The Pizzeria's Secret Weapon A Guide to the Back Bar Cooler

Share

When you think of a back bar cooler, you probably picture a pub sliding open a sleek glass door to grab an ice-cold beer. But in a pizzeria, this compact workhorse is your secret weapon for a faster, smoother, and more profitable pizza prep table.

Your Pizzeria's Unsung Hero: The Back Bar Cooler

It's easy to dismiss back bar coolers as just for drinks, but that's a huge missed opportunity in a pizza kitchen. The fast-paced world of pizza making is a game of seconds, and the distance between your main walk-in and your pizza prep table is an efficiency killer.

Imagine it's a slammed Friday night. Your pizza maker is in the zone, stretching dough like a pro, but runs out of pepperoni. They have to stop everything, walk across the kitchen, and grab more, completely breaking their rhythm. Now, picture that same scene with a back bar cooler tucked right under the pizza prep table. It changes everything.

The Ultimate Pizza Prep Table Assistant

This setup essentially creates a perfectly refrigerated ‘mise en place’ station—that classic French culinary term for having all your ingredients prepped and ready to go. No more running back and forth; your team has everything they need for the pizza prep table right at their fingertips.

A well-placed back bar cooler is more than just cold storage; it’s a workflow accelerator. By cutting out those unnecessary trips across the kitchen, you get faster ticket times, less tired staff, and more consistent pizzas.

This is all about strategic placement. The cooler becomes a seamless extension of the pizza prep table, keeping every topping—from mozzarella and mushrooms to sauces and pre-portioned dough—at a food-safe temperature right where the action happens. That integration is what keeps both speed and safety in check during the dinner rush.

A Strategic Investment in Efficiency

When you look at it this way, a back bar cooler stops being just another expense and becomes a powerful investment in your whole pizza operation. The benefits ripple through every part of your kitchen:

- Increased Speed: Drastically cuts down the time it takes to build each pizza at the prep table.

- Improved Consistency: Guarantees every pizza is made with the same fresh, properly chilled ingredients.

- Enhanced Food Safety: Keeps all your temperature-sensitive toppings out of the "danger zone."

- Optimized Kitchen Flow: Slashes foot traffic and kills the bottlenecks that always form around the main walk-in.

By rethinking its role, you can see how this one piece of equipment is absolutely essential for any serious pizzeria. It sets the stage for a smoother, faster, and more profitable kitchen.

Decoding Back Bar Cooler Features for Pizzerias

Choosing the right back bar cooler for a pizzeria involves way more than just looking at the price tag. The features you pick are going to have a direct impact on your kitchen's speed, your food safety, and even your monthly utility bills. Let's break down the essential components to look for, translating the tech specs into what they actually mean for your pizza prep table.

The first big decision you'll face is the door style. While those sleek glass doors look fantastic in a customer-facing bar, a pizzeria's back-of-house needs are a different beast entirely. It's the classic battle of insulation versus visibility.

For a pizzeria's pizza prep table, solid doors are almost always the smarter choice. Their superior insulation is absolutely critical for holding consistent, cold temperatures for sensitive ingredients like proofed dough and cheese, especially when the crew is constantly opening and closing the unit during a dinner rush.

Glass doors, while great for showing off drinks up front, lose cold air much faster. In a hot, hectic pizza kitchen, this temperature rollercoaster can mess with your food quality and force the compressor to work overtime, which means higher energy costs. Solid doors act as a thermal shield, keeping your pizza ingredients perfectly chilled and safe.

The Engine Behind The Chill

Just as important as the doors is the refrigeration system itself. A forced-air refrigeration system, sometimes called a dynamic or fan-assisted system, is non-negotiable for a busy pizzeria. This technology uses internal fans to push cold air evenly throughout the entire cabinet.

This constant circulation is what gives you a rapid temperature recovery every single time a door is opened. Think of it like a convection oven but for cold—it gets rid of hot spots and guarantees that the mozzarella in the back corner is just as cold as the pepperoni right by the door. Coolers without this feature can really struggle to keep up, creating unsafe temperature zones for your pizza toppings right in the middle of a busy service.

Built for the Trenches of a Pizza Kitchen

A pizzeria kitchen is a tough place to work. Your equipment has to be durable, a breeze to clean, and designed for pure function. When you're sizing up a back bar cooler for your pizza prep table, pay close attention to its construction and internal layout.

