Best Commercial Deep Fryer & Pizza Prep Table Guide for Pizzerias

Share

A commercial deep fryer is a high-volume workhorse designed to cook massive amounts of food by submerging it in hot oil. It's the secret to those perfectly crispy wings, fries, and appetizers that customers crave. For a pizza restaurant, it’s a game-changer, letting you expand your menu far beyond just pies. Suddenly, you're not just a pizza joint; you're a full-service spot capturing a bigger slice of every order.

Your Pizzeria's Unsung Hero: The Pizza Prep Table

Picture the Saturday night rush. Dough is being tossed, cheese is flying, and the order tickets are stacking up. Right in the middle of this controlled chaos sits the pizza prep table. It's the command center that dictates your pizzeria's speed, efficiency, and ultimately, its profit. While a commercial deep fryer adds menu variety, the prep table is where your signature product is born.

This guide will look past the technical jargon to show you why the right pizza prep table is a strategic investment in your quality and workflow. It's so much more than a refrigerated counter—it’s the anchor of your entire pizza production line.

The Foundation of Your Pizzeria's Workflow

Think of your pizza prep table as your kitchen's assembly line. A poorly designed one creates frustrating bottlenecks, slows everyone down, and leads to sloppy, inconsistent pizzas. But a great one? It ensures every single ingredient is perfectly chilled, within easy reach, and ready to go. This one piece of equipment impacts everything from how fresh your toppings are to how fast a pizza gets to the oven.

The goal is to find a pizza prep table that actually works for your pizzeria, not against it. That means you need to think about how your team moves, what your menu requires, and the physical space you have to work with.

A great pizza prep table doesn't just hold ingredients; it organizes your entire pizza-making process. By keeping everything chilled and accessible, it minimizes wasted motion and maximizes output, directly influencing your bottom line during peak hours.

More Than Just Refrigeration

Today’s pizza prep tables are highly specialized pieces of equipment, engineered to maintain food safety and quality in the most demanding pizzeria environments. They make sure your pepperoni, mushrooms, and cheese stay within that critical food-safe temperature zone, even when the lids are open during a relentless dinner rush. That kind of reliability is fundamental to your pizza restaurant's reputation.

This demand for dependable and efficient equipment is an industry-wide trend. The global commercial refrigeration equipment market was valued at USD 33.68 billion in 2023 and is projected to hit USD 57.51 billion by 2033. This surge is powered by a growing foodservice industry and a rising need for advanced gear like high-performance pizza prep tables.

As you perfect your pizzeria with equipment like prep tables and a commercial deep fryer, it's also worth looking into comprehensive solutions for the restaurant industry that can help optimize your entire operation, from the kitchen line to customer service. Now, let's get you ready to choose the perfect pizza prep table for your kitchen.

Standard Models vs Mega Top Pizza Prep Tables

When you start shopping for a pizza prep table, you'll quickly run into two main styles: the Standard Top and the Mega Top. This isn't really a "which one is better" debate. It's about finding the right fit for your pizzeria's menu, your kitchen's flow, and how many pies you're slinging on a busy Friday night. Getting this choice right can make or break your team's efficiency during a rush.

Standard Top: The Classic Pizzeria Workhorse

Think of a Standard Top pizza prep table as the reliable, everyday workhorse. It’s the industry classic for a reason. These units come with two rows for ingredient pans, which is more than enough space for the core toppings of a traditional pizzeria. If your menu is focused and straightforward, this is your go-to.

Mega Top: The High-Capacity Beast for Pizzerias

The Mega Top is built for one thing: capacity. By adding a third row of pans, it gives your team a massive amount of real estate for toppings. This is an absolute game-changer for pizzerias that offer sprawling menus, build-your-own options with tons of ingredients, or also pump out a lot of complex sandwiches and salads.

Let Your Pizzeria's Menu Be Your Guide

The best way to decide is to take a hard look at your menu.

If you’re a classic pizzeria that thrives on pepperoni, mushrooms, and sausage, a Standard Top pizza prep table will serve you perfectly. Its two-row setup keeps your most popular ingredients right at your fingertips, which is key for a fast, consistent assembly line.

But what if your menu is loaded with a dozen specialty pizzas and over 30 different toppings for custom orders? That’s when a Mega Top stops being a luxury and becomes a necessity. That third row means every single ingredient has its own chilled, organized spot, cutting down on cross-contamination and saving your pizza makers from constantly running to another cooler.

