access to shelves, which is great for storing bulky stuff like large sauce containers or boxes of produce. Drawers, on the other hand, are a dream for organizing dough trays and smaller items, letting your staff pull out exactly what they need without having to bend down and hunt for it.

Many modern tables actually offer a mix of both, giving you the flexibility to store different items efficiently. For kitchens that need even more specialized cold storage right on the line, it's worth looking into something like a dedicated refrigerated chef base to add extra drawer space for your most-used ingredients.

How to Choose Your Pizzeria's Workhorse

Picking out the right pizza restaurant prep table isn't just about filling a spot in your kitchen—it's about choosing the command center for your whole production line. The decision really boils down to a few critical things: how busy your pizzeria gets, how many toppings you offer, and the actual layout of your workspace. Get this right, and you're looking at faster ticket times and happier customers.

Think of it like choosing a vehicle. A small café might only need a compact car, but a busy pizzeria needs a heavy-duty truck. It's the same logic here. A low-volume spot can get by just fine with a smaller 48-inch unit, but a high-volume shop pumping out hundreds of pizzas on a Friday night will need a beastly 93-inch model to keep the line moving.

This isn't just about size, though. The market for this kind of equipment is booming; the closely related sandwich prep table segment was valued at a whopping USD 1.2 billion in 2024. This surge, fueled by the growth of quick-service restaurants, shows just how much demand there is for efficient, refrigerated stations that keep ingredients fresh and ready. You can learn more about the growth in this specialized equipment market and see how it mirrors what's happening in the pizza world.

Matching Size to Your Sales Volume

The first, and most important, call you'll make is on size. A prep table that’s too small will create a constant traffic jam, with pizza makers bumping elbows and fighting for space. One that's too big is just a waste of prime kitchen real estate and electricity.

To find your sweet spot, think about your peak hours. How many pizzas are you building at the same time? This will tell you how many topping pans you need in the refrigerated rail and how much dough you need staged and ready in the base.

- Low-Volume Shops (Under 100 pizzas/day): A compact 44-inch to 60-inch unit usually does the trick. It gives one or two pizzaiolos plenty of room without hogging the whole kitchen.

- Mid-Volume Pizzerias (100-250 pizzas/day): You'll want to look at models in the 67-inch to 72-inch range. These offer more rail capacity for a bigger variety of toppings and plenty of under-counter storage for backups.

- High-Volume Operations (250+ pizzas/day): The big 93-inch models are your best bet. These workhorses are designed for multiple chefs working shoulder-to-shoulder during the craziest rushes.

Decoding Refrigeration and Materials

Once you've nailed down the size, the next thing to consider is the tech that keeps your ingredients fresh and your table standing strong. The refrigeration system is the engine of your prep table, and there are two main types you'll run into.

Forced-air refrigeration uses fans to blow cold air around, making sure the temperature is consistent everywhere in the cabinet and rail. This is perfect for busy pizzerias where the doors are always opening and closing. On the other hand, cold-wall refrigeration cools the unit through coils built into the walls. It can be more energy-efficient, but it might take a little longer to get back to temperature after being opened.

The durability of your investment really comes down to materials. Keep an eye out for 304-grade stainless steel, which has much better corrosion resistance than the more common 430-grade. This is a huge deal in a pizza kitchen, especially with acidic stuff like tomato sauce splashing around all day.

