Your Guide to Stainless Steel Kitchen Work Tables for Pizzerias

Share

Walk into any high-volume pizzeria during the Friday night rush, and you'll see one piece of equipment at the center of the action: the stainless steel kitchen work table. It's the unsung hero of the kitchen, the foundation for speed, hygiene, and the consistency of every single pizza that goes out the door. This isn't just a surface; it's the strategic core of your entire pizza-making operation.

The Foundation of Every Great Pizzeria Workflow

The difference between seamless service and total gridlock in a pizzeria often comes down to your kitchen's layout. At the heart of that workflow, you’ll find the humble stainless steel work table, often working in tandem with a pizza prep table.

These tables aren't just passive pieces of metal. They are the active stage where your pizza creation unfolds. From the first slap of the dough to stretching, saucing, and final topping placement, every step relies on having a stable, clean, and durable surface. In a pizzeria, where acidic sauces, oils, and fresh ingredients are flying around constantly, the right table is a non-negotiable asset.

Why Stainless Steel Dominates Pizzerias

The choice of stainless steel in commercial kitchens, especially pizzerias, is no accident. It’s a smart decision driven by three core benefits that solve the unique challenges of making pizza day in and day out.

- Unmatched Durability: These tables are built to take a beating. They can handle the weight of heavy dough mixers and withstand the constant scraping of pizza peels without batting an eye.

- Effortless Sanitation: The non-porous surface of stainless steel is a health inspector's dream. It prevents bacteria from hiding in cracks and doesn't absorb liquids, making it incredibly easy to clean and sanitize after a busy pizza service.

- Versatile Functionality: A stainless steel table is a chameleon. It can be a dough prep station one minute and a staging area for finished pies the next, adapting to whatever the rush demands.

This blend of toughness and cleanliness has made stainless steel kitchen work tables the undisputed industry standard for pizzerias. It's no surprise that the market for essential pizza prep tables is projected to hit USD 0.6 billion by 2030, a testament to their vital role in modern food service.

A well-chosen work table does more than just fill space—it actively reduces staff movement, eliminates bottlenecks, and creates a more ergonomic and productive pizza prep line.

Ultimately, investing in the right work surfaces is a foundational step in your overall kitchen strategy. When you design a restaurant kitchen for maximum flow, smart table selection is where it all begins. It's the starting point for building a more successful and profitable pizza business from the ground up.

Choosing the Right Steel Grade for Pizza Prep

When you're outfitting your pizzeria, one of the most important decisions you'll make for your stainless steel kitchen work tables is picking the right grade of steel. This choice isn't just about looks; it directly impacts how long your tables will last, how they stand up to stains, and whether they can handle the daily grind of a busy pizza kitchen.

