Your Guide to Commercial Pizza Prep Tables

Share

Think of a commercial pizza prep table as the command center of your entire pizza-making operation. It’s not just a piece of kitchen furniture; it’s the central hub where speed, organization, and quality all come together, making it the single most critical piece of equipment for any serious pizzeria.

The Command Center of Your Pizzeria

Forget thinking of it as just a table. This is the heart of your production line, the one spot where everything crucial to crafting the perfect pizza happens. It’s built to do two essential jobs at once, perfectly.

First, its refrigerated base and top-mounted cold wells keep your cheese, pepperoni, fresh veggies, and sauces perfectly chilled and well within food-safe temperature zones. At the same time, its huge work surface gives your pizza makers a dedicated area for stretching dough and building pies with lightning speed.

Solving Key Pizzeria Challenges

This dual-function design is a brilliant solution to the biggest headaches in a high-volume pizzeria. By merging cold storage with a durable workspace, it elegantly solves several persistent problems:

- Ingredient Freshness: It keeps perishable toppings like mozzarella and fresh basil at their ideal temperatures, preserving flavor and preventing spoilage right where you need them.

- Workflow Efficiency: Everything your pizza maker needs is within arm's reach. This simple change eliminates wasted motion—like constant trips to a separate walk-in cooler—and shaves precious seconds off every single order.

- Food Safety Compliance: The unit is designed to hold ingredients at temperatures below 40°F (4°C), helping you sail through health code inspections and stamp out the risk of bacterial growth.

A purpose-built commercial pizza prep table isn’t just a convenience; it's a non-negotiable tool for achieving consistent quality and peak productivity. The wrong setup can increase labor costs by up to 25% due to inefficient workflow alone.

More Than Just a Table

When you get down to it, this equipment is the backbone of your pizzeria. Its design truly understands the unique—and often messy—process of making pizza. The raised rail for ingredient pans helps contain stray sauce and toppings, while the deep cutting board, often 19 inches or more, is specifically designed to handle large pizza skins without ingredients spilling over the edge.

For any pizzeria that's serious about consistency, speed, and safety, a dedicated prep table is an absolute must-have. It streamlines the entire operation, from dough to oven, ensuring every single pizza you serve meets the high standards your customers have come to expect. It truly is the heart of a productive and profitable pizzeria.

Anatomy of a High-Performance Pizza Prep Table

To really get what makes a commercial pizza prep table tick, you have to look past the shiny stainless steel. These aren't just glorified refrigerators; they're sophisticated workstations where every single part is designed for performance, durability, and most importantly, speed. Breaking it down reveals why certain features are absolute must-haves for any serious pizzeria.

To really get what makes a commercial pizza prep table tick, you have to look past the shiny stainless steel. These aren't just glorified refrigerators; they're sophisticated workstations where every single part is designed for performance, durability, and most importantly, speed. Breaking it down reveals why certain features are absolute must-haves for any serious pizzeria.

From the surface where your team builds each pie to the compressor humming away below, every component plays a crucial role in your day-to-day grind. Understanding how these parts work together is the first step in picking a machine that will be a reliable partner, not a headache, during the Friday night rush.

The Workspace: The Cutting Board and Work Surface

The top of the prep table is where all the action happens, and the material you choose directly affects how smoothly your team can sling dough. You’ve got a couple of primary options, and each one has its own personality.

- Marble or Granite: These natural stones are the gold standard for a reason. Their surfaces stay naturally cool, which is a lifesaver for preventing dough from sticking. This is a game-changer for pizzerias that hand-stretch every pizza, as it cuts down on excess flour and makes for a much cleaner workflow. The trade-off? They're heavier, pricier, and need to be sealed to keep them from staining or cracking.

- Stainless Steel: This is the undisputed champion of durability and sanitation in the pizza world. It's tough as nails, non-porous, and a breeze to clean. While dough might stick a bit more than it would on stone, its incredible resilience and affordability make it the go-to, practical choice for the vast majority of pizzerias.

The work surface also includes the cutting board, and this is where pizza prep tables really stand out. A true pizza prep table is defined by its extra-deep cutting board, often 19 inches or more. That generous depth is essential for handling large pizza skins, giving your team plenty of room to work without sending sauce and toppings flying onto the floor.

The Topping Zone: The Refrigerated Rail System

Right behind the cutting board is the heart of your pizza assembly line: the refrigerated rail. This is a row of insulated wells, perfectly designed to hold food pans full of every topping you can imagine, from classic pepperoni and mushrooms to fresh mozzarella and basil.

