Propane Power! Commercial Deep Fryers That Bring the Heat

Share

Power Up Your Menu: Commercial Propane Deep Fryers Explained

Looking for a commercial propane deep fryer for your restaurant? Here's what you need to know:

- Capacity Range: Commercial propane deep fryers typically offer oil capacities from 4 gallons (portable models) up to 195 lbs for high-volume floor models

- Power Output: Standard models deliver between 90,000-150,000 BTU per hour

- Temperature Range: 200°F to 400°F, with safety shutoffs at 450°F

- Propane Usage: Medium-sized units (40-50 lb capacity) use 30,000-50,000 BTUs per hour

- Production Rate: A 50 lb propane fryer can produce up to 130-150 dozen donuts per hour

Commercial propane deep fryers are the workhorses of busy restaurant kitchens, delivering the intense heat and rapid recovery times needed for high-volume food production. Unlike their electric counterparts, propane fryers bring superior heating power and don't require electrical outlets, making them ideal for food trucks, outdoor events, and kitchens with limited electrical capacity. Their ability to quickly reach and maintain consistent cooking temperatures ensures crispy, golden results batch after batch.

Propane fryers come in various configurations to suit different needs – from compact countertop models perfect for small spaces to heavy-duty floor units designed for non-stop production. The best models feature cool-zone technology that extends oil life by trapping food particles below the heating elements, full-port drain valves for easy cleaning, and precision thermostats that maintain exact cooking temperatures.

I'm Sean Kearney, and after years of helping restaurants select the right equipment for their kitchens, I've seen how the right commercial propane deep fryer can dramatically improve a kitchen's efficiency and food quality.

How Does a Commercial Propane Deep Fryer Work?

Ever watched the dance of flames beneath a bubbling vat of oil and wondered what's really happening inside your commercial propane deep fryer? Let's lift the lid on these kitchen powerhouses.

At heart, these fryers work on a beautifully simple principle. Propane gas flows through a valve and into burner tubes positioned strategically beneath your frying vat. When you fire it up, either with a match or by pressing an ignition button, those burners create controlled flames that heat metal tubes running through your cooking oil. It's these heat exchangers that efficiently transfer all that thermal energy into your oil, creating the perfect environment for crispy, golden food.

What makes professional-grade commercial propane deep fryers so effective is their multiple burner design. Most quality models feature three to five burner tubes that distribute heat evenly throughout your frying chamber. Each tube typically pumps out between 30,000-40,000 BTUs, with total outputs ranging from 90,000 BTUs in standard models up to a whopping 150,000 BTUs in high-capacity units. That's some serious cooking power!

Temperature control is where the magic happens. A thermostat probe constantly monitors your oil temperature, signaling the gas valve to adjust flow as needed. Set your dial between 200°F and 400°F, and the system maintains that sweet spot. When you drop in a basket of frozen fries and the temperature dips, the fryer kicks into recovery mode, increasing gas flow to quickly bounce back to optimal frying temperature. In busy kitchens, this recovery time can make or break your service.

One of my favorite design features in quality commercial propane deep fryers is the "cool zone" – that deeper section at the bottom of the fry pot where temperature stays lower than the main cooking area. This isn't just clever engineering; it's a practical solution that allows food bits and crumbs to settle below where they won't burn and taint your oil or other foods. Your oil lasts longer, your food tastes better, and your customers keep coming back.

The combustion chamber itself is carefully designed to maximize efficiency while minimizing heat loss. Many modern fryers incorporate heat exchangers that capture and redirect heat that would otherwise escape – good for your propane bills and good for the environment.

Of course, safety is paramount when you're dealing with propane and hot oil. High-limit thermostats automatically shut off gas flow if temperatures climb too high (typically around 450°F). Flame failure detection systems cut gas supply if the pilot light goes out, preventing dangerous gas buildup that could lead to explosions.

This perfect combination of powerful heat generation, precise temperature control, and thoughtful safety features is why commercial propane deep fryers remain the top choice for restaurants where speed, consistency, and reliability are non-negotiable kitchen requirements.

Types, Capacities & Key Features Explained

When shopping for a commercial propane deep fryer, understanding the different types and their specific applications can make all the difference in your kitchen's success. I've helped hundreds of restaurant owners find their perfect match, and trust me—the right fryer can be a game-changer for your operation.

