Finding the Best Commercial Freezers for Your Pizza Restaurant

Share

For any pizzeria owner, the freezer isn't just a cold box in the back—it's the heart of your operation, directly tied to how smoothly your kitchen runs and the quality of every pizza that goes out the door. The smartest freezer choices work hand-in-hand with your pizza prep tables, making sure everything from dough balls to shredded mozzarella is perfectly frozen but ready to go at a moment's notice. When you get this pairing right, the freezer stops being just an appliance and becomes the engine of your kitchen's productivity.

Choosing the Right Freezer for Your Pizzeria Workflow

Let’s be honest, a great pizza starts with fresh, properly stored ingredients. That makes picking the right commercial freezer one of the most important decisions you'll make for your business, impacting everything from food quality to your bottom line. It isn't a standalone purchase; it's the core of your entire ingredient management system, especially how ingredients flow to your pizza prep tables.

A freezer’s design, capacity, and features have a direct, daily impact on your kitchen’s rhythm. The real goal is to create a seamless flow from freezer to prep table to oven. When your crew can grab frozen toppings or dough without breaking stride, service speed skyrockets. This is where you win or lose the dinner rush.

Linking Freezers to Pizza Prep Tables

The connection between your freezer and your pizza prep tables is fundamental. Think about it: an undercounter or worktop freezer tucked right into the prep line puts high-demand items like specialty meats or extra cheese within arm’s reach. This setup cuts down on wasted steps and shaves precious seconds off the time it takes to build each pizza.

Here are the integration points that really matter for a pizzeria:

- Proximity and Access: Placing smaller, dedicated freezers near the prep station kills travel time across the kitchen. Your pizza makers stay focused on making pizzas, not running errands for dough or pepperoni.

- Inventory Management: A well-placed line freezer makes it obvious when you need to restock your pizza prep table's ingredient rails from the main walk-in, preventing those "we're out of pepperoni!" moments mid-service.

- Temperature Consistency: Moving ingredients from a stable freezer environment directly to a refrigerated prep rail is crucial for maintaining food safety and quality, especially for sensitive items like cheese and meats.

Your freezer shouldn't be an afterthought. It needs to be chosen to support the specific layout and pace of your pizza-making process. The right unit is a direct extension of your prep table, creating one unified, efficient workspace.

Getting a handle on the unique demands of a busy pizzeria is everything. For a deeper look into the mechanics of running a successful shop, checking out resources on pizza restaurant operations can offer some valuable perspective. At the end of the day, the right freezer choice protects your ingredients, streamlines your workflow, and helps drive your profits.

Comparing Key Freezer Integration Styles

Matching the freezer type to your pizzeria's workflow is where the magic happens. A small, neighborhood pizzeria will have different needs than a high-volume shop that’s slinging hundreds of pies a night. A smaller operation might prioritize compact, accessible units that integrate with a single pizza prep table, while a larger one needs a system combining bulk storage with on-the-line speed across multiple prep stations.

| Integration Style | Freezer Type | Ideal For | Workflow Impact |

|---|---|---|---|

| Direct Line Integration | Undercounter / Worktop | High-use toppings & backup dough | Maximizes speed by keeping ingredients right at the pizza prep table. |

| Bulk Storage Support | Reach-In / Walk-In | Bulk cheese, cases of dough, meats | Centralizes your main inventory for efficient restocking of the prep lines. |

Comparing Freezer Types for Pizza Operations

Not every commercial freezer can handle the heat of a pizza kitchen. The right choice isn't just about keeping ingredients frozen; it’s about finding a unit that slots perfectly into your kitchen's rhythm, supports your pizza prep table, and protects your bottom line. Let's look at the main players through the eyes of a busy pizzeria owner.

We'll break down the pros and cons of reach-in, undercounter, chest, and walk-in freezers, but this isn't a generic feature list. It's a real-world comparison to help you match the equipment to your unique pizza prep workflow.

Reach-In Freezers: The Versatile Workhorse

For most pizzerias, the reach-in freezer is the backbone of their cold storage. These upright units strike a perfect balance, offering plenty of storage without demanding a massive footprint—a huge plus in kitchens where every square foot counts. Their vertical shelving makes organizing everything from boxes of pepperoni to bags of shredded cheese a breeze.

When you place a reach-in near the prep line, it becomes a crucial link in your workflow. Staff can quickly grab backups to restock the pizza prep table's refrigerated rails without making a long trek to a back storage room. You can learn more about how a commercial undercounter freezer can optimize your kitchen and see if its versatility is the right fit for your operation.

