Prep Like a Pizza Pro with These Topping Stations

Share

Why Pizza Topping Prep Stations Are Game-Changers for Your Kitchen

A pizza topping prep station combines refrigerated storage with an organized workspace to keep ingredients fresh and your workflow efficient. Whether you're running a busy pizzeria or hosting backyard pizza parties, these stations eliminate the back-and-forth trips to your walk-in cooler while maintaining food safety temperatures.

Top Pizza Topping Prep Station Options:

- Home/Outdoor: Ooni Pizza Topping Station (6 containers, 8.7 lbs, weather-resistant)

- Small Commercial: Atosa 44" Two-Door (155 lb shelf capacity, 33-38°F range)

- Mid-Size Pizzeria: True TPP-AT-67 (angled rail, 6-pan capacity, energy-efficient)

- High-Volume: Randell Dual-Tier (11-25 pans, 60% energy savings overnight)

The research shows that commercial pizza prep tables can maintain ingredient temperatures between 33°F to 40°F to ensure food safety and freshness. Models range from compact 44-inch units to massive 119-inch stations that can accommodate multiple staff members working simultaneously.

Modern stations feature forced-air refrigeration, stainless steel construction, and can yield up to 60% energy savings when the rail is shut off overnight. The deeper 14-19 inch prep areas (compared to 8-9 inches on sandwich tables) give you the workspace needed for extra-large pizzas.

I'm Sean Kearney, and my background in sales has taught me that having the right equipment makes all the difference in restaurant efficiency and profitability. Through years of helping food establishments choose the perfect pizza topping prep station, I've seen how the right setup can transform a chaotic kitchen into a smooth operation.

Pizza topping prep station helpful reading:

What Is a Pizza Topping Prep Station & How It Boosts Your Workflow

Think of a pizza topping prep station as your kitchen's Swiss Army knife – it's the one piece of equipment that solves multiple problems at once. Unlike your typical prep counter that leaves you running back and forth to the walk-in cooler, these stations bring everything you need right to your fingertips.

The magic happens in the combination of cold storage below and an organized work surface on top. The raised rail system holds your ingredient pans at the perfect angle and height, so you're not constantly bending or reaching. Meanwhile, the refrigerated base keeps backup ingredients, dough balls, and sauces at safe temperatures.

What really sets these stations apart is the cutting board depth of 14-19 inches – that's nearly double what you get on a sandwich prep table. This extra space means you can comfortably stretch and dress even your largest pizzas without ingredients spilling everywhere.

The ingredient organization through standardized pan systems transforms chaos into efficiency. No more digging through random containers or wondering if your pepperoni is still cold enough. Everything has its place, and everything stays at the right temperature.

When it comes to NSF-7 compliance, these stations take the guesswork out of food safety. They maintain consistent temperatures automatically, so you can focus on making great pizza instead of constantly checking thermometers.

The time-savings are real – we've seen pizzerias cut their assembly time by up to 40% just by switching to a dedicated topping station. When everything you need is within arm's reach and properly organized, your team can work faster and more efficiently.

| Feature | Traditional Counter Setup | Pizza Topping Prep Station |

|---|---|---|

| Ingredient Access | Walk to cooler repeatedly | All toppings within reach |

| Temperature Control | Manual ice baths | Automated 33-40°F |

| Workspace Depth | 8-12 inches | 14-19 inches |

| Organization | Scattered containers | Standardized pan system |

| Setup Time | 15-20 minutes | 2-3 minutes |

| Food Safety Compliance | Manual monitoring | NSF-7 certified |

The Science of Staying Fresh

The cooling technology in modern pizza topping prep stations isn't just about keeping things cold – it's about keeping them fresh, safe, and energy-efficient.

Forced-air cooling works like a gentle breeze constantly circulating around your ingredient pans. It maintains consistent temperatures throughout the rail, but requires shallower pans (maximum 6 inches deep) so the air can flow properly. This system shines in high-volume operations where pans are constantly being accessed and refilled.

