A Pizzeria Guide to Commercial Food Storage Boxes

Share

When you're running a professional pizzeria, the containers you use to store ingredients, prepped toppings, and proofing dough are more than just boxes—they're a critical part of your operation. We're talking about specialized, durable containers built for the grind. For pizzerias, this covers everything from dough proofing boxes that are key to a perfect crust, to the modular prep table pans that keep your toppings organized for lightning-fast service.

These containers are the backbone of food quality, waste prevention, and a smooth pizza line workflow.

The Secret Ingredient to a Flawless Pizza Service

Picture this: It's the peak of a Friday night dinner rush. The ticket printer is spitting out orders nonstop, and your pizza line is the heart of the storm. Every second counts. But instead of a well-oiled machine, you've got chaos.

Staff are fumbling for the right toppings. Mismatched lids are everywhere. The prepped veggies you sliced hours ago are starting to look tired. This isn't a failure of your team; it's a failure of your storage system.

In the fast-paced world of a pizzeria, commercial food storage boxes are far more than simple plastic tubs. They are mission-critical tools that directly impact your profitability, efficiency, and the quality of every single pizza that goes out the door. Think of them as the unsung heroes working behind the scenes on your pizza prep table.

From Chaos to Control

A smart, organized system of food storage boxes brings order to the busiest parts of your pizzeria. It can turn a cluttered walk-in and a messy prep line into models of efficiency. This isn't just about looking good for the health inspector—it's about speed and accuracy when it matters most.

Just think about the real-world benefits for a pizza shop:

- Faster Service Times: When every topping—from shredded mozzarella to sliced pepperoni—is in a clearly labeled, easy-to-grab container on your pizza prep table, your pizza makers can assemble orders in record time.

- Reduced Food Waste: Proper airtight seals keep your ingredients fresher for much longer, which means less spoilage and more money in your pocket. Clear containers also let you see inventory at a glance, so you stop over-prepping.

- Improved Food Safety: Good storage is your first line of defense against cross-contamination and health code violations. It keeps both your customers and the inspectors happy.

- Consistent Product Quality: The right box prevents dough balls from drying out and keeps bell peppers crisp. It's all about maintaining the integrity of your ingredients from the moment they arrive to the moment they hit the pizza.

The difference between a struggling pizzeria and a high-performing one often comes down to workflow. The right storage containers on your prep table eliminate those little friction points, allowing your staff to focus on crafting great pizza instead of hunting for a lid that fits.

More Than Just a Box

Ultimately, choosing the right commercial food storage boxes is an investment in your pizzeria's bottom line. It’s about seeing these containers not as an expense, but as a core part of your operational strategy.

This guide is your blueprint for building that system. We'll dive into how to select the perfect containers for everything—from bulk pizza sauce in the walk-in to the precise organization of your pizza prep table—and turn your kitchen into a safer, smarter, and more profitable powerhouse.

Choosing the Right Box Material for Every Ingredient

Picking the right commercial food storage boxes for your pizzeria is a lot like a chef choosing their knives. You wouldn't use a heavy cleaver for delicate garnishes, and you definitely shouldn't use a single type of plastic for every ingredient on your prep line. Every material has a specific job to do, and knowing their strengths is the key to running an efficient, safe, and profitable pizzeria.

Trying to make one box fit all is a recipe for stained containers, cracked lids, and—worst of all—compromised pizza quality. Instead, matching the box material to the ingredient ensures everything from your proofed dough to your diced onions stays fresh and ready for service.

