Slice and Dice in Style – Your Guide to Pizza Prep Chillers

Share

The Essential Workhorse of Every Pizzeria

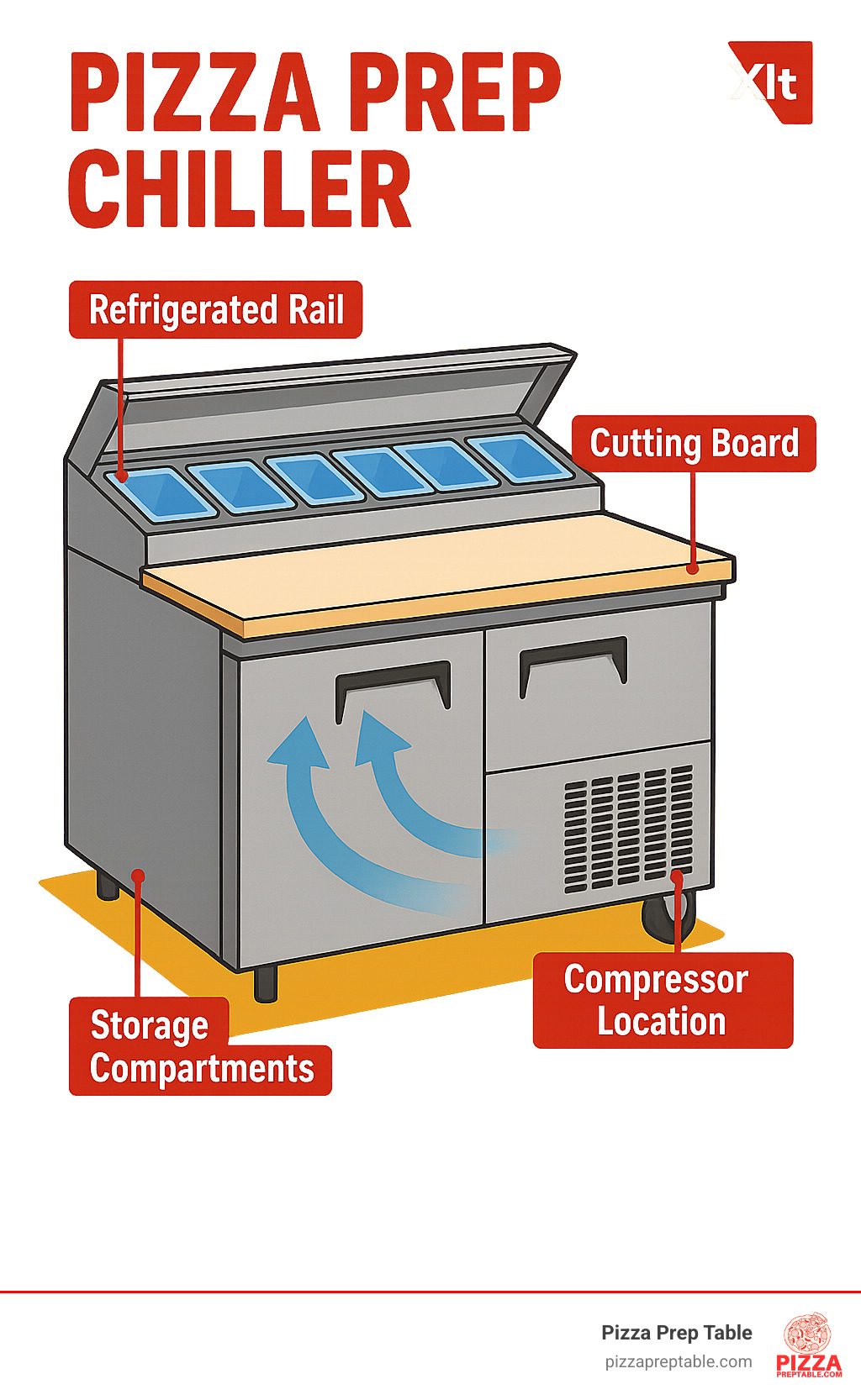

A pizza prep chiller is a specialized refrigeration unit designed to store and display pizza toppings while providing a workspace for pizza assembly. If you're setting up a pizzeria or upgrading your kitchen equipment, here's what you need to know:

