A Guide to Pizza Restaurant Supply Chain Management

Share

A rock-solid restaurant supply chain management system is the real backbone of any pizzeria that's built to last. It’s the behind-the-scenes magic ensuring every single ingredient—from your flour and yeast to your pepperoni and mozzarella—shows up fresh, on schedule, and without blowing your budget. Think of it as the operational engine that turns great raw materials into the consistently amazing pizzas your customers rave about, all starting at your pizza prep table.

Why Your Supply Chain Is Your Pizzeria's Secret Ingredient

Let's stop thinking about your supply chain as a list of boring logistical chores. It's actually the secret ingredient that elevates a local pizza spot into a neighborhood legend. It’s the entire journey your ingredients take—from the tomato farm and the dairy all the way to your kitchen's pizza prep table.

When this system hums along perfectly, the results speak for themselves. Your walk-in is always stocked with fresh mozzarella, your dough proofs flawlessly because the yeast supply never fails, and you're never out of that signature pepperoni. This kind of consistency builds trust, one delicious slice at a time.

The Foundation of Pizzeria Success

A strong supply chain is so much more than just ordering stuff; it’s a powerful strategic advantage that directly fuels your bottom line and protects your brand. It makes sure that the heart of your operation—the pizza prep station—is always primed for action. The best commercial pizza prep tables are built for peak efficiency, but even they can't save you from a broken supply chain. A smooth flow of goods prevents those nightmare scenarios, like running out of cheese on a Friday night or discovering your basil wilted before its time.

This whole process has become even more vital in today's restaurant world. The U.S. food service industry is rocketing toward $1 trillion in sales, with digital orders expected to make up 70% of that by 2025. That digital boom puts immense pressure on pizzerias to forecast demand and tighten up inventory control to serve online customers without creating mountains of waste. On top of that, with 78% of consumers saying they prefer restaurants that source locally, supply chains have to be nimble enough to incorporate regional farms and producers.

At its core, restaurant supply chain management for a pizzeria is the art of getting the right ingredients to the right place at the right time—and for the right cost. Nailing this protects your profits, perfects your pizza, and keeps your regulars coming back for more.

Ultimately, every single step is a crucial link in the chain, from striking a deal with a flour mill to organizing toppings in your prep table's refrigerated wells. When you get it right, you'll see massive benefits:

- Enhanced Food Quality: Fresh, consistent ingredients mean a far superior pizza. Simple as that.

- Improved Profit Margins: Smart purchasing and slashing food waste are the fastest ways to boost your bottom line.

- Greater Operational Efficiency: A smooth flow of supplies means less stress for your team and faster service, especially when the dinner rush hits.

- Stronger Customer Loyalty: A consistently fantastic pizza is the best marketing tool you have for building a loyal following.

The Journey from Supplier to Pizza Prep Table

Every single ingredient in your pizzeria has a story. That story is your supply chain—a carefully planned journey that turns raw materials into the perfect pizza. For a pizzeria owner, this isn't just about ordering supplies; it's a strategic process where your pizza prep table acts as the final report card, showing off the success or failure of your entire restaurant supply chain management system.

This path from the farm to your prep table can be broken down into four critical stages. Nailing each one is the secret to making sure the final product—your pizza—is consistently excellent.

Stage 1: Strategic Sourcing of Quality Suppliers

It all starts with finding the right partners. This isn't just a hunt for the lowest price; it's about building relationships with suppliers who deliver consistent, high-quality ingredients for your pizzas.

Your choice of a tomato supplier, for instance, directly shapes the taste of your signature sauce. A farm that sends you vibrant, ripe tomatoes one week and bland, watery ones the next will create an inconsistent product that your regulars will absolutely notice.

The same goes for your pepperoni and sausage. Sourcing from a producer with high standards for meat quality and food safety protects both your customers and your reputation. This first stage is the foundation—a weak link here can compromise everything that comes after.