Fryer Types

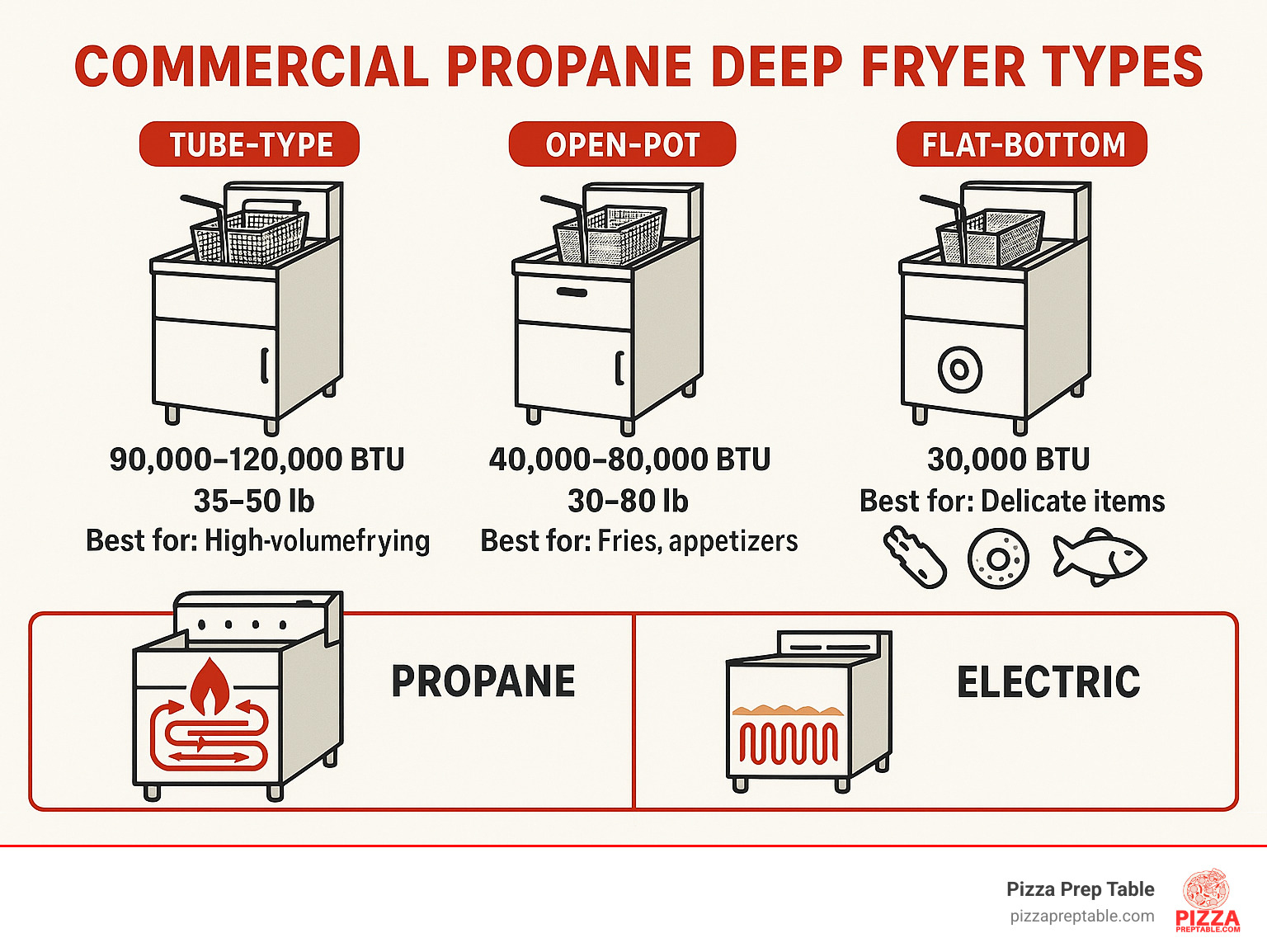

The world of propane fryers is more diverse than you might think. Tube-type fryers are the workhorses you'll find in most busy kitchens. These popular models feature multiple tubes running through the oil vat, housing the burners that distribute heat evenly. They're absolute champions at handling breaded favorites like mozzarella sticks and chicken tenders. Their quick recovery times and higher BTU outputs make them perfect when your ticket rail is filling up fast.