A well-equipped pizza prep station is all about ergonomics. For a busy shop, a Mega Top table can slash a cook's wasted movement and physical effort by up to 50%. By putting everything they could possibly need right in front of them, you turn a chaotic scramble into a smooth, efficient flow.

A Quick Comparison for Your Pizza Restaurant

Here’s a side-by-side look at the key differences to help you decide which pizza prep table style fits your pizzeria's workflow and menu.

Standard Top vs. Mega Top Pizza Prep Table Comparison

| Feature | Standard Top Table | Mega Top Table |

|---|---|---|

| Pan Rows | Two rows of pans | Three rows of pans |

| Best For | Traditional, focused pizza menus | Extensive menus, build-your-own concepts, sandwiches & salads |

| Footprint | Standard depth, better for tight pizza kitchens | Deeper, requires more floor space |

| Workflow | Streamlined for essential pizza toppings | Maximum ingredient consolidation in one station |

This table makes it clear: the choice hinges on balancing your ingredient needs against your available space.

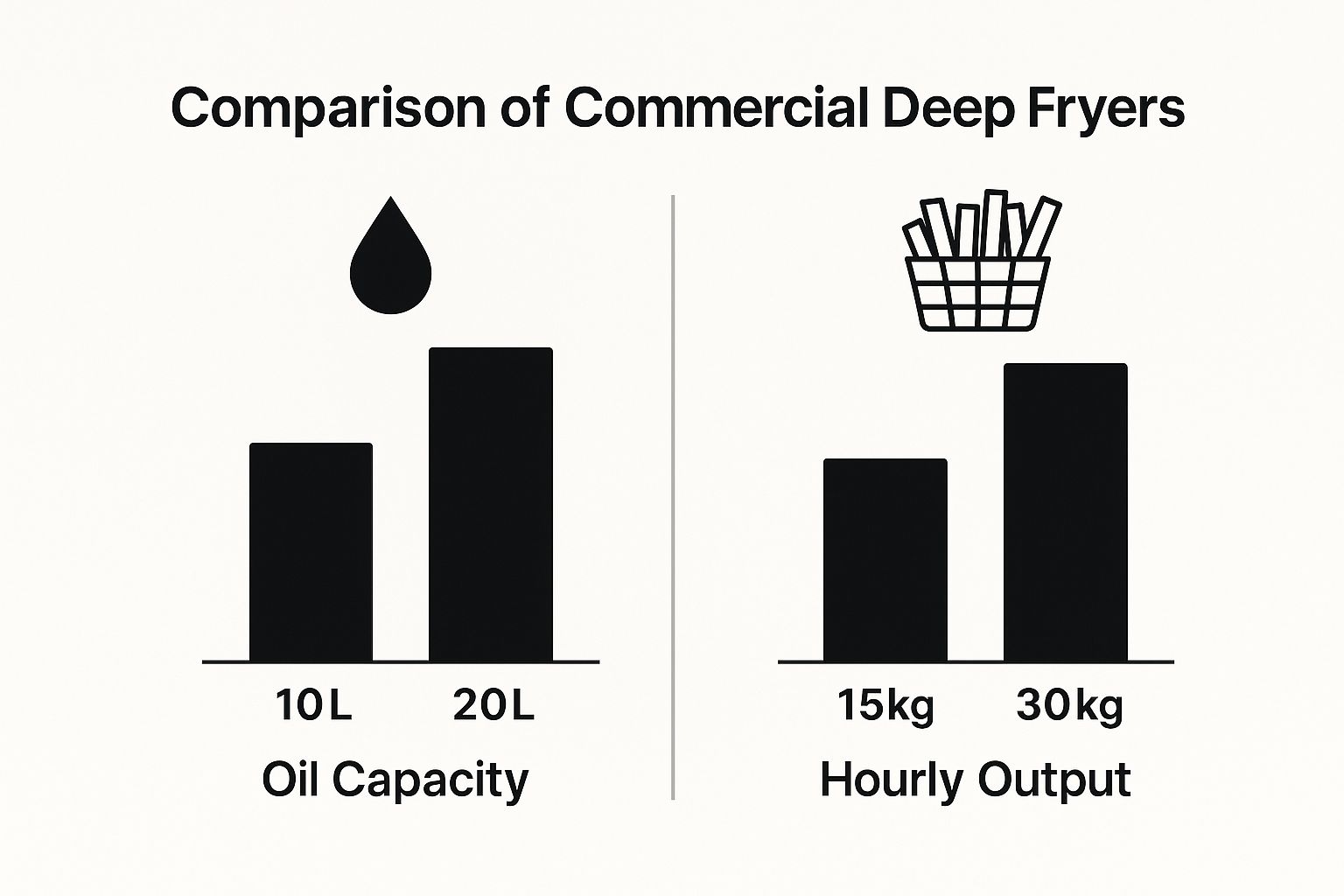

Just as your pizza prep table keeps cold ingredients organized, a great commercial deep fryer is essential for expanding your hot menu with items like wings and mozzarella sticks. Choosing a fryer involves the same logic—you have to match its capacity to your volume. This visual shows just how much output you gain by stepping up in size.

As you can see, jumping from a 10L to a 20L commercial deep fryer literally doubles your potential hourly output. That’s a massive difference and a critical detail when you’re trying to keep up with demand for appetizers during peak hours.

Don't Forget About Pizzeria Space and Workflow

Your pizzeria's layout plays a huge role here. To fit that extra row of pans, Mega Top tables are physically deeper than Standard Top models—often by 4 to 8 inches. That might not sound like much, but in a cramped pizza kitchen, it can be the difference between a smooth workflow and a constant bottleneck.

Get out the tape measure before you buy a pizza prep table. Make sure you'll have enough room for your staff to move around the table safely and without bumping into each other.

- A Standard Top is a lifesaver in narrower kitchens. Its shallower depth helps preserve that precious floor space.

- A Mega Top needs a bit more room to breathe, but it consolidates so many ingredients that it might save you from needing a whole separate prep cooler.

In the end, it’s a simple trade-off: do you need more ingredient capacity or more physical floor space? The right table should feel like an extension of your pizza maker's hands, not a constant obstacle. And if you're looking to add some serious firepower to your hot line, check out these propane-powered commercial deep fryers that bring the heat to see how you can maximize your kitchen's potential.