Stage 2: Smart Procurement and Cost Management

Once you've vetted your suppliers, the next step is procurement. This is the art of buying the right amount of pizza ingredients, at the right time, and for the right price. It's a tricky balancing act.

Order too much, and you're just throwing money away. Fresh items like basil or dough yeast have a short shelf life. But under-ordering is just as bad, leaving you high and dry during a Friday night pizza rush.

Imagine a simple yeast shipment gets delayed. That one hiccup can derail your entire dough production schedule, forcing you to use dough that hasn't proofed correctly or, even worse, run out completely. Good procurement uses accurate sales forecasts to stop these nightmares before they happen.

The goal of smart procurement isn't just to save a few bucks on an invoice. It's to ensure that every dollar spent on ingredients translates directly into a high-quality pizza served to a happy customer, cutting the painful cost of waste.

Stage 3: Reliable Logistics for Transport and Storage

After you've bought the ingredients, they begin their physical journey to your kitchen. Logistics—the coordination of transportation and storage—is where a lot of supply chains fall apart. For pizzerias, this is especially true for perishable items that need a strict cold chain.

The journey for mozzarella cheese, for example, has to be temperature-controlled from the dairy all the way to your walk-in cooler. If the refrigerated truck breaks down, even for a few hours, it can wreck the cheese's texture and taste, leaving you with an oily, separated mess on your pizza. Proper logistics ensure ingredients arrive not just on time, but in perfect condition for your pizza prep table.