Open-pot fryers take a different approach, with heating elements positioned below rather than inside the fry pot. This creates a clean, unobstructed cooking chamber that's a dream to clean. If your menu stars traditional French fries or delicate seafood, an open-pot design might be your best friend. The tradeoff? Slightly slower recovery times compared to their tube-style cousins.

For specialty operations, flat-bottom fryers shine when it comes to wet-batter items. Without a cool zone, these fryers maximize cooking surface area, making them perfect for turning out beautiful funnel cakes, donuts, and tempura. The even heating across the entire pot surface ensures consistent results batch after batch.

If mobility matters to your business, outdoor mobile fryers come equipped with smart features like wind guards and sturdy frames designed specifically for portable use. These rugged units connect easily to standard propane tanks, making them ideal companions for food trucks, catering gigs, and outdoor festivals.

Space constraints? Consider whether countertop models (offering 10-30 lb capacities) will meet your needs, or if you need the production power of floor models (40-195 lbs) for serious volume.

Capacity Considerations

When it comes to sizing your commercial propane deep fryer, think about both your current needs and room to grow. Capacities typically range from portable units holding just 4-10 gallons (about 30-40 lbs of oil) up to production powerhouses that accommodate 195 lbs for high-volume operations.

A helpful rule of thumb: each pound of oil capacity typically produces about 1.5-2 pounds of fried food per hour in a well-designed fryer. So a 50-pound fryer could reasonably handle up to 100 pounds of product hourly when running at full capacity.

BTU Ratings

The BTU rating essentially tells you how much heating power your fryer packs. Standard commercial propane deep fryers deliver between 90,000-120,000 BTUs, while high-output models crank it up to 120,000-150,000 BTUs. Those higher numbers translate directly to faster preheat times and quicker recovery between batches—absolutely critical during your busiest service periods when every second counts.

Essential Features to Consider

Quality construction makes all the difference in a fryer's performance and longevity. Look for stainless steel exteriors and fry pots that can stand up to the rigors of commercial kitchen life. Cast iron burners offer superior heat retention and will serve your kitchen faithfully for years.

The temperature control system is the heart of any good fryer. The best models feature precision thermostats (many chefs swear by the Robert Shaw® thermostat) that maintain temperatures within ±2°F of your setting—crucial for consistent food quality.

Don't overlook the importance of a well-designed cold zone. This deeper section at the bottom of the fryer where food particles settle can dramatically extend your oil life. V-bottom designs and sediment traps take this feature to the next level, saving you money on oil costs over time.

When it comes to maintenance, full-port drain valves with extensions make filtering and changing oil much less of a chore. Smart safety features like drain locks prevent accidental opening—and potential disasters during busy service.

Consider your menu when selecting basket configurations. Some operations thrive with a single large basket, while others need multiple smaller baskets for variety. Split-pot designs allow you to cook different items simultaneously without flavor transfer—perfect for menus featuring both savory and sweet fried items.

Safety should never be an afterthought. High-limit shutoffs, flame failure protection, and pilot light indicators provide peace of mind during hectic kitchen operations.

Menu Compatibility Guide

| Fryer Type | Best For | Cleaning Ease | Recovery Speed |

|---|---|---|---|

| Tube-Type | Breaded items, high-volume operations | Moderate (tubes require special brushes) | Excellent |

| Open-Pot | Traditional fries, delicate items | Excellent (unobstructed access) | Good |

| Flat-Bottom | Wet-batter foods (donuts, funnel cakes) | Good (no cold zone to clean) | Very Good |

Matching your commercial propane deep fryer to your specific menu items isn't just about efficiency—it's about food quality. The right fryer can be the difference between soggy disappointments and crispy perfection that keeps customers coming back. For food trucks and mobile operations especially, portable propane fryers offer best flexibility and performance without electrical requirements.

More info about Crispy Profits Await with These Food Truck Deep Fryers

Product Roundup: Best Commercial Propane Deep Fryer Models of 2024

I've spent years helping restaurant owners find their perfect kitchen equipment, and if there's one thing I've learned, it's that the right commercial propane deep fryer can make or break your operation. After watching hundreds of kitchens in action and gathering feedback from chefs across the country, I'm excited to share the standout models that are truly delivering in 2024.

Avantco FF400 Commercial Propane Deep Fryer

The Avantco FF400 has earned its place as the reliable workhorse in kitchens across America. With its hefty 50 lb oil capacity and impressive 120,000 BTU output from four heating tubes, this beauty doesn't mess around when it comes to high-volume frying.

