Affordable Restaurant Equipment for Your Pizzeria

Share

Finding affordable restaurant equipment isn't about chasing the cheapest price tag. It’s about making strategic, informed choices that balance what you pay upfront with the long-term value you get back. For a new pizzeria, this means getting laser-focused on the gear you absolutely need—like a rock-solid pizza oven and an efficient pizza prep table—while being smart about sourcing everything else.

The goal isn't to buy the cheapest option, but the smartest one for your pizzeria's budget and unique workflow.

Building Your Pizzeria Kitchen Without Breaking the Bank

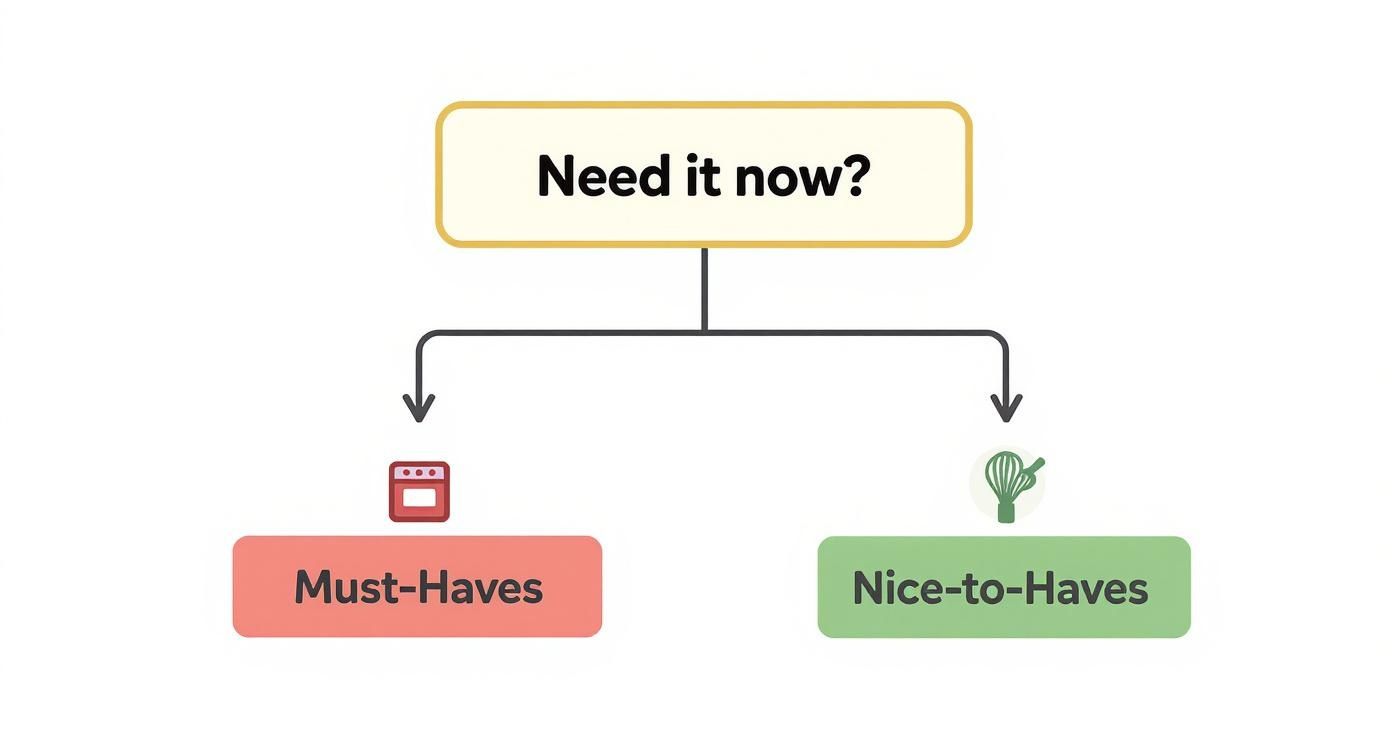

Opening a pizzeria is a dream for so many, but that initial investment can feel like a mountain. The key to climbing it is approaching your kitchen build-out with a clear, strategic plan. It all starts with separating your absolute must-haves, like your pizza prep table, from the "nice-to-have" items you can add later as your business finds its footing.

Every single dollar you spend needs to directly support your ability to pump out high-quality pizza efficiently from the moment you open your doors.

Your kitchen is the engine of your restaurant, but it doesn't need to be decked out in brand-new, top-of-the-line everything. A hybrid approach almost always wins. Invest in a new, high-performance pizza oven that delivers consistent results every time, but maybe find a quality used pizza prep table or mixer to save a huge chunk of cash.