Features That Boost Pizzeria Speed and Freshness

Deciding between a standard and a mega top pizza prep table is the first step, but the real magic is in the details. The specific features built into your unit are what elevate a simple cooler into a high-octane pizza-making station. These might seem like minor points on a spec sheet, but when the dinner rush hits, they make all the difference in your team’s speed, ingredient quality, and the final product.

Beyond its physical size, a pizza prep table’s main job is to solve a huge pizzeria challenge: keeping toppings perfectly chilled and food-safe, even when the lids are flying open every few seconds. This is where the refrigeration system becomes the unsung hero, quietly guarding the freshness of every ingredient.

Keeping Your Cool Under Pressure

Think of an invisible blanket of cold air hovering over your pepperoni and peppers, shielding them from the pizza kitchen's heat. That’s the basic idea behind features like Forced-Air Refrigeration and Air Curtains. These aren't just fancy buzzwords; they're essential technologies for any pizzeria that takes quality seriously.

A basic refrigeration unit can really struggle to recover its temperature once the lid is opened. An advanced system, on the other hand, constantly circulates cold air around and over the ingredient pans. This consistent airflow ensures even the toppings at the very top of the pan stay safely chilled—a must for passing health inspections and serving a great pizza.

A pizza prep table with a powerful forced-air system can keep ingredients up to 10°F cooler than a basic model during a busy service. This technology is your best defense against the temperature danger zone, cutting down on food waste and keeping your customers safe.

This focus on top-tier equipment makes sense when you look at the industry's growth. The global pizza market was valued at a massive USD 197.8 billion in 2023 and is only getting bigger. That kind of demand requires specialized gear that can keep up without cutting corners.

The Pizza Prep Surface: Your Cutting Board and Stage

The cutting board on your pizza prep table is more than just a place to put things—it's the stage where every single pizza is built. The material you choose has a direct impact on your workflow, how long the unit lasts, and even how your pizza tastes.

- Polyethylene: This is the workhorse of the pizza industry, and for good reason. It's tough, non-porous, and a breeze to clean. High-density polyethylene boards can take a beating from constant slicing and won't hang onto odors or bacteria. Best of all, they're easy to replace, making them a smart, cost-effective choice for most pizza restaurants.