| Pizza Prep Chiller Essentials | Description |

|---|---|

| Temperature Range | 32°F to 41°F (0°C to 5°C) |

| Common Sizes | 44" to 119" wide (10.9 to 40+ cu ft) |

| Price Range | $1,399 (entry-level) to $16,000+ (high-end) |

| Key Components | Refrigerated base storage, topping rail, cutting board |

| Popular Brands | True, Atosa, Maxx Cold, Avantco, Beverage-Air |

A pizza prep chiller combines refrigerated storage with a convenient workspace, making it the backbone of efficient pizza preparation. The top section holds refrigerated ingredient pans within arm's reach, while the bottom compartment provides additional cold storage for backup supplies.

These units are specially designed to maintain food safety while maximizing productivity in busy kitchens. Unlike standard refrigerators, pizza prep chillers feature a wide cutting board surface and a refrigerated rail that keeps toppings fresh during high-volume service periods.

The best models offer features like:

- Stainless steel construction for durability and easy cleaning

- Self-closing doors to maintain temperature

- Digital temperature controls for precise cooling

- Heavy-duty casters for mobility

- Removable cutting boards and pan dividers

I'm Sean Kearney, and I've spent years helping restaurant owners select the right pizza prep chillers for their operations, understanding that the perfect pizza prep chiller can dramatically improve workflow efficiency and ingredient freshness in even the smallest kitchen spaces.

Pizza prep chiller terms simplified:

What Is a Pizza Prep Chiller & How Does It Work?

Imagine a refrigerator and a workstation had a baby – that's essentially what a pizza prep chiller is! This clever piece of equipment is the unsung hero of pizzerias everywhere, combining cold storage with a convenient workspace where the pizza magic happens.

At its heart, a pizza prep chiller uses forced-air refrigeration to keep your ingredients perfectly chilled. The system works like your home refrigerator but with a commercial-grade twist. A powerful compressor (usually between 1/5 and 1/2 horsepower) circulates refrigerant through coils. As this refrigerant evaporates, it pulls heat from inside the unit – like a sponge soaking up water – cooling everything down to that sweet spot between 33°F and 41°F.

What makes these units truly special is their thoughtful two-zone design:

The refrigerated pan rail sits on top, keeping all your toppings within arm's reach in those handy 1/3-size pans. Cold air gently circulates around these ingredients, ensuring your pepperoni and mushrooms stay fresh even during the Friday night rush.

Meanwhile, beneath your workspace, the base cabinet provides additional cold storage for backup supplies and bulkier items. It's like having a mini walk-in cooler right at your fingertips!

"I couldn't imagine running my pizzeria without our prep chiller," says Marco DiNapoli, owner of Chicago's Slice of Heaven. "It's like having an extra pair of hands during rush hour – everything I need is right there."

Most modern pizza prep chillers now use eco-friendly R290 hydrocarbon refrigerant. This isn't just better for the planet (with significantly lower environmental impact than old-school refrigerants) – it actually delivers more efficient cooling performance. Win-win!

Why Your Kitchen Needs a Pizza Prep Chiller

If you've ever witnessed the controlled chaos of a busy pizzeria kitchen, you'll understand immediately why a pizza prep chiller isn't just nice to have – it's essential.

Speed and efficiency transform your operation when all ingredients are within reach. No more running back and forth to the walk-in cooler during rush hour! Your pizza makers can stay in their zone, assembling orders rapidly without interruption. Many pizzerias report assembly time improvements of up to 35% after installing the right prep chiller.

Your workflow becomes buttery smooth with these ergonomic units. One person can stretch dough on the spacious cutting board while simultaneously grabbing toppings from the rail. It's like conducting a delicious symphony where every movement is purposeful.