Prioritizing Your Pizzeria Equipment List

Before you even think about spending money, make a detailed list and sort every single item into categories. This simple exercise forces clarity and stops you from making those impulse buys that bleed startup capital dry.

- The Must-Haves: These are your non-negotiables for making pizza. This list is refreshingly short: a powerful oven, a functional pizza prep table with built-in refrigeration, a commercial-grade dough mixer, and your essential refrigerators and freezers.

- Important, But Flexible: Items like dough presses, slicers, and a full arsenal of smallwares are things you can often source used or upgrade down the line.

- Future Upgrades: This is where you put the dream gear. Think about that specialized wood-fired oven or a much larger mixer that can wait until you have a steady, predictable cash flow.

The real objective is to launch with a lean, efficient pizzeria kitchen that has absolutely mastered your core menu. Overspending on non-essential equipment is one of the fastest ways to put a new restaurant in a financial hole before the first customer even walks in.

Smart Financial Planning for Your Kitchen

When you're in the thick of a build-out or renovation, it's easy to forget that equipment is just one piece of the financial puzzle. Looking into strategies for reducing overall construction costs can free up a surprising amount of cash that you can then put toward better gear.

And make no mistake, investing in the right tools is more important than ever. As demand for efficient pizza kitchen equipment skyrockets, the global market is projected to nearly double, hitting an incredible $10.2 billion by 2035. This trend just underscores how critical it is to make smart, forward-thinking investments in your pizzeria from day one.

Choosing the Right Pizza Prep Table for Your Workflow

Your pizza prep table isn't just another piece of equipment; it's the heart of your production line. Think of it as the command center that dictates how fast, organized, and consistent your kitchen can be. Picking the right one is a critical decision that will directly hit your workflow and, ultimately, your bottom line.

This is one area where finding affordable restaurant equipment doesn’t mean just grabbing the cheapest option off the shelf. Real value comes from selecting a pizza prep table that perfectly matches your menu, your physical space, and your order volume. This way, you're not overspending on fancy features you'll never use or, even worse, underspending on a table that will become the bottleneck for your entire pizza-making operation.

When you're starting out, the sheer number of choices can be paralyzing. The decision tree below is a great way to visualize the process and separate what you absolutely need on day one from what would be nice to have down the road.

This visual guide drives home a core principle for any new pizzeria owner: focus your initial investment on the absolute "must-have" equipment that starts generating revenue the moment you open your doors.

Material and Refrigeration Considerations

The first big fork in the road is deciding between a refrigerated prep table and a simple stainless steel worktable. For nearly every pizzeria, a refrigerated pizza prep table is a non-negotiable must-have. Keeping ingredients like cheese, sauce, and toppings within arm's reach and at a food-safe temperature isn't just about efficiency—it's essential for passing health inspections.

Next up, you have to think about the countertop material. The two most common options you'll see are stainless steel and marble.

- Stainless Steel: This is the workhorse of most pizzerias for a reason. It's durable, a breeze to sanitize, and generally much more affordable.

- Marble: The big advantage here is that it's naturally cool, which is fantastic for working with pizza dough because it prevents sticking. However, it's pricier, heavier, and needs more delicate care to avoid stains and chips.

Honestly, for a new pizzeria trying to stick to a budget, a high-quality stainless steel top is almost always the most practical and cost-effective way to go for your pizza prep table.

Sizing Your Prep Station for Your Menu

The size of your pizza prep table, especially the number of ingredient pans (often called bains) it holds, should be dictated entirely by your menu. Don't just guess—actually map it out. Make a list of every single topping you plan to offer from day one.

A "Mega Top" style unit, for example, gives you a third row of pans, which translates to roughly 50% more ingredient capacity than a standard model of the same width. This is a game-changer for pizzerias with a ton of topping choices, as it helps prevent cross-contamination and keeps the pizza line moving during a crazy dinner rush.

Selecting the right size isn't just about the length of the table; it's about optimizing your entire pizza prep process. A well-organized pizza prep table with enough ingredient storage means your team isn't constantly running to the walk-in cooler, saving precious seconds on every single order.

Another feature people often overlook is the depth of the cutting board. A deeper board, somewhere in the 17-19 inch range, gives you more real estate for assembling large pizzas without toppings spilling all over the place. While some tables can pull double duty, it's worth exploring a detailed comparison to see if a dedicated pizza prep table is different from a sandwich prep station for what you need.

To help you decide, here’s a quick breakdown of how different pizza prep tables stack up.