Here are the must-have build features:

- Durable Stainless Steel Interior: Forget about plastic liners that can crack and soak up odors. A stainless steel interior is built to handle the daily grind of a commercial kitchen. It's tougher, resists corrosion from acidic stuff like tomato sauce, and is way easier to sanitize.

- Adjustable Shelving: Your ingredient needs are always changing. Adjustable shelving gives you the flexibility to organize everything from shallow third-pans of sliced olives to deeper bins of shredded cheese or dough balls, letting you maximize every last inch of space.

- NSF Certification: This one is an absolute must. The NSF (National Sanitation Foundation) certification is your proof that the cooler is designed and built to promote food safety, with smooth, easily cleanable surfaces. Health inspectors will look for this seal, and not having it can cause serious compliance headaches.

Making the right call means looking at how all these features work together. It's a lot to juggle, which is why we put together a detailed guide to help you weigh your options.

Our back bar cooler comparison survival guide offers a much deeper dive into matching specific models with your pizzeria's unique workflow and needs.

Back Bar Cooler Feature Breakdown for Pizzerias

To really nail down what's important for a pizza shop, it helps to see the features side-by-side and understand why they matter in your specific environment. This isn't about buying the most expensive unit; it's about buying the smartest one for your pizza prep table.

| Feature | Best Choice for Pizzerias | Why It Matters | Consideration |

|---|---|---|---|

| Door Style | Solid Doors | Superior insulation maintains consistent temperatures for sensitive ingredients like cheese and dough, even with frequent opening. | Glass doors look nice for merchandising but are inefficient for a hot pizza prep line. |

| Refrigeration | Forced-Air System | Ensures rapid temperature recovery and eliminates hot spots, keeping all pizza ingredients safely chilled during a rush. | A static cooling system simply can't keep up with the demands of a busy pizza kitchen. |

| Interior Material | Stainless Steel | Durable, easy to sanitize, and resists corrosion from acidic ingredients like tomato sauce and pineapple. | Plastic liners can crack, stain, and absorb odors over time, becoming a food safety risk. |

| Certification | NSF Certified | This is a non-negotiable requirement for health code compliance and ensures the unit is designed for safe food storage. | Non-certified units can lead to failed health inspections and potential fines. |

| Shelving | Adjustable | Provides flexibility to store various container sizes, from shallow pans of toppings to deep bins of dough balls. | Fixed shelves limit your storage options and lead to wasted space. |

Ultimately, it's the small details that can make a huge difference in your day-to-day operations. Look for things like self-closing doors that prevent energy waste when a busy pizza maker forgets to shut them. Bright, energy-efficient LED lighting also makes it easier to quickly spot pizza toppings without fumbling around in the dark. By prioritizing performance-driven features over flashy looks, you're investing in a back bar cooler that will be a reliable workhorse for your pizza prep table for years to come.

Sizing And Placement For Seamless Pizza Prep Integration

Picking the right back bar cooler is only half the job; putting it in the wrong spot can throw a wrench into your entire kitchen's workflow. For any pizzeria, the whole game is about creating a smooth, efficient dance between the cooler, the pizza prep table, and the oven. This is your game plan for sizing and placing your unit to max out your speed and efficiency, turning your prep line into a money-making machine.

The secret is cutting out wasted motion. Every single step a pizza maker takes to grab something from a fridge across the room is a lost second. Those seconds add up fast, bloating your labor costs and slowing down ticket times. The right placement puts every crucial pizza ingredient just an arm's length away.

Calculating Your Pizzeria's Capacity Needs

Before you figure out where to stick your cooler, you need to know what size you're even looking for. A unit that’s too small means you're constantly running to the walk-in during a rush, killing your momentum. One that's too big just eats up valuable floor space and electricity.

A pretty solid way to ballpark your needs is to figure out your peak daily use for your key pizza ingredients. Think about how much pepperoni, mushrooms, and mozzarella you burn through on a busy Friday night. Don't forget how much pre-portioned dough you need to have ready to go.

Rule of Thumb: Your back bar cooler should hold enough prepped ingredients to get you through at least one full, peak service. This is how you stop those mid-rush trips to the walk-in, which are notorious for killing workflow at the pizza prep table.

Once you have a rough idea of the cubic footage you need, you can start checking out different models. Keep in mind, the back bar cooler is a hot commodity. North America and Europe make up over 60% of the global demand. In the U.S. alone, the market is expected to jump from $2.4 billion in 2025 to $3.0 billion by 2030. That growth is all about restaurant owners like you trying to get the most out of their space.

