Doughn't Settle for Less – Choosing the Perfect Pizza Preparation Refrigerator

Share

Why Every Pizzeria Needs a Pizza Preparation Refrigerator

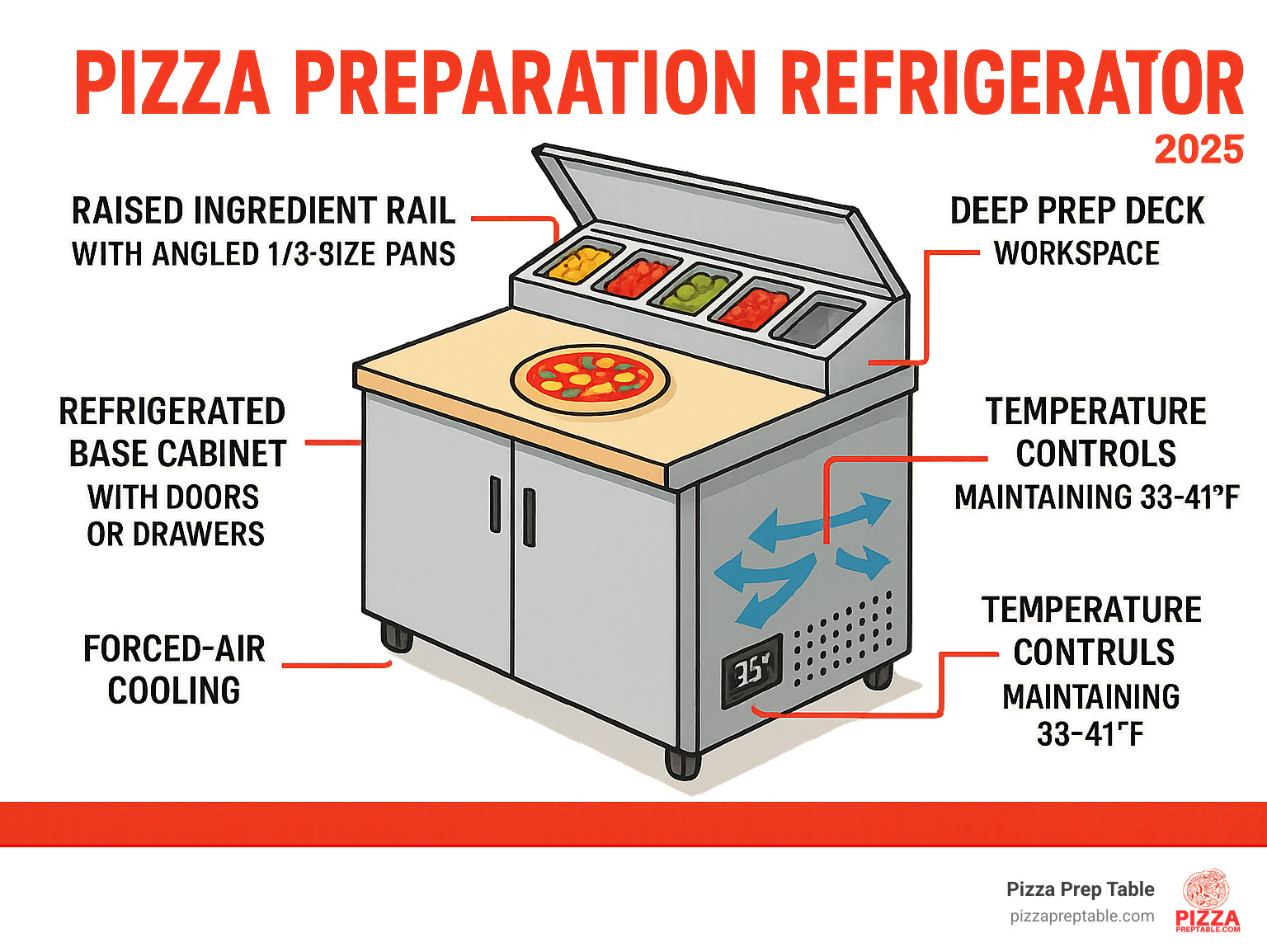

A pizza preparation refrigerator is a specialized commercial unit that combines a raised ingredient rail with refrigerated base storage, designed specifically for pizza assembly. Unlike standard reach-in refrigerators, these units feature:

- Raised pan rail holding 1/3-size ingredient pans at an ergonomic angle

- Deep prep deck (14-19 inches) for assembling extra-large pizzas

- Refrigerated base storage with doors or drawers for bulk ingredients

- NSF 7 certification maintaining 33-41 °F temperatures for food safety

- Forced-air cooling creating a cold blanket under ingredient pans

The typically raised, angled refrigerated rail holding ingredient pans on pizza prep tables makes them ideal for assembling pizzas—dispersing toppings onto pizza crusts is easy, and a deep prep area of 14 inches to 19 inches provides enough room to prep extra-large pies.

