The Secret Sauce Behind Efficient Pizza Prep Stations

Share

The Backbone of High-Volume Pizzerias

A pizza prep station is a specialized food preparation table designed for pizzerias and restaurants that combines refrigerated storage with an accessible workspace for assembling pizzas.

What is a Pizza Prep Station?

- Definition: A commercial workstation that combines refrigerated ingredient storage, a food preparation surface, and organized topping containers

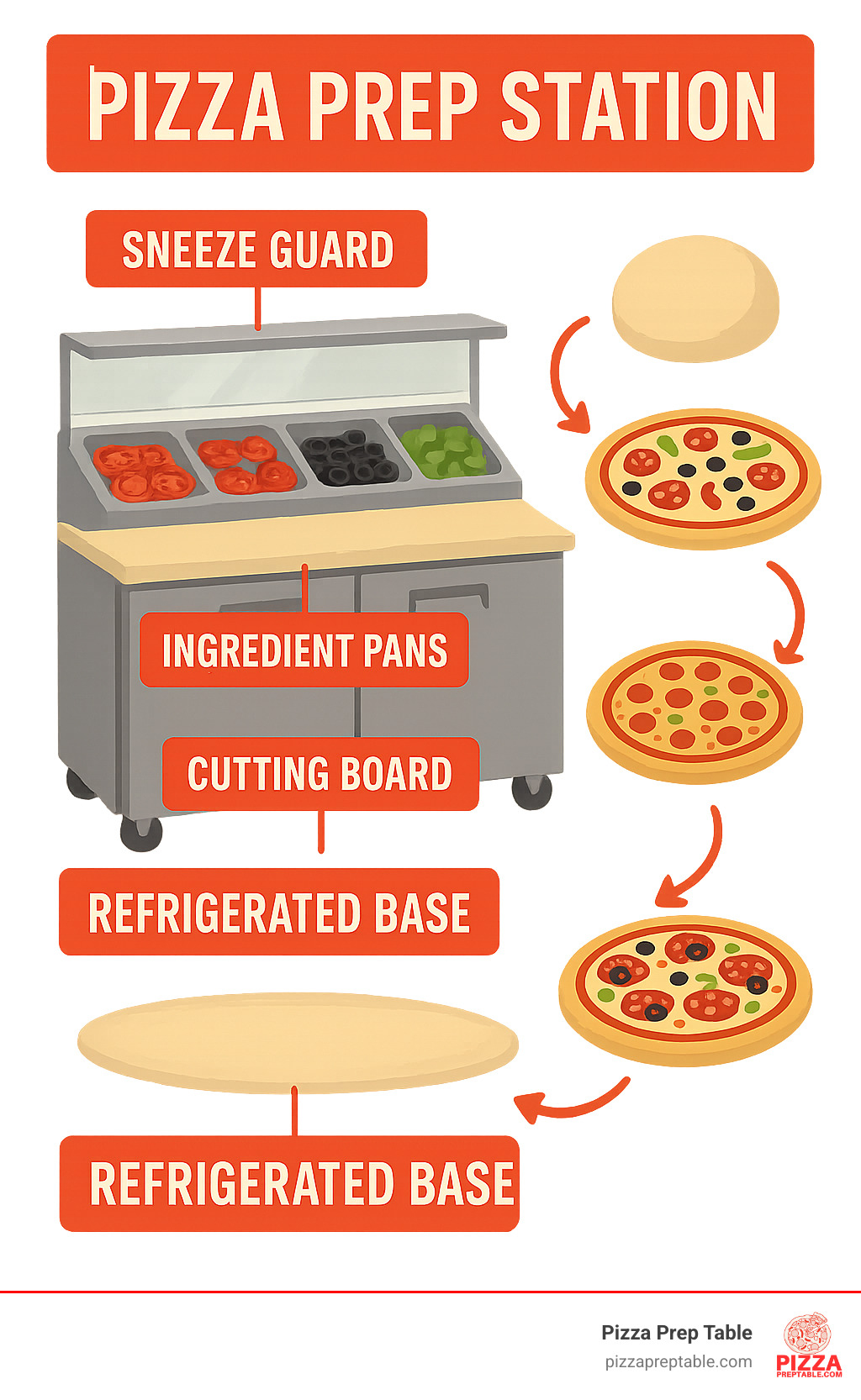

- Main Components: Refrigerated base, cutting board/work surface, refrigerated ingredient pans, sneeze guard, and often mobility features

- Price Range: $1,500 for entry-level models to $14,000+ for premium large-capacity units

- Common Sizes: From compact 44-inch models (10.9 cu ft) to large 119-inch units with up to 8 drawers and 4 doors

Pizza prep stations form the operational center of any successful pizzeria. They're the unsung heroes behind efficient pizza assembly, allowing staff to quickly access fresh ingredients while maintaining food safety standards. When designed correctly, these stations can dramatically reduce preparation time, increase ingredient freshness, and improve overall kitchen workflow.