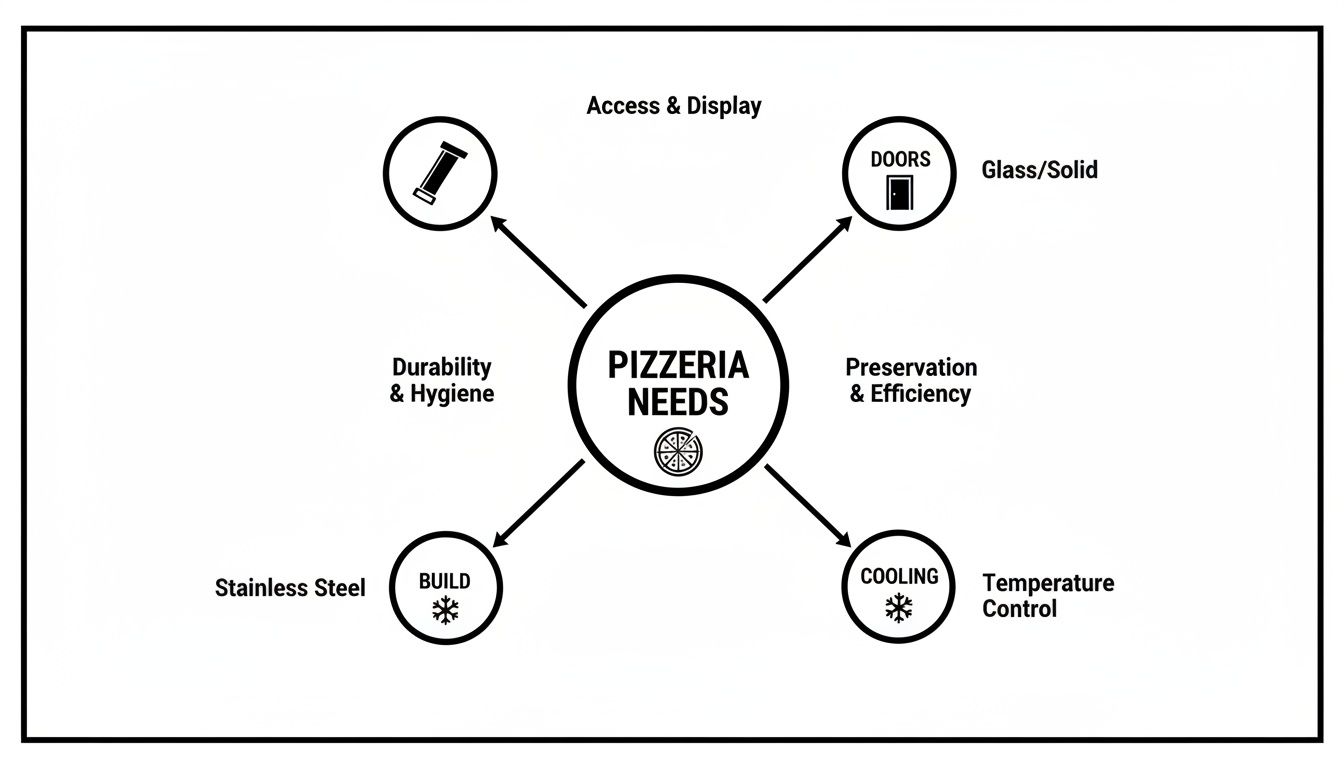

This breakdown shows the key features a pizzeria should be thinking about when picking out a cooler that fits their unique operation.

This visual really hammers home how things like door type, cooling systems, and build quality directly impact how well a unit holds up in the chaos of a pizza kitchen.

Integrating Your Cooler With The Pizza Prep Table

The ultimate goal here is to make the cooler feel like a natural extension of your pizza prep table. Its placement will literally define the rhythm of your entire make-line. In pizzerias, there are two main strategies that just plain work.

1. The Under-Counter Layout

This is, hands down, the most efficient setup for saving space and moving fast. By sliding the back bar cooler directly under the pizza prep table, you create one self-contained, powerhouse workstation.

- Immediate Access: Your toppings, sauces, and dough are right below your workspace. No steps, no wasted motion.

- Reduced Footprint: This is a lifesaver for smaller kitchens where every single square foot is prime real estate.

- Ergonomic Benefits: It cuts down on all the twisting and reaching that wears your staff out during a long shift.

If you go this route, you absolutely must get a front-breathing or front-venting model. These units are built specifically for being tucked into tight spaces. They pull air in and push it out through the front grille, which stops the compressor from burning itself out. A lot of the best under-counter refrigerators are designed this way for exactly this reason.