- Marble: If you stretch dough right on the line, a marble top is an incredible upgrade. Marble is naturally cool to the touch, which keeps dough from getting sticky or tough. The result is a lighter, more tender crust. It definitely requires more care and a bigger upfront investment, but for pizzerias dedicated to the craft of hand-stretched pies, the quality it adds is undeniable.

Your choice really comes down to your process. If the pizza prep table is just for saucing and topping, polyethylene is the practical way to go. If the art of the stretch is part of the show, marble is worth a serious look.

Ergonomics in Action: Drawers and Raised Rails on Pizza Prep Tables

A smooth-running pizzeria is all about eliminating wasted movement. Smart features like heavy-duty drawers and raised rails on a pizza prep table are designed to put everything your crew needs right at their fingertips, turning a clunky process into a seamless one.

Take a raised rail, for example. It elevates the ingredient pans and angles them slightly toward the pizza maker. It’s a subtle tweak, but over a long shift, it reduces back and wrist strain, making the entire prep process faster and more comfortable.

Likewise, choosing a pizza prep table with drawers instead of simple cabinet doors can be a game-changer for your daily operations.

Why Drawers Beat Doors for Pizzerias:

- Speed: Pull open a drawer, and you see everything inside at a glance. No more kneeling down and digging around in a dark cabinet to find what you need.

- Organization: Drawers are perfect for stashing extra bags of cheese, sauce containers, or backup dough balls, keeping them chilled and organized right where the action is.

- Space: In a cramped pizza kitchen, a swinging cabinet door can be a real obstacle. A drawer pulls straight out, keeping walkways clear for your team.

While these features will streamline your pizza line, a truly profitable menu often goes beyond pies. Many pizzerias boost their sales with fried appetizers like wings, mozzarella sticks, and fries made in a commercial deep fryer. To do that, you'll want to learn how you can electrify your menu with these commercial electric deep fryers and easily expand your offerings.

Choosing Your Pizza Prep Table's Cooling System: Side vs. Rear Mount

It’s easy to get laser-focused on the size and features of a pizza prep table, but one of the most practical decisions you'll make is where the cooling system's compressor is located. This isn't some minor technical detail—it directly impacts your kitchen's layout, ambient heat, and how much of a headache the unit will be to maintain.

Think of the compressor as the engine of your pizza prep table. It's working constantly to pull heat out of the cabinet and keep your ingredients perfectly chilled. And just like any engine, it needs to breathe. Where it gets that air—from the side or the back—is a choice with real consequences for your pizzeria's workflow and future repair bills.

Let's break down the practical trade-offs.

Rear-Mounted Systems: The Pizzeria Space Saver

A rear-mounted compressor is your go-to when every inch counts in a pizza kitchen. With the entire cooling mechanism tucked neatly at the back, the pizza prep table can sit much closer to a wall. In a cramped kitchen where floor space is prime real estate, this can feel like a lifesaver.

But this compact design has a major catch: airflow. A rear-mounted unit pulls air from the back, so you absolutely must leave several inches of clearance between the unit and the wall. Shoving it flush against the wall is like asking someone to run a marathon while holding their breath. The compressor will overheat, struggle to keep up, and eventually burn out.

A shockingly common mistake that voids warranties and leads to expensive service calls is failing to leave enough clearance. Most manufacturers require 3-5 inches of open space around the back and sides for proper ventilation on a pizza prep table.

This design also makes routine maintenance a real chore. To clean the condenser coils—a critical task for keeping the unit efficient—your staff has to pull the whole heavy pizza prep table away from the wall. Let's be honest, that hassle means it often gets skipped, leading to higher energy bills and a shorter lifespan for your equipment.

Side-Mounted Systems: The Maintenance Hero for Pizza Restaurants

On the other hand, a side-mounted compressor is the undisputed maintenance hero for a busy pizza restaurant. The entire cooling system is housed on one side (usually the right), making it a breeze to access for cleaning and repairs. Your team can just pop off a side panel to clean the coils without wrestling the table out of place. This simple access makes it far more likely that essential upkeep will actually happen.

Side-mounted units are also generally better at handling the heat of a busy pizzeria. They draw in cooler air from the side of the unit, not from the hot, stagnant air pocket that can get trapped behind it. Better airflow means the compressor runs more efficiently, uses less energy, and suffers less strain—a huge advantage in a hot kitchen with pizza ovens and a commercial deep fryer blasting all day.