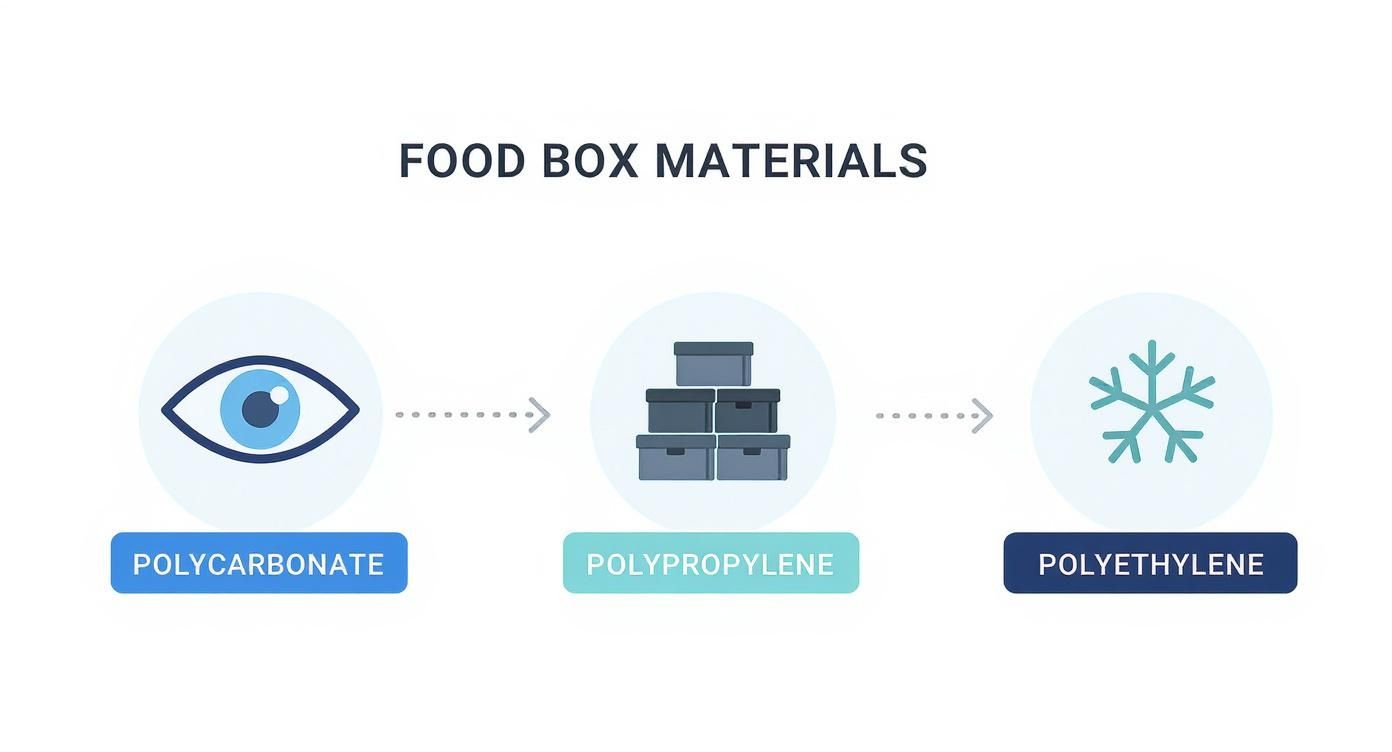

Polycarbonate The Clear Choice for the Pizza Prep Table

Think of your refrigerated pizza prep table as the command center of your kitchen. When the dinner rush hits, speed and accuracy are everything. This is precisely where polycarbonate containers shine.

Their biggest advantage is their crystal-clear visibility. Your crew can instantly spot the pepperoni, mushrooms, or olives without lifting a single lid. Shaving those precious seconds off every order really adds up, leading to faster service and happier customers.

But polycarbonate isn't perfect. Its one major weakness in a pizzeria setting is how easily it stains from acidic foods. That rich, vibrant tomato sauce you’re famous for will leave its mark, eventually clouding up the container for good.

- Best For: Sliced vegetables, meats, and cheeses on the pizza prep table where quick visual ID is critical.

- Avoid Using For: Long-term storage of tomato sauce or other highly acidic ingredients.