Speed matters in pizza kitchens. A proper pizza prep refrigerator keeps your most-used toppings within arm’s reach while maintaining safe temperatures. Modern units use eco-friendly R290 refrigerant that can yield up to 40 % energy savings compared to traditional refrigerants.

Granite vs. stainless steel tops each offer benefits—granite helps maintain lower temperatures for ingredient freshness, while stainless steel provides easier cleaning and durability.

I’m Sean Kearney, and I’ve spent years helping restaurant owners choose the right commercial equipment, including countless pizza preparation refrigerator installations. My sales background taught me that the right equipment makes all the difference in kitchen efficiency and profitability.

Pizza preparation refrigerator helpful reading:

How a Pizza Preparation Refrigerator Stacks Up Against Standard Reach-Ins

Picture this: it's Friday night, orders are flying in, and your pizza maker is running back and forth to a standard reach-in cooler. Every time they need pepperoni, they have to stop, open a door, dig through shelves, and then get back to work. It's a recipe for chaos.

A pizza preparation refrigerator changes everything. Instead of hunting for ingredients, everything you need is right at your fingertips. The raised rail system positions ingredient pans at the perfect angle—no more bending, reaching, or interrupting your flow.

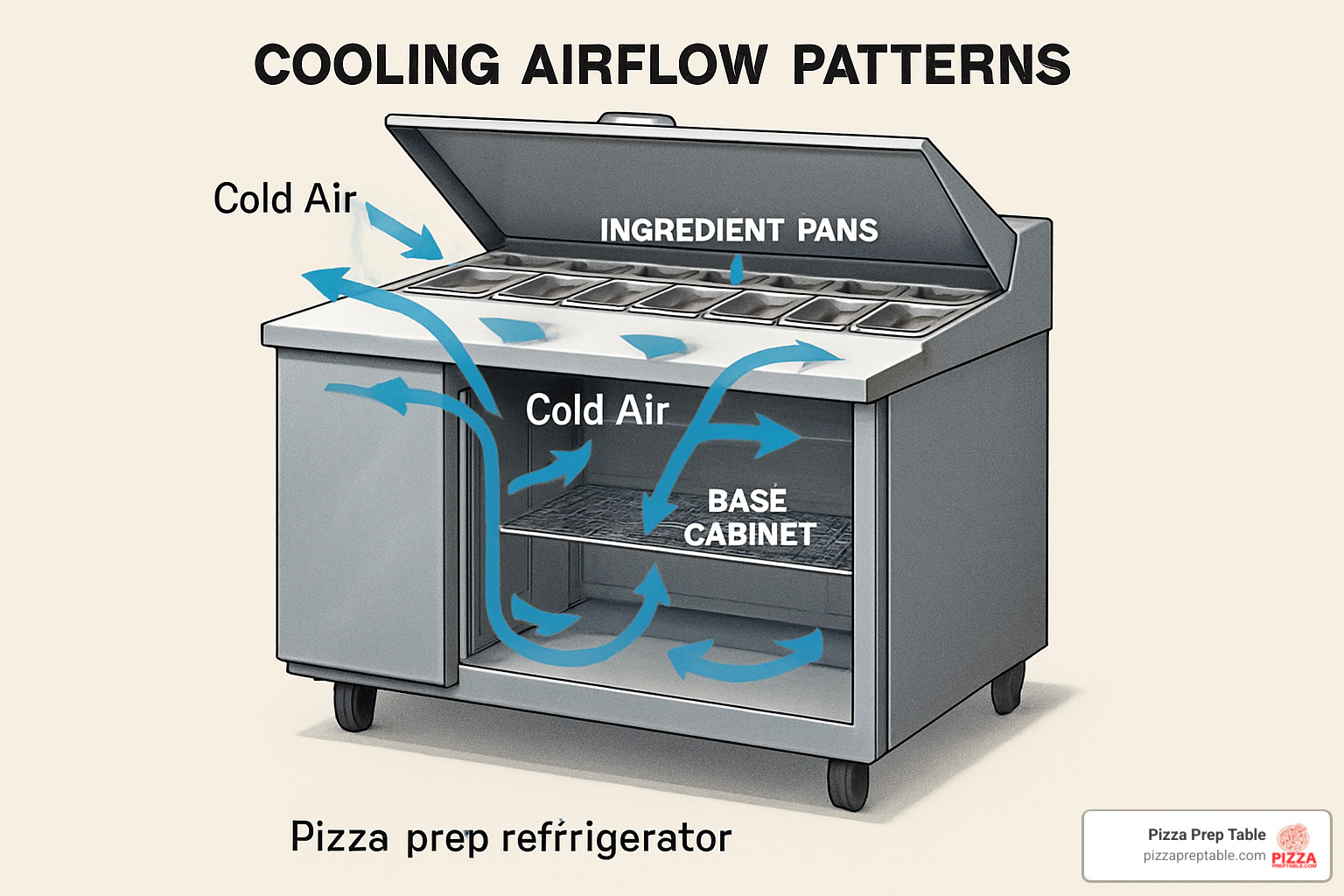

Here's where the magic happens: NSF 7 regulations require that pans be recessed at least 2 inches below the rail surface. This isn't just a safety rule—it creates a forced-air curtain that wraps around your ingredients like an invisible blanket, keeping everything at that perfect 33-41°F temperature.

The deep deck workspace gives you 14-19 inches of room to work with. Compare that to the 8-9 inches you get on sandwich prep tables, and you'll see why pizza makers love the extra space. When you're stretching dough for a 20-inch pizza, every inch counts.

| Feature | Pizza Prep Refrigerator | Standard Reach-In |

|---|---|---|

| Prep Space | 14-19" deep deck | No prep surface |

| Ingredient Access | Raised rail with angled pans | Shelves behind doors |

| Temperature Control | Dual zones (rail + base) | Single zone |

| Workflow | Continuous assembly | Stop-and-go access |

| Pan Capacity | 6-12 1/3-size pans | No pan rail |

The difference in workflow is like comparing a sports car to a delivery truck. Both get you there, but one makes the journey so much smoother.