A reach-in freezer is often the first major freezer investment a pizzeria makes. It's the perfect middle-ground solution, offering significant storage for bulk ingredients without demanding the massive space or investment of a walk-in unit. Its versatility supports growth from a small startup to a bustling local favorite.

Undercounter and Worktop Freezers: The Pizza Prep Line Powerhouse

Undercounter and worktop freezers are the unsung heroes of an efficient pizza line. These compact units slide right under your pizza prep table, putting high-demand frozen items directly at the point of use. This isn't about bulk storage; it's about pure, unadulterated speed.

Imagine having backup portions of specialty toppings, gluten-free dough, or extra cheese right where your crew builds the pizzas. This simple change kills wasted motion and keeps your pizza makers focused. A worktop model takes it a step further, giving you a durable, refrigerated stainless steel surface for extra prep space right next to your main pizza prep table. For high-volume shops obsessed with shaving seconds off ticket times, these are non-negotiable.

Walk-In Freezers: The Bulk Storage Champion

As your pizzeria grows, so does your need for inventory. A walk-in freezer is the ultimate solution for bulk storage, giving you the power to buy ingredients like cheese, dough, and meats by the pallet. That kind of buying power translates into serious cost savings and ensures you never get caught short during a surprise rush.

Think of the walk-in as the central command for your entire ingredient supply chain. It’s the mothership that resupplies your smaller reach-in and undercounter units on the line, which in turn feed the pizza prep table. While it’s a significant upfront investment, its ability to hold a massive inventory is simply unmatched. For multi-location pizzerias or those with a huge delivery operation, a walk-in isn't a luxury—it's essential infrastructure.

Chest Freezers: Niche Applications in a Pizzeria

While you won't see them on the main prep line, chest freezers have their place in a pizzeria. Their design is incredibly energy-efficient because less cold air spills out when you open the lid. They're fantastic for deep-freezing items you don't need to access quickly, like bulk seasonal ingredients or large bags of flour for dough making.

The catch is organization. The top-down access can make finding a specific box of toppings a hassle, which is why they don't work for the fast pace of pizza service. You might find a chest freezer in a back storage area holding bulk dough that gets thawed in batches, but it’s a supporting character, not the star of the show.

A Situational Comparison for Your Pizzeria

Picking the right commercial freezer comes down to understanding these tradeoffs and aligning them with your kitchen layout, pizza prep table setup, and daily volume. The ideal freezer system for a small carry-out spot is worlds apart from what a large, full-service restaurant needs. To make it clearer, here’s a breakdown of how each type fits into different pizzeria scenarios.

Commercial Freezer Comparison for Pizzeria Applications

This table provides a situational analysis of different freezer types, helping pizzeria owners match the right equipment to their operational needs and kitchen layout.

| Freezer Type | Best For | Pizza Prep Workflow Integration | Space Consideration | Ideal Operation Size |

|---|---|---|---|---|

| Reach-In Freezer | General-purpose storage of cheese, toppings, and backup dough. | Acts as a secondary storage hub near the prep line for quick restocking of the pizza prep table. | Moderate footprint, fits in most kitchen lines. | Small to Medium Pizzerias |

| Undercounter/Worktop | Point-of-use storage for high-demand items directly at the prep station. | Integrates directly under the pizza prep table for maximum efficiency. | Minimal footprint, built into the prep line. | Medium to High-Volume |

| Walk-In Freezer | Bulk purchasing and long-term storage of palletized inventory. | Serves as the central inventory source for restocking all line freezers that support pizza prep tables. | Requires significant dedicated space, often in a back room. | High-Volume & Multi-Location |

| Chest Freezer | Long-term, deep-freeze storage of infrequently accessed bulk items. | Minimal direct integration; used for backroom dough or ingredient storage. | Flexible, but requires clear floor space for the lid. | Any size, for specific needs |

Ultimately, the most efficient pizzerias create a system using a mix of these types. A walk-in holds the bulk supplies, a reach-in handles the daily overflow, and undercounter units provide lightning-fast access right at the pizza prep table. This combination creates a powerful and streamlined ingredient management system that keeps up with any rush.

Matching Freezer Specs to Your Kitchen and Menu

Once you've picked a general freezer type, the real work starts. The spec sheet is where the rubber meets the road—it dictates how a unit will actually perform in your pizza kitchen day in and day out. Learning to decode these numbers is the key to finding a freezer that truly fits your pizzeria's unique rhythm.