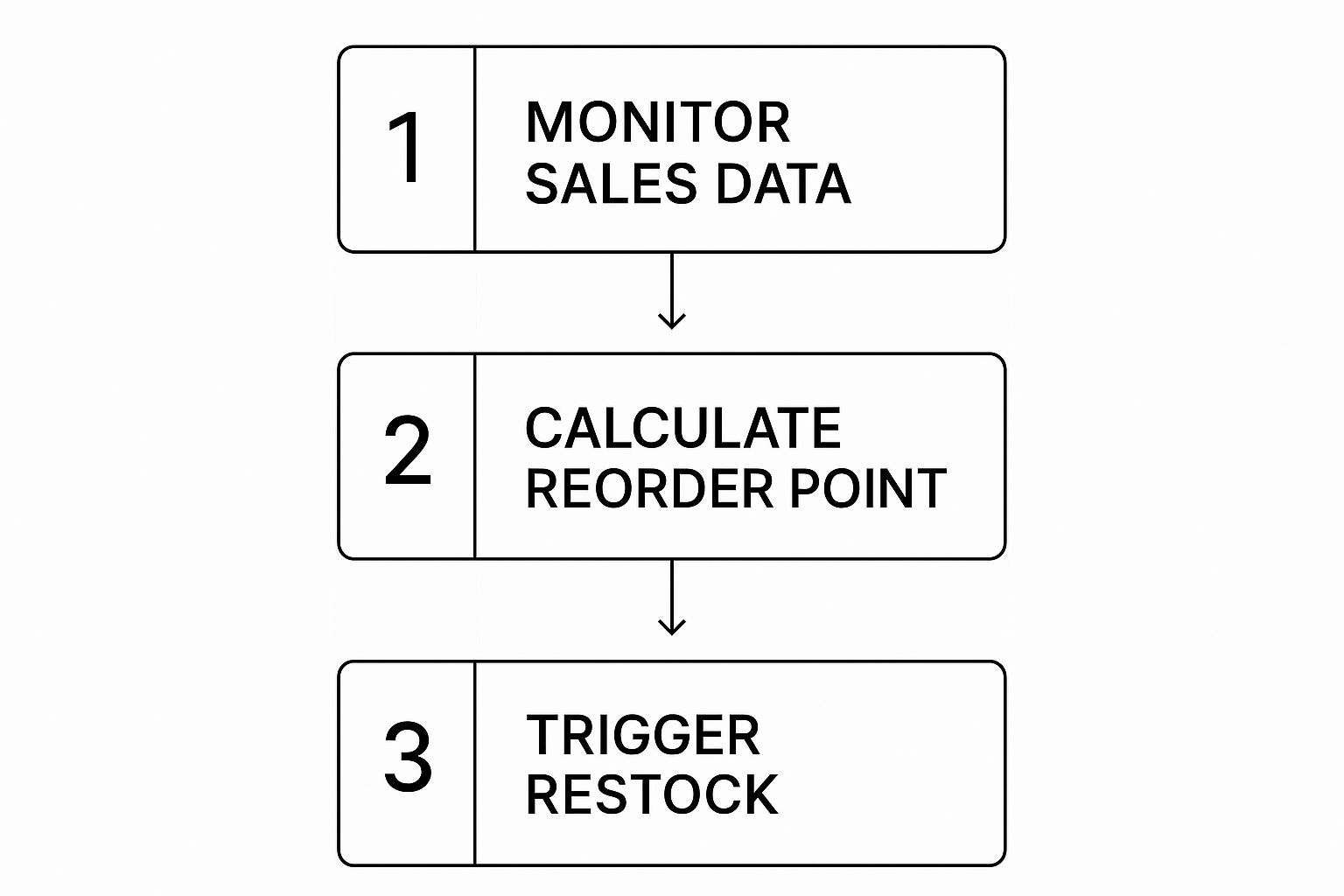

This simple infographic shows the core feedback loop for triggering a new order.

As you can see, monitoring your sales data directly tells you when it's time to reorder. It's a crucial part of the supply chain that can be automated to make your life easier.

Stage 4: Precise Inventory Management at the Prep Table

The final stop is your kitchen, and specifically, your pizza prep table. This is where your supply chain's effectiveness is truly put to the test. Getting inventory management right at this final stage comes down to a few key practices:

- First-In, First-Out (FIFO): This is non-negotiable. You have to make sure older ingredients are used before newer ones to stop spoilage, especially for the items in your prep table's refrigerated wells like pepperoni, mushrooms, and cheese.

- Par Levels: Always maintain a set minimum amount of each topping. This simple habit prevents you from running out mid-shift.

- Organization: A well-organized pizza prep table prevents cross-contamination and helps your team work faster and more efficiently.

When a team member opens a prep table drawer and finds fresh, perfectly portioned ingredients, it's a sign of a healthy supply chain. On the other hand, finding wilted greens or nearly-empty topping bins signals a breakdown somewhere, turning your prep station from a hub of efficiency into a source of stress and waste.

Solving Common Pizzeria Supply Chain Problems

Even the most buttoned-up restaurant supply chain management system can spring a leak. When you're running a pizzeria, these problems feel personal and can hit your food costs, pizza quality, and daily operations right where it hurts. Let's skip the vague advice and get right into the specific hurdles that keep pizzeria owners up at night—and the practical ways to clear them.

These issues usually rear their ugly heads right at the pizza prep table. A missing ingredient or a low-quality topping can bring a busy Friday night service to a screeching halt. From cheese prices that swing wildly to the unforgiving demands of the cold chain, tackling these challenges head-on is the only way to protect your profits and your reputation.

Problem 1: The Volatile Cost of Cheese and Wheat

For any pizzeria owner, one of the biggest financial headaches is the constant seesaw of prices for core ingredients like mozzarella and flour. A sudden spike in the cheese market can instantly vaporize your margins, turning your most popular pies into money-losers overnight.

You can't just ride these market waves and hope for the best. Simply accepting whatever price your one-and-only supplier quotes you is a recipe for disaster. What you need is a more nimble, strategic approach to sourcing the ingredients you buy the most of.

Solutions to Manage Ingredient Costs

- Diversify Your Suppliers: Never put all your eggs—or all your cheese—in one basket. Building solid relationships with two or three vetted suppliers gives you serious negotiating leverage. It also saves you when one supplier has a sudden price hike or can't fill your order.