Ingredient Rail & Deep Deck – the Signature of a Pizza Preparation Refrigerator

The ingredient rail is the heart and soul of any pizza preparation refrigerator. Most units hold between 6-12 1/3-size pans, giving you plenty of room for all your favorite toppings. The bigger units, like the Migali C-PP93, can handle up to 12 pans—that's enough variety to make even the pickiest customer happy.

Those angled lids aren't just for show. They swing open easily when you need them and snap shut to protect your ingredients from contamination. The air-over design is the secret sauce here—cold air flows directly over each pan, maintaining that crucial 33-41°F temperature even when you're opening and closing lids all day long.

The recessed pans do more than just look neat—they create the perfect microclimate for your ingredients. Fresh mozzarella stays creamy, pepperoni keeps its snap, and your vegetables stay crisp all shift long.

Shared Base Storage – Doors, Drawers or Both?

The refrigerated base storage is like the basement of your pizza preparation refrigerator—it's where all the bulk magic happens. This is your home for bulk dough bins, cheese blocks, sauce containers, and all those behind-the-scenes ingredients that make great pizza possible.

Doors are the workhorses of base storage. They give you tons of space for large containers and make organization a breeze. The 90-degree stay-open feature on most units means you can load and unload without playing a balancing act.

Drawers are all about speed and convenience. They're perfect for pre-portioned ingredients and drawer cages that keep everything organized. Plus, your staff won't have to bend down as much—their backs will appreciate the ergonomic advantage during busy shifts.

Key Features & Cooling Technologies to Consider

Choosing the right pizza preparation refrigerator means understanding the features that will make your kitchen run smoothly. Let me walk you through the key considerations that can make or break your decision.

Size matters, and these units come in widths from compact 32-inch models perfect for small shops to massive 119-inch giants that can handle multiple staff members during your busiest Friday night rush. The sweet spot for most pizzerias falls between 48-72 inches, giving you enough pan capacity without overwhelming your kitchen space.

The worktop material you choose will impact both performance and your daily workflow. Granite tops are fantastic for maintaining lower temperatures—they actually help keep your ingredients fresher longer and provide an excellent surface for stretching dough.