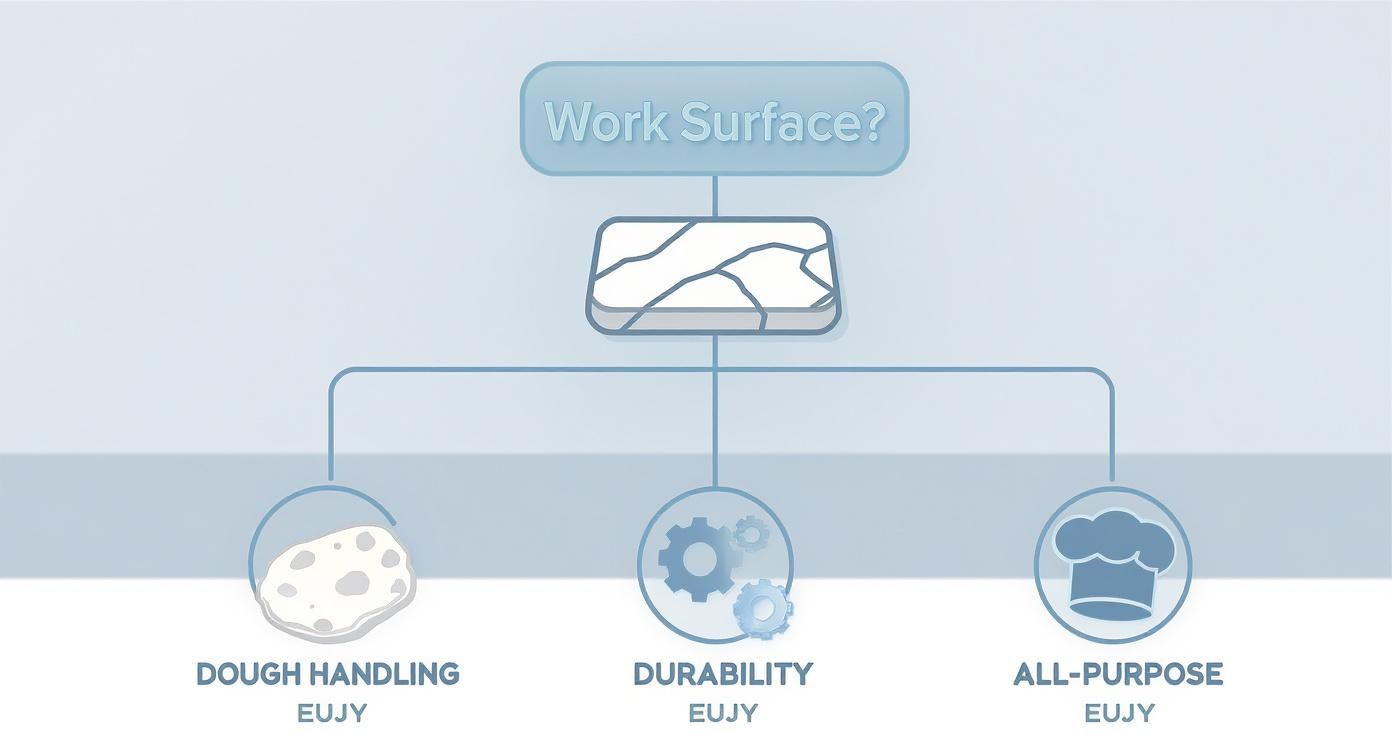

This decision tree gives you a visual on how to pick the right work surface based on what your pizzeria really needs.

As the infographic shows, while nothing beats marble for handling dough, those tough synthetic surfaces are a fantastic all-around solution that can handle the abuse of most high-volume pizzerias.

Designing Your Ultimate Pizza Workflow

A high-end prep table is a beautiful piece of equipment, but it can't fix a chaotic process. The real magic happens when you build a smart system around it. By designing an efficient workflow, you can turn your prep station into a high-speed production line that cranks out perfect pizzas and minimizes mistakes.

This all starts by applying the classic culinary principle of mise en place—"everything in its place"—to your pizza line. Think about the journey a pizza takes from a ball of dough to a finished pie ready for the oven. Every single ingredient should be positioned to reduce hand movements and shave precious seconds off every order.

Organizing Your Topping Rail for Speed

During a dinner rush, that refrigerated topping rail is your primary battlefield. A disorganized rail forces your pizzaiolos to hunt for ingredients, which kills their speed and opens the door for errors. The solution is a logical, consistent layout that becomes pure muscle memory.