Cold-wall cooling creates a frost layer above the pans that acts like a natural blanket of cold. Randell's raised rail systems use this technology and can handle deeper 8-inch pans. The real genius is the independent rail cooling – you can shut down just the rail overnight for energy savings up to 60% while keeping the base refrigeration running.

Glycol cooling uses liquid coolant instead of air, eliminating those annoying defrost cycles entirely. No more frost buildup, no more energy waste from defrost cycles, and more consistent temperatures.

The 33-40°F sweet spot isn't just a random number – it's the perfect balance between food safety and ingredient quality. Too cold and your cheese becomes hard to work with; too warm and you're risking bacterial growth. NSF-7 standards require that ingredients stay at or below 41°F for at least four hours with lids off, ensuring your toppings remain safe even during the busiest rush periods.

For more detailed information on choosing the right cooling system, check out this latest research on choosing the right prep table.

Types of Pizza Topping Prep Stations for Every Pizza Lover

Finding the perfect pizza topping prep station depends on your specific needs and space. Whether you're making weekend pizzas at home or running a busy commercial kitchen, there's a station designed to make your life easier.

Home & Outdoor Heroes

Home pizza lovers and outdoor entertainers need portability, weather resistance, and the ability to move your setup wherever the party is happening.

The Ooni Pizza Topping Station has become the gold standard for home use. With two larger 1.6L containers and four smaller 0.8L bins, you can organize everything from pepperoni to fresh basil. At just 8.7 pounds, it's light enough to carry from kitchen to patio without breaking a sweat.

What really sets the Ooni apart is its stackable design with clear lids. You can prep all your toppings inside, stack the containers in your fridge, then grab the whole station when it's time to cook. The carbon steel frame with stainless steel cover means it won't rust if you forget it outside overnight.

The Everdure Pizza Oven Preparation Stand takes outdoor pizza parties to restaurant level. This 155-pound unit features five covered trays for toppings, slide-out shelves for storing finished pizzas, and lockable castors so you can roll it exactly where you need it.

Commercial Workhorses — Refrigerated

When you're running a commercial operation, your pizza topping prep station needs to handle serious volume while keeping ingredients at safe temperatures all day long.

The Atosa MPF8203GR 93-inch model shows what's possible when you need maximum capacity. With 28.4 cubic feet of storage and space for 12 third-size pans in the raised rail, it can handle the busiest dinner rush. The front-breathing Embraco compressor means you can build it right into your kitchen line without worrying about ventilation.

True TPP-AT series units have earned their reputation through years of reliable service. The angled rails make topping access incredibly comfortable, which your staff will appreciate during those long Friday night shifts. The 6-pan capacity hits the sweet spot for most pizzeria operations.

The Maxx Cold V-Series delivers 11 cubic feet of storage with a no-drain condensate system that makes installation a breeze. The built-in polyethylene cutting board and adjustable shelving give you flexibility as your menu evolves.

For operations that need maximum pan capacity, Randell's raised rail systems are industry leaders. Their dual-tier models can hold anywhere from 11 to 25 third-size pans, and the independent rail cooling system can cut your energy costs by up to 60% when you shut down the rail overnight.

The choice between drawers and doors comes down to your workflow. Doors give you more bulk storage space for backup ingredients, while drawers make it faster to restock during busy periods. Many operators prefer the R290 refrigerant systems for their environmental benefits and energy efficiency.

For detailed comparisons of commercial options, check out our 2-door pizza prep fridges guide.

Non-Refrigerated & Hybrid Options

Not every situation calls for full refrigeration. Sometimes you need the organization and workflow benefits without the complexity of a refrigerated system.

Granite-top stations like the Marra Forni models use the natural thermal properties of stone to keep ingredients cooler than standard stainless surfaces. The 30-inch deep granite work surface stays naturally cool while providing an incredibly durable prep area.

Ice-cooled rail systems work beautifully for outdoor events or locations where electrical service isn't reliable. These systems use NSF-approved food pans sitting in ice baths, maintaining safe temperatures for hours without power.