What really impresses me about this model is its recovery time. Even during Friday night rushes, it bounces back almost immediately after dropping in frozen appetizers. The cool-zone technology is a game-changer too – one chef told me he's saving nearly 30% on oil costs since switching to this model because food particles drop below the heating elements instead of burning and contaminating the oil.

The stainless steel construction takes the daily beating of a busy kitchen without complaint, and that full-port drain valve makes end-of-day cleaning so much less painful. When 70% of users give a piece of equipment five stars, you know it's doing something right. As one pizzeria owner put it, "This thing has handled 150+ covers every Friday and Saturday for two years without even a hiccup."

The only quirk worth mentioning is that some users needed a little patience with the pilot light during initial setup, but once dialed in, it's smooth sailing.

Carnival King 30 lb Commercial Propane Deep Fryer

If you've ever enjoyed a perfectly crispy funnel cake at a fair, chances are it came from a Carnival King. This 30 lb countertop marvel delivers 54,000 BTUs through two U-shaped burners that distribute heat evenly across its flat-bottom design.

What makes this model special is its specialty in wet-batter applications. Without a cold zone (intentionally), it maximizes cooking space and can handle four 8-inch funnel cakes at once. I've watched vendors crank out over a thousand funnel cakes in a weekend with this reliable performer.

I particularly love its adaptability – you can convert it from propane to natural gas in the field with an optional kit. This flexibility has saved several of my clients significant money as their operations evolved. The included stainless steel mesh strainer is a thoughtful touch that makes batch frying safer and more efficient.

One carnival operator told me, "Between funnel cakes and fried Oreos, this fryer paid for itself in the first weekend." Just keep in mind that in windy outdoor conditions, you might need to shield the pilot light, but the protective lid/drip tray design shows that real working chefs had input in designing this unit.

Carolina Cooker 2-Burner Fryer

The Carolina Cooker brings something special to the table with its dual independent vats. This design is brilliant for operations that fry multiple items – no more French fries tasting like yesterday's fish! Each burner pumps out 46,000 BTUs for a combined 92,000 BTU output that handles outdoor cooking demands with ease.

This model shines at catering events and mobile food service. The UL-listed hose and regulator connect smoothly to standard propane tanks, and the sturdy four-leg design keeps everything stable even on uneven surfaces. The aluminum vats measure 7-1/8" H x 13-1/2" L x 7" D – perfect for balancing capacity with portability.

What really makes this unit versatile is its ability to double as a steamer or boiler. I've seen caterers use one side for frying chicken while the other simmers a pot of gumbo – talk about maximizing equipment space at outdoor events!

Carolina Cooker 2 Burner Fryer | Agri Supply

Bayou Classic 9-Gallon Propane Fryer

The Bayou Classic's clever V-bottom design is a revelation for oil management. By keeping the base oil cooler than the frying zone, it prevents that dreaded batter burning that ruins both oil and food. With approximately 70 lbs of oil capacity, this unit handles medium-volume operations beautifully.

The heat tube running through the back creates a gentle rolling oil effect that maintains consistent cooking temperatures – crucial for perfect results every time. The three included stainless steel baskets let you fry different items simultaneously, a feature my restaurant clients particularly appreciate during busy service.

What often goes unmentioned but deserves attention is this model's relatively quiet operation. Unlike the jet-engine roar of some commercial propane deep fryers, you can actually hold a conversation near this one. For operations where staff-customer interaction matters, this is huge.

The lockable casters and drain valve with hose attachment reflect thoughtful safety considerations that make daily operation and maintenance less hazardous. The included 10 PSI regulator kit and stainless steel braided hose provide peace of mind for secure propane connection.

Avalon ADF34PBA Donut Fryer

When serious donut production is your business, the Avalon ADF34PBA is the heavyweight champion you need in your corner. With its massive 195 lb oil capacity and 120,000 BTU output, this beast can churn out 130-150 dozen donuts per hour – numbers that make bakery owners smile.

The tube-fired design prevents scorching, while the thermostatic control maintains temperatures precisely up to 400°F. I love that it requires no electricity – just propane – making it perfect for stadium concessions, farmers markets, and carnival settings where power access might be limited.

At 40" W × 40" D × 34" H, this is a substantial piece of equipment, but every inch is purposefully designed for serious production. The ETL Sanitation certification gives health inspectors one less thing to flag, and the adjustable drain tray accommodates different products with ease.