- Foundation First: Always place your core ingredients—sauce and cheese—at the very start of the line, right where the dough is stretched. The base of every single pizza should start in the same spot, every time.

- Group by Popularity: Your most popular toppings, like pepperoni and mushrooms, belong in the most accessible central pans. Less-used items like anchovies or specialty cheeses can live toward the ends of the rail.

- Logical Flow: Think about your order of operations. If you always put down a layer of cheese before adding meats, position them that way. This creates a natural left-to-right assembly line that feels intuitive.

This systematic approach doesn’t just boost speed. It also helps with inventory management, letting you see at a glance which popular items are running low.

A well-organized pizza prep table workflow is like a perfectly choreographed dance. Each movement is deliberate, efficient, and contributes to the final performance, reducing ticket times by an average of 15-20% during peak hours.

Mastering the Flow from Station to Oven

Your pizza prep table doesn't exist in a vacuum; it’s a critical link in a larger chain. Where you physically place the table in relation to your dough station and oven is fundamental to creating a production line that flows without hitting any bottlenecks.

The ideal setup forms a clean triangular or linear path. Dough moves from the proofer to the prep area, then directly to the prep table, and finally straight to the oven with minimal travel. Any crisscrossing paths or backtracking creates inefficiency and the potential for staff to collide during a busy service.

By strategically placing your pizza prep table, you create a fluid system where each station feeds directly into the next, boosting overall throughput and making your entire operation run smoother.

Essential Maintenance for Lasting Performance

A pizza prep table is a serious investment. Like any high-performance machine in your kitchen, it needs consistent care to keep humming along. Think of maintenance less as a chore and more as an insurance policy—one that protects your equipment, sidesteps those dreaded emergency repair bills, and keeps your production line from grinding to a halt.

It's easy to overlook basic upkeep, but that's a fast track to problems like inefficient cooling, surprisingly high energy bills, and even premature equipment failure. Protecting this asset ensures it stays the reliable workhorse your pizzeria depends on. A simple routine of daily, weekly, and monthly checks is all it takes to extend its life for years.

Daily and Weekly Upkeep Routines

Your first line of defense is built right into your daily closing procedures. These simple habits are non-negotiable for food safety and the long-term health of your equipment.

- Sanitize All Surfaces: This means everything—the cutting board, the refrigerated rail, and all stainless steel areas. Lingering food bits are a playground for bacteria and can cause corrosion over time, especially from acidic tomato sauce.

- Inspect Door Gaskets: Once a week, take a moment to run your fingers along the door gaskets. If you feel a wisp of cool air escaping, that seal is failing. A bad seal forces the compressor to work overtime and is a classic culprit behind temperature problems.

These checks take just a few minutes but can save you from major headaches down the road. They ensure your pizza restaurant prep table is always ready for service.

Monthly and Annual Maintenance Checks

Deeper cleaning and inspections need to happen on a regular schedule to tackle the parts of the unit you don't see every day. These tasks are absolutely vital for cooling efficiency and performance.

The condenser coil, which basically acts as the unit's radiator, is a magnet for all the flour, grease, and dust floating around a busy pizzeria. When it gets clogged, it can't release heat properly, putting a massive strain on the entire refrigeration system. At least once a month, you need to carefully clean the condenser coils to guarantee good airflow and prevent overheating.

A well-maintained condenser coil can improve a refrigeration unit's energy efficiency by up to 15%. This simple task not only prevents breakdowns but also translates directly into lower electricity bills for your pizzeria.

To keep all your commercial kitchen appliances running like a well-oiled machine, it’s a smart move to follow an ultimate yearly appliance maintenance checklist. This helps you stay on top of all the essential tasks, from calibrating thermostats to checking refrigerant levels, preserving the health of all your valuable equipment.

Where Prep Table Innovation Comes From

You might think the prep table sitting in your pizzeria is just a simple piece of equipment, but its features are actually the result of some pretty powerful global forces. The design of that perfect table for your New York pizzeria has been shaped by everything from food safety laws in North America to sustainability trends in Europe.