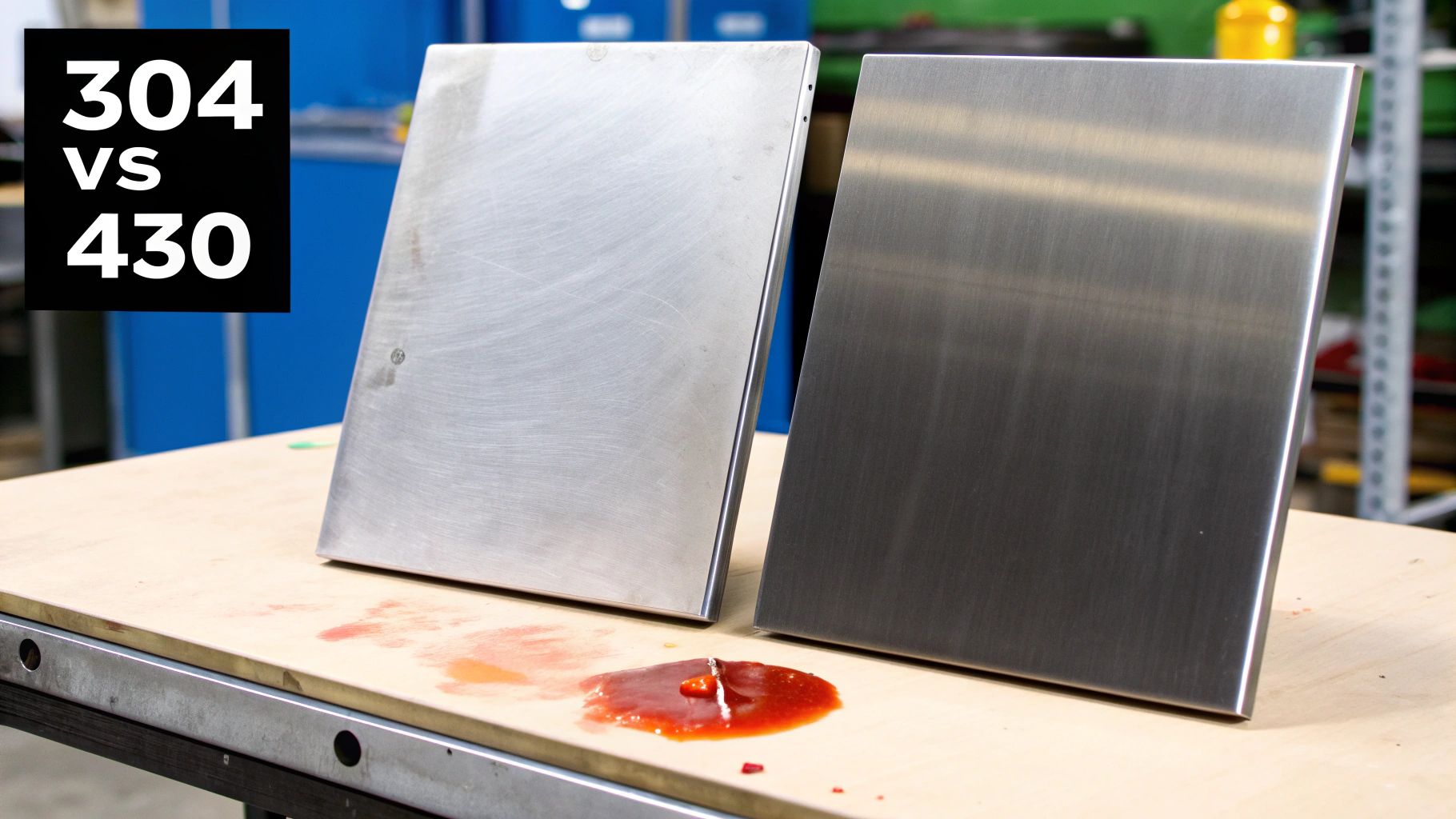

The two players you’ll see most often are 304 grade and 430 grade.

Think of it like choosing tires for your pizza delivery car. 304 grade is your premium, all-weather tire. It’s built with more nickel, which makes it incredibly tough against corrosion from salt, acidic tomato sauce, and harsh cleaning chemicals. It’s the go-to choice for any surface that's going to see constant action, like your main pizza prep table.

On the other hand, 430 grade is the reliable, budget-friendly tire that’s perfect for dry, indoor use. It has more iron in the mix (which is why a magnet will stick to it) and is more likely to show rust over time, especially when it’s constantly wet or exposed to acidic foods.

The Chemistry Behind the Shine

So what really sets these two apart? It all comes down to their chemical recipe, specifically how much chromium and nickel are in the steel. The chromium is the magic ingredient that reacts with the air to create an invisible, protective shield on the surface. This is what stops rust in its tracks.

The nickel in 304 grade steel is like a superpower booster for that shield. This makes it the undisputed champion for any surface where you're prepping pizza. We’re talking about constant contact with acidic tomato sauces, salty cured meats, and briny olives. A 430 grade table in that same spot might start to show pitting or rust spots, which is a headache for both looks and food safety.

It's no surprise that 85% of top pizza prep table brands like True and Atosa build their equipment with 304-grade stainless steel, which contains 18% chromium for unbeatable rust resistance in humid kitchens. The intense focus on sanitation from 2020-2024 even caused demand to jump by 22%, as U.S. pizzerias upgraded 40% of their work surfaces to stainless steel to stay compliant.