Modular add-on systems and service carts give you the flexibility to build exactly what you need. These can include everything from waste chutes to hand sinks, all integrated into one efficient workstation.

Key Features & Materials to Compare Before You Buy a Pizza Topping Prep Station

The construction quality and features of your pizza topping prep station will determine both its longevity and daily performance. Here's what we look for when evaluating different models.

Construction Materials make a huge difference in durability and maintenance. 304-gauge stainless steel is the gold standard for commercial units, offering superior corrosion resistance and easy cleaning. Powder-coated carbon steel works well for outdoor units like the Ooni, providing weather resistance at a lower cost. Granite surfaces offer unique thermal properties but require more careful handling.

Cutting Board Depth is crucial for pizza assembly. Look for 14-19 inch depth minimum - this extra space compared to 8-9 inch sandwich prep tables makes all the difference when working with large pizzas. The deeper workspace prevents ingredients from falling off the back edge during assembly.

Pan Configurations vary significantly between models. Sixth-size pans (6.75" x 6.25") offer more variety but less volume per ingredient. Third-size pans (12.75" x 6.75") hold more of each topping but limit your total variety. Consider your menu complexity when choosing.

Refrigeration Features can dramatically impact operating costs. Self-cleaning condensers reduce maintenance requirements. Front-breathing compressors allow built-in installation and often use less energy. Adaptive defrost systems only run defrost cycles when actually needed, saving energy and preventing unnecessary temperature fluctuations.

Sealed Rails prevent spills from dripping into the refrigerated base, reducing cleaning frequency and protecting internal components. This feature alone can save hours of maintenance time per week in busy operations.

For detailed analysis of station efficiency, check out our article on efficient pizza prep stations.

Must-Have Accessories & Add-Ons

The right accessories can transform a good pizza topping prep station into a great one. Here are the add-ons that make the biggest difference:

Overshelves double your storage capacity without increasing floor space. They're perfect for storing backup ingredients, plates, or equipment like infrared thermometers.

Clear Insulated Lids are essential for maintaining temperatures while keeping ingredients visible. They seal in cold air and prevent contamination while allowing customers to see fresh ingredients.

Dough Trays and Sheet Pan Slides in the base cabinet maximize storage efficiency. The ability to store full-size sheet pans and dough trays in the same unit streamlines your entire prep process.

Infrared Thermometers help monitor surface temperatures of ingredients, ensuring food safety compliance without opening containers unnecessarily.

Adapter Bars allow you to use different pan sizes in the same rail, providing flexibility as your menu changes.

Product Round-Up: The Best Pizza Topping Prep Stations of 2024

After working with countless pizzerias across New York City, Los Angeles, Chicago, and other major markets, I've seen which pizza topping prep stations truly deliver on their promises. These aren't just my opinions—they're based on real feedback from busy kitchen operators who depend on this equipment every single day.

Best Overall Home Pick — Ooni Pizza Topping Station

The Ooni Pizza Topping Station has completely changed how home pizza makers approach their craft. What makes it special isn't just the two 1.6L and four 0.8L containers—it's how thoughtfully everything works together.

At just 8.7 pounds, you can easily move this station from your kitchen counter to your backyard without breaking a sweat. The stackable design with custom-fit clear lids means you can prep all your ingredients on Sunday afternoon, store everything in your refrigerator, and have pizza night ready to go in minutes.

The weather-resistant powder-coated carbon steel frame handles everything from summer heat to unexpected rain showers. I've watched customers use these stations for months outdoors with zero rust or corrosion issues. The stainless steel cover wipes clean with just warm soapy water, making cleanup almost effortless.

What really impresses me is how this integrates with Ooni's table system. You're not just buying a topping station—you're building a complete outdoor pizza kitchen that rivals what you'd find in restaurants.

Best Outdoor Entertainer — Everdure Pizza Oven Preparation Stand

When you're hosting backyard pizza parties for a crowd, the Everdure Pizza Oven Preparation Stand transforms you into the neighborhood pizza hero. Those five removable topping trays with lids keep everything organized and fresh, even during long outdoor events.