2. The Adjacent Layout

Got a little more room to play with? Placing the cooler right next to the pizza prep table can also be a killer setup. This essentially creates a dedicated "cold station." One person can focus on managing and restocking ingredients while the pizza maker stays laser-focused on building pies.

This layout is perfect for bigger, high-volume shops where you might have multiple people working the make-line at the same time. It helps keep the workflow organized and stops your crew from tripping over each other.

Essential Technical Considerations

Okay, before you start moving equipment around, take a minute to check the technical stuff. You need to have the right electrical outlet nearby—most commercial coolers need their own dedicated circuit to run safely and efficiently. Also, make sure the floor is level. If it's not, the doors won't seal right and the whole refrigeration system will struggle. A little bit of planning here will save you from some massive installation headaches later on.

The Financial Case For Investing In The Right Cooler

When you're outfitting a pizzeria, it's easy to look at a back bar cooler as just another line item on a long, expensive list. But that’s the wrong way to think about it. The right unit isn't a cost—it's a profit-driving asset. The real value isn't just in keeping your toppings cold; it's in the return on investment (ROI) you get from a faster, more efficient pizza prep table.

Let's do some quick math. Imagine your pizza maker shaves just 10 seconds off the prep time for each pizza because all their ingredients are right there, perfectly organized under the counter. If you sell 200 pizzas on a busy night, that’s a savings of over 33 minutes of labor. Every. Single. Shift. Annually, that simple efficiency gain can add up to hundreds of hours in saved labor costs.

This streamlined workflow means a faster ticket-to-table time, which directly impacts customer satisfaction and how quickly you can turn tables. A well-integrated back bar cooler transforms your pizza prep table into a high-performance workstation, paying for itself through pure operational speed.

Slashing Your Monthly Utility Bills

Beyond labor, the biggest long-term financial impact comes from energy efficiency. Let's be honest, those older, second-hand coolers you see online are often energy vampires. They have worn-out compressors and shot insulation that will absolutely punish your utility bills month after month. Modern units, on the other hand, are engineered for sustainability.

Energy efficiency is a huge deal in the back bar cooler market, with eco-friendly refrigerants like R290 helping to slash carbon footprints. This shift is a key driver behind the market's projected growth from $5.9 billion in 2024 to $13.84 billion by 2034. Restaurants are catching on, adopting these greener alternatives that can cut energy bills by up to 30% in some models while ensuring you meet environmental standards.

The initial cost of an ENERGY STAR® certified cooler might be higher, but the monthly savings on your electricity bill provide a consistent and predictable return. Over the cooler's lifespan, these savings can easily surpass the initial price difference compared to a less efficient model.

Understanding the true cost involves more than the sticker price. You need to do a full Life Cycle Cost Analysis. This approach accounts for the purchase price plus the long-term energy and maintenance costs, giving you a complete financial picture of your investment.

New Vs. Used: The Smart Pizzeria's Checklist

Buying used equipment can seem like a great way to save a few bucks upfront, but it comes with some serious risks. A cheap, used back bar cooler can quickly become a money pit, bleeding you dry with unexpected repair bills and lousy performance. If you're even considering a secondhand unit, you absolutely must inspect it like a hawk.

Here’s a practical checklist for evaluating a used back bar cooler for your pizzeria:

- Check the Compressor: Is it running loudly or constantly? Those are classic red flags for an impending, and expensive, failure.

- Inspect the Door Gaskets: Look for cracks, gaps, or brittleness in the seals. A poor seal means the cooler is leaking cold air and wasting energy 24/7.

- Verify Temperature Consistency: Bring a reliable thermometer and check if the unit actually holds a steady, food-safe temperature. Don't just take the seller's word for it.

- Look for Rust and Damage: Examine the interior and exterior for corrosion or physical damage that could compromise its structure or sanitation.

While the upfront savings of a used cooler are tempting, a new unit gives you reliability and a manufacturer's warranty, protecting you from those costly surprises that always seem to happen on a busy Friday night.

Financing and Warranty: Your Financial Safety Net

A new back bar cooler is a significant purchase, but you don't have to pay for it all at once. Plenty of equipment suppliers offer financing or lease-to-own options that make the investment much more manageable for a new or growing pizzeria. To get a better handle on your options, check out our guide on how to finance restaurant equipment for a breakdown of what might work for your business.