Comparing 304 vs 430 Stainless Steel for Pizzeria Use

To make the decision clearer, let's break down how these two steel grades stack up in the real world of a pizzeria. This isn't just a technical comparison; it's about matching the right material to the right job to protect your investment and keep your kitchen running smoothly.

| Feature | 304 Grade (The Premium Choice) | 430 Grade (The Budget-Friendly Workhorse) |

|---|---|---|

| Corrosion Resistance | Excellent. Resists rust from acids (tomato sauce), salt, and moisture. | Good. Vulnerable to rust and pitting with prolonged exposure to acids and moisture. |

| Best For | Pizza prep tables, dishwashing zones, walk-in cooler shelving, high-humidity environments. | Dry storage shelving, equipment stands (for mixers, ovens), table undershelves in dry areas. |

| Durability | Higher nickel content makes it tougher and more resilient to dings and dents from pizza peels. | More iron content makes it slightly softer and more prone to scratching over time. |

| Cost | Higher upfront investment. | More budget-friendly, allowing for cost savings on non-critical surfaces. |

| Magnetism | Not magnetic. | Magnetic, which is an easy way to tell it apart from 304 grade. |

| Longevity | A long-term investment that maintains its appearance and integrity for years of pizza making. | Can have a shorter lifespan if used in the wrong environment, requiring earlier replacement. |

Ultimately, using both grades strategically is the smartest play. You get the premium performance of 304 grade where it matters most, and you save money with 430 grade where it's perfectly suitable. This balanced approach protects your budget without compromising on quality or safety.

A Game Plan for Your Pizzeria

The secret to a smart purchase is putting the right steel in the right place. Not every surface in your pizzeria needs the top-of-the-line 304 grade. This is the same logic behind choosing table materials based on intended use for any piece of equipment; you match the material's toughness to the job it has to do.

A 304 grade work surface is a non-negotiable investment for primary pizza prep stations and areas near dishwashing sinks where humidity and chemical exposure are high. Forgetting this can lead to premature equipment failure and costly replacements.

Here’s a simple guide for deciding where each grade belongs in your pizzeria:

-

When to Insist on 304 Grade Steel:

- Main Pizza Prep Lines: Any table where you're stretching dough and adding toppings is a prime candidate. This surface is ground zero for acidic and salty ingredients.

- Dishwashing Areas: The constant humidity, water, and cleaning chemicals demand the superior protection of 304 grade for tables and shelves in this zone.

- Walk-In Cooler Shelving: To fight off rust in a permanently damp environment, 304 grade shelving is the only reliable long-term choice.

-

When 430 Grade is a Smart, Cost-Saving Choice:

- Dry Storage Shelving: For holding bags of flour, boxes of pizza screens, and dry goods far from any wet areas, 430 grade is more than enough and will save you money.

- Equipment Stands: A stand for a mixer or a pizza oven that won’t get splashed with corrosive ingredients can safely be 430 grade.

- Table Undershelves: If you're just using the undershelf to store clean, dry items like dough boxes or pans, 430 grade is a very practical and economical option.

By using both grades where they make sense, you can equip your pizzeria with durable, long-lasting stainless steel kitchen work tables that perfectly balance performance and your budget.

Nailing the Perfect Table Size and Configuration

Once you’ve sorted out the right grade of steel, it's time to get practical. This is where we move from the what to the how—matching the table’s physical shape to your pizzeria's unique rhythm. Get this right, and you can turn a chaotic pizza prep line into a thing of beauty. Get it wrong, and you're just creating frustrating bottlenecks for your team.

Think about table size in terms of pizzas, not inches. Standard dimensions like 48", 72", and 96" are just abstract numbers until you translate them into how many pies you can pump out during the dinner rush. A compact 48-inch table might be perfect for a small takeout spot where one chef is slinging one or two large pizzas at a time. But a sprawling 96-inch beast? That's a team player, giving two chefs enough elbow room to assemble multiple orders side-by-side without a turf war breaking out over the pepperoni.

Choosing the right size is the first step in designing an ergonomic workspace. Studies show that poorly chosen work surfaces can reduce prep space efficiency by up to 40%, directly impacting your staff's speed and your pizzeria's output.

Decoding Table Dimensions for Your Pizzeria

To figure out the best fit, take a hard look at your kitchen layout, your menu, and how many pizzas you're making when things get crazy. A table that’s too big will clog up walkways in a tight kitchen, but one that’s too small will have your crew wasting precious seconds shuffling toppings around.

-

48-Inch to 60-Inch Tables: These are the champs for smaller pizzerias, dedicated gluten-free prep stations, or as a secondary surface for things like boxing up finished pies. They comfortably fit one chef prepping 1-2 large pizzas at a time.

-

72-Inch Tables: This is the sweet spot for a lot of pizzerias. It gives one chef plenty of room to spread out with all their toppings or lets two chefs work together on 2-3 large pizzas during a moderate rush without feeling cramped.

-

96-Inch to 120-Inch Tables: These are the workhorses of high-volume pizza shops. They offer a massive landing zone for prepping, essential for places that handle huge orders and need multiple staff members assembling 4+ pizzas at once.