Cross-contamination prevention is another major benefit. With separate compartments and dedicated pans, you can easily keep allergens separated and ingredients organized. This isn't just good practice – it's essential for food safety and accommodating customers with dietary restrictions.

Perhaps most importantly, quality control becomes second nature. By maintaining perfect temperatures, your pizza prep chiller ensures toppings stay fresh, flavorful, and texturally perfect. Your customers will taste the difference, even if they can't put their finger on exactly why your pizzas are so much better than the competition's.

Inside the Cooling Loop

Let's peek under the hood of your pizza prep chiller to understand the cooling magic:

The evaporator works as the cold-maker, hidden within the unit where refrigerant absorbs heat from the interior. Think of it as the air conditioner for your ingredients.

Meanwhile, the condenser (typically located at the back or side) releases all that collected heat outside the unit. Premium models from brands like True and Atosa use high-quality Danish condensers that work more efficiently and last longer.

German-engineered fan motors circulate that lovely cold air throughout both the cabinet and pan rail. The best models feature adjustable air ducts so you can fine-tune exactly where that cold air flows – perfect for accommodating different ingredient needs.

To prevent ice buildup (which would reduce efficiency), pizza prep chillers run through automatic defrost cycles. Advanced models like the Hoshizaki Steelheart® series even feature day/night modes that prevent freezing during those quiet overnight hours.

All this cooling power would be wasted without proper insulation. That's why quality units use CFC-free polyurethane foam insulation (typically 2-3 inches thick) to keep cold air in and warm air out. It's like a cozy winter jacket – but for keeping things cold instead of warm!

"The difference between a good and great pizza prep chiller often comes down to the testing process," explains a representative from Atosa. "Our units undergo 100% run testing with helium leak checks and vibration analysis before they ever leave the factory. When you're making hundreds of pizzas a day, that reliability matters."

Core Features & Components You Can't Ignore

When you're in the market for a pizza prep chiller, there are certain features that separate the workhorses from the headaches. These aren't just fancy add-ons – they're the backbone of a unit that will serve your kitchen faithfully through countless busy shifts.

Stainless steel construction isn't just about looking professional – it's your first line of defense against the chaos of a busy kitchen. These units take a beating from spills, splatters, and the occasional bump from a hurried staff member. Commercial-grade stainless exteriors paired with aluminum interiors make cleanup a breeze while standing up to years of intense use.

Those insulated lids that cover your ingredient pans might seem simple, but they're working overtime to keep your toppings fresh and your energy bills lower. Whether you opt for stainless steel or clear polycarbonate, these lids are the unsung heroes of temperature maintenance during slow periods.

"The quality of the cutting board is often overlooked," says Miguel Sanchez, head chef at Napoli's Pizzeria in Phoenix. "But when you're making hundreds of pizzas a day, having a durable, easy-to-clean surface makes a huge difference in efficiency and hygiene."

The self-closing doors on quality units are a small feature with big impact. They'll automatically swing shut even when your hands are full of dough balls, keeping cold air in where it belongs. Look for models with that handy 90° stay-open feature for those times when you're restocking or deep cleaning.

Temperature precision can make or break your ingredients, which is why a good digital thermostat isn't optional. Modern units give you easy-to-read displays that take the guesswork out of food safety. Step up to premium models like the Hoshizaki Steelheart® series, and you'll get a dual controller system that lets you set different temperatures for the rail and cabinet – perfect when your cheese needs a different environment than your prepped vegetables.

Don't overlook the importance of removable magnetic gaskets – these door seals should pop off without tools for regular cleaning. Trust me, you'll appreciate this feature the first time someone spills marinara sauce down the front of your unit.

These chillers typically weigh as much as a small motorcycle (400-500 pounds), so heavy-duty casters with reliable locks aren't just convenient – they're essential for both moving the unit when needed and keeping it firmly in place during service.

The flexibility to change your menu starts with divider bars that let you reconfigure your ingredient pans as your offerings evolve. And if you're in an open kitchen or customer-facing environment, sneeze guards provide that extra layer of protection that both health inspectors and customers appreciate.

