The Ultimate Guide to Dukers Sandwich Prep Tables for Busy Kitchens

Share

What Makes a Dukers Sandwich Prep Table a Kitchen Essential?

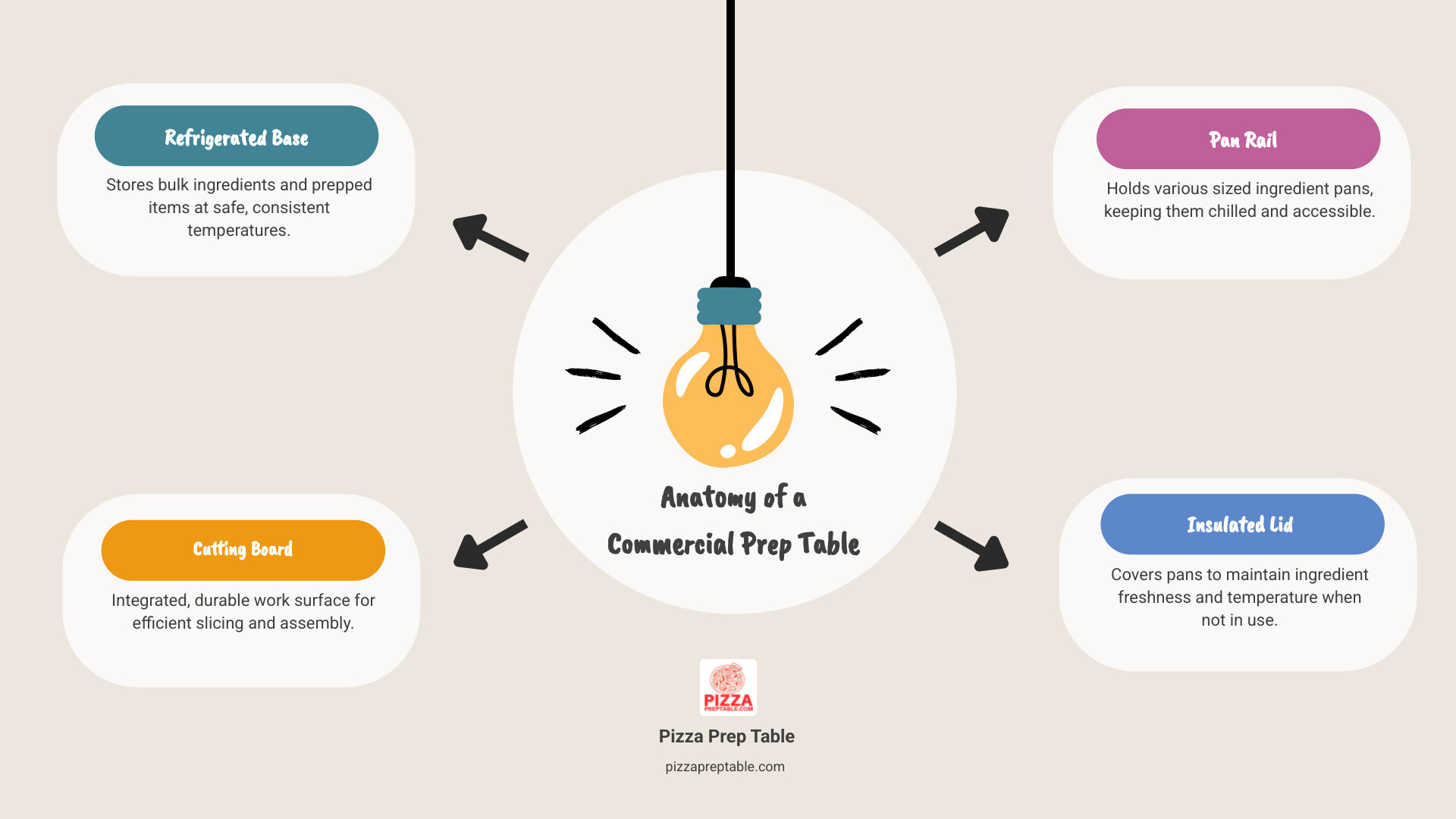

A Dukers sandwich prep table combines refrigerated storage with a convenient work surface, making it an essential piece of equipment for busy commercial kitchens. These units keep ingredients fresh while providing easy access for food preparation.