The best pizza prep tables combine stainless steel construction for durability with efficient refrigeration systems that keep ingredients at ideal temperatures (typically 33°F to 41°F). Most commercial models are ETL or NSF certified, ensuring they meet strict food safety requirements.

I'm Sean Kearney, and with over a decade of experience in restaurant equipment sales, I've helped hundreds of pizzeria owners find the perfect pizza prep station for their unique kitchen layouts and production volumes. My background in connecting customers with the right equipment solutions has given me knowledge of how the right prep station can transform a pizza operation's efficiency.

Quick look at pizza prep station:

What Is a Pizza Prep Station?

The heart and soul of every successful pizzeria is its pizza prep station. This isn't just another piece of kitchen equipment—it's where culinary creativity meets practical efficiency, where fresh ingredients transform into mouthwatering pizzas ready for the oven.

A pizza prep station combines several essential elements into one streamlined workstation that makes pizza-making a breeze. Think of it as your pizza command center, with everything you need within arm's reach.

The typical station includes a refrigerated base for storing backup ingredients, a full-length cutting board where the assembly magic happens, refrigerated pans that keep your toppings fresh and accessible, a protective sneeze guard, and wheels for easy mobility when it's time to clean.

As one of our long-time customers likes to say, "My prep table is like my trusted sous chef—always reliable, keeps everything organized, and never complains about overtime!"

Core Components Explained

Let's peek under the hood of what makes a pizza prep station truly special.

The compressor is the beating heart of your station's cooling system. Most commercial units feature either front-breathing Embraco compressors (perfect for built-in installations) or side/rear-breathing systems. They typically run on standard 115V or 120V power, drawing between 2.4-3.1 amps depending on the unit's size.

Modern stations often use environmentally friendly R290 hydrocarbon refrigerant, which not only helps our planet but also creates shorter run times and lower energy bills—a win-win for your business and the environment. These systems maintain perfect temperatures between 28.4°F and 46.4°F, ensuring your ingredients stay fresh all day long.

The construction quality matters tremendously for equipment that faces daily abuse. That's why commercial pizza prep stations feature durable stainless steel inside and out. Those rounded interior corners aren't just for looks—they prevent annoying food buildup and make your closing cleanup much faster.

For pizzerias looking for the ultimate in durability, granite top options like the Atosa MPF8203GR offer a marble stone surface that lets you prepare and finish pizzas on the same workspace. These premium surfaces stand up to years of heavy use while maintaining their professional appearance.

Pizza Prep Table vs. Salad & Sandwich Tables

While they might look similar at first glance, a pizza prep station differs from other food prep tables in important ways that directly impact your pizza-making efficiency.

The work surface on a pizza table is significantly deeper—typically 19-20 inches compared to the 8-10 inches on sandwich tables. This extra depth gives you the crucial space needed for stretching dough and adding toppings without feeling cramped.

The pan rails are designed differently too. Pizza tables feature larger, deeper ingredient pans (often 1/3 size Gastronorm) that hold more of your high-volume toppings like cheese and pepperoni. Sandwich units typically use smaller 1/6 pans that wouldn't keep up with a busy pizza service.

The refrigeration system is engineered specifically for pizza ingredients. The cold wells maintain perfect temperatures for cheese and other toppings that need consistent cooling throughout service, preventing that dreaded end-of-night waste.

"When I upgraded from a standard prep table to a real pizza prep station, my prep time dropped by nearly 40%," shared Mike, owner of a busy Chicago pizzeria. "The right tool for the right job makes all the difference."

Want to learn more about selecting the perfect kitchen prep surface? Check out our comprehensive guide on picking the perfect kitchen prepping table where we dive even deeper into making the right choice for your specific operation.