The obvious downside? You need that side clearance. A side-mounted pizza prep table can’t be installed right next to another piece of equipment or a wall. It needs room to breathe, which can throw a wrench in your kitchen line design.

Making the Right Choice for Your Pizzeria

So, which one is for your pizza restaurant? It really boils down to your kitchen's layout versus your long-term operational goals.

-

Choose a rear-mounted unit if: You’re in a tight spot and absolutely need to maximize every inch of floor space in your pizzeria. Just be ready to enforce a strict rule about leaving that gap behind it and factor in the extra labor for maintenance.

-

Choose a side-mounted unit if: You have a little more wiggle room in your layout and value long-term efficiency and easy maintenance. The simplified cleaning and potentially longer lifespan of your pizza prep table will almost certainly save you money and headaches in the long run.

Ultimately, the best pizza prep table is the one that fits your space and encourages the regular care needed to protect your investment. A little planning now will keep it running smoothly for years to come.

Commercial Deep Fryer Installation and Maintenance for Your Pizza Restaurant

Think of your new commercial deep fryer as a long-term investment in your pizzeria's success. Like any piece of high-performance equipment, how you treat it from day one makes all the difference. Proper installation isn't just about getting it up and running; it's about setting the stage for safety, efficiency, and a long, productive life in your pizza restaurant.

From there, a simple but consistent maintenance routine will protect that investment. This isn't about adding a bunch of complicated chores to your list. It’s about building smart habits that prevent costly breakdowns, keep your food quality high, and ensure your kitchen runs smoothly.

Setting Up Your Commercial Deep Fryer for Success

One of the most common mistakes we see with new commercial deep fryer installations is failing to give the unit enough breathing room. Your fryer generates a tremendous amount of heat, and if it's crammed against a wall or other equipment, that heat has nowhere to go. This can create a serious fire hazard and cause the fryer to overheat, leading to premature failure.

Always follow the manufacturer's guidelines for clearance, but a good rule of thumb is to leave at least 6-12 inches of space on all sides and behind the unit. It’s also absolutely critical to ensure the fryer is perfectly level. An uneven commercial deep fryer means uneven oil levels, which leads to food cooking inconsistently—some pieces burnt, others undercooked.

Building a Simple Maintenance Routine for Your Fryer

The secret to a long-lasting commercial deep fryer isn't some complex, time-consuming process. It's all about consistency. Breaking down maintenance into daily, weekly, and monthly tasks makes it completely manageable and ensures nothing critical gets missed in your busy pizza restaurant.

Start with the simple stuff. Daily tasks should include wiping down the exterior and checking the oil quality. On a weekly basis, you'll want to do a full boil-out to remove carbonized gunk from the frypot. These small, consistent actions are your best defense against bigger, more expensive problems down the road.

Your commercial deep fryer is a workhorse that directly impacts your profits. A disciplined maintenance schedule isn't just another task—it's a core strategy for extending equipment life, ensuring food safety, and avoiding the chaos of an unexpected breakdown during a dinner rush.

The Monthly Deep Fryer Deep Dive

Once a month, it’s time for a more thorough check-up. This is when you'll want to inspect the heart of the unit—the burners, gas lines (for gas models), or heating elements (for electric models). Look for any signs of wear, corrosion, or buildup that could interfere with performance.

Cleaning the components of your cooling equipment, like when you maintain your refrigerator condenser coils on your pizza prep table, is a similar principle. Buildup of any kind, whether it's grease on a fryer or dust on a coil, forces the equipment to work harder and less efficiently.

Properly managing waste is another critical aspect of fryer ownership in a pizza restaurant. You can't just pour used oil down the drain. Understanding the regulations and having a system for grease disposal is a key part of running a responsible kitchen. To get a better handle on this, check out our guide on grease trap sizing.

Here’s a simple checklist to get you started:

Your Monthly Commercial Deep Fryer Checklist

- Inspect Heating Elements/Burners: Look for any carbon buildup or damage.

- Check and Calibrate Thermostat: Use a separate, reliable thermometer to make sure the fryer’s thermostat is accurate. An inaccurate thermostat can lead to burnt oil and poorly cooked food.

- Inspect Drain Valve: Ensure it opens and closes smoothly without any leaks. A faulty valve can be a safety and sanitation nightmare.