Polypropylene The Workhorse for Bulk Storage

For all the ingredients you’re stashing in the walk-in cooler, polypropylene is the undisputed champ. These containers are the economical, durable workhorses of any pizzeria. They're usually translucent or opaque, which is perfect for items that don’t need constant visual monitoring.

Polypropylene stands up much better to acidic foods and is generally more budget-friendly than polycarbonate. This makes it the no-brainer choice for storing big batches of pizza sauce, gallons of olive oil, or bulk bags of shredded mozzarella.

Its sturdiness also means it can handle the daily grind of pizzeria life, standing up to stacking and frequent handling without cracking.

Polyethylene The Specialist for Frozen Goods

Every pizzeria has a stash of items in the freezer, and that’s where polyethylene comes into play. Its main superpower is its excellent performance at low temperatures. While other plastics can get brittle and crack in the freezer, polyethylene stays flexible and durable.

This makes it the go-to material for storing extra pizza dough balls, pre-portioned sausage, or anything else you need to keep locked in your deep freezer. Using the right freezer-safe boxes prevents dreaded freezer burn and protects the quality and flavor of your pizza ingredients.

A smart investment in the right types of commercial food storage boxes pays dividends. It extends the life of your containers, protects the quality of your ingredients, and creates a more organized and efficient workflow for your entire pizza line.

The importance of having these specialized containers is a big deal in the wider food storage market. The global food container market was valued at USD 164.75 billion in 2023 and is projected to hit USD 222.60 billion by 2030. That growth is being driven by professional kitchens demanding durable, temperature-specific storage that guarantees food safety and freshness. You can find more insights on this growing market over at nextmsc.com.

Food Storage Box Material Comparison for Pizzerias

To make it even clearer, let's break down how these materials stack up for the specific needs of a busy pizzeria. Think of this as your cheat sheet for building the perfect container arsenal for your pizza prep table and walk-in.

| Material | Key Features | Best For in a Pizzeria | Potential Drawbacks |

|---|---|---|---|

| Polycarbonate | Crystal-clear, durable, rigid | Toppings on the pizza prep table (meats, veggies, cheese) | Stains easily from acidic foods like tomato sauce |

| Polypropylene | Translucent/opaque, acid-resistant, budget-friendly | Bulk storage of pizza sauce, dough, shredded cheese | Not transparent, making quick identification harder |

| Polyethylene | Flexible at low temps, durable in freezers | Freezing dough balls, pre-portioned meats, bulk items | Can be less rigid than other plastics at room temp |

By building a versatile collection of food storage boxes, you’re not just buying plastic; you’re equipping your pizzeria with the right tools for every single task. This strategic approach ensures your ingredients are stored safely, your prep line runs like a well-oiled machine, and the quality of your pizza stays consistently excellent. Of course, pairing these containers with the right surfaces is just as crucial; you can check out our guide on commercial stainless steel tables to complete your kitchen setup.

Optimizing Your Pizza Prep Table with Smart Sizing

In any pizzeria, your refrigerated pizza prep table isn't just a piece of equipment—it's the most valuable real estate you have. Every square inch has to pull its weight, especially when the dinner rush hits. The secret to unlocking that potential starts with something simple: choosing the right size for your commercial food storage boxes.

A messy prep station, cluttered with mismatched containers and wasted gaps, doesn't just look bad; it slows down your entire pizza line. The key to a perfectly organized, lightning-fast pizza station is getting familiar with the industry-standard sizing system: Gastronorm (GN).

Playing Tetris with Your Toppings Using Gastronorm Sizing

Think of Gastronorm sizing as playing a professional game of Tetris on your pizza prep table. It’s a universal European standard that makes pans and boxes completely modular and interchangeable. This system guarantees that containers from different brands will fit together perfectly in your prep table, steam table, or storage racks.

Instead of a chaotic pile of random containers, GN sizing lets you build a custom layout that makes sense for your pizza toppings. You can mix and match different sizes to hold over a dozen ingredients, fitting them together without a single wasted gap.