- Explore High-Quality Blends: Talk to your suppliers about testing different cheese blends, like mixing whole-milk and part-skim mozzarella. A well-crafted blend can often give you that perfect melt and amazing flavor profile at a much more stable price point.

- Lock in Pricing with Contracts: For something non-perishable like flour, try negotiating a longer-term contract. Locking in a favorable price for six months or even a year can shield you from market chaos and make your budget far more predictable.

The goal here is to shift your mindset. Procurement isn't just about placing an order; it's a strategic part of your business. When you actively manage the cost of your core ingredients, you're building a defensive wall around your pizzeria's bottom line.

Problem 2: Inconsistent Ingredient Quality

Your customers walk in expecting the exact same delicious pizza they got last time. But what happens when your tomato supplier drops off a case of watery, pale tomatoes? All of a sudden, your signature sauce tastes off, and the consistency you've built your brand on is at risk.

This problem isn't just about tomatoes. It could be pepperoni that's suddenly twice as greasy or basil that shows up looking sad and wilted in the pizza prep table pan. Inconsistent quality is a silent killer of profits; it leads to customer complaints, bad reviews, and wasted product you can't possibly serve.

Solutions to Ensure Consistent Quality

- Establish Clear Quality Specifications: Don't leave things to chance. Create a detailed "spec sheet" for your suppliers that outlines your exact standards for pizza ingredients. Specify the color, size, and firmness for produce, or the fat-to-meat ratio for your sausage. Putting it in writing eliminates any gray areas.

- Implement a Receiving Checklist: Train your crew to be your first line of defense. They should inspect every single delivery before signing off on it. Use a simple checklist to verify quality, check temperatures, and count items against the invoice. Most importantly, empower them to reject anything that doesn't meet your pizzeria's standards.

- Maintain a Backup Supplier: Always have a reliable, vetted backup supplier on speed dial. If your main vendor drops the ball on quality, you can pivot quickly without having to 86 half your menu or compromise on the pizza you serve.

Problem 3: Broken Cold Chains and Food Waste

In a pizzeria, the cold chain is a sacred pact. Perishables like cheese, meats, and fresh veggies have to stay at a consistent, safe temperature from the distributor's refrigerated truck all the way to your prep table's cooling wells. A single breakdown—a faulty truck cooler or a walk-in door propped open for too long—can lead to spoilage, waste, and a massive food safety risk.

This isn't just your problem; it's a huge drain on the entire industry. Globally, a shocking 30% of food produced for us to eat is lost or wasted somewhere along the supply chain. For your shop, that looks like whole cases of sausage or bags of expensive toppings getting tossed out. It's like throwing cash straight into the dumpster. You can learn more about how to fight back in this insightful article on the food supply chain.

Solutions to Protect the Cold Chain

- Verify Temperatures at Receiving: Your first line of defense is a good digital food thermometer. Check the temperature of every refrigerated and frozen item the moment it arrives to make sure it's in the safety zone.

- FIFO is Non-Negotiable: The First-In, First-Out (FIFO) rule has to be law in your kitchen. This simple system ensures older products get used before newer ones, slashing the risk of spoilage. Make sure everything is clearly labeled with dates, especially in the pizza prep table.

- Regular Equipment Audits: Check on your refrigeration units every single day. That means your walk-in, your low-boy fridges, and the pizza prep table itself. A quick check to ensure they're holding the right temperature is all it takes to keep thousands of dollars worth of pizza ingredients safe and fresh.

How Pizza Prep Tables Drive Supply Chain Efficiency

Your pizza prep table is much more than just a chilled stainless steel workspace. It's the physical command center where your entire restaurant supply chain management strategy comes to life. This is where all your planning, ordering, and forecasting meets the real world. A clean, organized, and fully stocked prep station is the clearest sign of a healthy supply chain. A chaotic one? That’s an immediate red flag that something is broken further up the line.