Understanding these bigger-picture dynamics gives you a peek behind the curtain, showing you why your equipment works the way it does and what kind of cool new features are just around the corner.

What Drives Design in Different Corners of the World?

If you look at the global market for prep tables, you’ll see that different regions have completely different priorities. In North America, where the foodservice industry is mature and heavily regulated, the biggest driver is food safety. This constant pressure pushes manufacturers to create versatile pizza prep tables with incredibly precise temperature control systems to make sure every last topping stays in the safe zone.

Across the pond in Europe, the story is a bit different. They have a huge focus on sustainability and protecting culinary traditions. This means pizzeria operators are actively looking for equipment made from eco-friendly materials. As a result, European manufacturers are leading the way in energy-efficient refrigeration and clever modular designs that let chefs create highly customized kitchen layouts.

The features you see on today’s pizza prep tables are a direct response to global demands. Strict North American safety standards are pushing refrigeration tech forward for everyone, while European sustainability goals are making all our units more energy-efficient.

Meanwhile, the Asia Pacific region is exploding with growth thanks to rapid urbanization and a rising middle class. This has kicked off a massive demand for prep tables that are compact, multi-functional, and energy-efficient—perfect for the diverse and often smaller kitchens you find there.

All these unique market forces end up influencing the designs and features available to pizzeria owners everywhere. You can get a deeper look at how these regional factors mold the equipment market by checking out some market research on prep table trends. As these global trends keep shifting, they’ll directly shape the next generation of equipment that lands in your pizzeria.

Got Questions? We've Got Answers.

Stepping into the world of professional pizza prep tables always brings up a few questions. It’s a big investment, and you want to get it right. Here are some of the most common things we hear from pizzeria owners, with straight-to-the-point answers to help you choose and run your equipment like a pro.

What’s the Magic Number for Temperature in the Rail?

When it comes to food safety, there's no room for guesswork. Your refrigerated rail needs to keep all those precious pizza toppings between 33°F and 41°F (that’s 0.5°C to 5°C).

This isn’t just an arbitrary range; it's the critical zone that stops bacteria in its tracks. Keeping your cheese, pepperoni, and veggies in this sweet spot ensures every pizza that leaves your kitchen is fresh, delicious, and completely safe for your customers. Thankfully, any modern, commercial-grade pizza prep table is built to nail this temperature range without breaking a sweat.

Can I Just Use a Sandwich Prep Table to Make Pizzas?

You can, but you probably shouldn't. It's like trying to bake a large pizza in a toaster oven—sure, it's possible, but it's going to be awkward and slow.

The real difference-maker is the cutting board depth. A true pizza prep table gives you a deep, 19-inch (or more) workspace designed for large pizza skins. Sandwich prep tables usually have much narrower boards, maybe 8-12 inches deep. Try stretching a large pie on one of those, and you'll be fighting for every inch of space. That wider surface on a dedicated pizza table is what allows for a fast, efficient workflow when the orders start piling up.

The most significant difference is the workspace. A proper pizza prep table gives your pizzaiolos the room they need to work without compromise, directly impacting speed and consistency during a busy service.

How Often Should I Be Cleaning Those Condenser Coils?

This is easily one of the most overlooked but critical maintenance tasks. Mark your calendar: you need to clean the condenser coils on your pizza prep table at least once every 90 days.

If your pizzeria kitchen has a lot of flour and grease flying around—which most do—you should bump that up to a monthly cleaning. When coils get clogged with dust and grease, the compressor has to work overtime, which leads to sky-high energy bills and, eventually, a total system failure. A few minutes of cleaning is a tiny price to pay to avoid a massive repair bill down the road.

Ready to build the ultimate pizza workflow? Explore a wide range of high-performance pizza prep tables and find the perfect workhorse for your kitchen today at Pizza Prep Table.