Key Features of Dukers Sandwich Prep Tables:

- Temperature Range: 33-41°F for optimal food safety

- Construction: Durable stainless steel interior and exterior

- Pan Capacity: 8-24 1/6 size pans depending on model

- Refrigeration: Bottom-mounted compressor with R290 eco-friendly refrigerant

- Warranty: 3-year parts & labor, 5-year compressor coverage

- Certifications: NSF/ANSI 7 Standard, ETL Listed for commercial use

Dukers offers models ranging from compact 29-inch units perfect for small cafes to spacious 60-inch tables that can handle high-volume operations. Popular models include the DSP29-8-S1 with 6.56 cu. ft. capacity, the DSP48-18M-S2 Mega Top with 18 pan containers, and the DSP60-16-S2 with 11.4 cu. ft. of storage space.

Whether you're running a small deli or a busy pizzeria, these prep tables streamline your workflow by keeping ingredients at the perfect temperature while providing a dedicated workspace for sandwich assembly and food preparation.

I'm Sean Kearney, and my experience in restaurant equipment sales has shown me how the right Dukers sandwich prep table can transform kitchen efficiency and food safety compliance. From helping small cafes choose compact models to outfitting large restaurant chains, I've seen how these units become the backbone of successful food operations.

Core Features: The Dukers Standard of Quality and Performance

When you're running a busy kitchen, your equipment needs to work as hard as you do. That's exactly what you get with a Dukers sandwich prep table - a piece of equipment that's built to handle whatever your kitchen throws at it, day after day.

Durable Construction

Let's start with what really matters: how these tables are built. Dukers uses brushed stainless steel for both the interior and exterior, and this isn't just about looking professional (though they certainly do). This material choice is all about making your life easier.

Stainless steel wipes clean in seconds, won't rust or corrode, and naturally resists bacteria - which is exactly what you need when you're prepping food all day long. The sealed floors and rounded cabinet corners might seem like small details, but they're game-changers when it comes to cleaning. No more scrubbing food particles out of hard-to-reach crevices.

The foamed-in-place polyurethane insulation does double duty - it keeps the unit structurally sound while maintaining those consistent internal temperatures that keep your ingredients fresh. This isn't just about today's service; it's about ensuring your Dukers sandwich prep table keeps performing for years to come.

Digital Temperature Control

Here's where precision meets practicality. The digital temperature controls with LED display take the guesswork out of food safety. You can monitor and adjust temperatures with just a glance, keeping everything in that sweet spot between 33°F and 41°F.

Some compact models like the DSP29-8-S1 operate within 34°F to 47°F, which is still perfectly safe for most ingredients. The beauty of digital controls is that your staff can check temperatures instantly - no more wondering if that lettuce is staying crisp or if the deli meats are at safe temperatures.

Efficient Refrigeration

The refrigeration system is where Dukers really shows their engineering smarts. The bottom-mounted compressor design isn't just different - it's better. By positioning the compressor at the bottom, it stays cooler (since heat rises), works more efficiently, and puts your ingredient storage at a comfortable working height.

But here's what really sets Dukers apart: they use R290 hydrocarbon refrigerant in many models. This natural refrigerant has zero ozone depletion potential and an incredibly low global warming potential. It's not just better for the environment - it actually provides superior cooling performance while using less energy. Your electric bills will thank you.

User-Friendly Design

The devil is in the details, and Dukers gets the details right. Those self-closing doors might seem basic, but they're constantly saving you energy by preventing cold air from escaping when things get hectic.

The stay-open feature for doors that swing past 90 degrees is a lifesaver during prep time - no more struggling to load ingredients while fighting a door that wants to close. Inside, you'll find adjustable wire shelves that let you customize your storage space for different container sizes.

And let's talk about those heavy-duty casters - usually 4-inch or 5-inch wheels that make moving your prep table for cleaning or repositioning surprisingly easy. These aren't just convenience features; they're designed to make your daily operations smoother and more efficient.

Exploring the Dukers Sandwich Prep Table Model Lineup

Finding the perfect Dukers sandwich prep table for your kitchen is like finding the right tool for the job – it makes all the difference in your daily operations. Dukers understands that every commercial kitchen has unique needs, which is why they've developed a comprehensive lineup that ranges from space-saving compact units to high-capacity workhorses.