A well-designed rail system keeps every single ingredient within arm's reach and at a consistent, food-safe temperature, typically below 40°F (4°C). This feature alone slashes prep time by getting rid of all those trips to a separate walk-in cooler.

Many high-performance models have an angled rail, which tilts the pans towards the pizza maker for a better view and easier access. It sounds like a small detail, but over a long shift, that little ergonomic touch makes a huge difference in comfort and speed. The rail is also raised, creating a smart barrier that stops stray ingredients from falling into the wrong pans—a crucial detail for maintaining quality and avoiding cross-contamination.

The Powerhouse: The Refrigeration System

The engine that drives any commercial pizza prep table is its refrigeration system. The design and efficiency of this system don't just determine temperature consistency; they also have a direct impact on your monthly energy bill. A robust system makes sure that both the top rail and the refrigerated base cabinet stay consistently cold, even when the doors are being opened constantly during a busy service.

The compressor is the core component. Modern, energy-efficient compressors, especially those in ENERGY STAR rated units, now use eco-friendly refrigerants like R290. These systems don't just run quieter and use less power; they also have a much smaller environmental footprint.

Airflow design is just as critical. Advanced forced-air systems use fans and strategically placed ducts to circulate cold air evenly from top to bottom. This gets rid of hot spots and ensures every pan in the rail and every item in the base stays perfectly chilled, protecting both your inventory and your reputation. These systems also help the unit recover its temperature faster after the lid or doors are opened, which is a vital function in any fast-paced pizzeria.

Picking the right size for your commercial pizza prep table is one of the most important calls you'll make for your pizzeria. This isn't just about finding something that fits a gap in your floor plan. It’s a decision that sets the entire rhythm of your production line.

Get it right, and your kitchen flows like a well-oiled machine. Get it wrong, and you’ve just created a frustrating bottleneck that costs you money every single day. You're not just buying a table; you're designing the heart of your pizzeria's workflow.

The size you need has to match your pizzeria’s unique output. It's such a vital piece of equipment that the global market for these tables is booming—it was valued at $1.75 billion in 2024 and is expected to climb to $4.92 billion by 2033. That growth is all thanks to the non-stop demand for pizzerias and delivery.

Translate Dimensions into Production Power

When you see models listed as 48-inch, 67-inch, or 93-inch, those numbers are about more than just physical width. They're a direct measure of your production power. A wider table doesn't just give your staff more elbow room; it means a bigger cutting board, more refrigerated storage underneath, and—most critically—more space for your ingredient pans on the rail.

Here’s a practical way to think about it for your pizzeria:

- A smaller 44-inch to 48-inch unit is a great fit for a small, local pizzeria or a café that has pizza on the menu. It typically holds about six to eight 1/3-size pans and lets one pizza maker work without feeling cramped.

- A mid-range 67-inch to 72-inch table is the workhorse for most busy pizzerias. It can handle a dozen or more pans and comfortably fits two pizza makers working side-by-side during a rush.

- A large 93-inch model (or bigger) is built for high-volume delivery and takeaway pizzerias. With room for 12 to 18+ pans and space for multiple staff, this beast is designed to pump out a ton of pizzas per hour without breaking a sweat.

Think about your busiest hour on your busiest day. The right table needs to handle that peak demand without creating a traffic jam. Choosing a table that's too small is like putting a speed limiter on your sales.

Commercial Pizza Prep Table Sizing Guide

To make this even clearer, let's break down how table size translates to real-world pizzeria performance. This table will help you match a prep table's dimensions to your pizzeria's output and ingredient needs.

| Table Width (Inches) | Typical Pan Capacity (1/3 size) | Pizza Output (per hour) | Best For |

|---|---|---|---|

| 44" - 48" | 6 - 8 pans | 20 - 40 pizzas | Small pizzerias, cafes, or bars with limited menus |

| 60" - 72" | 9 - 12 pans | 50 - 80 pizzas | Busy pizzerias, restaurants with popular pizza menus |

| 93"+ | 12 - 18+ pans | 80+ pizzas | High-volume delivery/takeout, ghost kitchens |

As you can see, the jump in width directly impacts how many pies you can get out the door. The right choice depends entirely on your business model and volume.

Matching Size to Your Pizzeria's Reality

Let's look at two different pizzerias. First, imagine a cozy, family-owned Italian spot that serves amazing artisanal pizzas alongside pasta dishes. Their pizza volume is steady but not overwhelming. For them, a 48-inch unit is probably perfect. One person can handle the orders, and it fits neatly into their existing kitchen line.

Now, picture a ghost kitchen that only does pizza delivery. Their entire business is built on speed and volume. A 93-inch table isn't a luxury for them; it's a necessity. It allows multiple staff to top pizzas at the same time, ensuring orders are flying out the door. The larger size is a direct investment in their core promise: fast, hot pizza.