The cutting surface is where all the assembly happens, so a full-length polyethylene board gives your team the space they need to work efficiently. Some premium models even feature marble stone tops that help maintain dough temperature – a nice touch if you're serious about your crust quality.

More info about prep station efficiency

Rail & Pan Configuration

The rail is the heartbeat of any pizza prep chiller – it's where all your toppings live during service. Most standard rails comfortably hold 9-12 1/3-size pans (those 12.75" × 7" workhorses of the pizza world), typically 4" deep.

For kitchens with ambitious topping selections, mega-top models offer deeper or wider rails. The Maxx Cold MXCPP92HC, for example, accommodates an impressive 12 1/3-size pans, giving you plenty of room for everything from classic pepperoni to more adventurous offerings.

"When selecting a pizza prep chiller, consider not just how many pans you need today, but how your menu might expand in the future," advises kitchen consultant Lisa Chen from San Francisco. "Having flexibility in your rail configuration can save you from needing to upgrade your equipment as your business grows."

Some operations need deeper depth options – if you're going through toppings at lightning speed, models that accommodate 6" deep pans might be worth the investment.

Cabinet Storage & Shelving

What's happening below the workspace is just as important as what's happening on top. The refrigerated cabinet is your backup singer – not always in the spotlight, but essential to the performance:

The capacity range is impressive – from about 11 cubic feet in compact 44" models to over 30 cubic feet in those massive 93" three-door units like the Maxx Cold 3 Door Refrigerated Pizza Prep Table (MXSPP92HC).

When it comes to load capacity, quality shelves should handle between 90-155 pounds each – because cheese gets heavy, and you don't want a shelf collapse during Friday night rush.

Look for adjustable shelving with epoxy-coated steel that can be moved around to fit your specific storage needs. Those tall containers of sauce need different accommodation than your flatter items.

"One of the most common mistakes I see is underestimating storage needs," notes restaurant consultant James Wilson from Boston. "During peak hours, you need enough refrigerated storage to minimize trips to the walk-in cooler. This keeps your prep line moving efficiently."

Smart Temperature Control

Today's pizza prep chillers have gotten a lot smarter about keeping things cool:

The day/night mode feature is like having an energy-conscious assistant who turns things down during slow periods but keeps everything food-safe. Your utility bills will thank you.

Nobody wants to find temperature problems after it's too late, which is why temperature alarms on advanced models are so valuable – they'll alert you before small issues become expensive inventory losses.

For operations serious about documentation, data logging capabilities record temperature histories, making HACCP compliance easier and providing valuable information if you ever need to troubleshoot.

"The dual controller system in higher-end models is a game-changer," explains refrigeration technician David Lopez from Los Angeles. "It allows you to maintain the perfect temperature in both the rail and the cabinet, accommodating ingredients with different ideal storage temperatures."

Size, Type & Brand Comparison Guide

Picking the right pizza prep chiller is a bit like choosing a car – there's a perfect match for everyone, but you need to know what you're looking for. Let me walk you through the options that might work for your kitchen.

Pizza prep chillers come in a range of sizes to suit different operations. The compact 44" models (about 10.9 cubic feet) are perfect for cozy neighborhood pizzerias where space is at a premium. Mid-sized restaurants typically opt for 60-67" units (13-16 cubic feet), while busy pizzerias often need the extra capacity of 71-72" models (16-20 cubic feet). For high-volume shops cranking out hundreds of pies daily, the spacious 93-94" units (28-30 cubic feet) provide ample space. And for those massive operations? The expansive 119" behemoths offer a whopping 40+ cubic feet of storage.

The configuration options are just as varied. You'll find single-door models in the 44-50" range, two-door options spanning 60-72", and three-door units measuring 93-95". Many operators are now choosing drawer configurations instead of traditional doors for easier access to ingredients. There are even combination door/drawer units that offer the best of both worlds.

"I started with a standard two-door model, but after our third expansion, we upgraded to a three-door unit with drawers on one section," shares Mike from Mike's Famous Pizza in Portland. "The drawers make a huge difference during rush periods – my prep team can grab cheese without disrupting the topping station."