Types & Configurations of Pizza Prep Stations

When it comes to pizza prep stations, one size definitely doesn't fit all. The market offers a variety of configurations to match your specific needs, whether you're running a small neighborhood pizzeria or a high-volume restaurant chain. Let's explore the options that could transform your pizza-making process:

Refrigerated Workhorses

The backbone of most pizzerias is the refrigerated pizza prep station - the true workhorse of the kitchen. These reliable units keep your ingredients fresh while providing the workspace you need.

These models use forced-air cooling systems that circulate cold air around your ingredient pans, maintaining food-safe temperatures between 33°F and 41°F. As one manufacturer puts it, "Food pans are cooled with forced-air refrigeration to maintain consistent temperature."

Many newer models have acceptd eco-friendly R290 hydrocarbon refrigerants. This isn't just good for the planet - these systems actually improve efficiency with shorter run times and lower energy usage. Your electric bill will thank you!

Quality matters when it comes to food safety, which is why reputable pizza prep stations come with ETL and NSF certifications. These ensure your equipment meets strict safety and sanitation standards - something health inspectors and insurance companies look for.

Non-Refrigerated & Marble-Top Units

Already have plenty of refrigeration but need more prep space? Non-refrigerated and marble-top units might be your perfect solution.

The stone surfaces on these units are a pizza maker's dream. Marble and granite tops stay naturally cool and don't stick to dough - a game-changer for stretching and forming pizza bases. The Atosa MPF8203GR, for example, features "an integrated marble stone top enables simultaneous preparation and finishing of pizzas on the same surface."

These stations excel at dough staging, giving you dedicated space for preparing, rolling, and staging dough before moving to the assembly process. Many pizzerias use these alongside refrigerated units for a complete prep solution.

Outdoor & Cart-Style Stations

The pizza world is going mobile, and equipment manufacturers have responded with weather-ready options.

These units feature weather-resistant construction that can handle the elements. The Everdure Pizza Station "is uniquely designed to bring your indoor preparation space outdoors," perfect for patio dining areas or food trucks.

Mobility is key with these units, which typically include "lockable, multi-directional castors enable easy portability on uneven surfaces." This makes them ideal for catering events, food festivals, or restaurants with flexible outdoor cooking areas.

Many outdoor pizza prep stations are designed as BBQ cart crossovers, working seamlessly with popular equipment like Ninja Woodfire Grills or Blackstone Griddles. The "Pizza Oven Table with Topping Station" is a perfect example of this versatile approach.

Doors, Drawers, or Combo?

How you access your ingredients and backup supplies can make or break your kitchen workflow. Here's how the storage options compare:

| Feature | Doors | Drawers | Combo |

|---|---|---|---|

| Best for | Bulk storage of large items and backup ingredients | Organized access to frequently used items | Maximum flexibility |

| Access | Requires bending down, full cabinet access | Slide-out access at standing height | Best of both worlds |

| Capacity | Higher overall storage volume | Better organization but slightly less total space | Optimized for different item types |

| Cost | Most economical | Premium price point | Mid-range to premium |

| Common Sizes | All sizes (44"-119") | Usually on larger units (67"+) | Mid to large units (67"-119") |

As one pizza equipment specialist notes, "Different access types optimize workflow and organization in a busy kitchen." Many busy pizzerias prefer a combination approach, with drawers positioned where staff need frequent access and doors for less-used backup supplies.

The right configuration can save your team countless steps and seconds - which add up to minutes and hours over a busy shift. That's why at PizzaPrepTable.com, we help you find the perfect match for your specific operation.

Choosing the Perfect Pizza Prep Station

Finding your ideal pizza prep station feels a bit like dating – you need the right match for your kitchen's personality, workflow, and long-term goals. Let's walk through what really matters when making this important decision.

Size & Pan Capacity

When it comes to pizza prep stations, size definitely matters – but bigger isn't always better. Your perfect fit depends on your daily pizza volume and kitchen space:

Most pizzerias gravitate toward the middle range, with 67-inch and 93-inch models being the crowd favorites. These workhorses typically offer 2-3 doors and hold between 20.8 to 30+ cubic feet of ingredients and supplies.

If you're running a cozy neighborhood shop, a compact 44-inch unit with a single door might be perfect. But if you're slinging hundreds of pies on busy nights, you'll want to look at those impressive 119-inch behemoths that can hold up to 18 ingredient pans.