For a deeper look at optimizing your entire refrigerated setup, check out our guide on choosing the perfect pizza preparation refrigerator.

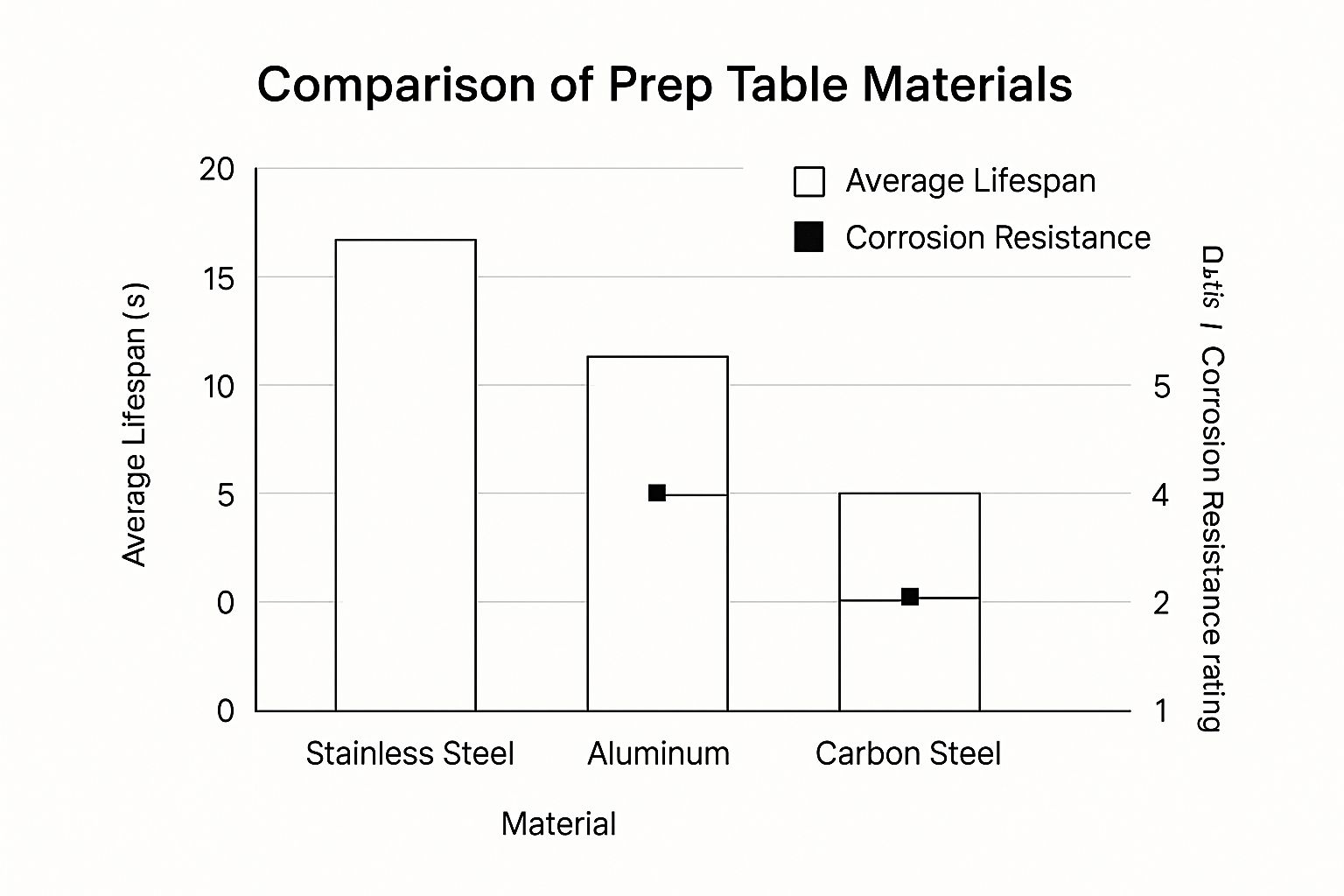

The material your table is made from is just as important as its size. This chart breaks down the durability of the most common options.

It’s pretty clear that while other materials are out there, stainless steel offers the best mix of a long lifespan and high resistance to corrosion—making it a solid choice no matter which size you land on for your pizzeria.

Beyond the Footprint: Measuring for Success

Okay, before you hit that "buy" button, go grab a tape measure. And don't just measure the spot where the table is going to sit. You have to plan for what I call "breathing room."