For kitchens with special needs, manufacturers offer several custom solutions. Compact models feature reduced depth for tight spaces, while low-height units can slip under existing countertops. Some operators swear by granite-top models that naturally keep dough cool during stretching. For shops with open kitchen concepts, glass canopy units showcase ingredients while keeping them protected.

When it comes to brands and pricing, there's quite a range:

| Brand | Entry-Level | Mid-Range | Premium |

|---|---|---|---|

| True | $4,000-5,000 | $5,000-8,000 | $8,000-16,000+ |

| Atosa | $2,500-3,500 | $3,500-5,000 | $5,000-7,000 |

| Maxx Cold | $1,800-2,500 | $2,500-4,000 | $4,000-5,500 |

| Avantco | $1,399-2,000 | $2,000-3,000 | $3,000-4,500 |

| Beverage-Air | $3,000-4,000 | $4,000-6,000 | $6,000-9,000 |

"When comparing brands, look beyond the initial price tag," advises restaurant equipment specialist Maria Gonzalez from San Antonio. "Consider energy efficiency, warranty terms, and availability of service technicians in your area. A slightly more expensive unit from a reputable brand often proves more economical over its lifespan."

Need specifications? You can Download the Manual for detailed information.

Entry-Level Champions

If you're just starting out or working with a tight budget, several reliable entry-level pizza prep chillers deliver impressive bang for your buck.

The Avantco SSPPT-2 68" runs around $2,000 and has earned a loyal following among independent pizzeria owners. With its 12-pan capacity and solid 4.5-star rating, it handles the demands of daily service without breaking the bank. It's like the reliable sedan of pizza prep chillers – not flashy, but it gets the job done day after day.

For even tighter spaces and budgets, the Arctic Air AST48R 48" (approximately $1,600) packs surprising functionality into its compact frame. At just 48 inches wide, it fits into kitchens where space is at an absolute premium while still providing adequate prep area for smaller operations.

"Many of my clients start with entry-level units and are pleasantly surprised by how well they perform," notes Robert Chen, a restaurant startup consultant from NYC. "Today's budget-friendly models incorporate features that used to be premium-only, like digital temperature controls and eco-friendly R290 refrigerant systems."

Mid-Tier Workhorses

For established operations looking for reliability with extra features, the mid-tier range offers excellent options that balance quality and affordability.

The Atosa MPF8203 93" (around $5,000) is the Toyota Camry of pizza prep chillers – dependable, well-built, and designed to last. This three-door model uses premium components including a Danish condenser, Italian controllers, and German fan motors. Its front-breathing Embraco compressor is particularly handy for kitchens where space is tight, as it doesn't require clearance at the back.

The Beverage-Air DP67 (approximately $4,500) has earned a reputation for consistency in challenging environments. With improved insulation and heavy-duty compressors, these units maintain stable temperatures even in hot kitchens where lesser units struggle.

For operators who want precise temperature control, the Hoshizaki Steelheart® Series (around $5,500) offers a sophisticated dual controller system. This allows you to set different temperatures for the rail and cabinet – perfect if you're storing different ingredients that require varied conditions.

"We upgraded to a mid-tier Atosa after our budget unit couldn't keep up with weekend rushes," explains Carlos Mendez, owner of Slice Heaven in Austin. "Three years later, it's still running like new despite Texas summer heat and Friday night chaos."

Premium Powerhouses

For high-volume operations where downtime simply isn't an option, premium pizza prep chillers deliver peace of mind along with superior performance.

The True TPP-93 (around $9,000) is widely considered the gold standard in the industry. Like a commercial-grade refrigeration tank, these units feature oversized cooling systems that maintain rock-solid temperatures even during constant opening and closing in hot kitchens. Many operators report True units still running perfectly after 10+ years of service.

Not all premium options break the bank, though. The Maxx Cold MXCPP92HC (around $4,600) offers tremendous value at its price point. This three-door model provides nearly 31 cubic feet of storage and accommodates up to 12 1/3-size pans, making it suitable for high-volume operations while costing significantly less than some competitors.