The very design of your pizza prep table—from how many refrigerated ingredient wells it has to its overall size—should directly shape your ordering strategy and inventory pars. Think of it as a live dashboard for your kitchen's operational health. When your supply chain is running smoothly, your team has exactly what it needs, right where they need it, to build perfect pizzas without a single wasted movement.

The Prep Table as a Supply Chain Report Card

Think of your pizza prep table as the stage where the success or failure of your supply chain is put on full display. During a hectic dinner rush, there's absolutely no place to hide from a supply breakdown. The consequences show up instantly, right at the point where pizzas are made.

A broken supply chain isn't just an empty shelf in the walk-in cooler; it creates immediate, painful problems that torpedo both your efficiency and your profits. These issues often look like this:

- Missing Ingredients Mid-Rush: Reaching for mushrooms in your prep table only to find an empty container is a direct failure of your inventory forecasting and supplier reliability.

- Spoiled Toppings: Finding wilted basil or discolored peppers in a prep well means your stock rotation or ordering frequency is off, leading to direct food cost losses.

- Cross-Contamination Risks: A disorganized station, which is often a symptom of rushed restocking or poor inventory management, dramatically increases food safety hazards at the prep table.

The state of your pizza prep table at 7 PM on a Friday is the most honest report card your supply chain will ever get. It tells you everything you need to know about your sourcing, ordering, and inventory control in one glance.

Connecting Workflow to Ordering with Mise en Place

The classic culinary principle of mise en place—having every single ingredient in its place before service starts—is the perfect way to think about supply chain success in a pizzeria. To make that happen, your back-of-house workflow has to be perfectly synced with your supplier orders and inventory practices. This is where your prep table's design becomes a critical strategic tool.

For example, a big pizza prep table with eight large topping wells demands a completely different ordering par than a smaller model with only four. The layout itself should guide your First-In, First-Out (FIFO) system, making it easy to place older ingredients where they'll be used first. For more advanced setups, you might consider how specialized equipment supports high-volume items. Learning about a refrigerated chef base can show you how the right gear underpins an efficient supply chain.

Ultimately, your pizza prep station is where abstract ideas like "procurement" and "logistics" become concrete actions. A well-managed supply chain ensures your prep table is a hub of speed and quality, not a source of stress and waste. By lining up your ordering pars with your prep table’s capacity and your team’s workflow, you build a resilient system that protects your food costs and keeps your customers coming back.

Choosing The Right Tech For Your Pizzeria's Supply Chain

Trying to run a modern pizzeria's supply chain without the right tech is like taking phone orders with a pen and paper on a packed Friday night. Sure, you can technically do it, but it’s a recipe for chaos, costly mistakes, and a whole lot of stress for your team.

The reality is, today's sharpest pizzerias are leaning on technology to automate and sharpen their restaurant supply chain management. These tools aren't a luxury anymore; they’re essential for keeping up. Think of them as the digital nervous system that connects the orders coming in at the front counter directly to the purchasing you do in the back office. This vital link makes your whole operation smarter, faster, and way more profitable.

Key Technologies For A Modern Pizzeria

To really get a handle on your supply chain, you need a few core tools that talk to each other. The goal is simple: stop guessing and start using real data to make better decisions. These technologies are the foundation of any well-run pizzeria.

With labor costs on the rise and a huge chunk of sales coming from digital orders, pizzerias have been forced to get smarter. This means integrating online ordering platforms directly with supply chain tools. It's the only way to accurately match what customers are buying with what you're ordering from suppliers. An in-depth analysis of global restaurant trends highlights just how critical this integration has become.

Three pieces of technology can completely change the game for your pizzeria:

- Integrated Point-of-Sale (POS) Systems: A modern POS is so much more than a cash register. It’s the brain of your entire operation, tracking every single pizza sold. This real-time sales data is the fuel for accurate demand forecasting.

- Inventory Management Software: This is the heart of your supply chain tech. It hooks into your POS to automatically subtract ingredients—dough, sauce, cheese, pepperoni—from your stock as you sell them, giving you a live, honest look at what you have on the shelves.