The beauty of Dukers' approach lies in their variety. Whether you're running a cozy neighborhood cafe or managing a busy pizzeria, there's a model designed specifically for your volume and space requirements. Let me walk you through their most popular configurations and help you understand which might be the perfect fit for your operation.

| Model | Width (approx.) | Doors/Drawers | Pan Capacity (1/6 size) | Cu. Ft. Capacity | Best For |

|---|---|---|---|---|---|

| DSP29-8-S1 | 29-1/8 inches | 1-door | 8 | 6.56 cu. ft. | Small cafes, low-volume sandwich shops |

| DSP48-18M-S2 | 48-1/8 inches | 2-door | 18 (Mega Top) | N/A | Delis, medium-volume sandwich shops |

| DSP60-16-S2 | 60 inches | 2-door | 16 | 11.4 cu. ft. | High-volume restaurants, pizzerias |

When you're exploring Dukers models, you'll encounter two main top configurations. The standard top features a single row of 1/6 size pans along the front – perfect for streamlined operations with focused menus. The Mega Top configuration is where things get exciting. These units accommodate additional rows of containers, dramatically increasing your ingredient accessibility. Take the DSP48-18M-S2, for instance – it holds an impressive 18 containers, giving you the variety needed for extensive menus without constant restocking.

The choice between doors and drawers in the refrigerated base depends on your workflow preferences. Traditional doors with adjustable shelves offer flexibility for larger items, while drawer configurations provide organized storage with minimal cold air loss. Many operators find drawers particularly efficient for frequently accessed ingredients.

Sizing your space correctly is crucial. Dukers offers widths from compact 29-inch units to expansive 72-inch models. A table that's too small creates bottlenecks during busy periods, while one that's too large wastes valuable kitchen real estate. Consider both your current volume and potential growth when making this decision.

Compact Powerhouse: The 29-inch Dukers Sandwich Prep Table (DSP29-8-S1)

Sometimes the smallest packages deliver the biggest impact. The Dukers DSP29-8-S1 proves this point beautifully – it's a compact powerhouse that maximizes every inch of available space while delivering professional-grade performance.

At just 29-1/8 inches wide, this Dukers sandwich prep table fits into tight spaces that would challenge larger units. But don't mistake its compact footprint for limited capability. With 6.56 cubic feet of refrigerated storage and eight 1/6 size pans on top, it provides everything a small cafe or sandwich shop needs to operate efficiently.

The DSP29-8-S1 operates within a 34°F to 47°F temperature range, keeping your ingredients fresh and safe throughout the day. Its 1/7 HP compressor and R290 natural refrigerant ensure energy-efficient operation while maintaining consistent temperatures. The self-closing door with stay-open feature and adjustable heavy-duty shelf make daily operations smooth and hassle-free.

This model shines in operations where space is at a premium but quality can't be compromised. Coffee shops adding sandwich service, small delis, or food trucks find this unit particularly valuable.

View the Official DSP29-8-S1 Spec Sheet | Prep Sandwich Refrigerators That Keep Your Ingredients Fresh And Your Customers Happy

The Versatile Mid-Size: 48-inch Models (DSP48-18M-S2)

The 48-inch Dukers sandwich prep table models represent the sweet spot for many foodservice operations. They offer substantial capacity without overwhelming your kitchen space, making them ideal for busy delis and growing sandwich shops.

The DSP48-18M-S2 Mega Top is particularly impressive with its 18 1/6 pan containers – that's enough variety to handle complex orders without missing a beat. This expanded top capacity means less time restocking during peak hours and more time focusing on customer service.

Powered by a robust 1/5 HP bottom-mounted compressor, this unit maintains precise temperatures between 33°F and 41°F. The bottom-mount design keeps the compressor cool and accessible for maintenance while elevating the storage area for comfortable staff access.

The brushed stainless steel construction and digital temperature controls reflect Dukers' commitment to both durability and user convenience. The self-closing doors help maintain consistent temperatures even during busy service periods.

This Dukers sandwich prep table excels in medium-volume operations where menu variety and efficient workflow are equally important. It's the workhorse that grows with your business.

See the DSP48-18M-S2 Technical Data | Top Dukers Pizza Prep Tables To Keep Your Dough Cool And Your Customers Happy

High-Capacity Hero: The 60-inch Dukers Sandwich Prep Table (DSP60-16-S2)

When your kitchen operates at full throttle, cranking out orders at breakneck speed, you need equipment that can match your pace. The 60-inch Dukers sandwich prep table DSP60-16-S2 is built for exactly these demanding environments.

This high-capacity hero provides 11.4 cubic feet of refrigerated storage in its two-door base, giving you ample space for bulk ingredients and pre-made components. The 16 1/6 pan containers on top offer extensive ingredient variety while the 60-inch width provides generous workspace for multiple staff members.