"When you're doing $10,000 in sales on a Friday night, the last thing you can afford is equipment failure," explains Frank Romano, owner of Romano's Pizzeria in Chicago. "We invested in a True unit eight years ago, and it's still running perfectly despite constant use. The repair costs we've avoided have more than made up for the higher initial investment."

Choosing, Maintaining & Troubleshooting Your Pizza Prep Chiller

Let's face it – your pizza prep chiller is the backbone of your pizzeria's operation. Selecting the right one and keeping it running smoothly isn't just about equipment management – it's about protecting your business and your sanity during those Friday night rushes.

When I help restaurant owners choose their equipment, I always start with the kitchen footprint. You'd be surprised how many folks forget to measure door clearance or leave enough breathing room (usually 3-5 inches on all sides) for proper ventilation. Trust me, your compressor will thank you for that extra space!

"I learned the hard way that bigger is usually better," says Marco from Marco's Slice Shop in Denver. "We outgrew our first prep table within six months of opening." That's why I recommend selecting a unit that can handle at least 20% more volume than your current needs – giving your business room to grow without another major investment.

The good news is today's pizza prep chillers are more energy-efficient than ever. Look for ENERGY STAR certified models, which typically save 20-30% on utility bills compared to standard units. Many newer models use R290 hydrocarbon refrigerant, which is not only better for the planet but often delivers better cooling performance too.

Don't let sticker shock scare you away from quality equipment. Many suppliers (including PizzaPrepTable.com) offer flexible financing options with monthly payments starting around $60-70 for entry-level models. When you spread that cost across the thousands of pizzas you'll make, we're talking pennies per pie for reliable cold storage.

Warranty coverage matters too. Standard warranties typically range from 1-3 years, with many manufacturers offering extended 5-year coverage on compressors. When comparing models, this protection can be the tiebreaker between similar units.

"When calculating total cost of ownership, don't just look at the purchase price," advises restaurant equipment consultant Sarah Johnson from Washington, D.C. "Factor in energy consumption, maintenance requirements, and expected lifespan. A quality pizza prep chiller should last 7-10 years with proper care, making it a long-term investment in your operation's efficiency."

Prep Sandwich Refrigerators That Keep Your Ingredients Fresh and Your Customers Happy

Selection Checklist

Before you click that "buy" button, run through this quick mental checklist for your pizza prep chiller:

Have you measured your kitchen space completely, including width, depth, height, and clearance for ventilation? That 72" unit won't do you any good if your doorway is only 68" wide!

Consider your ingredient lineup – how many pans do you need for your menu? Are you running a simple pepperoni-and-cheese operation, or do you offer twenty specialty toppings?

Think about your workflow. Would your team benefit more from door access (better for large backup containers) or drawer storage (easier access during service)? Some kitchens work best with combination units.

Don't forget the basics: Does your kitchen have the right electrical supply (typically 115V/60Hz)? Is there adequate airflow around the installation spot? Do you need heavy-duty casters for moving the unit during cleaning?

"Don't forget to consider your future needs," recommends kitchen designer Elena Perez from Miami. "It's more cost-effective to purchase a slightly larger unit now than to replace an undersized one in a year or two as your business grows."