This isn't about marketing fluff; it's about the numbers that matter to a pizza operation. We’ll get into calculating the right capacity for your inventory, why temperature range is non-negotiable for dough and cheese quality, and how things like defrost systems and door types will impact your workflow and energy bills.

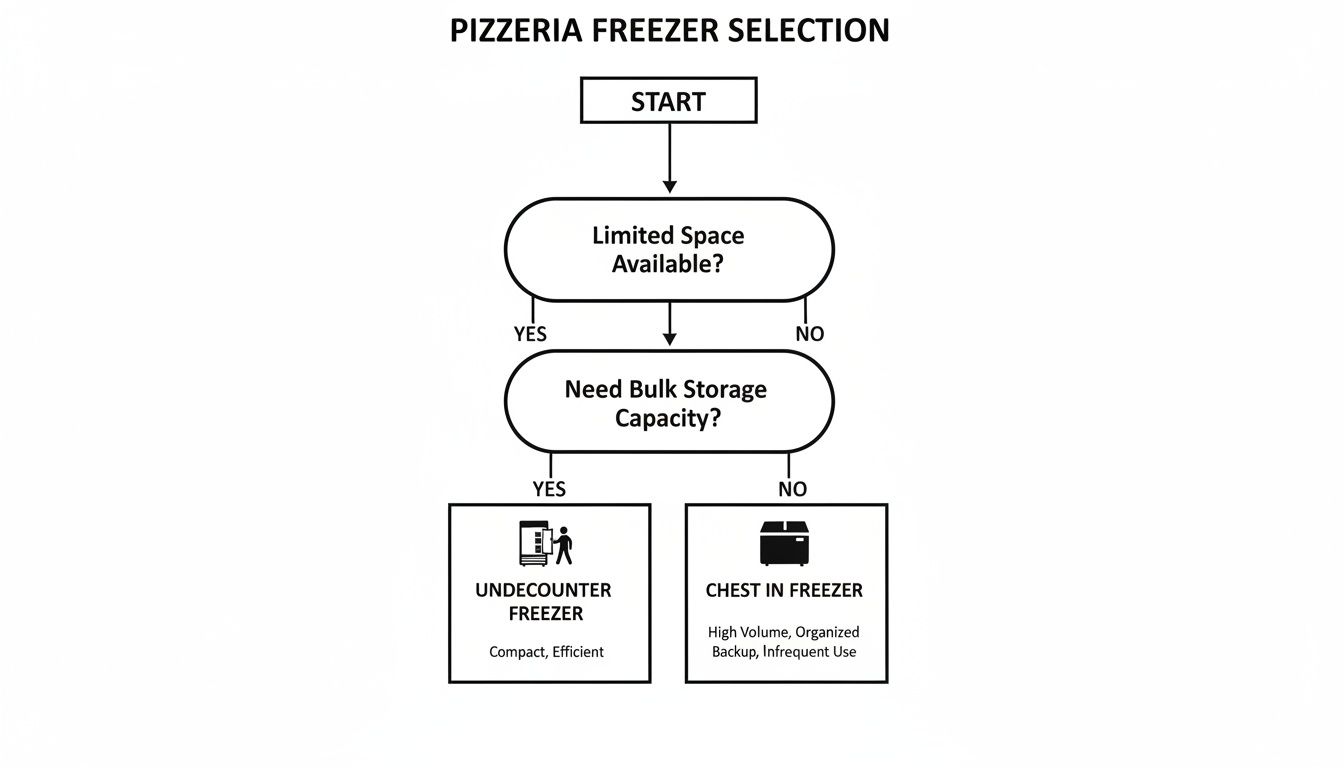

This decision tree is a great starting point for narrowing things down based on your kitchen's layout and how much you need to store.

As you can see, the first big choice between a space-saving under-counter unit for your prep table and a bulk-storage walk-in really just comes down to physical space and how much inventory you move.

Calculating Your Required Capacity

Freezer capacity, measured in cubic feet, is one of the most important specs to nail down. Go too small, and you’ll constantly be playing inventory Tetris and miss out on bulk-buy savings on cheese and toppings. Go too big, and you're just paying to cool empty air.