Pizza Prep Table Feature Comparison

| Feature | Standard Prep Table | Refrigerated Prep Table | Mega Top Prep Table |

|---|---|---|---|

| Ingredient Storage | None | 2 rows of pans | 3 rows of pans |

| Best For | Dough prep, simple setups | Standard pizzeria menus | Extensive topping options |

| Countertop Material | Stainless Steel | Stainless Steel or Marble | Stainless Steel or Marble |

| Under-Counter | Open shelving | Refrigerated cabinets/drawers | Refrigerated cabinets/drawers |

| Cost | Low | Medium | High |

This table shows how a Mega Top offers a significant capacity boost, but a standard refrigerated unit is often the perfect sweet spot for most new pizzerias balancing features and budget.

Finally, take a hard look at the under-counter storage. Most pizza prep tables will offer a mix of refrigerated cabinets and drawers. Cabinets are perfect for bulk storage of dough trays and sauce buckets, while drawers provide quick, organized access to portioned items like cheeses and sliced meats. It all comes down to shaving seconds off your workflow.

How to Source New and Used Pizzeria Equipment

You’ve nailed down the exact pizza prep table your kitchen needs—that’s a huge step. But now comes the real hustle: finding that perfect piece of equipment at a price that doesn’t blow up your budget.

Your sourcing strategy is going to have a massive impact on your startup costs, and getting it right can save you thousands. The smartest move is usually a hybrid approach, mixing new and used gear to get the best of both worlds.

For a new pizzeria, this often means splurging on a brand-new, warrantied pizza oven (your moneymaker) while hunting down a great deal on a used pizza prep table or dough mixer. It's all about building a kitchen that works reliably from day one without draining your capital.

Where to Look for Used Equipment

The second-hand market for restaurant gear is on fire, and for good reason. As the primary equipment market grows, the used sector is exploding right alongside it. It's projected to more than double from $7.7 billion in 2025 to $15.3 billion by 2035.

This is a massive opportunity for independent pizzeria operators to snag high-quality tools for pennies on the dollar. You can learn more about what's driving this growth in the used equipment market and how to take advantage of it.

Here’s where I tell my pizzeria clients to start their search:

- Specialized Online Dealers: These are your best bet. Websites focused on used pizzeria equipment, especially pizza prep tables, usually inspect and refurbish their gear. Some even offer a limited warranty, which is a huge plus.

- Restaurant Auctions: Keep your ear to the ground for local and online auctions from restaurants that are closing down or remodeling. You can find absolute steals here, but you have to be ready to inspect items on the spot and make quick decisions.

- Local Supply Stores: Don’t forget your local brick-and-mortar suppliers. Many have a used section in the back, and the biggest advantage is getting to see, touch, and even plug in the equipment before you buy.

Your Used Pizza Prep Table Inspection Checklist

Buying used can feel like a roll of the dice, but a solid inspection process takes most of the guesswork out of it. A used pizza prep table can be a fantastic find, but you have to go over it with a critical eye. Don't be shy.

Get your hands dirty and check these key points:

- Test the Refrigeration System: This is non-negotiable. Plug the pizza prep table in and let it run for a solid 30 minutes. Does it get down to a food-safe temp (under 40°F) and stay there? Listen for weird noises from the compressor—loud clanking or grinding sounds are a major red flag.

- Inspect Gaskets and Seals: Run your hand along every single door and lid gasket on the prep table. They need to be soft and flexible to create a tight seal. If they’re cracked, brittle, or moldy, you’ll have to replace them immediately, so factor that into your cost.

- Examine the Bones: Look for rust, especially on the legs and underneath the pizza prep table. Check the cutting board. If it’s deeply grooved or cracked, it’s a bacteria trap and needs replacing. Make sure all the drawers and doors open and close smoothly.

A great deal on a used pizza prep table is no longer a deal if you have to spend another $1,000 on repairs a month after you buy it. A thorough inspection is your best defense against hidden costs.

Ultimately, that blended approach works best for most new pizzerias. Sourcing a used pizza prep table from a reputable dealer while investing in a new oven gives you reliability where it counts most, freeing up serious cash you can put toward ingredients, marketing, or your grand opening.

Evaluating Energy Efficiency and Long-Term Costs

It’s easy to get fixated on the sticker price of a new piece of equipment. We've all been there. But trust me, that initial number is rarely the whole story when it comes to your pizzeria. The truly affordable restaurant equipment isn't the one with the lowest price tag today; it's the one that costs you the least to own and operate over its entire life.