Here's how it usually breaks down on the pizza line:

- 1/3 Size Pans: These are your workhorses, perfect for high-volume items like shredded mozzarella or pepperoni.

- 1/6 Size Pans: Great for those middle-of-the-road toppings like mushrooms, onions, or olives.

- 1/9 Size Pans: The go-to for less common ingredients that you still need handy, like jalapeños, anchovies, or specialty cheeses.

By combining these standardized commercial food storage boxes, you create a prep line that flows logically, putting every pizza topping exactly where it needs to be. This is a fundamental part of a well-designed pizzeria, and you can learn more about setting up your workstation in our guide to commercial pizza prep tables.

Why Container Depth Is a Game Changer

Once you've got the length and width figured out with GN sizes, the next dimension to master is depth. The depth of your food storage boxes has a huge impact on food waste, freshness, and how smoothly your pizzeria runs. Using one standard depth for everything is a common mistake that costs pizzerias money.

For ingredients you fly through, like your main cheese blend, a shallower pan (think 2.5 inches deep) is actually much smarter. It forces your staff to refill it more often from the walk-in, which means the cheese at the bottom of the pan never has a chance to sit there, warm up, and lose its quality. This one small change can slash spoilage.

On the flip side, for lower-volume toppings like artichoke hearts or sun-dried tomatoes, a deeper pan (maybe 4 or 6 inches) makes perfect sense. It holds more product, so your team isn't constantly running for refills during a busy shift. This frees them up to focus on what matters: making pizzas.

The goal isn't just to cram as many toppings as possible onto the line. It's to build an intelligent system that manages your inventory right there at the pizza prep table, cutting down on waste and boosting quality with every single order.

Reclaiming Space with Smart Bulk Storage

This whole idea of smart sizing goes beyond the pizza prep table and right into your walk-in cooler. When it comes to storing bulk ingredients like diced peppers or pre-portioned sausage, the shape of your containers makes a massive difference.

So many pizzerias still use big, round buckets for storage, but they're incredibly inefficient. That circular shape creates a ton of "dead" space between each container sitting on a shelf. Making the switch to stackable, square, or rectangular commercial food storage boxes instantly reclaims all that wasted area, letting you store more inventory in the exact same footprint.

It’s all part of a larger move towards hyper-organized spaces, driven by the need for efficiency in kitchens everywhere. As cities get denser, the pressure to maximize every inch of storage grows, and you can see the data on how this is shaping the market when you read the full research about these trends. At the end of the day, optimizing your storage—from the smallest pan on the line to the biggest box in the walk-in—is a direct investment in a faster, leaner, and more profitable pizzeria.

Mastering Your Dough with Proofing Boxes

Perfect pizza starts way before it ever sees an oven. It begins with the dough—a living, breathing thing that needs a stable, controlled environment to develop the amazing flavor and texture your customers keep coming back for. This is where the single most important container in any pizzeria comes into play: the commercial food storage box built for proofing dough.

Don't think of a dough proofing box as just some plastic tub. It's more like a dedicated incubator. Its main job is to create a perfect micro-environment for fermentation, that magical process where yeast turns sugars into carbon dioxide. This is what gives your crust its airy pockets and complex taste. Without this control, your dough is at the mercy of a chaotic kitchen, and that leads to nothing but inconsistent pizza.

These specialized boxes shield your dough balls from the two biggest enemies of a perfect crust: wild temperature swings and air exposure. A drafty kitchen can stop yeast in its tracks, while air creates a dry, tough skin on the dough that keeps it from rising the way it should. A good proofing box handles both problems in one shot.

Critical Features of a Pizzeria Dough Box

Not all commercial food storage boxes are cut out for the demanding job of proofing. When you're picking out boxes for your pizzeria, there are a few non-negotiable features to look for. These elements all work together to make sure every single batch of dough performs exactly the way you need it to.