To figure out your sweet spot, start by auditing your weekly frozen goods. Tally up the space you need for:

- Cases of dough balls

- Bags of shredded mozzarella and other cheeses

- Boxes of pepperoni, sausage, and other high-volume toppings

A solid rule of thumb is to shoot for a capacity that can hold 1.5 times your peak weekly inventory. This buffer gives you breathing room for supplier delays and lets you handle those unexpected rushes, like a last-minute catering order. For a smaller pizzeria, a 23-cubic-foot reach-in might be perfect, while a high-volume place could easily need 49 cubic feet or more to support its pizza prep tables.

Temperature Range and Stability

For any pizzeria, ingredient integrity is everything. The ideal temperature for long-term storage of dough, cheese, and meats is between 0°F and -10°F. This narrow range is critical for stopping freezer burn, preventing bacterial growth, and preserving the texture and flavor that make your pizza great.

When you're looking at spec sheets, hunt for units that can hold this temperature rock-steady, even when your kitchen feels like a furnace. A powerful compressor and quality insulation are the two biggest clues that a freezer can maintain that deep, stable cold needed to protect your pizza ingredients.

A freezer that fluctuates even a few degrees can ruin the quality of your cheese and mess with the proofing potential of your dough. Consistent, deep-cold temperatures aren't a "nice to have"—they're a non-negotiable feature for protecting your most important ingredients.

Defrost Systems and Door Types

The defrost system might feel like a minor detail, but it has a huge impact on maintenance and food quality. Automatic defrost systems are incredibly convenient and stop ice from building up. The trade-off is they briefly raise the internal temperature to melt frost, which can impact really sensitive items. Manual defrost freezers keep a more consistent temperature but require you to shut them down for cleaning. For a busy pizzeria, an automatic system is almost always the more practical choice.

When it comes to doors, you’re choosing between convenience and efficiency.

- Solid Doors: These offer way better insulation, making them more energy-efficient. This is the go-to choice for back-of-house units where temperature stability is the absolute priority.

- Glass Doors: They give you great inventory visibility, so staff can find what they need without opening the door and letting cold air out. The downside? They’re less efficient and can struggle to hold temp in a hot kitchen next to a pizza oven.

For maximizing your workflow in tight spots, under-counter freezers placed right in the prep line are a total game-changer. You can check out detailed guides on selecting the right commercial undercounter freezer to see how these compact units can be integrated for maximum impact. They give your pizza makers instant access to key items, perfectly complementing a larger reach-in or walk-in that handles the bulk storage.

The Critical Role of Energy Efficiency and NSF Certification

A commercial freezer is a long-term relationship, and the sticker price is just the first date. The real cost of ownership comes down to two things that often get ignored in the rush to get a pizza kitchen running: energy bills and food safety compliance.

These aren’t just boring technical details; they’re the silent partners that will either pad your profits or drain your bank account. Choosing the right freezer means looking past the shiny stainless steel to see how it will perform financially over its entire lifespan. An inefficient freezer will quietly eat away at your profits, while a non-certified unit is a ticking time bomb with health inspectors.

Decoding ENERGY STAR and Its Impact on Your Bottom Line

When you see that blue ENERGY STAR label, it's not just marketing fluff. It’s a guarantee that the freezer is built to be more efficient than standard models, and the difference is significant. These units use high-performance compressors, better insulation, and smarter motors to keep your dough and cheese frozen while sipping, not gulping, electricity.

For a pizzeria, refrigeration is a massive, non-stop expense. The savings from an efficient freezer add up fast. A single ENERGY STAR certified freezer can put hundreds of dollars back in your pocket every year—money that could cover a few cases of mozzarella or go toward a new marketing push.

Let’s be real: commercial refrigeration systems are energy hogs, sometimes accounting for a staggering 40% of a restaurant's total energy use. Switching to energy-efficient freezers can slash those electricity bills by 20-25%. That’s a direct boost to your bottom line. This trend is a big reason the commercial refrigeration market is projected to jump from USD 85.6 billion in 2024 to USD 161 billion by 2034, as highlighted in these commercial refrigeration market insights.

The Shift to Eco-Friendly Refrigerants Like R290

The type of gas running through your freezer’s veins is another critical piece of the puzzle. Old-school refrigerants like R404A are on their way out because of their high Global Warming Potential (GWP). The industry is now moving to eco-friendly options, with R290 (propane) leading the charge.

R290 is a natural hydrocarbon that's non-toxic and has a very low GWP, making it the responsible choice. But here’s the kicker for your business: it's also a highly efficient refrigerant. Freezers using R290 often recover temperature faster after the door is opened and use less energy to maintain it. Choosing a freezer with R290 is simply a smart, future-proof move that keeps you ahead of environmental regulations.