Finally, never, ever overlook the warranty. A solid manufacturer's warranty, especially one that covers parts and labor for the compressor, is your financial safety net. It protects your investment and ensures that if something goes wrong, you won't get slammed with a massive, unexpected repair bill. That peace of mind lets you focus on what really matters—making great pizza.

Maintaining Your Cooler For Peak Performance And Longevity

Let's be honest, a neglected back bar cooler is more than just an eyesore on your pizza prep table. It's a ticking time bomb—a pile of future repair bills and a potential health code violation just waiting to happen. For a busy pizzeria, consistent maintenance isn't some chore you get to when you have time; it's a core business practice.

Think of your cooler's maintenance routine as an insurance policy against chaos. A few minutes of preventive care each day, week, and month can save you from the nightmare of a failed unit during a Friday night rush. This isn't just about extending the cooler's lifespan; it's about protecting your pizza ingredients, your customers, and your bottom line.

Your Pizzeria's Maintenance Playbook

In a pizza kitchen, food safety is everything. Spilled sauce, stray bits of cheese, and rogue toppings can quickly become a breeding ground for bacteria if you're not careful. A disciplined cleaning schedule is completely non-negotiable if you want to prevent cross-contamination and serve a consistently safe, high-quality product.

Here’s a simple but incredibly effective schedule to keep your cooler in prime condition:

- Daily Tasks (5 Minutes): At the end of every single shift, wipe down all interior surfaces. That means shelves, walls, and door liners, all with a food-safe sanitizer. This simple habit stops residue from building up and kills odors from strong ingredients like onions or garlic.

- Weekly Tasks (15 Minutes): Give the door gaskets a good, thorough cleaning using warm, soapy water. When gaskets get dirty or sticky, they create a poor seal, forcing the compressor to work overtime and burn through electricity. A clean gasket means a tight, efficient seal.

- Monthly Tasks (20 Minutes): Now for the big one—cleaning the condenser coils. This is the single most important task you can do to prevent a catastrophic breakdown.

Neglecting the condenser coils is like trying to run a marathon while breathing through a straw. When they get clogged with dust, flour, and grease, the coils can't release heat. This forces the compressor to overheat and, eventually, fail. This is the number one cause of costly refrigeration repairs in a pizzeria.

For a deeper dive into keeping all your equipment in top shape, you can check out these general Top 10 Preventive Maintenance Best Practices.

Troubleshooting Common Cooler Issues

Even with a perfect maintenance routine, you'll probably run into small issues from time to time. Knowing how to spot and fix the common problems empowers your team to handle them before they spiral out of control, saving you a ton of time and money.

Problem 1: Temperature Swings

If you notice the internal temperature is bouncing around, the first thing to check is that the doors are closing properly and the gaskets are sealing tightly. Also, make sure your staff isn't blocking the internal fans with big ingredient bins—that's a classic way to obstruct airflow and create warm spots for your pizza toppings.

Problem 2: Frost Buildup

A little bit of frost is normal, but if you're seeing excessive ice, it almost always points to an air leak. Take a close look at the door seals for any gaps, cracks, or tears. This problem can also pop up if the team is propping the door open for too long during a busy service, letting all that humid pizza kitchen air rush inside.

Problem 3: The Cooler Won't Turn On

Before you pick up the phone and call a technician, run through these basic checks. First, is the unit plugged in securely? It sounds obvious, but you'd be surprised. Next, walk over to your restaurant’s circuit breaker and see if it has been tripped. These two simple steps can often get you back up and running without a service call.

By making these maintenance and troubleshooting habits part of your pizzeria's daily DNA, you transform your back bar cooler from a potential liability into a reliable, long-lasting workhorse.

Beyond The Prep Line How Your Cooler Can Boost Sales

You’ve got your pizza prep table humming and the workflow is smooth. It might feel like your back bar cooler's job is done. But what if that back-of-house workhorse could pull a double shift as a front-of-house money-maker? By placing a second unit right where your customers can see it, you can turn a simple storage box into your best salesperson.

This move is all about tapping into the power of the impulse buy. A sleek, glass-door cooler near the checkout counter or takeout waiting area is an irresistible billboard for high-margin drinks, craft sodas, and grab-and-go desserts. Think about it: a brightly lit case filled with chilled cannolis or tiramisu is hard to ignore.

Turning Wait Time Into Profit

Picture a customer waiting for their pizza on a Friday night. Instead of just scrolling on their phone, their eyes wander over to a display of ice-cold beverages and delicious-looking desserts. Suddenly, that single pizza order turns into a full meal deal. You've just boosted your average ticket size without any extra effort from your staff.