For donut shops looking to maximize their operation, complementary accessories like shortening filter systems, pan racks for cooling, proofing cabinets, and cake fillers create a complete production system. Several of my clients have paired this fryer with a dedicated gas hose kit for continuous operation during peak weekend hours.

Each of these commercial propane deep fryers brings something special to the table, and at PizzaPrepTable.com, we're happy to help you steer which one fits your specific operation. With our nationwide presence from New York to Los Angeles and Chicago to Houston, plus flexible financing options, we make equipping your kitchen with the right fryer straightforward and affordable. Your perfect golden-fried future is just a conversation away!

Operating Costs, Safety & Maintenance Essentials

If you've invested in a commercial propane deep fryer, understanding what it takes to keep it running efficiently isn't just good business—it's essential for your bottom line and kitchen safety. Let's break down what you need to know about the dollars and sense of running these workhorses.

Propane Consumption & Operating Costs

Your typical commercial propane deep fryer (the 40-50 lb capacity ones most restaurants use) will consume between 30,000 to 50,000 BTUs every hour it's fired up. What does this mean for your wallet?

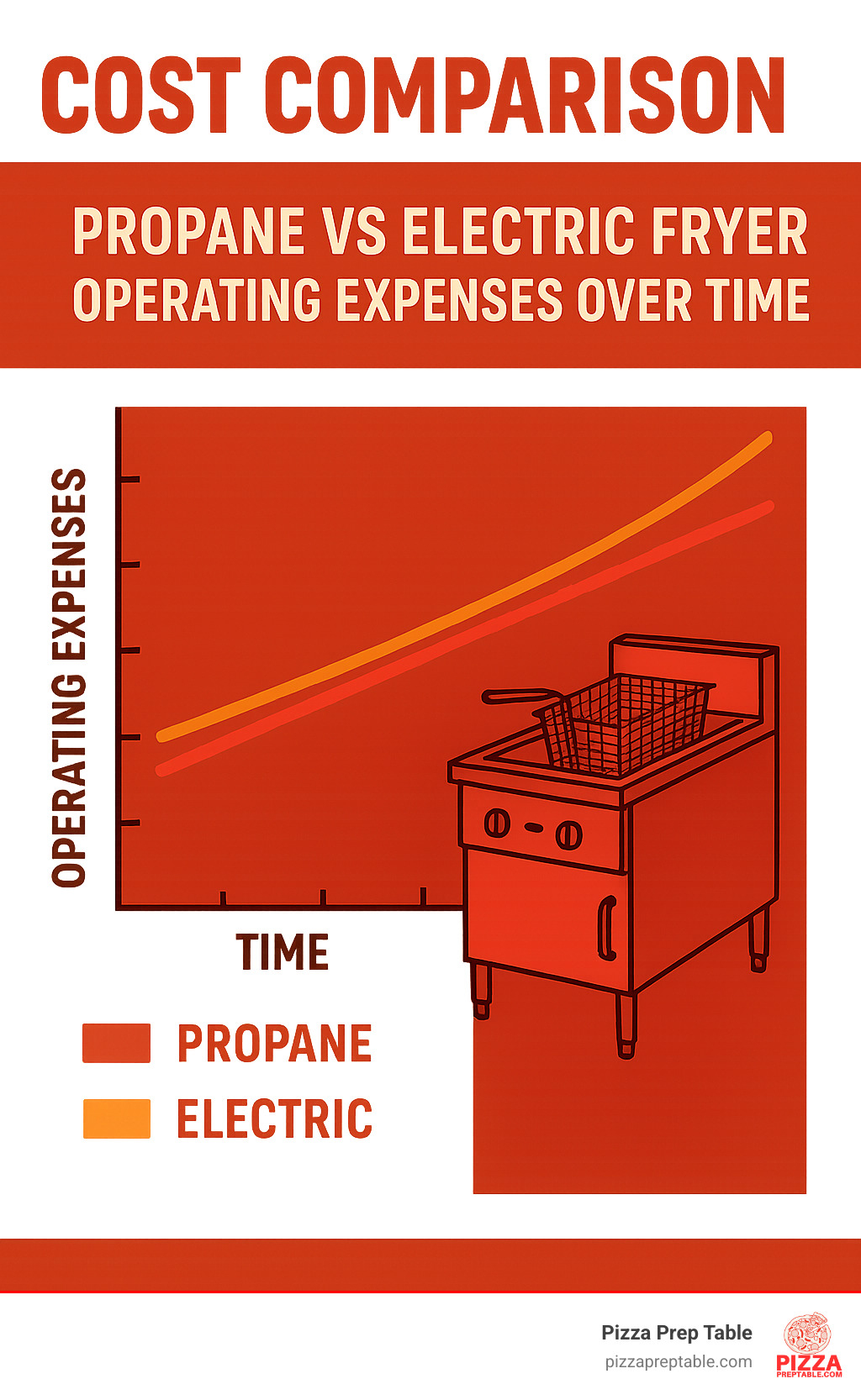

A standard 40-lb propane tank packs about 430,000 BTUs of cooking power. If your fryer burns through 40,000 BTUs hourly, you'll get roughly 10-11 hours of continuous frying from one tank. At today's propane prices (about $2.50-3.50 per gallon), you're looking at operating costs between $1.75-2.50 per hour.

The good news? Propane fryers generally cost less to run than their electric counterparts, especially during those crazy lunch and dinner rushes. Most food truck operators tell me they get a full 8-12 hour day of cooking at 360°F from a single 30 lb cylinder—enough to cover even your busiest shifts.

Safety Considerations

Let's be real—we're talking about combining hot oil and open flames. Safety isn't optional; it's mandatory.

Your commercial propane deep fryer needs proper ventilation. This means a commercial hood system that extends at least 6 inches beyond your fryer on all sides. No exceptions. Local fire codes demand it, and your insurance company won't cover you without it.

You'll also need a Class K fire suppression system specifically designed for grease fires. Water on a grease fire? That's a disaster waiting to happen. These systems need professional installation and regular inspections.

Gas connections are another critical safety point. That 3/4" gas line should be installed by a pro—not your cousin who "knows a thing or two about plumbing." Using the right flexible connectors and regulators rated for your fryer's BTU output isn't just smart—it's required to keep your warranty valid.