Stainless steel tops, on the other hand, are the workhorses of high-volume operations. They're incredibly easy to clean and can handle the daily abuse of a busy kitchen without showing wear.

Here's something that'll make your accountant happy: modern units increasingly use R290 refrigerant, which isn't just better for the environment—it can slash your energy costs by up to 40 % compared to traditional refrigerants. Over the life of your equipment, that's serious money back in your pocket.

Look for smart features like adaptive defrost cycles that only kick in when actually needed, rather than running on a fixed schedule. Self-cleaning condensers are another game-changer, reducing the maintenance headaches that can put your unit out of commission during peak hours.

For more detailed information about selection criteria, check out The Ultimate Guide to Buying a Pizza Prep Table.

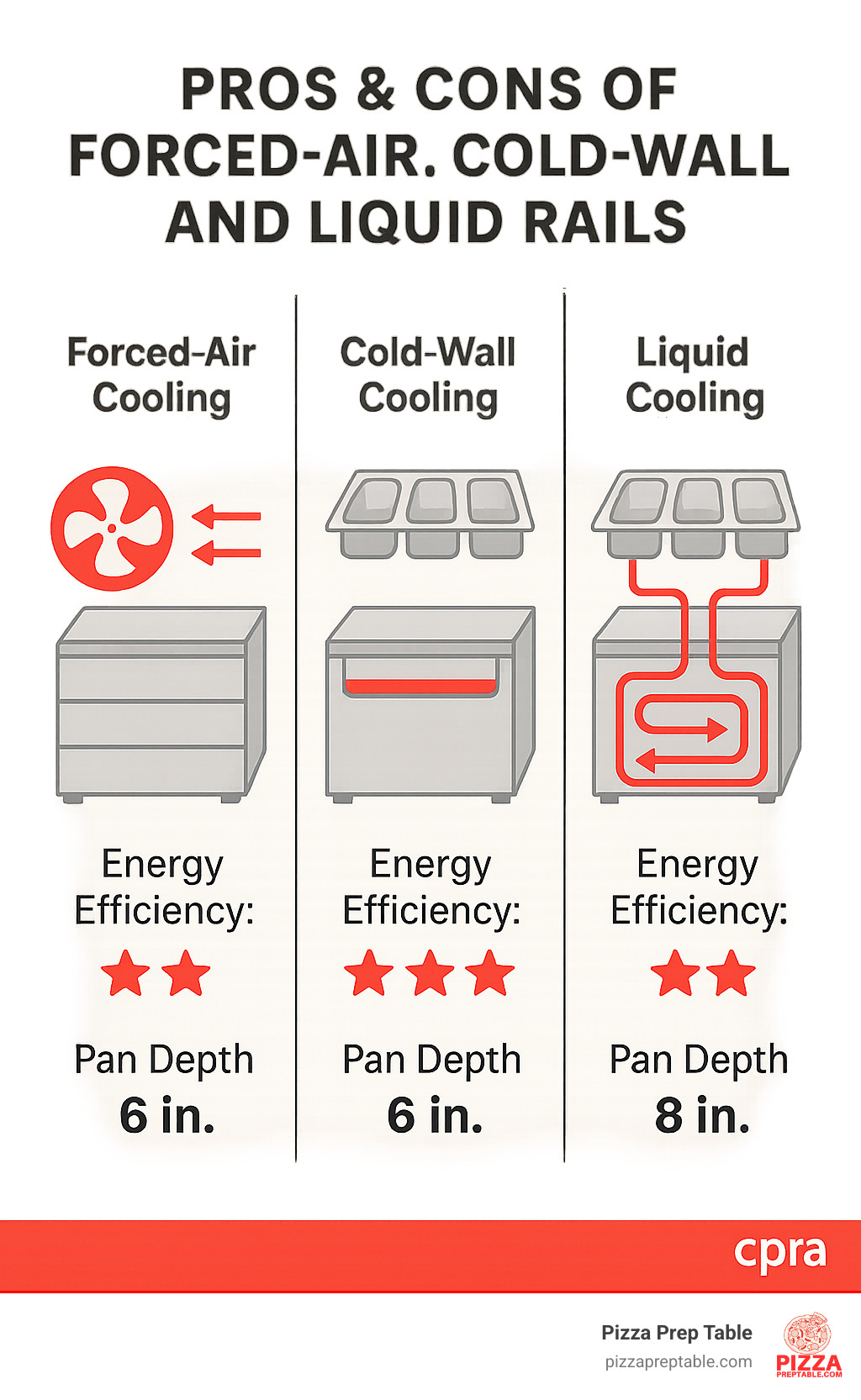

Pros & Cons of Forced-Air, Cold-Wall and Liquid Rails

The cooling system in your pizza preparation refrigerator is like the engine in your car—it's what keeps everything running smoothly. Each type has its own personality, and understanding these differences will help you pick the right one for your operation.