Your pizza prep station is likely to be with you longer than some relationships – most operators keep theirs for 7-10 years or more. Think about where your business is heading, not just where it stands today.

Refrigeration & Energy Efficiency

The cooling system is the beating heart of your pizza prep station, and getting this right affects both food safety and your monthly bills.

Front-breathing compressors are fantastic if you're tight on space – they can snuggle right up against walls or be built into counters. Side or rear-breathing models need more room to breathe but sometimes offer better cooling performance in warmer kitchens.

I always recommend looking for Energy Star certified models when possible. They might cost a bit more upfront, but they'll thank you every month when the electric bill arrives. Some clever innovations worth considering include self-cleaning condensers (found in brands like Turbo Air) and precise digital temperature controls that maintain the perfect environment for your precious cheese and toppings.

"The switch to eco-friendly R290 refrigerant has been a game-changer," a kitchen equipment specialist recently told me. "Not only is it better for the planet, but these systems actually run more efficiently with shorter cycles." This matters both for your operational costs and for keeping those ingredients at their peak freshness.

Worktop Materials & Build Quality

Your pizza prep station's work surface takes a daily beating, so durability isn't optional.

Most units come with polyethylene cutting boards that span the full length of the unit. Look for ones at least ½-inch thick that can be removed for proper sanitizing. For those working extensively with dough, the granite-topped models like KoolMore's KM-RPCPS-2D59-GRT offer a naturally cool surface that dough won't stick to – a little luxury your pizza makers will appreciate during busy shifts.

The body construction matters just as much as the top. Commercial-grade 304 stainless steel has become the industry standard for good reason – it stands up to the punishment of busy kitchens while being easy to clean. The little details make a big difference too: fully welded corners prevent food buildup in crevices, reinforced door hinges withstand thousands of openings, and magnetic gaskets that pop off without tools make cleaning a breeze.

Budget & Financing

Let's talk money – because pizza prep stations represent a significant investment in your business.

Entry-level models start around $1,500, but most pizzerias find their sweet spot with mid-range units in the $2,500-$6,000 range. If you're looking for all the bells and whistles, premium models can climb past $14,000.

Here at PizzaPrepTable.com, we understand that restaurant cash flow can be as unpredictable as customer rushes. That's why we've created flexible financing options for qualified businesses. Our monthly payment plans help you get the equipment you need today while preserving your capital for other expenses like inventory and marketing.

When calculating the true cost, the right prep station doesn't just cost money – it makes money. Faster prep times mean more pizzas per hour, consistent temperatures mean less spoilage, and ergonomic designs mean happier staff who stick around longer.

Leading Brands & Models

After years in this industry, I've seen certain manufacturers consistently deliver quality pizza prep stations that stand the test of time:

True has earned its reputation for building tanks disguised as prep tables. Their TPP-93 model seems to run forever with minimal maintenance – I know operators who've had theirs for 15+ years.

Turbo Air brings innovation to the category with their self-cleaning condenser technology, which means less maintenance and more consistent temperatures.

Frigos offers solid value, with their popular FG-PZPT-93 providing an impressive 30+ cubic feet of capacity in a three-door configuration, all backed by ETL certification.

Atosa's MPF8203GR combines the luxury of a marble stone top with reliable refrigeration at a price point that won't make you wince.

Maxx Cold delivers dependable performance in both their V-Series and X-Series lines, making them popular choices for operators watching their budgets.

Each brand brings something special to the table – whether it's True's legendary durability, Turbo Air's smart features, or Maxx Cold's value proposition. We carry them all at PizzaPrepTable.com because we know every pizzeria has unique needs and priorities.

For an in-depth look at commercial refrigeration options, check out Frigos Commercial Refrigeration.

Boosting Workflow & Multi-Menu Versatility

A well-designed pizza prep station doesn't just store ingredients—it revolutionizes your entire kitchen operation. Think of it as the command center where efficiency meets creativity.

Streamlining Kitchen Efficiency with a Pizza Prep Station

When we talk with pizzeria owners, they often tell us the same thing: a strategically positioned pizza prep station can transform how quickly they serve customers.

Creating an assembly-line layout is key to this change. By positioning your prep station to create a natural flow from dough preparation to topping application to the oven, you'll minimize unnecessary steps and significantly reduce ticket times. Your staff will thank you, and so will your hungry customers!