- Supplier Relationship Management (SRM) Platforms: These tools help you manage all your vendors in one place. You can track pricing, see who delivers on time, and make your ordering process for pizza ingredients a whole lot smoother.

When you connect these systems, you create a powerful feedback loop. A customer’s online order for a pepperoni pizza instantly tells your inventory system to deduct pepperoni, which then flags your ordering system that a new shipment is needed. This kind of automation kills manual errors and saves a ton of time.

Essential Software Features For Pizzerias

When you start shopping for software, it’s easy to get overwhelmed by a long list of features. The key is to focus on what will actually make a difference in your day-to-day grind, especially at the pizza prep table where your supply chain efficiency is put to the test.

A well-chosen tech stack will make your whole kitchen more effective, right down to the equipment. If you're looking to optimize your kitchen's central hub, our guide on the top pizza prep tables for restaurant success is a great place to start.

Here’s a simple checklist of must-have features to look for:

- Real-Time Stock Tracking: The software absolutely must update your ingredient levels automatically as sales come through the POS. This is non-negotiable and the only way to prevent running out of essentials like cheese or dough.

- Automated Low-Stock Alerts: Your system should tap you on the shoulder when a key ingredient—like your special San Marzano tomatoes or whole-milk mozzarella—is getting low. This stops those last-minute, panicked runs to the store.

- Supplier Performance Dashboards: Look for the ability to track how your suppliers are doing. Are they delivering on time? Are their prices creeping up? This data gives you real leverage when it's time to negotiate better deals for your pizzeria.

- Food Costing and Waste Reporting: The best systems can tell you the exact cost of every pizza on your menu and track what's getting thrown out. This is how you spot your most profitable items and find out where spoilage at the prep table is eating into your bottom line.

To help you navigate the options, we've put together a table comparing the most important technology tools for your pizzeria's supply chain.

Essential Tech for Your Pizzeria's Supply Chain

A comparison of key technology solutions to help you manage your pizza restaurant's supply chain more effectively.

| Technology Tool | What It Solves | Must-Have Feature |

|---|---|---|

| Point-of-Sale (POS) System | Inaccurate sales data and forecasting | Real-time sales tracking that integrates with inventory software. |

| Inventory Management Software | Running out of key ingredients or over-ordering | Automated low-stock alerts triggered by sales data from the POS. |

| Supplier Management (SRM) Platform | Disorganized vendor relationships and manual ordering | A centralized supplier database with performance tracking and order history. |

| Food Costing Software | Unclear menu profitability and high food waste | The ability to calculate per-pizza costs and generate waste reports. |

Choosing the right combination of these tools gives you a complete picture of your operation, from the moment a customer places an order to the moment you pay your supplier. This visibility isn't just about efficiency—it's about making smarter, more profitable decisions for your pizzeria every single day.

Your Pizza Supply Chain Questions, Answered

Even with the best game plan, running a pizzeria means you're going to have questions. Restaurant supply chain management isn't just about big-picture strategy; it's about solving the real, on-the-ground problems that pop up every day.

Think of this as your practical troubleshooting guide. We're tackling the most common questions from pizzeria owners, with direct answers to help you fine-tune your operation, from finding the freshest basil to keeping your pizza prep table perfectly stocked.

How Do I Find Reliable Local Suppliers for My Pizzeria?

This is a great question. Sourcing locally is a fantastic way to make your pizza stand out and connect with customers who care about where their food comes from. But it takes more than a quick Google search; you have to get out there and become part of your local food community.

Your best first step? Head to the nearest farmers' market. This is where you can meet producers face-to-face, see and taste their products, and start building real relationships. Ask them about how they grow their produce and what kind of volume they can handle for a pizzeria.

Don't overlook your network. Chat with other local restaurant owners (the ones you're not in direct competition with, of course). They can be an incredible source for honest feedback and can often give you a warm introduction to suppliers they already lean on.