Forced-air cooling is the most popular choice, and for good reason. These systems place fans every 12 inches to create consistent airflow across all your ingredient pans. The temperature stays remarkably even, and when something goes wrong, most technicians can fix it quickly. The downside? That constant air movement can dry out your ingredients faster than you'd like.

Cold-wall systems take a different approach, using conductive plates to chill the rail area. The big win here is energy efficiency—you can literally shut off the rail overnight and save up to 60 % on energy costs. Perfect for operations that prep everything fresh each morning. The trade-off is patience: when you flip that rail back on, it takes longer to reach proper temperatures.

Liquid cooling is the premium option, using glycol loops to maintain temperatures. These systems are impressive—they can handle deeper pans (up to 8 inches versus 6 inches for forced-air) and never need defrost cycles. But they're more complex, which means higher repair costs.

Temperature Ranges & Food Safety Standards

Food safety isn't just about passing inspections—it's about protecting your customers and your reputation. Every pizza preparation refrigerator must maintain temperatures between 33-41 °F to meet NSF 7 standards, and this isn't negotiable.

Here's what's really impressive: your rail pans must stay at or below 41 °F for four hours with the lids completely off, and indefinitely with lids on. That's a tough standard, but it's what separates real pizza prep units from modified sandwich tables.

ANSI/NSF 7 certification is your golden ticket for health inspections. Without this certification, you're asking for trouble with health inspectors and potentially putting your customers at risk.

Modern units make compliance easier with digital temperature displays and audible alarms that alert your staff the moment temperatures drift out of the safe zone. Some advanced models even log temperature data automatically for HACCP compliance—no more clipboards and manual logging.

For more information about food safety standards, reference Scientific research on food safety.

Top Pizza Preparation Refrigerator Models for 2024

After helping hundreds of pizzeria owners choose the right equipment, I've seen which models consistently deliver the best performance. The 2024 lineup offers some impressive options, whether you're running a small neighborhood shop or a high-volume operation.

The True TPP-AT series continues to set the benchmark with its precision-engineered 13.5° angled rail and rock-solid construction. I've installed dozens of these units, and they just keep running year after year. The Turbo Air Super Deluxe line has really impressed me with features like adaptive defrost that only kicks in when needed and self-cleaning condensers that reduce your maintenance headaches.

For serious capacity, the Migali C-PP93 is a beast. With 26 cubic feet of storage and room for twelve 1/3-size pans in the rail, it's perfect for pizzerias with extensive topping selections. The forced-air system creates that perfect cold blanket under every pan.

The Omcan 59-inch granite model brings together the best of both worlds - that heavy-duty granite prep surface that dough loves, paired with modern R134a refrigerant technology. Meanwhile, the Saba SPP-70-9 proves you don't have to break the bank to get professional-grade performance.

When space isn't an issue, the Victory 119-inch models are game-changers. I've seen kitchens where three staff members can work simultaneously on these massive units during the dinner rush. The Randell cold-wall units deserve special mention for operators watching their energy bills - the efficiency gains really add up over time.

The Nor-Lake AdvantEDGE series brings some clever engineering to the table, while the Beverage-Air DP and Master-Bilt Fusion lines offer solid mid-range options that won't disappoint.

For more detailed information about topping stations, visit More info about topping stations.

2-Door Workhorses for Small Shops

Small pizzerias face a unique challenge - they need professional-grade performance but can't sacrifice precious kitchen space. The True TPP-44 has become my go-to recommendation for these situations. At just 44 inches wide, it fits almost anywhere while delivering the same quality you'd expect from True's larger units.

The Ikon IPP-47 offers incredible value without cutting corners on the essentials. The stainless steel construction feels solid, and the temperature control is spot-on. I've recommended this to several startup pizzerias, and they've all been thrilled with the performance.