- Review Safety Features: Test the high-limit shutoff to ensure it’s functioning correctly. This is a critical safety feature that prevents the oil from reaching a dangerous flashpoint.

Got Questions About Pizza Prep Tables? We've Got Answers.

Stepping into the world of commercial kitchen equipment can feel overwhelming, especially when you're looking at a piece as central as a pizza prep table. It's a big investment for your pizza restaurant, and getting it right can make or break your kitchen's workflow. Let's walk through some of the most common questions we hear from pizzeria owners to help you choose wisely and avoid those classic rookie mistakes.

How Do I Figure Out the Right Size Pizza Prep Table for My Pizzeria?

Choosing the right size pizza prep table is part art, part science. You're really trying to find the sweet spot between your menu's demands and the actual square footage you have to work with. The first step is to get honest about your peak hour volume.

A smaller pizzeria cranking out 10-15 pizzas per hour can usually get by just fine with a compact 48" table. But if you're a high-volume powerhouse slinging 50 or more pies an hour and juggling over 20 different toppings, you'll want to be looking at the bigger 72" or even 93" models. The whole point is to give your team elbow room while keeping every ingredient within easy reach.

Here's the one thing you can't forget: measure your space! You absolutely must leave 3-4 inches of clearance around the compressor for air to circulate. It sounds small, but that little gap is what keeps the engine of your pizza prep table from overheating, saving you from a world of hurt with premature breakdowns and expensive repair bills.

Is a Marble Top Pizza Prep Table Really Worth the Extra Money?

This all boils down to your dough. If you have pizzaiolos stretching dough right on the pizza prep surface, then yes, a marble top is a fantastic investment. Marble is naturally cool to the touch, which is a huge advantage—it keeps the dough from getting sticky or tough while it's being worked. That cool surface helps you get a better, more consistent crust every single time.

On the other hand, if your crew stretches dough on a separate bench and the pizza prep table is just for saucing and topping, a standard polyethylene cutting board is the smarter, more economical choice. Those surfaces are workhorses—durable, a breeze to clean, and much cheaper to replace when they inevitably get scarred up from use.

Your pizza prep surface is a key ingredient in your final product. For the artisan who hand-stretches every pie on the line, the cooling properties of marble are a game-changer. For a high-speed assembly line, the sheer durability and low-maintenance nature of polyethylene wins out.

What Are the Most Common Pizza Prep Table Maintenance Mistakes I Should Avoid?

I see the same two costly mistakes over and over again in pizza restaurants: operators neglecting the condenser coils and completely ignoring busted door gaskets. They both seem like minor details, but trust me, they can wreak havoc on your pizza prep table's lifespan and your monthly utility bills.

Clogged condenser coils are public enemy number one for any refrigeration unit. When they get caked in dust and grease, they can't breathe. This buildup acts like a thick winter coat, forcing the compressor to work overtime just to keep things cool. That extra strain not only wastes a ton of energy but is a fast track to complete system failure.

A torn or warped door gasket is just as bad. It creates a constant leak, letting all that precious cold air seep out of the cabinet. The compressor then has to run nonstop to compensate, sending your electricity bill through the roof and, more importantly, putting your ingredients at risk of entering the temperature "danger zone." That's a food safety nightmare waiting to happen for any pizzeria.

How Often Should I Be Cleaning My Pizza Prep Table?

A solid cleaning schedule is non-negotiable for food safety and for keeping your pizza prep table in fighting shape. The trick is to break it down into daily, weekly, and monthly tasks so nothing falls through the cracks.

- Daily: Wipe down all the exterior surfaces, sanitize the cutting board, and give the interior of the refrigerated base a quick clean.

- Weekly: Pull out all the food pans and give that pan rail a deep clean. This is also a good time to check and wipe down the door gaskets to get rid of any built-up grime.

- Monthly: This is your condenser coil day. A simple cleaning with a stiff brush or a vacuum can boost your pizza prep table's energy efficiency by up to 15%. Seriously.

By turning these steps into a simple, regular routine, maintenance becomes a manageable habit instead of a monster task you dread. It's the best way to make sure your pizza prep table stays a reliable workhorse in your kitchen for years to come.

Ready to build the perfect pizza-making station for your restaurant? At Pizza Prep Table, we offer a wide selection of high-quality prep tables and commercial deep fryers to fit any kitchen size and budget. Explore our collection of commercial deep fryers and pizza prep tables today!