A great local tomato farmer isn't just a vendor; they become a partner. Their story becomes part of your pizzeria's story, and that's a huge advantage you can't buy from a national distributor.

Also, look into regional food hubs. These are organizations that act as middlemen, gathering products from various small, local farms. It can simplify your ordering while still giving you access to amazing regional ingredients for your pizzas.

Key Vetting Steps:

- Ask for References: Any good supplier should be happy to share a list of other pizzerias or restaurants they work with.

- Check Their Paperwork: Make sure they have the right food safety certifications to meet both legal standards and your own quality bar.

- Do a Trial Run: Before you commit to a big contract, place a small order to test their product quality, consistency, and delivery reliability.

What Is the Best Way to Track Inventory for a Small Pizzeria?

For a small or new pizzeria, inventory can feel like a monster, but taming it is the key to controlling your food costs. The classic starting point is the "sheet-to-shelf" method. This is exactly what it sounds like: you physically count what's on your shelves at a regular cadence and track it in a spreadsheet. Then you compare that count to your sales data to see how much dough, sauce, and cheese you're using.

A spreadsheet is a good start, but it's a manual process, and humans make mistakes. The most effective way to handle inventory is to use software that plugs directly into your Point-of-Sale (POS) system.

This is where technology really shines. Every time you sell a pepperoni pizza, the system automatically subtracts the right amount of dough, sauce, cheese, and pepperoni from your digital stock. This gives you a live look at what's in the storeroom, what's in the pizza prep table, and what you need to order, without having to do constant hand counts.

How Can I Reduce Food Waste in My Pizzeria Supply Chain?

Food waste is the silent killer of profit in a pizzeria. Every bit of spoiled cheese or wilted basil is money straight out of your pocket. It's a sign that something, somewhere in your supply chain, broke down. Tackling it requires a sharp, three-part focus.

First, get serious about accurate forecasting. Dig into your sales data. What toppings fly out the door on a Tuesday compared to a Saturday? Knowing these patterns helps you order with precision, avoiding the kind of over-purchasing that leads to spoilage.

Second, make inventory rotation a law in your kitchen. The First-In, First-Out (FIFO) rule must be gospel, especially for the perishables in your pizza prep table's refrigerated wells. Every ingredient needs to be dated when it arrives and organized so the oldest stock gets used first. It’s a simple discipline that makes a massive difference.

Finally, turn potential waste into profit. Get creative with your kitchen team. Can you use ingredients nearing their expiration to make a killer daily special, a new side dish, or a staff meal? This is a smart move that protects your bottom line.

Should I Use One Main Supplier or Multiple Suppliers?

This is a classic restaurant supply chain management puzzle. The truth is, the best answer for almost every pizzeria is a hybrid approach. Putting all your eggs in one basket is risky, but managing too many suppliers is a logistical headache you don't need.

It makes a lot of sense to use one main, high-volume supplier for your commodity items—things like flour, sugar, and canned goods. This lets you build a strong relationship, consolidate deliveries, and usually get better pricing based on volume. It simplifies things for the non-critical stuff.

But for your most important pizza ingredients, you need to diversify.

For the ingredients that define your pizza—your cheese, specialty meats, and fresh produce—you should always have at least two or three vetted suppliers you can call. This is your insurance policy against a sudden shortage, a surprise price hike, or a drop in quality from one of your regulars.

Having options gives you leverage and makes your business resilient. If your main mozzarella guy has a problem, you can pivot to your backup without skipping a beat. This strategic diversification protects the quality and consistency of the pizza your customers love.

Ready to build a kitchen that’s as efficient as your supply chain? At Pizza Prep Table, we specialize in providing the high-quality, reliable refrigerated prep tables that form the heart of any successful pizzeria. From compact models for tight spaces to expansive workstations for high-volume shops, our equipment is designed to keep your ingredients fresh, organized, and ready for action. Explore our selection and find the perfect foundation for your pizzeria's success at https://pizzapreptable.com.