- Ventilation Space: The refrigeration unit needs to breathe. Check the manufacturer's specs and leave at least a few inches of clearance at the back and sides for proper airflow. If you don't, you'll burn out the compressor.

- Staff Movement: Your crew needs to move around safely and freely. Make sure there are clear paths for carrying hot trays from the oven and restocking ingredients without bumping into each other.

- Door Swing: This is the one everyone forgets! Account for the full swing of the refrigerator doors and drawers. A door that can't open all the way because it bangs into another piece of equipment is a daily headache you absolutely don't need in a pizzeria.

Comparing the Top Pizza Prep Table Brands

Picking the right commercial pizza prep table brand is just as critical as choosing the right size. When you're staring at a market full of different names, it can feel like a tough call to figure out which one actually fits your pizzeria's real-world needs and budget. But this isn't just another purchase; it's a long-term investment in your kitchen's daily rhythm.

The brand you choose will have a real impact on everything from your monthly utility bills to your maintenance schedule and the overall flow of your pizzeria. Let’s break down the major players and focus on what really matters to a pizzeria's bottom line.

True Manufacturing: The Industry Benchmark

When you ask seasoned pizzeria owners about rock-solid durability and performance that just won't quit, the name True Manufacturing almost always comes up. For decades, True has been the go-to brand for equipment that can take the heat of a high-volume pizzeria, shift after shift, without breaking a sweat.

Their tables are built like tanks, often featuring oversized and balanced refrigeration systems that hold precise, food-safe temperatures even when you’re slammed during a dinner rush. Yes, the initial price for a True unit can be higher, but many pizzeria operators see it as a smart investment because of their legendary lifespan and solid warranty.

Turbo Air: The Energy-Efficient Innovator

For the pizzeria owner who keeps a close eye on utility bills and wants to run a greener operation, Turbo Air is a name you need to know. This brand has carved out a reputation for its incredibly energy-efficient designs, with many of its models being ENERGY STAR certified.

Turbo Air units are packed with features designed to cut down on energy use, like their famous self-cleaning condensers and high-density polyurethane insulation. That self-cleaning condenser is a real game-changer for pizzerias—it automatically brushes away dust and flour daily, which is a leading cause of cooling problems and compressor failure. This single feature can lead to major savings on energy and maintenance over the years.

Turbo Air really appeals to pizzeria operators who look at the total cost of ownership, not just the sticker price. When you factor in the long-term savings from lower electricity bills, their models become a very compelling choice.

Atosa Pizza Prep Tables: The Budget-Friendly Choice

If you're launching a new pizzeria, a food truck, or just working with a tighter budget, Atosa Pizza Prep Tables strikes a fantastic balance between solid performance and affordability. Atosa delivers dependable equipment without the premium price tag of the bigger names, making it a great way to get professional-grade gear in your pizzeria from day one.

While they might not have all the bells and whistles of their pricier competitors, Atosa prep tables absolutely nail the core functionality every startup pizzeria needs. You get reliable refrigeration and a sturdy workspace, allowing you to equip your kitchen without draining your initial capital. This makes Atosa a smart move for proving your concept before you scale up to more expensive machinery.

Ultimately, choosing a brand comes down to what your pizzeria values most. Whether it’s long-haul reliability, energy savings, or upfront cost, there’s a commercial pizza prep table out there that’s a perfect match for your business goals. Getting your workflow right is key, and you can learn more by reading our guide on the secret sauce behind efficient pizza prep stations.

Essential Maintenance to Ensure Peak Performance

Your commercial pizza prep table is the MVP of your pizzeria, running nonstop to keep toppings perfectly chilled and your pizza line humming. But just like any high-performance machine, it needs consistent care to stay in the game. Think of it this way: proactive maintenance isn't just about cleaning; it's about protecting your investment, guaranteeing food safety, and preventing a catastrophic breakdown during a Friday night rush.

Following a simple but steady maintenance routine is the secret to getting years of reliable service out of your unit. This isn't just a friendly suggestion—it's a must-do for any serious pizzeria.

Your Daily Maintenance Checklist

These quick tasks should become muscle memory at the end of every single shift. They only take a few minutes but are your best defense against health code violations and premature wear.

- Sanitize All Food-Contact Surfaces: Get in there and thoroughly clean the cutting board, the refrigerated rail, and all exterior surfaces. This is non-negotiable for passing health inspections.

- Wipe Down Interior and Gaskets: Clean up any spills inside the refrigerated base. You'll also want to carefully wipe the door gaskets with a damp cloth to get rid of any food bits that can break the seal.

- Verify Temperatures: Give the temperature readouts a quick look. Both the rail and the base cabinet have to hold steady below 40°F (4°C) to keep your ingredients in the safe zone.