Think about it this way: a slightly cheaper pizza prep table might feel like a smart win right now. But if that unit is an energy hog, it will quietly drain your profits every single month through higher utility bills. After a few years, that "deal" could end up costing you thousands more than the more efficient model you passed on.

Looking beyond that initial investment is absolutely critical for the long-term financial health of your pizzeria. The real savings are found in operational efficiency, and nothing hits your monthly budget harder than energy consumption.

This shift toward efficiency isn't just something savvy pizzeria owners are doing; it’s a major industry-wide trend. A recent analysis projects the restaurant equipment market will jump from $3.88 billion in 2024 to $4.2 billion in 2025. A huge driver of that growth? The demand for energy-efficient appliances that slash operating costs. You can read more about this market growth and its drivers.

Decoding Efficiency in Pizza Prep Tables

When you’re kicking the tires on a refrigerated pizza prep table, the compressor is the heart of the machine. It’s also the component that guzzles the most electricity.

I've seen it time and time again: a modern pizza prep table with advanced compressor technology and better insulation might have a higher upfront cost, but its lower energy draw delivers a surprisingly fast return on that investment.

Imagine you're choosing between two delivery cars. One is cheaper but gets 15 miles per gallon. The other costs a bit more but gets 30. For a busy pizzeria making dozens of deliveries a night, the fuel savings from the more efficient car will quickly wipe out that initial price difference. The exact same logic applies to your pizza prep table.

Choosing an ENERGY STAR® certified pizza prep table isn't just about being green—it's a stone-cold financial strategy. On average, these models are 10-20% more energy-efficient than standard units. That translates directly into lower monthly utility bills and a healthier bottom line for your pizzeria.

Key Features That Cut Long-Term Costs

Beyond that big blue ENERGY STAR® sticker, a few specific features tell you if a pizza prep table is truly built for long-term savings. When you're comparing models, keep an eye out for these elements. They are the difference between a good purchase and a great investment.

Here are the features that really matter for trimming your operational expenses:

- High-Density Insulation: Look for polyurethane foam insulation. This stuff is incredible at keeping cold air locked in the pizza prep table, which means the compressor doesn't have to work as hard or as often. This is a lifesaver in a hot pizzeria kitchen where ambient temperatures are always fighting against your refrigeration.

- Self-Closing Doors and Lids: How many times have you seen a cook grab ingredients and leave a pizza prep table door slightly ajar in the middle of a rush? Every time that happens, cold air pours out, and your compressor kicks into overdrive. Self-closing mechanisms are a simple but brilliant feature that puts a stop to that energy waste.

- Efficient Gasket Seals: High-quality, magnetic gaskets create an airtight seal around doors and drawers. Before you buy a pizza prep table, check to see how durable they feel and how easy they are to replace. Worn-out, cracked gaskets are one of the most common—and most expensive—sources of energy loss in a pizzeria kitchen.

Making a slightly larger investment in a pizza prep table with these features is one of the smartest financial moves a pizzeria owner can make. The monthly savings on your electricity bill will not only cover the difference but will continue to boost your profitability for years to come.

Smart Financing Options for Your Pizzeria Equipment

Let's be honest. Even after you’ve hunted down the best deals and kicked the tires on every used piece of equipment, outfitting a full pizzeria kitchen is a serious investment. Getting the funding together is often the last big hurdle standing between your dream and opening day. It can feel like a mountain to climb, but once you know your options, it's a lot more manageable.

For most independent pizzeria owners I’ve worked with, the cash for big-ticket items like a deck oven or a refrigerated pizza prep table doesn't just magically appear from a savings account. It comes from a smart financing plan that keeps cash in the bank for those first few critical months when you need it most.

Comparing Your Funding Paths

When you start digging into business financing, you’ll find a few well-worn paths. Each has its own rules, perks, and potential headaches. There's no single "best" choice—the right one for your pizzeria depends entirely on your business's financial health, your credit score, and how fast you need that cash.

Here’s a quick rundown of the most common routes pizzeria owners take:

- Traditional Bank Loans: These guys usually offer the best interest rates, but they also have the tightest velvet rope. Banks want to see a rock-solid pizzeria business plan, great personal credit, and often some form of collateral.

- SBA Loans: Backed by the Small Business Administration, these loans are often a bit more forgiving for new pizzerias. The government guarantee makes lenders feel safer, so they're more willing to take a chance on a startup.

- Equipment Leasing: Instead of buying that shiny new pizza prep table outright, you lease it. You get brand-new, top-quality gear for a fixed monthly payment, which is fantastic for keeping your initial cash outlay low.