The DSP60-16-S2 maintains precise temperatures between 33°F and 41°F using its reliable 1/5 HP bottom-mounted compressor. Even during the busiest service periods, your ingredients stay perfectly chilled and food-safe.

The brushed stainless steel construction handles constant use while remaining easy to clean and maintain. This durability is essential in high-volume operations where equipment downtime isn't an option.

High-volume restaurants, busy pizzerias, and institutional kitchens find this Dukers sandwich prep table indispensable. It's the backbone that supports ambitious operations and growing businesses.

The Dukers Advantage: Warranty, Certifications, and Brand Commitment

When you're running a busy kitchen, the last thing you want to worry about is whether your equipment will hold up under pressure. That's where Dukers really sets itself apart from the competition. Beyond just making quality Dukers sandwich prep tables, they back up their products with serious commitments to safety, reliability, and customer support.

Industry Certifications

Let's talk about the certifications that matter. When health inspectors walk through your kitchen, they're looking for equipment that meets strict standards. Dukers makes sure you're covered with NSF/ANSI 7 Standard certification, which is the gold standard for commercial refrigeration. This means your prep table meets rigorous requirements for food safety and sanitation.

You'll also find ETL Listed and ETL Sanitation marks on these units. These aren't just fancy stickers - they're proof that independent testing labs have put the equipment through its paces. The ETL Listed mark confirms electrical safety, while ETL Sanitation verifies that the unit performs properly for food service use.

Many models also meet UL Standards for electrical safety, giving you another layer of protection in your commercial environment. When you choose a Dukers sandwich prep table, you're choosing equipment that health departments recognize and trust.

Robust Warranty

Here's where Dukers really shows confidence in their products. They offer a 3-year parts and labor warranty that covers manufacturing defects. That means if something goes wrong that isn't your fault, they'll fix it without charging you for parts or labor. That's three full years of protection for your investment.

But they don't stop there. The 5-year compressor warranty is where things get really impressive. The compressor is the heart of any refrigeration unit, and Dukers knows it. By extending the warranty to five years on this critical component, they're telling you they expect their compressors to last - and they're willing to bet on it.

This kind of warranty coverage gives you real peace of mind. No one wants their prep table breaking down during the lunch rush, but if it happens, you know you're covered.

Manufacturer Background

Dukers isn't some fly-by-night operation. They've been perfecting their craft for over 30 years as both a manufacturer and OEM supplier. In fact, many commercial kitchen equipment brands you might recognize actually use Dukers units as their foundation - they just put their own label on them.

What really sets Dukers apart is their commitment to the US market. They've established five warehouse and office facilities across California, Illinois, Georgia, New Jersey, Florida, and Texas. This means faster shipping, better support, and easier access to parts when you need them.

With over 600 US equipment dealers in their network, you're never far from help if you need it. This isn't just about selling you a prep table - it's about supporting your business for the long haul.

Environmental Responsibility

Running a restaurant is tough enough without worrying about your environmental impact, but Dukers makes it easier. They use lean production practices that minimize waste and make their manufacturing more efficient. This isn't just good for the planet - it often translates to better prices for you.

The real game-changer is their use of R290 hydrocarbon refrigerant. This natural refrigerant has zero ozone depletion potential and a very low global warming potential. It's also more energy-efficient than traditional refrigerants, which means lower utility bills for your business.

When you buy a Dukers sandwich prep table, you're supporting a company that cares about more than just profits. They're thinking about the future of the restaurant industry and the world we're leaving for the next generation.

Frequently Asked Questions about Dukers Prep Tables

After helping hundreds of restaurant owners choose the right equipment over the years, I've noticed the same questions come up again and again. Let me share the answers that will help you make the best decision for your kitchen.

What is the difference between a standard top and a Mega Top prep table?

Think of it this way: a standard top is like having a well-organized toolbox, while a Mega Top is like having a full workshop at your fingertips. The difference comes down to how much ingredient storage you get right on top of your Dukers sandwich prep table.

A standard top gives you a single row of ingredient pans, usually along the front edge. This leaves plenty of cutting board space for prep work and keeps your essential ingredients within easy reach. It's perfect for operations with focused menus or when you want maximum workspace for assembling orders.

The Mega Top configuration takes things up a notch. Take the DSP48-18M-S2, for example - it holds an impressive 18 pans compared to what a standard top would offer. This extra capacity means you can keep more variety right at your fingertips, which is a game-changer during busy lunch rushes. You'll spend less time restocking from the refrigerated base below and more time serving customers.