The most important feature is an airtight seal. A secure lid is your first line of defense, locking in moisture to stop the dough's surface from drying out and forming that nasty crust. It’s what creates the humid, stable atmosphere that yeast absolutely loves.

Next up, you need a reinforced stacking design. Pizzerias go through mountains of dough, and floor space is always tight. Dough boxes are built to stack securely, one on top of the other. This lets you proof dozens of batches vertically without ever crushing the delicate dough balls inside, saving you precious real estate in your walk-in or prep area.

Finally, the material itself is a big deal. Most high-quality dough boxes are made from tough plastics like polypropylene or polycarbonate. These are a breeze to clean, won't hold onto old odors, and won't have any weird chemical reactions with your dough.

Managing Your Dough Workflow Like a Pro

Having the right gear is only half the battle. Using it the right way is what separates the good pizzerias from the great ones. A solid dough box workflow is all about consistency and cutting down on waste.

Here are a few practical tips for your dough proofing boxes:

- Stack Smart: Even though they're made to stack, don't build a leaning tower of dough. A stable stack lets some air move around the boxes, which helps keep the temperature more consistent from the top box to the bottom one.

- Track Your Batches: Use a simple labeling system—colored stickers or dissolvable labels work great—to keep track of different dough batches. This makes it easy to follow the First-In, First-Out (FIFO) rule, so you’re always using your oldest, most flavorful dough first.

- Give Them Space: Don't cram the box full. Leave enough room between dough balls so they can expand as they proof. This keeps them from sticking together and makes them much easier to grab and stretch later.

A consistent cleaning regimen is just as important as your dough recipe. Leftover flour and moisture can become a breeding ground for mold, which can impart off-flavors to new batches of dough. A clean box is the foundation of a clean-tasting crust.

You absolutely need a strict cleaning protocol. After every use, boxes should be washed out with warm, soapy water and—this is critical—allowed to air dry completely. Stacking damp boxes creates the perfect dark, moist playground for mold and bacteria to thrive.

By making these practices second nature, your commercial food storage boxes for dough become a reliable asset, helping you crank out a consistently fantastic pizza crust, day in and day out.

Getting Serious About Food Safety and Labeling

Think of your commercial food storage boxes as more than just containers. They are your first, and most important, line of defense in the daily battle for food safety. A neat and tidy walk-in is great, but a rock-solid labeling system turns that organization into a foolproof safety net. This is how you kill the guesswork, avoid expensive mistakes, and turn a surprise visit from the health inspector into a non-event.

It all starts with a non-negotiable in any professional pizzeria: NSF certification. That little mark from the National Sanitation Foundation isn't a suggestion. It's your guarantee that a box is made from food-safe materials, is tough enough for the daily grind of a commercial kitchen, and has a smooth, non-porous surface that won't harbor nasty bacteria. Using anything else is a gamble with your customers' health and your pizzeria's reputation.

Nailing Your FIFO Labeling System

The absolute cornerstone of any smart kitchen labeling system is the First-In, First-Out (FIFO) principle. It’s a dead-simple concept with a massive impact: always use the oldest ingredients first. Following this rule dramatically slashes food waste and ensures everything you serve is at peak freshness. A clear, consistent label on every single box—from the bulk pizza sauce in the dry storeroom to the prepped onions on the prep table—is how you bring FIFO to life.

A good labeling system doesn't have to be complicated. In fact, simpler is usually better.

- Item Name: Be specific. "Diced Green Peppers" is way better than a scribbled "Peppers."

- Prep Date: The day the item was prepped or the package was opened. This starts the clock on its shelf life.

- Use-By Date: The hard deadline. This is the date the food must be used or tossed, no exceptions.

- Employee Initials: This adds a simple layer of accountability and makes it easy to track down who prepped an item if questions pop up.