Choosing a freezer with R290 refrigerant is a smart move for any pizzeria. It not only reduces your carbon footprint but also typically leads to a more efficient and responsive cooling system, protecting your ingredients and lowering your operating costs.

Understanding the financial benefits of modern equipment is key. You can learn more by exploring our detailed breakdown of energy-efficient commercial refrigeration and how it impacts a restaurant's budget.

Why NSF Certification Is Non-Negotiable

Let me be blunt: if a freezer isn't NSF certified, it has no business being in a professional pizzeria. Period. The NSF (National Sanitation Foundation) certification is the gold standard for food safety. It’s your guarantee that the equipment is designed to be easily cleaned and to prevent food contamination.

Here’s what that NSF seal really means for your pizzeria:

- Safe Materials: Any surface that touches your food is non-toxic and won't corrode over time.

- Hygienic Design: The freezer is built with smooth surfaces and coved corners. There are no cracks or crevices where flour dust and bacteria can hide.

- Performance Standards: The unit has been rigorously tested to prove it can hold safe, consistent temperatures in a real, chaotic pizza kitchen environment.

Using non-certified equipment is like waving a giant red flag at a health inspector. It can lead to hefty fines or, in worst-case scenarios, a forced shutdown. For a pizzeria owner, NSF certification isn't a feature—it's your insurance policy, protecting both your customers and your business license.

Maximizing Your Investment with Smart Financing and Maintenance

Getting the best commercial freezer for your pizzeria is a huge step, but making that investment work for you long-term is what really counts. The goal is to protect your equipment and your cash flow, ensuring your freezer remains a workhorse asset, not a financial headache.

Think of smart financing and proactive maintenance as two sides of the same coin. One gets the right equipment into your kitchen without emptying your bank account, while the other keeps it running like a top for years, protecting your inventory and preventing those dreaded emergency repair calls. It's a powerful one-two punch for getting the most out of your investment.

Smart Financial Options for Pizzeria Owners

For most independent pizzerias, that big upfront cost is the toughest hurdle to clear. A high-quality commercial freezer isn't cheap, but financing options like lease-to-own plans can make them much more attainable. These plans let you get top-tier equipment in your kitchen with predictable, manageable monthly payments, freeing up your cash for other critical things like marketing or payroll.

This kind of financial flexibility is a lifesaver, especially for new shops. The North American commercial refrigeration market is on track to grow from USD 17.75 billion in 2025 to USD 22.12 billion by 2030, and a lot of that is driven by restaurant growth. For a startup, grabbing an energy-efficient model that cuts running costs by 15-20% is a massive win. Pair that with a lease, and suddenly premium equipment becomes a smart, viable choice right from day one. You can read the full research on commercial refrigeration trends to see just how big this market is getting.

A lease-to-own plan isn't just about kicking a payment down the road; it's a strategic move. It lets you equip your pizza prep line with the ideal freezer now, so it can start generating the revenue that helps pay for itself as you grow.

A Practical Checklist for Preventative Maintenance

Once your freezer is humming away in the kitchen, the game shifts to preservation. A consistent maintenance routine is the single best way to extend its lifespan, keep it efficient, and protect the thousands of dollars of cheese, dough, and toppings you have stored inside. Trust me, neglect is the fastest way to rack up emergency repair bills and toss out spoiled inventory.

Regular upkeep is just plain smart for any major piece of kitchen equipment. For a bigger-picture view on keeping your kitchen's core systems in shape, it's worth looking into commercial equipment servicing strategies. The same principles apply directly to your freezers.

Here’s a simple, no-nonsense checklist to keep your commercial freezer in peak condition:

-

Clean Condenser Coils Monthly: The coils are your freezer's lungs. In a pizza kitchen, they get caked with flour dust and grease in no time, forcing the compressor to work harder and suck down more energy. A quick monthly brushing keeps them breathing easy.

-

Inspect Door Seals Weekly: The gaskets are the guardians of your cold air. Give them a quick check for cracks, tears, or brittleness. A leaky seal lets cold air pour out, causing temperature swings and higher energy bills. Try the dollar bill test: if you can slide a bill out easily when the door is closed, it's time for a new gasket.

-

Monitor Temperature Accuracy Daily: Don't just rely on the external display. Stick an independent thermometer inside to make sure it’s holding a steady temperature between 0°F and -10°F. This quick daily check is your first warning if a thermostat or compressor is starting to fail.