I always tell my clients: if you're constantly running back and forth to grab ingredients, or if your menu has lots of options, the Mega Top will pay for itself in efficiency gains.

How do I clean and maintain my Dukers sandwich prep table?

Keeping your Dukers sandwich prep table clean isn't just about following health codes - it's about protecting your investment and ensuring it runs smoothly for years to come.

Daily cleaning should become second nature. At closing time, remove all the food pans and cutting board. Wash them thoroughly with warm, soapy water, then sanitize and let them air dry. The stainless steel surfaces wipe down easily with a mild cleaner and soft cloth. Those rounded corners and sealed floors that Dukers includes aren't just for looks - they make cleaning much easier by eliminating spots where food can hide.

Weekly deep cleaning keeps everything running smoothly. Check the door gaskets for any buildup, and if you can access the condenser coil, give it a gentle cleaning. Dust on the coil makes your compressor work harder, which costs you money in energy bills. Also, make sure the drain lines are clear to prevent any water backup issues.

Monthly maintenance is simple but important. Test your casters to make sure they're working properly, and keep an eye on that digital temperature display. If you notice anything unusual - strange noises, temperature fluctuations, or doors not sealing properly - address it quickly. Small problems become expensive repairs if you ignore them.

The beauty of Dukers units is that they're designed for easy maintenance. With proper care, your prep table will be a reliable workhorse for many years.

Can I use a Dukers sandwich prep table for other food items, like pizza ingredients?

Absolutely! Don't let the name fool you - these tables are incredibly versatile. I've sold Dukers sandwich prep tables to pizzerias, taco shops, salad bars, and even sushi restaurants. The key is that consistent temperature range of 33°F to 41°F, which keeps all kinds of ingredients fresh and safe.

Pizza shops love these tables because they can organize all their toppings in the pan rail - pepperoni, mushrooms, peppers, different cheeses - while using the cutting board surface for stretching dough and assembling pies. The spacious work area gives you room to work with larger items like pizza boxes or multiple orders at once.

Taco restaurants use them for their build-your-own setups, keeping lettuce, tomatoes, cheese, and proteins perfectly chilled and organized. Salad operations appreciate the variety of ingredients they can keep accessible, from different greens to toppings and dressings.

The robust stainless steel construction handles whatever you throw at it, whether that's kneading dough, chopping vegetables, or assembling complex orders. The efficient refrigeration system doesn't care if it's keeping sandwich meats cold or pizza cheese - it just keeps everything at the perfect temperature for food safety and quality.

Conclusion: Choosing the Right Dukers Prep Table for Your Business

After running a restaurant equipment business for years, I've learned that the right prep table can make or break a kitchen's efficiency. A Dukers sandwich prep table isn't just another piece of equipment—it's the command center where your team's productivity either soars or stalls.

Throughout this guide, we've seen how Dukers delivers on the three pillars that matter most: durability through their robust stainless steel construction, efficiency with precise digital temperature controls and eco-friendly R290 refrigeration, and food safety through industry certifications like NSF/ANSI 7 and ETL listings. These aren't just features—they're your insurance policy against costly breakdowns and health code violations.

The beauty of the Dukers lineup lies in its model variety. Whether you're running a cozy cafe that needs the compact DSP29-8-S1, a busy deli that would benefit from the DSP48-18M-S2 Mega Top's 18-pan capacity, or a high-volume pizzeria requiring the DSP60-16-S2's expansive workspace, there's a perfect fit for your operation.

What really sets Dukers apart is their commitment beyond the sale. That 3-year parts and labor warranty, plus 5-year compressor coverage, means you're not just buying equipment—you're investing in peace of mind. With over 30 years of manufacturing experience and a network of 600+ US dealers, support is always within reach.

At PizzaPrepTable.com, we've helped countless businesses find their perfect Dukers sandwich prep table. From small independent shops to larger establishments across major cities like New York, Los Angeles, Chicago, and beyond, we understand that every kitchen has unique needs. That's why we offer expert guidance to match you with the right model and financing options to make your investment manageable.

Choosing the right prep table isn't just about today's needs—it's about setting your kitchen up for years of reliable service. When you're ready to upgrade your operation with equipment that works as hard as you do, we're here to help.

Explore our full range of Dukers Prep Tables and find the perfect fit for your kitchen