"Keep ingredients at arms-length in the top condiment pans for an efficient prep line," one equipment manual wisely advises. This mise en place approach ensures everything needed is within easy reach, eliminating the dreaded "where's the pepperoni?" mid-assembly scramble.

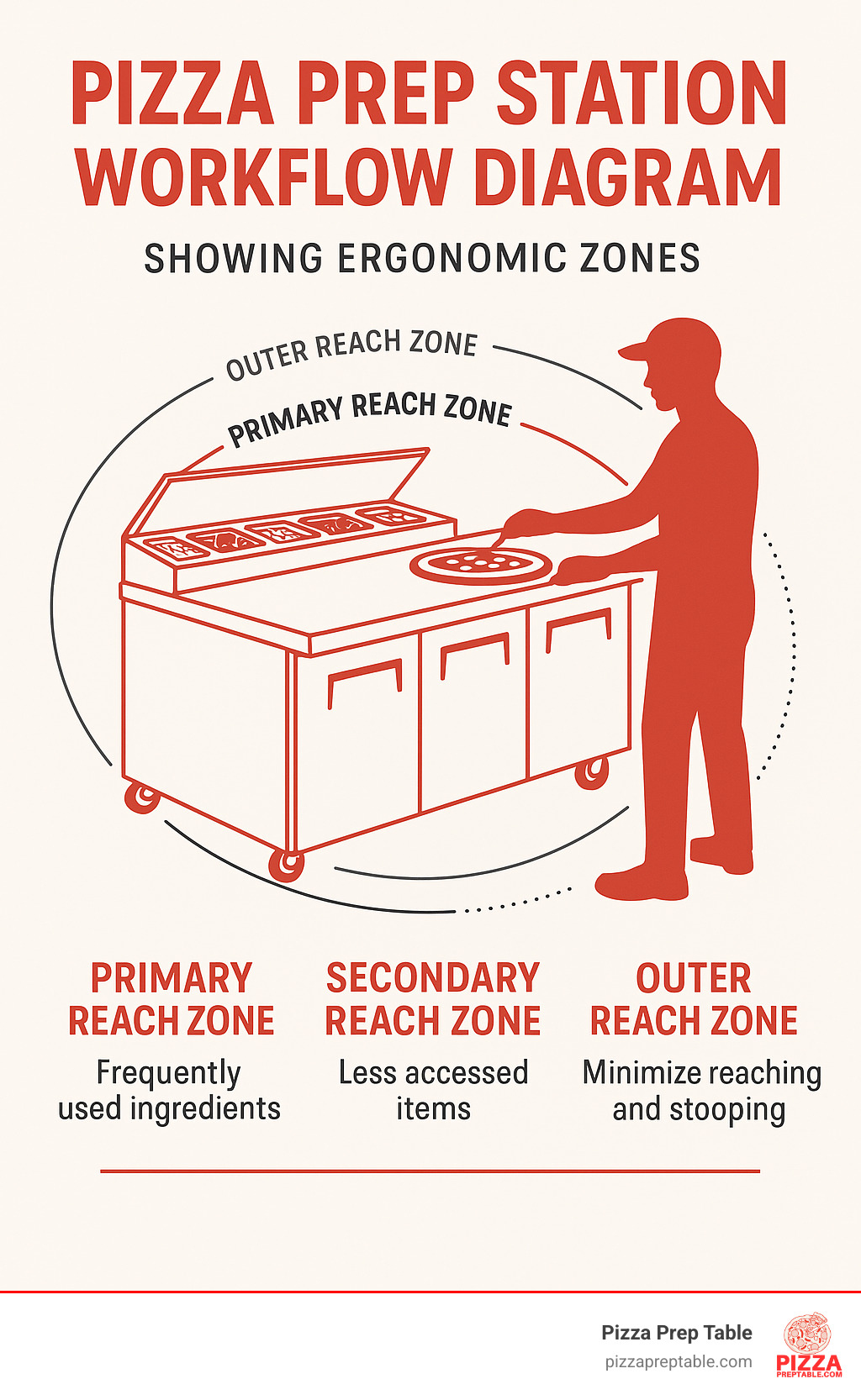

The best pizza prep stations are designed with worker comfort in mind. Ergonomic reach zones place frequently used ingredients directly in front of staff (the primary reach zone), reducing strain and speeding up the assembly process. Meanwhile, digital temperature controls maintain ingredients safely below 41°F, ensuring your operation stays in compliance with HACCP food safety guidelines.