-

Keep the Interior Organized and Clean: Good organization isn't just about workflow; it promotes better airflow, which is critical for consistent cooling. Wipe up spills right away to stop ice from building up and prevent any chance of contamination.

By weaving these simple tasks into your weekly routine, you shift from reacting to problems to preventing them. This discipline stops most common freezer failures in their tracks, saves you real money on your utility bills, and ensures your ingredients are perfectly preserved for every single pizza you sell.

Your Top Commercial Pizza Freezer Questions Answered

Even when you think you’ve got it all figured out, a few specific questions always pop up right before you’re about to invest in a major piece of equipment like a commercial freezer. Getting these details right can be the difference between a good purchase and the perfect one for your pizzeria. I've heard them all over the years, so let's tackle the most common ones pizza shop owners ask.

We’ll get into the nitty-gritty of calculating capacity, clear up the confusion between similar-looking models, and settle the debate on crucial features like where the compressor should live.

How Do I Figure Out the Right Freezer Size for My Pizzeria?

Calculating freezer size has less to do with the physical footprint and more to do with your inventory flow. Start by tracking your weekly usage of core frozen items—dough balls, shredded mozzarella, and heavy hitters like pepperoni. A solid rule of thumb I always recommend is to get enough capacity to hold 1.5 times your peak weekly inventory.

That buffer is your safety net. It lets you handle a surprise catering order or a supplier delay without sweating it. For a small to mid-sized shop, a 20 to 30 cubic foot reach-in freezer usually hits that sweet spot. But if you’re a high-volume powerhouse or you save money by buying ingredients in bulk, you’ll want to look at a 49 cubic foot model or even a dedicated walk-in freezer to support your pizza prep table.

Here's a pro tip that's saved countless operators a massive headache: Before you click "buy," measure your kitchen's entryway, hallways, and the spot where the freezer will live. The best freezer in the world is just an expensive doorstop if you can't get it inside.

What's the Real Difference Between a Worktop and an Undercounter Freezer?

While they both look like space-savers designed to slide under a counter, their jobs are completely different, and it all comes down to the top surface.

- An undercounter freezer has a simple, flat top. It’s built to disappear under an existing counter or pizza prep table, adding cold storage without taking up new floor space.

- A worktop freezer is designed to be an active part of your prep line. It has a beefed-up stainless steel top, often with a backsplash, ready to handle light prep work.

For a pizza station, the worktop freezer is almost always the smarter move. It turns a storage unit into a dual-purpose powerhouse, giving your crew precious, refrigerated prep space right in the middle of the action. This kind of integration with your main pizza prep table is how you shave seconds off every order and speed up the entire pizza-making process.

Should I Get a Bottom-Mount or Top-Mount Compressor?

The compressor's location is a bigger deal than you might think. It directly affects your freezer's performance and maintenance needs, especially in a pizza kitchen.

For pizzerias, a top-mount compressor is typically the hands-down winner. Why? It breathes in cooler, cleaner air from above the floor, far away from the flour dust, grease, and other debris that inevitably coat a kitchen floor. This means less strain on the unit, better energy efficiency, and fewer calls for coil cleaning.

A bottom-mount compressor, on the other hand, is more ergonomic since it raises the bottom shelf to an easier-to-reach height. The tradeoff is that it sucks in warmer air from floor level and is a magnet for all that pizza kitchen dust, forcing it to work harder and demand more frequent cleaning to avoid burning out. For the long haul, a top-mount unit is the safer bet for most pizzerias.

Are Glass Door Freezers a Good Idea in a Pizza Kitchen?

Glass door freezers have one obvious perk: you can see what’s inside. This lets your staff find things in a hurry without opening the door, which can speed things up just a little during a rush.

But that convenience has a price. Glass just isn't as good an insulator as a solid, foam-filled door, which makes these freezers less energy-efficient. In a hot pizza kitchen, the compressor on a glass door model will be running constantly to hold its temperature, and you’ll see the difference on your utility bill.

For back-of-house storage where rock-solid temperature and efficiency are king, a solid door freezer is the better choice. The small advantage of visibility is easily outweighed by the long-term energy savings and superior temperature stability a solid door offers next to a blazing hot pizza oven.

Ready to build the perfect pizza prep line? At Pizza Prep Table, we specialize in providing the best commercial freezers and refrigerated prep tables that empower pizzerias to achieve maximum efficiency and quality. Explore our curated selection of NSF-certified, energy-efficient equipment designed for the demands of your kitchen. Find your ideal setup at https://pizzapreptable.com and start building better pizzas today.