Must-Have Configurations for a Pizza Prep Line

Beyond sheer size, a few key features are what really turn a simple steel surface into a high-performance pizza prep table. Each of these add-ons solves a specific headache that every pizzeria owner knows all too well.

The Backsplash Shield

A backsplash is just a raised lip along the back of the table, but its job is critical. It stops flour, sauce, and liquids from splashing all over your wall or, even worse, falling into that impossible-to-clean gap behind the table. If your pizza prep table is going against a wall, a backsplash isn't just a nice-to-have; it's a must. It makes cleanup faster and keeps your whole kitchen more hygienic.

Undershelves for Strategic Storage

That open space under your work surface is prime real estate. An undershelf instantly doubles your storage without eating up more floor space. This is the perfect spot to stash bulky but essential pizza-making items so they're always within arm's reach.

- Stacking dough boxes

- Storing big bins of cheese or pepperoni

- Keeping extra pizza screens and pans organized

Casters for Essential Mobility

Putting your stainless steel kitchen work tables on casters (wheels) gives you incredible flexibility. In a cramped pizzeria, just being able to roll a table out of the way for a deep clean is a massive win. It also lets you reconfigure your prep line on the fly if you need to adapt. Just make sure you get locking casters—especially for a table where you’ll be kneading heavy dough. You need that table to stay put when you're putting your back into it.

Thinking through these features is how you build a truly efficient kitchen. When you learn how to team up a standard work surface with a dedicated commercial pizza prep table, you unlock a whole new level of workflow potential. A smart setup gets rid of wasted steps, keeps your team organized, and ultimately helps you make better pizzas, faster.

Creating a Seamless Pizza Production Line

In a busy pizzeria, every second counts. The trip a pizza takes from a simple dough ball to a fully-topped masterpiece ready for the oven needs to be a smooth, straight shot. This is where you can turn your kitchen into a finely-tuned machine by pairing a standard stainless steel kitchen work table with a refrigerated pizza prep unit. It’s not just about adding more counter space; it’s about creating a single, powerful pizza production line.

The whole point is to build an assembly line where each step flows naturally into the next, cutting out wasted movement for your crew. Think of it like a well-choreographed dance. Your pizzaiolo shouldn't have to take more than a single step to go from stretching dough, to saucing the base, to grabbing handfuls of cold toppings from the refrigerated rail. That kind of speed only comes from a smart layout.

One of the most effective setups involves placing a simple, non-refrigerated work table right next to a refrigerated pizza prep table. The non-refrigerated table becomes your dedicated "dough zone"—a big, room-temperature surface that's perfect for slapping, stretching, and saucing. Immediately next to it, the refrigerated prep table holds all your chilled toppings, organized and ready to go. This simple side-by-side arrangement cuts out the back-and-forth, saving precious seconds on every single pizza order.

Designing for a Unified Workspace

Building this seamless workflow is about more than just shoving two tables together. For this system to really sing, the two surfaces have to feel like one continuous workspace. And that means you have to get obsessive about the dimensions.

The single most important factor is making sure the height and depth of both tables match perfectly. A mismatched height, even by just half an inch, creates a frustrating ledge. This little bump can cause pizza peels to snag, ingredients to spill, and the entire process to feel clunky. For a high-speed production line, a smooth, level transition from the dough station to the topping station is non-negotiable.