I remember chatting with a pizzeria owner from Chicago who shared: "After upgrading to a 93-inch prep table with the right ingredient layout, we cut our average pizza assembly time from 90 seconds to under 60 seconds. During Friday rush, that translates to about 20 more pizzas per hour." That's not just efficiency—that's money in the bank!

Beyond Pizza: Salads, Sandwiches & More

Here's where the versatility of your pizza prep station really shines. While "pizza" is in the name, these workhorses are secret weapons for menu expansion.

The organized refrigerated pans make these stations perfect for salad assembly, sandwich preparation, and even dessert finishing. Many of our customers find creative ways to use their stations throughout the day—pizzas during dinner rush, but breakfast sandwiches in the morning or late-night appetizers after the dinner crowd thins out.

"Pizza prep tables can hold up to 18 ingredient pans, allowing for nearly limitless topping combinations and efficient workflow in busy food service environments," notes one industry report. This flexibility means your investment works harder for you across your entire menu.

A Philadelphia pizzeria owner recently told me: "We use our 67-inch prep table for pizzas during dinner rush, but during lunch, we swap half the pans to sandwich ingredients. It's like having two different prep stations in one." This kind of adaptability is budget-friendly and space-efficient—two things every restaurant owner appreciates.

The cross-utilization potential means your labor dollars stretch further too. Your staff can handle multiple menu categories from a single station, reducing the training curve and keeping your kitchen footprint manageable.

For more creative ideas on maximizing your prep equipment's versatility, check out our guide on prep sandwich refrigerators that shows how these versatile stations can keep ingredients fresh while delighting your customers.

Maintenance, Safety & Pitfall Prevention

Taking proper care of your pizza prep station isn't just about protecting your investment—it's about ensuring food safety and keeping your operation running smoothly day after day. Let me walk you through some practical maintenance tips I've learned from years in the industry.

Cleaning Checklist

I can't stress enough how important daily cleaning is—it's the secret to both food safety and equipment longevity.

At the end of each shift, make sure to remove and thoroughly sanitize the cutting board. This simple step prevents cross-contamination and extends the life of your workspace. I've seen too many operators skip this step only to wonder why their boards crack prematurely!

When closing up shop, transfer all your ingredients to covered containers in your main refrigerator. Those stainless steel pans should be washed and sanitized daily—food residue left overnight can create odors and potential health hazards.

Don't forget to give all interior surfaces a good wipe-down, paying special attention to those gaskets and corners where food likes to hide. As one equipment manual wisely points out, "Detach magnetic door gaskets without tools for routine sanitation." Those gaskets are crucial for maintaining temperature but are magnets for food debris.

Most modern pizza prep stations have auto-defrost functions, but you'll still need to check occasionally for ice buildup that might need manual attention. Excessive frost can hamper cooling efficiency and drive up your electric bill.

Preventive Maintenance & Longevity

Think of your pizza prep station like your car—regular maintenance prevents breakdowns and extends its life.

I recommend establishing a quarterly maintenance schedule with a professional technician. They'll check refrigeration systems and spot potential issues before they become expensive problems.

Door and drawer gaskets typically need replacement every 12-18 months, depending on use. It's a relatively inexpensive maintenance item that makes a huge difference in temperature stability and energy efficiency.

Make sure to have your thermostat calibrated annually. Even small temperature discrepancies can affect food safety and energy consumption.

One maintenance item that's often overlooked is cleaning those condenser coils. In dusty environments, monthly cleaning is essential; in cleaner kitchens, quarterly is usually sufficient. Dirty coils force your compressor to work harder, shortening its lifespan.

As one manufacturer proudly notes, "Each unit undergoes a 100% run test (24 hrs), including computer refrigerant charging, vacuum leak decay and helium leak detection before shipping." While this initial testing is reassuring, ongoing maintenance is still your responsibility.

Common Mistakes & How to Avoid Them

Even seasoned restaurant professionals make these mistakes with their pizza prep stations. Here's how to avoid them:

Overloading pans is a common error I see in busy kitchens. When you pile ingredients above the rim, you block proper air circulation, compromising food safety. Keep everything below the pan rim for optimal cooling.

I once visited a pizza prep station installation where they'd placed the unit right next to a blazing hot pizza oven. This warm room placement forces the refrigeration system to work overtime, leading to premature failure. Try to maintain kitchen temperatures below 80°F around your prep table.