Keep your fryer at least 6 inches from walls and 16 inches from other cooking equipment. And please, outfit your team with heat-resistant gloves, face shields, and proper aprons. I've seen too many nasty oil burns that could have been prevented.

Maintenance Protocols

Think of your fryer maintenance like changing the oil in your car—skip it, and you're asking for trouble.

Daily upkeep doesn't take long but pays huge dividends. Filter your oil at least once daily (twice if you're slammed). Wipe down exterior surfaces before they become grease magnets. Check those sediment traps and inspect gas connections for leaks using soapy water—never an open flame!

Weekly maintenance should include a thorough "boil out" using the manufacturer's recommended cleaning solution. This deep cleaning removes carbon buildup and residue that affects performance and food taste. While you're at it, check those burner tubes, orifices, and verify your thermostat is reading accurately.

Monthly, you'll want to deep clean those heat exchangers and tubes with specialized brushes (they look like giant pipe cleaners). Check your gas pressure regulator, clean the pilot assembly, and test that high-limit safety switch.

Quarterly, bring in a certified technician for a comprehensive inspection. They'll replace worn gaskets, calibrate thermostats, and ensure your valves and regulators are functioning properly.

Oil Management

Nothing affects your operating costs—and food quality—more than how you manage your oil.

In high-volume operations, filter that oil 2-3 times daily. Medium volume? Once a day should do. If you're running a lighter operation, every other day might suffice.

How do you know when it's time to change oil completely? Trust your senses. When oil darkens significantly, smokes at normal cooking temperatures, foams excessively, develops that funky smell, or stops recovering temperature quickly—it's time for fresh oil.

Want to extend your oil life? Keep cooking temperatures consistent (avoid cranking up the heat), filter regularly, cover the fryer when not in use, and add oil stabilizers as recommended. Oh, and always salt food after frying, not before—salt in the oil accelerates breakdown.

When it's time to dispose of used oil, follow local regulations. Many areas now have recycling programs that might even put a few dollars back in your pocket.

Troubleshooting Common Issues

The number one headache with commercial propane deep fryers? Pilot light problems. If yours keeps going out, check for drafts, clean the pilot assembly and orifice, verify proper gas pressure, and make sure the thermocouple is positioned correctly in the flame.

If you're noticing inconsistent cooking temperatures, start by calibrating the thermostat. Check gas pressure, ensure heat tubes are clean, and verify your oil is at the proper level.