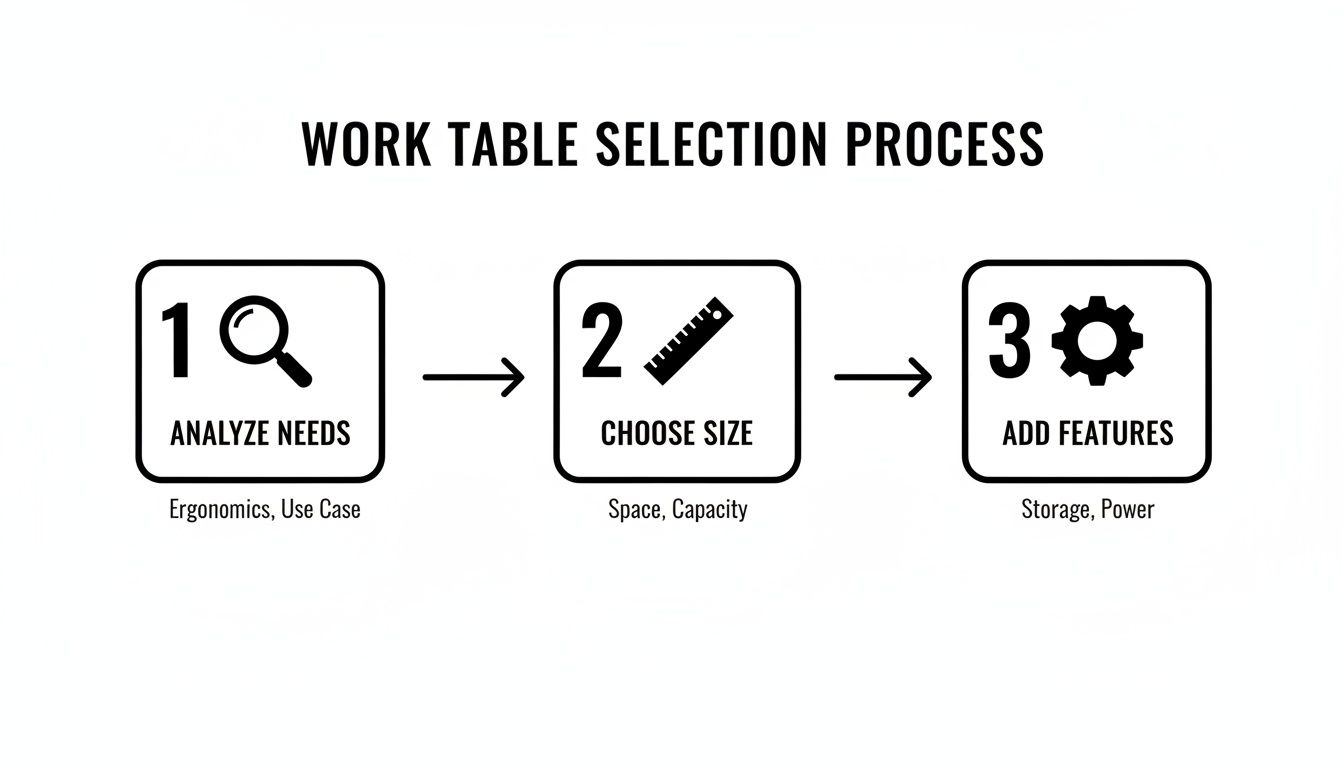

This infographic breaks down the simple three-step process for picking a work table that will slide right into your pizza production line.

As the visual shows, it all comes down to analyzing your pizza-making flow, nailing the dimensions, and adding the right features to tie it all together.

Bridging the Gap with Smart Features

Even with perfectly matched tables, a few clever add-ons can really lock the two units together, turning separate pieces of equipment into a single, high-performance zone. These features are designed to solve the everyday headaches of a pizzeria, like clutter and spills.

-

Overshelves for Vertical Storage: An overshelf installed above your work table can physically bridge the gap between the two units, creating one continuous storage area. This is the perfect spot for things you grab constantly, like spice shakers, squeeze bottles of olive oil, or stacks of pizza boxes, keeping your valuable counter space clear.

-

Marine Edges for Spill Containment: A marine edge—that raised, V-shaped rim around the table's edge—is a lifesaver on a pizza prep table. When you put it on the dough and saucing table, it acts like a tiny dam. It keeps stray flour from dusting the floor and stops drips of tomato sauce from spilling over onto your refrigerated unit.

A well-integrated pizza prep line is more than the sum of its parts. It reduces physical strain on your staff, minimizes cleaning time, and directly contributes to faster ticket times—especially during the peak dinner rush.

Start thinking of your stainless steel kitchen work tables not as standalone items, but as modular building blocks for a larger pizza prep system. By matching heights and depths and using smart features like overshelves and marine edges, you can design a pizzeria kitchen that's truly built for speed.

Let's Talk NSF Certification and Keeping Things Clean

When you're running a busy pizzeria, sanitation isn't just a buzzword—it's everything. This is where you'll see that little blue NSF (National Sanitation Foundation) mark on a stainless steel kitchen work table or pizza prep table. That isn't just a sticker; it's your promise of safety and a non-negotiable ticket to passing your health inspections.

What does that mark really mean for your pizzeria? It means the table is designed from the ground up to fight bacteria. NSF-certified tables have perfectly smooth, non-porous surfaces, leaving nowhere for germs to hide. Many also feature coved corners, which are the gently curved transitions where surfaces meet. They’re a dream to wipe down compared to sharp 90-degree angles that trap flour and food bits.