This isn't just a hunch; it's a strategy catching fire across the industry. The global market for these coolers is on a steady climb, projected to hit $2.3 billion by 2033. And restaurants are a massive piece of that pie, valued at $2.1 billion, which shows just how many operators recognize these units as versatile assets. You can explore the full research on back bar coolers to see the trends for yourself.

By merchandising beverages and desserts, a front-of-house cooler pays for itself not just through efficiency, but through direct, incremental sales. It’s an investment in both operational smoothness and customer spending.

This dual-purpose approach proves that every piece of equipment should be contributing to your bottom line. Your back bar cooler isn't just a tool for the pizza prep table; it's a multifunctional asset that bridges the gap between kitchen efficiency and front-of-house profits.

Solving Niche Storage Challenges

Beyond boosting sales, a second cooler can solve some tricky storage problems, keeping your main pizza prep area organized and safe. This is especially important for things like managing allergens or just keeping the kitchen in order.

- Gluten-Free Integrity: A dedicated cooler for gluten-free dough, sauces, and toppings is a game-changer. It eliminates any risk of cross-contamination and shows customers you take their dietary needs seriously.

- Staff Beverages: Keep employee drinks out of the main prep cooler. This simple move prevents clutter and, more importantly, keeps you compliant with health codes that frown on personal items mixing with pizza ingredients.

- Specialty Items: Got some unique, high-value ingredients that need a slightly different temperature? A separate cooler protects their quality without messing up the settings on your primary unit.

In the end, the back bar cooler proves its worth far beyond the pizza line. It’s a smart tool that streamlines your kitchen, drives profitable impulse buys, and solves those nagging storage issues, making it an indispensable part of any smart pizzeria's playbook.

Got Questions? We've Got Answers

Stepping into the world of commercial refrigeration can feel a little overwhelming, especially when you're trying to make a piece of equipment like a back bar cooler work in a busy pizza kitchen. Here are some of the most common questions I hear from pizzeria owners, with straight-to-the-point answers to help you get your pizza prep table dialed in.

Getting these little details right from the start can be the difference between a smooth shift and a chaotic one.

Is a Standard Back Bar Cooler Really Tough Enough for a Pizzeria?

Yes, but you have to pick the right one. While any commercial back bar cooler will hold your toppings, a pizza kitchen is a whole different beast than your average bar. The secret is to find a model with heavy-duty insulation (solid doors are your best friend here) and a forced-air refrigeration system.

Think about it: your cooler doors will be flying open constantly, and the kitchen is hot. Those two features are non-negotiable for keeping your pizza ingredients at a stable, food-safe temperature. A basic beverage cooler will wheeze and struggle to keep up, putting your food quality—and your customers—at risk.

What’s the Smartest Way to Organize Toppings for a Crazy-Busy Service?

Efficiency in a pizzeria is all about a smart layout. Your back bar cooler should be a map of your menu, set up to cut down on extra movements and make building pizzas second nature.

- Your Biggest Sellers Go Front and Center: Put your pepperoni, sausage, and mozzarella in the easiest-to-reach spots. Shaving a few seconds off every single pizza adds up fast on a Friday night.

- Group Ingredients by Pizza: Got a popular specialty pizza? Keep all its unique toppings together in one section. This "pizza kit" approach lets your crew grab everything they need in one fluid motion.

- Use the Same Bins for Everything: Stick with clear, standardized food pans (like third or sixth pans) and label them clearly. It keeps things looking clean and makes it dead simple for anyone on the line to find what they need in a hurry.

Can I Store Dough and Cheese in the Same Cooler?

You bet. A quality back bar cooler is more than capable of handling both your dough and your cheese, since their happy place temperature-wise overlaps nicely. Most pizza pros I know set their coolers between 36°F and 40°F (2°C to 4°C). This is the sweet spot for keeping cheese fresh while also keeping the fermentation of your proofed dough balls in check.

The number one rule when storing different ingredients is to prevent any cross-contamination. Always—and I mean always—keep your dough in its own sealed containers. Make sure every single topping bin has a lid. This is how you maintain the integrity of your ingredients and nail food safety, even when space is tight.

Ready to transform your pizzeria's workflow? At Pizza Prep Table, we specialize in matching your kitchen with the perfect refrigeration solution. Explore our curated selection of high-performance back bar coolers and under-counter refrigerators designed for the demands of a busy pizza prep line. Find the right back bar cooler for your pizzeria today at https://pizzapreptable.com.