For budget-conscious operators, the Atosa MSF8305 proves that you don't need to spend a fortune to get commercial-grade reliability. These compact units typically handle 6-8 pans in the rail and provide 10-15 cubic feet of base storage - plenty for most small operations.

3-Door Giants for High Volume

When you're slinging hundreds of pizzas during peak hours, you need a pizza preparation refrigerator that won't slow you down. The True TPP-93 is the workhorse that serious pizzerias rely on. The massive capacity and dual-zone temperature control mean you can keep everything at the perfect temperature, even during the craziest dinner rushes.

The Victory VTP-119 takes things to another level entirely. At 119 inches wide, it's like having a pizza assembly line built into your kitchen. I've seen kitchens where this unit transformed their entire operation, allowing multiple staff members to work simultaneously without getting in each other's way.

The Saba 3-door models deliver professional performance at a price point that makes sense for growing businesses. With 9-12 pan capacity and 20-30 cubic feet of base storage, they bridge the gap between small shop needs and high-volume demands perfectly.

For more information about large-capacity units, check out 3-Door Pizza Prep Fridges That'll Make You Say Cheese.

Granite-Top Specialists

There's something special about working with granite - ask any pizza maker who's used one. The Marra Forni pizza prep table features a massive 30-inch deep solid granite work surface that stays naturally cool. Your dough will thank you, and your ingredients stay fresher longer.

The Omcan 59-inch granite model combines that thermal advantage of granite with modern refrigeration technology. The surface is perfect for dough work, and the natural heat dissipation properties help maintain consistent temperatures even when you're working flat-out.

Everidge ThermalRite models take granite-top design seriously, pairing those dough-friendly surfaces with advanced insulation and energy-efficient operation. These units prove that traditional materials and modern technology can work beautifully together.

Smart Buying, Financing & Maintenance Tips

Investing in a pizza preparation refrigerator can feel overwhelming, especially when you're looking at price tags that can reach several thousand dollars. But here's the thing – you don't have to drain your bank account to get the equipment you need.

The Rent-Try-Buy program has become a game-changer for pizzeria owners. Think of it as a test drive for your kitchen equipment. You can rent a unit for 12 months with weekly payments that won't shock your cash flow. The best part? These payments are 100% tax-deductible, which means Uncle Sam helps cover the cost.

If you fall in love with your pizza preparation refrigerator (and most owners do), you can apply 60% of your net rental payments as credit toward purchasing it. If it doesn't work out, you simply return it. No strings attached, no buyer's remorse.

This approach works particularly well for new pizzerias still figuring out their volume, or established shops testing whether an upgrade will boost their efficiency.

Daily maintenance might sound tedious, but it's actually pretty straightforward. Wipe down surfaces after each shift, sanitize ingredient pans regularly, and take a quick look at those door seals. Think of it like brushing your teeth – a small daily habit that prevents big problems later.

The quarterly tasks are where you'll want to roll up your sleeves a bit more. Cleaning condenser coils and checking refrigerant levels keep your unit running efficiently. Skip these, and you might find yourself with a very expensive cabinet that doesn't keep things cold.

For more buying advice, visit Best Pizza Tables for Sale to Slice Your Prep Time.

Financing Programs: Rent-Try-Buy Explained

The beauty of the Rent-Try-Buy program lies in its flexibility. You're not locked into a purchase decision based on a showroom visit or online photos. Instead, you get to live with your pizza preparation refrigerator for a full year under real kitchen conditions.

Those weekly payments are designed to be cash-flow-friendly. Instead of writing one big check that might strain your budget, you spread the cost over time. Many owners find this approach easier to manage, especially during slower winter months when pizza sales typically dip.

The program requires a minimum of $1,000 in equipment funding, making it accessible whether you're a single-location startup or a growing chain. Both new and established businesses qualify, so your credit history won't necessarily disqualify you.

Maintenance Checklist for Long-Term Performance

Keeping your pizza preparation refrigerator running smoothly doesn't require a engineering degree, but it does need consistency. The daily tasks become second nature pretty quickly – wiping down the prep surface, checking that temperatures are holding steady, and making sure those rail lids snap shut properly.

Weekly deep cleaning keeps everything sanitary and running efficiently. This means thoroughly cleaning the prep surface, sanitizing all food-contact areas, and giving those door gaskets a good inspection. Worn gaskets are sneaky – they let cold air escape gradually, so you might not notice the problem until your electric bill spikes.