For a pizzeria, this is a game-changer. In fact, these tables can slash cross-contamination risks by up to 35%. The slick finish of stainless steel just doesn't give bacteria the same foothold as wood or plastic. If you're curious about how equipment choices impact safety, you can see how the market is evolving with the rise of certified equipment.

How to Keep Your Pizza Prep Tables Spotless

One of the best things about stainless steel is how tough it is, but it's not bulletproof. A solid cleaning routine is what protects the chromium layer that makes it "stainless" in the first place. Get this right, and your investment will last for decades.

Think of that chromium layer as a self-healing shield. When it's exposed to oxygen, it creates a passive, rust-resistant barrier. But when dirt, grime, and acidic pizza sauce sit on the surface, they block that process, leaving the steel vulnerable. This is why quick, gentle cleaning is so important.

The real goal of cleaning isn't just wiping off visible messes. It's about letting the steel breathe so it can protect itself. When you skip daily wipe-downs, you're allowing microscopic damage to build up, which eventually leads to stains and corrosion on your pizza prep table.

A Cleaning Guide Built for Pizzerias

Pizzerias are a unique battlefield of messes, from dried tomato sauce to that stubbornly baked-on cheese. Here’s a simple, step-by-step process to keep your stainless steel tables looking brand new.

- The Daily Wipe-Down: All it usually takes is a soft, wet cloth and a bit of mild detergent. Here's the key: always wipe in the direction of the steel's grain to avoid tiny scratches.

- Fighting Tough Stains: For those baked-on cheese and sauce messes, mix up a paste of baking soda and water. Dab it on the spot, let it sit for a few minutes, then gently scrub with a soft nylon brush—again, always moving with the grain.

- Rinse It Clean: After you’ve scrubbed, always rinse the surface with clean water. You want to get rid of any leftover soap or cleaning agents.

- Dry It Immediately: Grab a dry, soft cloth and wipe the surface completely. This simple step prevents those annoying water spots from hard water that can dull the finish of your pizza prep table.

This exact same routine works like a charm for your other stainless steel gear. For a deeper dive, check out our guide on the best way to clean a stainless steel refrigerator.

The Critical Do's and Don'ts of Cleaning

Keeping your stainless steel kitchen work tables in top shape is as much about what you don't do as what you do. Avoiding a few common mistakes will save you from causing irreversible damage.

- DON'T ever use steel wool or abrasive scouring pads. They'll scratch the surface, wrecking the protective layer and giving rust a place to start.

- DO stick with soft cloths, nylon brushes, or plastic scrapers for the really tough spots.

- DON'T use cleaners with chlorine or bleach. Yes, they sanitize, but they are extremely corrosive to stainless steel and will eat away at its protective shield.

- DO reach for an ammonia-based solution if you need some extra sanitizing power without the corrosive damage.

- DON'T let acidic foods like tomato sauce, lemon juice, or vinegar hang out on the surface for too long.

- DO wipe up acidic spills right away to stop the acid from etching the steel.

Making a Smart Investment in Your Pizzeria Equipment

Buying a stainless steel kitchen work table isn't just another line item on your pizzeria's expense sheet; it's a strategic investment in the future of your kitchen. I get it. For a lot of pizzeria owners, especially when you're just starting out, the upfront cost can feel like a big pill to swallow. But when you look at this through the lens of long-term value, you start to see the powerful return on your pizza prep tables.

The price tag on a table is a direct reflection of its grade, size, thickness (gauge), and any extras like undershelves or casters. It’s always tempting to grab the cheapest option you can find, but that's a classic rookie mistake that almost always leads to paying for a replacement way sooner than you'd like. A well-chosen table is a one-time purchase that pays you back for years.

Calculating Your Return on Investment

The real value of a quality work table is its incredible lifespan and the fact that you almost never have to replace it. That durability directly translates into better operational efficiency and a healthier bottom line for your pizzeria. Think of it this way: the right table helps you make more pizzas, faster, and for a lot longer.

For anyone running a pizza restaurant, this means looking at workhorses from brands like Atosa or True. Their pizza prep tables often feature 20-gauge stainless steel tops that can take a beating from heavy rolling pins or mixers without denting. This stuff is built to last—we’re talking up to 20 years with proper care. That kind of longevity slashes your replacement costs by 40% compared to flimsy aluminum alternatives, freeing up family-owned pizzerias to focus on their craft, not on equipment failures. You can see more on these trends in the latest market insights from HTF Market Insights.