When recovery time slows down (that's how quickly your fryer returns to temperature after adding food), clean those heat exchangers and tubes, check gas pressure, and verify all burners are working. If problems persist, you might have outgrown your fryer—time to consider a higher-capacity model.

Following these guidelines will keep your commercial propane deep fryer running efficiently for years. At PizzaPrepTable.com, we don't just sell equipment and walk away—we provide ongoing support, maintenance guides, and access to certified technicians across the country, from New York to Los Angeles, Chicago to Miami.

More info about Keep Calm and Store On: Food Truck Fryer Oil Storage Tips

Frequently Asked Questions about Commercial Propane Deep Fryers

Q: What size regulator do I need for my commercial propane deep fryer?

A: For most commercial propane deep fryers up to 100,000 BTU, a standard 10-11" WC (water column) regulator will do the job. If you're running a bigger unit (120,000+ BTU), you'll need a high-capacity regulator matched to your specific BTU output. Always check your fryer's manual for the exact requirements—this isn't an area to guess.

Q: How often should I change the oil in my commercial fryer?

A: It depends on what and how much you're frying. High-volume operations cooking breaded items should change oil every 3-5 days. If you're running at medium volume or frying mostly non-breaded items, you might stretch to 7-10 days. Daily filtering is non-negotiable, and those oil quality test strips are worth their weight in gold for objective monitoring.

Q: Can I convert my propane fryer to natural gas?

A: Many commercial propane deep fryers can indeed be converted to natural gas using manufacturer-approved kits. This typically involves switching out the orifices, adjusting air shutters, and replacing the regulator. Don't DIY this one—have a certified technician handle the conversion to maintain your warranty and ensure safety. Models like the Carnival King are specifically designed to be "field convertible."

Q: What's the difference between a cold zone and a flat bottom fryer?

A: Cold zone fryers feature a deeper section below the heating elements where oil stays cooler, allowing food particles to settle without burning. This design extends oil life and works great for breaded items. Flat bottom fryers eliminate this zone to maximize cooking surface for wet-batter specialties like funnel cakes and donuts. Your menu should dictate which design is right for you.

Q: How do I maintain consistent oil temperature during busy service periods?

A: Keep your fryer happy during the rush by never overloading beyond 50% of oil capacity per batch. Allow 30-45 seconds recovery time between batches, maintain proper oil levels, and ensure your fryer has enough BTU output for your volume (120,000+ for high-volume operations). Daily oil filtering removes impurities that can slow heat transfer.

Q: What safety certifications should I look for when purchasing a commercial propane fryer?

A: Look for ETL Sanitation certification for food safety compliance and ETL certification for gas safety standards. These certifications ensure your equipment meets the rigorous safety and sanitation standards required by health departments and insurance providers. They're not just stickers—they're your assurance that the equipment has been thoroughly tested.

Conclusion

Selecting the right commercial propane deep fryer is a critical decision that directly impacts your kitchen's efficiency, food quality, and bottom line. As we've explored throughout this guide, propane fryers offer significant advantages in terms of heating power, recovery time, and operational flexibility—particularly for high-volume operations and mobile food service.

The ideal fryer for your business depends on several factors: your menu items, production volume, available space, and budget. Tube-type fryers excel with breaded items, open-pot designs simplify cleaning, and flat-bottom models are best for wet-batter applications. Capacity requirements range from compact 30 lb units for limited menus to 195 lb powerhouses for dedicated frying operations.

At PizzaPrepTable.com, we understand that equipment purchases represent significant investments in your business's future. That's why we offer not just a wide selection of top-performing commercial propane deep fryers but also flexible financing options to make these essential tools accessible to operations of all sizes—from independent food trucks to multi-location restaurant chains.

Our nationwide presence—with locations in New York, Los Angeles, Chicago, Houston, and many other major cities—means we can provide prompt delivery and support wherever your business operates. Our team of equipment specialists can help you steer the selection process, ensuring you choose a fryer that aligns perfectly with your operational needs and growth plans.

Beyond the equipment itself, we provide comprehensive resources on installation best practices, maintenance protocols, and operational tips to maximize your return on investment. Our bundled equipment packages can save you both time and money when outfitting a new kitchen or upgrading existing facilities.

Ready to power up your menu with a high-performance commercial propane deep fryer? Contact our team today to discuss your specific needs and find how the right equipment can transform your frying operation. Whether you're launching a new concept or upgrading existing equipment, we're here to help you make informed decisions that drive your culinary and business success.