For high-volume pizzerias looking to get even more precise, some are exploring how to streamline inventory and logistics with QR codes, which can link to incredibly detailed product information with a quick scan.

Choosing the Right Labels for Your Pizzeria

The type of label you use can make or break how well your system works. Those cheap paper labels are a nightmare—they leave behind a sticky, gummy residue that’s a pain to scrub off and can become a breeding ground for bacteria. Instead, go with one of these pizzeria-friendly options.

- Day-Dot Stickers: These color-coded stickers give you a quick visual cue for the day of the week an item was prepped, making it insanely easy to spot what needs to be used next.

- Dissolvable Labels: A true game-changer for busy pizzerias. These labels completely dissolve in water in under 30 seconds, leaving zero sticky mess behind in the dishwasher.

- Masking Tape: It's a classic for a reason, but make sure you're using a quality painter's tape that peels off cleanly. Always use a permanent marker to keep condensation from smudging your writing.

A consistent labeling system transforms your walk-in cooler from a place of potential chaos into an organized library of pizza ingredients. At a glance, any team member can identify what an item is, when it was prepped, and when it needs to be used by.

This level of organization is the key to maintaining both fantastic pizza quality and unimpeachable safety. To see how this fits into the bigger picture, check out our detailed post on restaurant food storage guidelines.

This focus on smarter storage and safety isn't just happening in your pizzeria; it's a global trend. The food storage container market is projected to hit USD 265.3 billion by 2035, growing at a steady 4.5% each year. This growth is being driven by a huge industry-wide push to cut down on food waste and guarantee proper food preservation. By implementing a disciplined labeling system, you’re aligning your pizzeria with the best practices that define modern, successful, and safe food operations.

Keeping Your Containers in Fighting Shape

Taking proper care of your commercial food storage boxes isn't just about getting a few more years out of them—it's one of the most critical parts of your food safety plan. If you neglect them, these containers can quickly turn from assets into liabilities, becoming a breeding ground for bacteria that puts both your customers and your reputation on the line.

A simple, consistent cleaning routine is your first line of defense. It protects your investment and, more importantly, ensures every ingredient you pull from that box is safe to serve on a pizza.

It all starts with knowing what you’re working with. The plastics used in a busy pizzeria—from the clear polycarbonate pans on your prep table to the polypropylene dough boxes in the walk-in—aren't all the same. What cleans one type of plastic might actually ruin another.

For instance, a classic mistake is grabbing an abrasive scouring pad to attack a tough pizza sauce stain on a clear polycarbonate container. It might seem like it's working, but you're actually creating thousands of microscopic scratches. Those tiny grooves not only make the box look cloudy but also create the perfect hiding spots for bacteria, making it impossible to ever truly sanitize again.

How to Clean Different Types of Plastic

To keep your container collection in top shape, you've got to treat each material the right way. Following these simple guidelines will prevent damage and guarantee a thorough, safe clean every time for your pizzeria's storage boxes.

- Polycarbonate (The Clear Ones): Stick with soft cloths or sponges and a mild detergent. For those stubborn tomato sauce stains, make a paste with baking soda and water, let it sit for a couple of hours, then gently wash it away. No scrubbing required.

- Polypropylene (The Translucent/Opaque Workhorses): These guys are tough, but they can get mildew if stored improperly. The golden rule here is to make sure they are bone-dry before you even think about stacking them. Trapping even a tiny bit of moisture can lead to a moldy mess.

- Polyethylene (Your Freezer Boxes): This material is a champ in the cold but can get brittle with sudden temperature shocks. Always let your freezer boxes come back to room temperature gradually before hitting them with hot water in the wash. This simple step prevents stress cracks from forming on your dough boxes.

Your Daily and Weekly Maintenance Plan

Having a structured cleaning plan takes the guesswork out of the process and builds good habits with your kitchen crew. Think of it as a daily workout for your containers to keep them strong and safe for your pizzeria.