When your equipment is this reliable, you spend less time and money on repairs and replacements. That frees up cash for the things that actually grow your pizza business, like marketing or sourcing better ingredients.

Smart Financing for Your Pizzeria

For new pizzerias, every penny counts. A high-quality pizza prep table is essential, but it shouldn't drain your startup capital. This is where smart financing options, like lease-to-own programs, can be a game-changer.

Leasing equipment lets you build the pizzeria kitchen you need for immediate success without a massive upfront cash outlay. It’s a strategic move to protect your cash flow for other critical startup costs like inventory, payroll, and marketing.

These programs offer some serious advantages for a growing pizza business:

- Conserve Your Capital: Keep cash on hand for the day-to-day grind and those unexpected expenses that always pop up when running a pizzeria.

- Access Better Equipment: You can get the high-quality, durable pizza prep tables you actually need from day one, instead of settling for something that’ll just get you by.

- Predictable Monthly Payments: Budgeting gets a whole lot easier when you have fixed, manageable monthly payments.

- Path to Ownership: At the end of the lease, you have the option to buy the equipment and own it for good.

By reframing the purchase as a long-term asset and using flexible financing, you can set your pizzeria up for both immediate success and future growth. You’re not just buying a table; you’re building a foundation for your kitchen that’s made to last.

Got Questions? We've Got Answers.

Even after you've got a game plan, a few specific questions always pop up when you're hunting for the perfect stainless steel table for your pizzeria. Let's tackle the most common ones I hear from pizzeria owners so you can feel confident in your choice.

What Gauge of Stainless Steel Is Best for a Pizza Dough Table?

For the heavy-duty work of kneading and sheeting pizza dough day in and day out, you can't mess around. A lower gauge number means thicker, tougher steel, which is exactly what you need.

I always recommend 14-gauge stainless steel for any table that's going to be a primary dough station. It’s got the muscle to handle the constant pressure and impact without denting or bowing over time. For general prep—like topping pizzas—a 16-gauge table is a solid, reliable choice that balances strength and cost. You might see 18-gauge tables out there, but save those for light-duty tasks or undershelves; they just aren't built for the abuse of serious pizza dough work.

Can I Put a Hot Countertop Pizza Oven on My Work Table?

I get this question all the time, but my answer is always a firm no. While stainless steel can certainly take some heat, the kind of intense, prolonged heat blasted out by a countertop pizza oven is a different beast entirely. It can cause the steel to warp or discolor, permanently damaging your investment.

Always use a dedicated equipment stand designed to handle both the weight and the high temperatures of your pizza oven. A standard work table is built for prepping food, not for holding heavy, heat-cranking appliances.

How Do I Keep My Stainless Steel Pizza Prep Table from Getting Scratched?

The best defense is a good offense. The number one rule is simple: always use cutting boards. Never, ever cut directly on the steel surface with a pizza cutter—it will scratch instantly, creating tiny grooves where bacteria can hide. Steer clear of abrasive cleaners, too. That means no steel wool or gritty scouring pads.

Acidic spills from things like tomato sauce or vinaigrette should be wiped up quickly. For daily cleaning, a soft cloth with a little mild soap and water is all you need. Here's a pro tip: always wipe in the direction of the steel's grain. It helps maintain that clean, professional finish and avoids creating tiny cross-scratches.

Should I Get Casters for My Main Pizza Prep Table?

Casters—or wheels—are fantastic for making deep cleaning or rearranging your pizzeria layout a breeze. That flexibility is a huge plus. However, for a primary dough station where your staff is leaning in and applying serious force, stability is king. You don't want the table rolling away mid-knead.

A great middle-ground solution is to get locking casters. They give you the mobility when you need it but lock down tight for a sturdy work surface. If the table is a permanent fixture in your pizza line, though, stationary legs are usually the most dependable choice. Stability is so critical that 90% of pizza prep tables now come with adjustable feet to handle uneven floors. It just goes to show you how important a solid base is. For a deeper dive, you can learn more about advancements in pizza prep table design on growthmarketreports.com.

Ready to build the perfect pizza prep line? At Pizza Prep Table, we have the high-quality stainless steel work tables and refrigerated units to create a seamless, efficient pizzeria kitchen. https://pizzapreptable.com