- Supplier Financing: A lot of equipment dealers have their own in-house financing or lease-to-own deals. This can be one of the simplest ways to go since you’re dealing directly with the company that's selling you the pizza prep table.

Preparing a Strong Application

No matter which path you take, a killer application is what gets you a "yes" with good terms. Lenders need to see you’ve done your homework and have a realistic game plan for your pizzeria. They aren’t just investing in steel and compressors; they're investing in you and your ability to run a profitable shop.

Think of your financing application as the business plan for your kitchen. It should clearly show exactly what equipment you need, why you need it, and how it will help you make money. A detailed quote for your pizza prep table is way more convincing than a ballpark guess.

Before you even think about applying, get your paperwork in order. This means having your business plan, personal financial statements, and detailed quotes for the specific equipment you plan to buy. Walking in with a neatly organized package tells a lender you’re professional and serious. For a deeper look at all these options, check out our complete guide on financing restaurant equipment to help you make the smartest call.

At the end of the day, smart financing is about more than just getting a check. It’s about setting up a deal that helps your pizzeria grow without strapping your finances. Weigh your options, put together a solid application, and you'll get the capital you need to build the pizzeria kitchen you've been dreaming of.

Pizzeria Equipment FAQs: Your Questions Answered

Jumping into the restaurant business, especially a pizzeria, brings up a million questions. When you're working with a tight budget, getting straight, honest answers can be the difference between a smart buy and a mistake that haunts you for years. It’s easy to get overwhelmed trying to decide between shiny new gear and a promising used deal.

Let's cut through the noise. Here are some practical answers to the most common questions I hear from new pizzeria owners, focusing on the gear that really matters—like that all-important pizza prep table.

What Should My First Equipment Purchase Be?

This is the big one, and the answer is simpler than you think: your pizza oven. The pizza oven is the absolute heart and soul of your operation. Everything about your final product—the crust, the melt, the cook time—comes down to that single piece of equipment.

Your very next purchase should be a high-quality, refrigerated pizza prep table. No exceptions.

These two items are the foundation of your entire production line. Your mixer, your smallwares, your fryer... they all play a supporting role. By putting your money into the oven and prep table first, you’re investing in the gear that will make you money from the moment you open your pizzeria.

The most common mistake I see new pizzeria owners make is spreading their budget too thin across too many "nice-to-have" items. Focus your capital on a great pizza oven and a reliable prep table first. You can always add a second fryer or a fancier mixer later.

What Are the Biggest Red Flags When Buying Used Gear?

Going with used equipment is a fantastic way to find affordable restaurant equipment, but you have to put on your inspector hat. When you're looking at a used pizza prep table, the biggest deal-breakers are almost always tied to the refrigeration system.

Here's what to look for:

- A Noisy Compressor: If the pizza prep table is rattling, clanking, or making a loud grinding sound when it kicks on, just walk away. Replacing a compressor is one of the most expensive repairs you can get hit with. It's not worth the risk.

- Brittle or Torn Gaskets: Run your fingers along every single seal around the doors and lids. If they feel cracked, stiff, or torn, they won't hold a proper seal. This forces the compressor to run nonstop, which will absolutely kill your energy bill.

- Signs of Rust: Get down and look closely at the legs and the underside of the unit. A little surface rust can sometimes be cleaned up, but deep, flaky corrosion is a major red flag that can weaken the pizza prep table's structure.

How Do Warranties Work for New vs. Used Equipment?

This is a crucial detail that a lot of people overlook. Understanding the warranty situation protects your investment, and the difference between new and used coverage is night and day, especially for a core item like a pizza prep table.

For New Equipment: A new pizza prep table will almost always come with a manufacturer's warranty, which typically lasts from 1 to 3 years. This usually covers both parts and labor for any defects. Always read the fine print, though—sometimes the most important component, the compressor, will have its own separate, longer warranty.

For Used or Refurbished Equipment: Warranties on used gear are much less consistent. If you're buying a pizza prep table from a reputable dealer, they might offer a limited 30 to 90-day warranty on refurbished pieces. This usually covers parts but not always the labor to install them. If you're buying "as-is" from a private seller, an auction, or a restaurant that's closing down, you have to assume there is no warranty at all.

At Pizza Prep Table, we get the challenges of outfitting your dream pizzeria on a real-world budget. We offer a handpicked selection of both new and warrantied refurbished pizza prep tables to fit your needs, all backed by expert advice and flexible financing. Explore our collection and build your pizzeria's foundation with confidence at https://pizzapreptable.com.