Routine Care Schedule

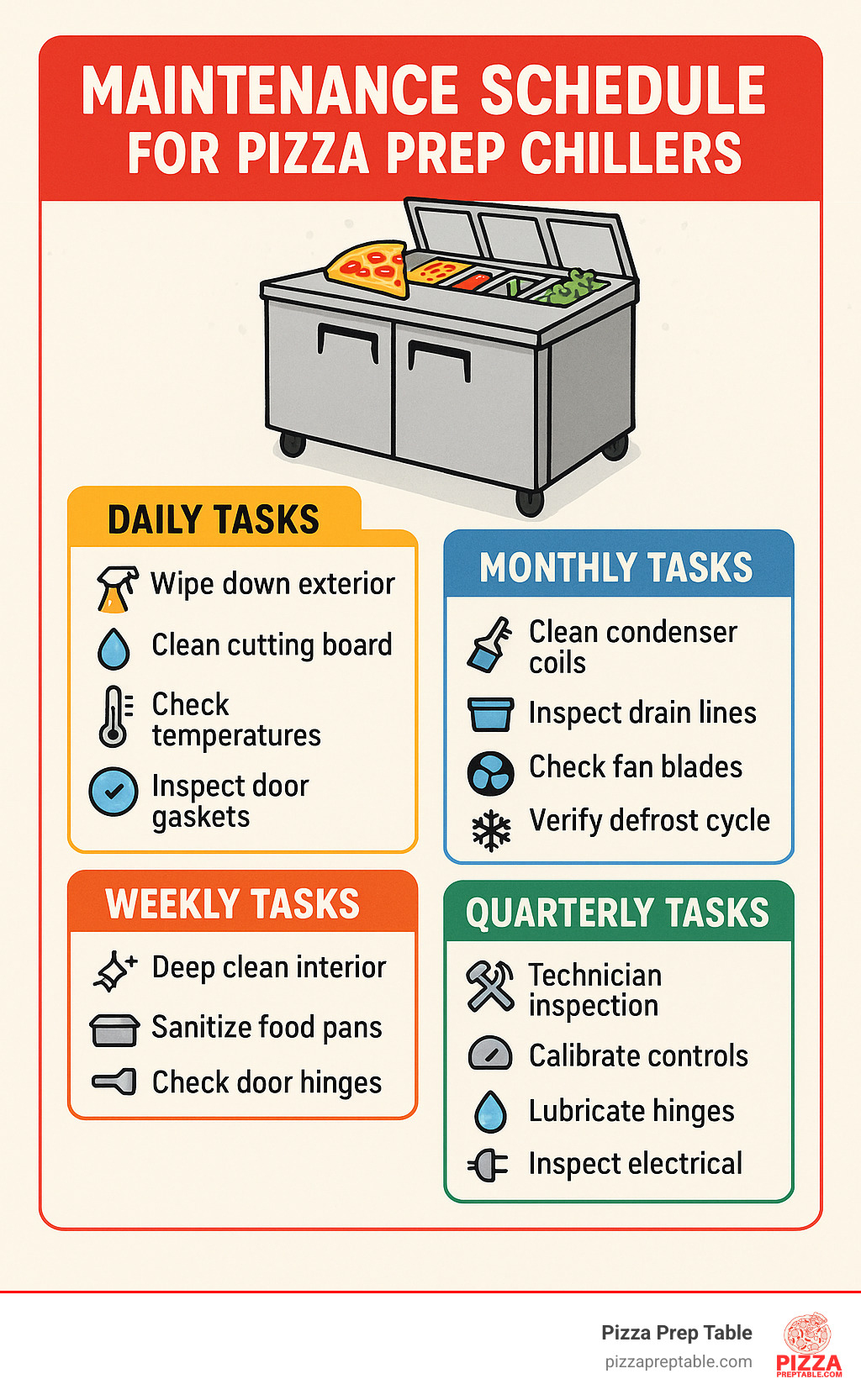

I've seen $10,000 pizza prep chillers die early deaths from simple neglect. Don't let that be you! Here's a practical maintenance schedule that won't overwhelm your staff:

Daily (takes about 10 minutes): Wipe down all exterior surfaces with food-safe sanitizer. Give that cutting board a thorough scrub with hot, soapy water (those little cheese bits add up!). Check and record interior temperatures – they should stay between 33-41°F. A quick inspection of door gaskets for food debris keeps seals tight.

Weekly (about 30 minutes): Time for a deeper clean of interior surfaces. Pull those shelves out if needed. Clean and sanitize all food pans – they collect more grime than you might think. Check that door hinges and catches are working properly.

Monthly (about an hour): This is when you show your pizza prep chiller some real love. Clean those condenser coils with a brush or vacuum – this single task can extend your unit's life by years. Check drain lines for clogs, clean fan blades, and verify the defrost cycle is running properly.