This daily ritual ensures your station is always ready for battle and meets health standards. It's this growing focus on hygiene that's fueling the market for these tables. In fact, the global market for commercial pizza prep tables was valued at around USD 1.5 billion in 2023 and is projected to climb to USD 2.3 billion by 2032. You can discover more about these market trends and their drivers at DataIntelo.com.

Weekly and Quarterly Deep Cleaning

While your daily wipe-downs handle the surface stuff, deeper cleaning is what keeps your table from giving up the ghost when you need it most.

Weekly Tasks:

- Deep-Clean Gaskets: Go beyond the daily wipe. Use a mild soap solution to really clean the door gaskets, which keeps them flexible and ensures an airtight seal. A bad seal makes your compressor work overtime, and your energy bill will show it.

- Clear Drain Lines: Check the condensate drain line and make sure it's clear. A clog can cause water to pool inside the unit, leading to nasty sanitary issues and potential damage.

A blocked condensate drain is one of the most common—and easily preventable—reasons for a service call. A quick weekly check can save you hundreds of dollars in repair costs.

Quarterly Tasks:

- Clean the Condenser Coils: This is, without a doubt, the most important maintenance task you can do for your pizza prep table. The coils, usually near the compressor, get caked with flour, grease, and dust. This buildup acts like an insulator and forces the compressor to run constantly. A simple brushing every 90 days is absolutely critical for cooling efficiency and preventing total compressor failure in a pizzeria environment.

- Check and Tighten Casters: Make sure the table’s wheels are secure and working right. This is also the perfect time to give the floor underneath a good, deep clean.

By sticking to this schedule, you turn maintenance from a chore into a secret weapon. It guarantees your commercial pizza prep table remains a reliable workhorse in your pizzeria for years. For more tips on getting your station set up for success, prep like a pizza pro with these topping stations.

Your Top Questions About Pizza Prep Tables, Answered

When you're looking to invest in a commercial pizza prep table, a lot of questions can pop up. I get it. As a pizzeria owner, you need straight answers to make a smart decision that will actually make your kitchen faster and more efficient. Let's walk through some of the most common questions I hear from operators just like you.

What’s the Real Difference Between a Pizza Prep and a Sandwich Prep Table?

The biggest giveaway is the cutting board depth. A true pizza prep table has a much deeper cutting board, usually 19 inches or more. This is specifically designed so you can work with large pizza bases without cheese and toppings spilling all over the floor. A sandwich prep table, on the other hand, typically has a much shallower board, maybe 10 to 12 inches deep.

Another key design element you’ll often see on pizza tables is a raised refrigerated rail. It’s a clever feature that helps keep messy sauce and toppings from falling into the ingredient pans below—a lifesaver during the chaos of a dinner rush.

Which Work Surface Is Best: Marble, Granite, or Stainless Steel?

This is a great question, and the right answer really depends on your pizzeria's priorities.

- Marble and Granite: These stone surfaces are fantastic for handling dough. They stay naturally cool, which is a huge help in preventing sticking. The downside? They come with a higher price tag and demand careful maintenance to prevent stains or cracks.

- Stainless Steel: This is the industry workhorse for a reason. Stainless steel is incredibly durable, a breeze to sanitize, and much more budget-friendly. For most high-volume pizzerias, it’s the most practical and popular choice by a long shot.

For a bustling pizzeria where durability and easy cleaning are top priorities, stainless steel is almost always the most reliable bet. While dough might stick a little more, its ability to stand up to heavy, constant use is a massive advantage.

How Often Should I Be Cleaning the Condenser Coils?

You absolutely need to clean the condenser coils on your commercial pizza prep table at least every 90 days. If your kitchen has a lot of airborne flour and grease—and most pizzerias do—cleaning them monthly is an even better habit to get into.

When those coils get clogged, the compressor has to work overtime. This leads directly to higher energy bills, poor cooling, and a much, much greater risk of the whole unit failing prematurely. A quick brushing is one of the easiest and cheapest ways to protect your investment.

What Is a Mega Top Prep Table?

Think of a "mega top" as a pizza prep table on steroids. It’s a special design that gives you an extra row of ingredient pans in that refrigerated rail. This simple change boosts your topping capacity by about 50% compared to a standard table of the same width.

They are the perfect solution for pizzerias with a huge, creative menu or any shop that wants to give customers a ton of customization options without slowing down the line.

Ready to find the perfect command center for your pizzeria? Pizza Prep Table offers a huge selection of new and used equipment from top brands, backed by financing options and free freight.

Explore Our Full Range of Pizza Prep Tables and Commercial Kitchen Equipment