Your cleaning protocols are just as important as your pizza recipes. A dirty container can compromise the taste and safety of the best ingredients, undermining all your hard work.

Beyond the daily wash, you need a bigger-picture cleaning schedule. For a wider view on keeping your entire pizzeria up to snuff, these restaurant kitchen deep cleaning tips offer some great advice that fits right in with your container care routine.

Daily Checklist:

- Wash all used containers right away with warm, soapy water. Don't let them sit.

- Rinse them out completely to get rid of any soap residue.

- Set them on a drying rack where air can circulate all around them.

- Wipe down every lid and double-check the gaskets for trapped food bits.

Weekly Inspection:

- Give every single container a quick look for signs of wear and tear.

- Be ruthless: immediately toss any boxes with deep scratches, cracks, or warping.

- Check stacking lids and corners for any stress fractures, especially on your dough boxes.

Damaged commercial food storage boxes are a serious food safety threat. A crack means a box can't be properly cleaned and might even leach plastic into your pizza toppings. A warped box won't create an airtight seal, and your ingredients will spoil faster. The only safe and professional approach is a strict "when in doubt, throw it out" policy.

Your Questions, Answered

Outfitting a pizzeria always brings up a few specific questions, even when you think you've got everything figured out. Here are some quick, practical answers to the real-world problems we see pop up all the time with commercial food storage boxes on the pizza prep table.

Can I Use the Same Boxes for Hot and Cold Toppings?

That all comes down to the material the box is made from. Think of polycarbonate containers as your all-around players—they’re versatile and can handle a massive temperature range, often from -40°F to 212°F. This makes them a safe bet for everything from chilled peppers on the pizza prep table to warm, cooked sausage waiting on the line.

Standard polypropylene boxes, on the other hand, are specialists built for the cold. They usually tap out around 160°F, which means they’re perfect for your refrigerated ingredients but will warp or crack if you try to hold hot items in them. When in doubt, flip the container over; the manufacturer's specs are almost always printed right on the bottom.

How Do I Stop Tomato Sauce From Staining My Clear Boxes?

Ah, the eternal battle for every pizzeria. Tomato sauce is the arch-nemesis of clear polycarbonate, famous for leaving behind that stubborn reddish-orange ghost stain on prep table pans.

To get ahead of it, you can create a barrier. Just give a clean, dry box a light spritz with a food-safe pan spray before you pour in the sauce. For stains that have already set in, try making a paste of baking soda and water, letting it sit for a few hours. It can often lift a surprising amount of the discoloration. Honestly, though, for long-term sauce storage where you don't need perfect visibility, opaque polypropylene containers are the smarter, stain-proof choice.

Pro Tip: Never, ever use bleach on polycarbonate boxes. It might seem like a quick fix for stains, but it will slowly degrade the plastic, making it brittle and way more likely to crack over time.

Are Color-Coded Food Storage Boxes Worth the Investment?

One hundred percent, yes. In the chaos of a busy pizzeria, a color-coded system is one of the easiest and most powerful ways to stop cross-contamination in its tracks. It’s a simple visual language that helps your crew move faster and safer, especially when the dinner rush hits.

Getting a system going is straightforward:

- Red for Meats: Use these for pepperoni, sausage, and any other raw or cooked meats.

- Green for Vegetables: The obvious choice for all your prepped veggies—onions, peppers, mushrooms, you name it.

- White or Yellow for Dairy: Perfect for keeping your different cheese blends organized and separate.

This little bit of organization helps staff grab the right ingredient without a second thought and constantly reinforces good food handling habits. The small upfront cost pays for itself almost immediately in better food safety and a smoother, more efficient pizza line.

Ready to get your pizza prep station dialed in with the right commercial food storage boxes? At Pizza Prep Table, we’ve hand-picked a selection of equipment built to make your pizzeria safer, faster, and more profitable. Find the perfect gear for your kitchen at pizzapreptable.com.