Quarterly (professional service): Have a technician inspect the refrigeration system, check and calibrate temperature controls, lubricate hinges and casters, and inspect electrical connections.

"The most common maintenance mistake is neglecting the condenser coils," warns refrigeration technician Carlos Mendez from Dallas. "Dust and grease buildup forces the compressor to work harder, increasing energy consumption and reducing equipment lifespan. A simple monthly cleaning can prevent costly repairs."

Troubleshooting Common Pizza Prep Chiller Issues

Even with perfect maintenance, sometimes things go sideways. Here's how to handle the most common pizza prep chiller problems:

When temperatures spike in the rail, first check the obvious – are staff leaving lids open during service? Are pans overfilled? (They should have at least 0.5" clearance from the top.) Check that air vents in the rail aren't blocked by food containers. And sometimes the issue is external – if your kitchen hits 95°F during summer service, your unit has to work much harder.

Finding ice buildup in the rail or cabinet? Check your defrost settings and adjust if necessary. Verify door gaskets are sealing properly – shine a flashlight from inside with doors closed to spot light leaks. Also ensure drain lines aren't clogged, which can cause water to freeze inside the unit.

If your compressor sounds like a washing machine full of shoes, first clean those condenser coils. Check for loose fan blades. Make sure the unit is perfectly level on all four legs/casters – even slight tilting can cause vibration. And always maintain adequate clearance around the compressor for proper airflow.

Door seal issues are usually an easy fix. Clean gaskets regularly with mild soap and water. Check for damage or deformation – they do wear out eventually. Verify proper door alignment, and replace worn gaskets (typically a simple DIY task that costs far less than a service call).

"If your unit is running constantly but not maintaining temperature, first check that the condenser isn't covered in dust," advises maintenance specialist John Peterson from Seattle. "About 70% of service calls for pizza prep chillers could be prevented with proper cleaning and preventive maintenance."

A well-maintained pizza prep chiller isn't just about avoiding repairs – it's about food safety, energy efficiency, and keeping your kitchen running smoothly during those crucial weekend rushes when every minute counts.

Conclusion & Next Slice

Your pizza prep chiller isn't just another piece of equipment—it's the beating heart of your pizza operation. I've seen how the right unit can transform a chaotic kitchen into a model of efficiency, keeping ingredients fresh while creating a streamlined workspace that makes busy Friday nights manageable instead of miserable.

When you're selecting your pizza command center, think beyond today's needs. The small shop serving 50 pies a night might be doing 150 in a year if things go well. Investing in a slightly larger unit now could save you thousands down the road. With proper care, a quality pizza prep chiller will faithfully serve your business for 7-10 years—making it one of the smartest investments you'll make.

Remember these essentials as you shop:

Size matters – Match your unit to both your kitchen space and production volume. That beautiful 93" model won't help if it doesn't fit your kitchen or if you're only using half its capacity.

Quality counts – Those heavy-duty casters, self-closing doors, and digital temperature controls aren't luxury features—they're the difference between equipment that lasts and equipment that fails during your busiest service.

Maintenance is non-negotiable – Even the best units need regular care. A simple monthly cleaning of the condenser coils can prevent the most common (and expensive) repairs.

Address small issues quickly – That slight temperature fluctuation or unusual noise probably won't fix itself. Small problems tend to become big, expensive ones if ignored.

At PizzaPrepTable.com, we understand that every pizzeria has unique needs. Whether you're a mom-and-pop shop opening your first location or a growing regional chain standardizing your kitchens, we offer pizza prep chillers in various configurations along with flexible financing that makes quality equipment accessible to operations of all sizes.

Ready to boost your kitchen's efficiency and your pizza's quality? Our team of pizza equipment specialists would love to help you find the perfect pizza prep chiller for your specific operation. Browse our full selection of commercial pizza prep tables and find how the right equipment can help you serve more customers without sacrificing quality.

Keep Cool and Carry On: The Ultimate Commercial Fridge Freezer Combo Guide