Monthly maintenance is where you tackle the bigger items. Cleaning condenser coils should happen at least every 90 days, but monthly is better in dusty environments. Those coils are like the lungs of your refrigerator – when they're clogged, everything works harder and costs more to run.

Frequently Asked Questions about Pizza Preparation Refrigerators

How big should my pizza preparation refrigerator be?

Choosing the right size pizza preparation refrigerator comes down to understanding your actual needs, not just your current volume. I've seen too many pizzeria owners buy too small and regret it within months.

Small shops typically do well with 44-67 inch models that hold 6-9 ingredient pans. If you're making 50-100 pizzas per day, this size range usually provides enough workspace and storage without overwhelming your kitchen.

High-volume operations need the big guns—93-119 inch units with 12+ pan capacity. These monsters can handle multiple staff members working simultaneously during your dinner rush.

Here's the key insight: size for your peak hours, not your average day. That quiet Tuesday afternoon doesn't matter when you're slammed on Friday night with a line out the door. It's always better to have slightly more capacity than to watch your staff struggle during busy periods.

Think about your menu complexity too. If you're offering specialty pizzas with lots of unique toppings, you'll need more pan space than a shop focused on classic pepperoni and cheese.

Which cooling system is the most energy-efficient?

Cold-wall systems take the crown for energy efficiency, potentially saving up to 60% on energy costs when you shut off the rails overnight. This makes them perfect for shops that close early or have predictable down times.

The catch? Temperature recovery takes longer when you turn the rails back on. If you're open late or have unpredictable hours, this might not work for your operation.

Liquid cooling systems offer a different advantage—they eliminate defrost cycles entirely. In high-humidity environments, this can provide significant energy savings since the unit never has to work extra hard to melt ice buildup.

Don't overlook R290 refrigerant systems regardless of the cooling method. These eco-friendly units provide up to 40% energy savings compared to traditional refrigerants. The environmental benefits are a nice bonus, but the cost savings are what really matter for your bottom line.

How often should I clean and service my prep table?

Daily cleaning isn't negotiable—it's about food safety and keeping your health inspector happy. Wipe down all food-contact surfaces after each shift and make sure your staff knows this is non-negotiable.

Condenser coils need attention every 90 days minimum. In dusty environments or if your kitchen gets particularly greasy, you might need to clean them monthly. Dirty coils make your unit work harder and can lead to expensive breakdowns.

Professional service should happen quarterly. This isn't just about cleaning—it's about catching small problems before they become expensive repairs. A good technician will check refrigerant levels, verify temperature accuracy, and inspect electrical connections.

I always tell my clients: preventive maintenance is cheaper than emergency repairs. That quarterly service call might cost you a few hundred dollars, but it can save you thousands in lost product and emergency repair costs.

Conclusion

Watching a perfectly topped pizza slide into the oven is the payoff for all your prep work. Getting to that moment smoothly and efficiently starts with choosing the right pizza preparation refrigerator.

Your selection journey should begin with honest assessment of your needs. How many pizzas do you make during your busiest hour? What's your available floor space? Do you need the energy efficiency of cold-wall cooling, or would the consistency of forced-air work better for your operation?

Don't forget about financing flexibility. The Rent-Try-Buy program takes the guesswork out of equipment selection. You can test drive your chosen unit for a full year before deciding to purchase—that's real-world experience you can't get from a spec sheet.

Once you've made your choice, proper maintenance becomes your best friend. Daily cleaning, quarterly coil maintenance, and regular gasket checks will keep your unit running efficiently for years. It's like taking care of any valuable tool—a little attention goes a long way.

At PizzaPrepTable.com, we've helped countless pizzeria owners find their perfect match. Our wide selection of pizza prep refrigerators means you won't have to compromise on features or settle for "close enough." Whether you're running a cozy neighborhood spot or a high-volume operation, we've got equipment that fits.

Our flexible financing options work for businesses at every stage. From startups watching every dollar to established operations ready to upgrade, we understand that cash flow matters as much as equipment quality.

The right pizza preparation refrigerator isn't just a purchase—it's an investment in your daily operations, your staff's efficiency, and ultimately your customers' satisfaction. Take the time to choose thoughtfully, and you'll have a reliable partner in your kitchen for years to come.

For more insights on pizza prep equipment selection, check out Slice and Dice in Style: Your Guide to Pizza Prep Chillers.