Many operators leave those ingredient pan lids open all day long. I get it—it seems more convenient. But during slow periods, closing those lids maintains proper temperature and reduces energy usage significantly.

Don't forget about certifications when purchasing a new unit. Always verify proper ETL and NSF certifications to avoid problems with health inspectors. I've seen restaurants forced to replace nearly-new equipment because it lacked proper certification.

A pizzeria owner in Las Vegas shared this cautionary tale with me: "We placed our new prep table right next to our brick oven. Within six months, the compressor failed because it was constantly running in that heat. Moving it just eight feet away to a cooler spot solved the problem completely."

Frequently Asked Questions about Pizza Prep Stations

How do I determine the right size pizza prep station?

Look at three key factors: your menu variety (how many different toppings you offer), your production volume (pizzas per hour during rush), and your available kitchen space. For smaller operations making fewer than 30 pizzas per hour with a limited topping selection, a 44" or 60" unit usually works perfectly. Medium-volume operations (30-60 pizzas per hour) typically benefit from 67" or 72" models. If you're cranking out more than 60 pizzas per hour, consider 93" or larger units, possibly with drawer configurations for improved workflow.

What's the difference between granite and stainless tops?

Granite tops have a natural cooling effect that's fantastic for working with dough—they significantly reduce sticking. They're also more resistant to knife marks and scratches than other surfaces. The downside? They're heavier and more expensive. Stainless steel tops with polyethylene cutting boards remain more common because they're lighter and typically less expensive. Plus, those cutting boards can be removed for thorough cleaning and replaced when worn—something you can't do with granite.

How often should I service the refrigeration system?

For high-volume pizzerias, I recommend professional service quarterly. Lower-volume operations can usually get by with semi-annual check-ups. That said, you should be doing monthly visual inspections of condenser coils, checking for ice buildup, and verifying proper temperature (33°F-41°F) as part of your regular maintenance. Many manufacturers require annual system checks to maintain warranty coverage. At PizzaPrepTable.com, we can connect you with certified technicians in all our service areas, including New York City, Los Angeles, Chicago, and other major markets.

Avoiding Pitfalls & Next Steps

A pizza prep station isn't just a piece of equipment—it's the beating heart of your pizza operation. Throughout my years working with restaurant owners, I've seen how the right prep station can transform a chaotic kitchen into a model of efficiency.

Pro Tips from Industry Veterans

I've had the privilege of collecting wisdom from successful pizzeria operators across the country, and they've shared some game-changing insights:

One Boston pizzeria owner told me, "We pre-fill all ingredient pans during morning prep, then store them covered in the walk-in. At shift start, we just swap the empty pans for full ones." This simple practice saves precious minutes during the rush and keeps ingredients at peak freshness.

Cross-training has proven invaluable for many operations. A San Francisco operator explained, "Everyone should know how to properly clean and maintain the prep station. We rotate cleaning responsibilities daily so all staff understand how the equipment works." This shared knowledge creates accountability and ensures proper maintenance.

I love the strategic approach a Chicago deep-dish specialist shared: "We arrange ingredients in order of use frequency. Cheese and tomato sauce are centered directly in front of the prep position, while specialty toppings are positioned at the ends." This thoughtful organization can shave seconds off each pizza—which adds up to hours saved during busy shifts.

Perhaps the most sobering advice came from a New York pizzeria veteran: "Always have a backup plan. If your prep table goes down during Friday night rush, do you have a contingency?" They keep a folding table and coolers ready just in case—a small preparation that could save thousands in lost revenue.

At PizzaPrepTable.com, we understand that choosing a pizza prep station represents a significant investment in your business's future. That's why we're committed to supporting you with:

- Comprehensive selection from trusted industry brands

- Flexible financing options that respect your cash flow needs

- Personalized consultation to match you with the perfect equipment

- Service connections throughout our nationwide network

Whether you're launching your first pizza venture or upgrading equipment in your established restaurant, the right pizza prep station often makes the difference between stressful service and smooth operations.

For deeper insights about equipment options, financing solutions, or expert recommendations, visit our pizza equipment blog or reach out to one of our specialists today.

Remember: in the pizza business, preparation extends beyond ingredients—it's about having reliable equipment that brings those ingredients together efficiently, consistently, and profitably. Your pizza prep station truly is the secret ingredient behind your operation's success.