The slide-out shelves are brilliant for storing finished pizzas while you work on the next batch. No more juggling hot pizzas while trying to prep the next one. The lockable castors make it easy to wheel the entire station wherever you need it, then lock it in place for stability.

At 155 pounds, it's substantial enough to feel rock-solid while you work, but the wheels mean you can still move it around your patio or store it in the garage when needed. The aluminum door fronts and rust-proof construction mean this investment will last for years of outdoor entertaining.

Best Budget Commercial — Atosa MPF8201 44″ Two-Door

Starting a pizzeria or working with limited space doesn't mean you have to compromise on quality. The Atosa 44-inch model proves that commercial-grade performance doesn't require a massive budget. That 155-pound shelf capacity handles serious ingredient loads, while the 33-38°F temperature range keeps everything food-safety compliant.

The front-breathing Embraco compressor is a game-changer for small spaces because it allows built-in installation. You're not wasting valuable kitchen real estate on clearance space. The R290 hydrocarbon refrigerant is environmentally friendly—something more operators are caring about these days.

We've made this model even more accessible with financing options because I believe every pizzeria deserves professional equipment. The 2-year parts and labor warranty gives you peace of mind while you're building your business.

For more detailed information about commercial cooling options, check out our guide on pizza prep chillers.

Best Mid-Size Pizzeria — True TPP-AT-67

The True TPP-AT series represents that sweet spot where reliability meets efficiency. The angled rail design might seem like a small detail, but after watching kitchen staff work 12-hour shifts, those ergonomic improvements make a real difference in reducing fatigue.

The 6-pan capacity handles most pizzeria menus without overwhelming your workspace. Too many pans and your staff spends more time deciding than assembling. The front-breathing design saves energy and gives you flexibility in where you place the unit.

True's reputation for reliability isn't just marketing—it's earned through decades of consistent performance. The forced-air refrigeration maintains consistent temperatures across all pans, and the adaptive defrost system only runs when necessary, saving energy while maintaining temperature stability.

Best High-Volume Chain — Randell 8000D-290 Dual-Tier

For operations pushing serious volume, the Randell dual-tier system is in a league of its own. With capacity for 11-25 third-size pans, it can handle the most complex menus and highest customer volumes without missing a beat.

The independent rail cooling feature is brilliant for 24/7 operations. Shutting down the rail overnight saves up to 60% on energy costs—that's real money back in your pocket every month. The cold-wall technology extends ingredient freshness and eliminates those annoying defrost cycles that interrupt service.

The oversized clean-out valve behind a hinged louver makes maintenance easier, while press-fit gaskets can be replaced without tools. This level of serviceability keeps the unit running efficiently for years, not months.

You can see the dual-tier system in action in this YouTube demo of Randell prep tables. Watching it work with a full load of ingredients really shows why high-volume operations choose this system.

Cleaning, Maintenance & Organization Hacks

Keeping your pizza topping prep station clean and well-maintained isn't just about following health codes—it's about protecting your investment and keeping your operation running smoothly.

Daily maintenance starts with a simple wipe-down of all surfaces using warm soapy water. Pay special attention to the stainless steel cover and frame. For portable units like the Ooni station, remove all containers and lids for thorough hand washing. Don't forget to remove the silicone seals from containers—bacteria love to hide in these spots.

The real magic happens with your weekly deep cleaning routine. Commercial units make this easier than you might think. Use the hinged louver to access coils and drains, and take advantage of features like the oversized clean-out valve on Randell units.

One of the best features of quality prep stations is their press-fit gaskets. Unlike cheaper units that require tools and downtime for gasket replacement, these can be swapped out in seconds without any equipment. Check them monthly for wear, and replace as needed to maintain temperature efficiency.

Smart organization systems can transform your prep station from functional to phenomenal. Implement FIFO topping rotation religiously—first in, first out prevents waste and ensures freshness. Color-coded pans make rotation obvious to all staff members, even during busy rushes when attention to detail can slip.

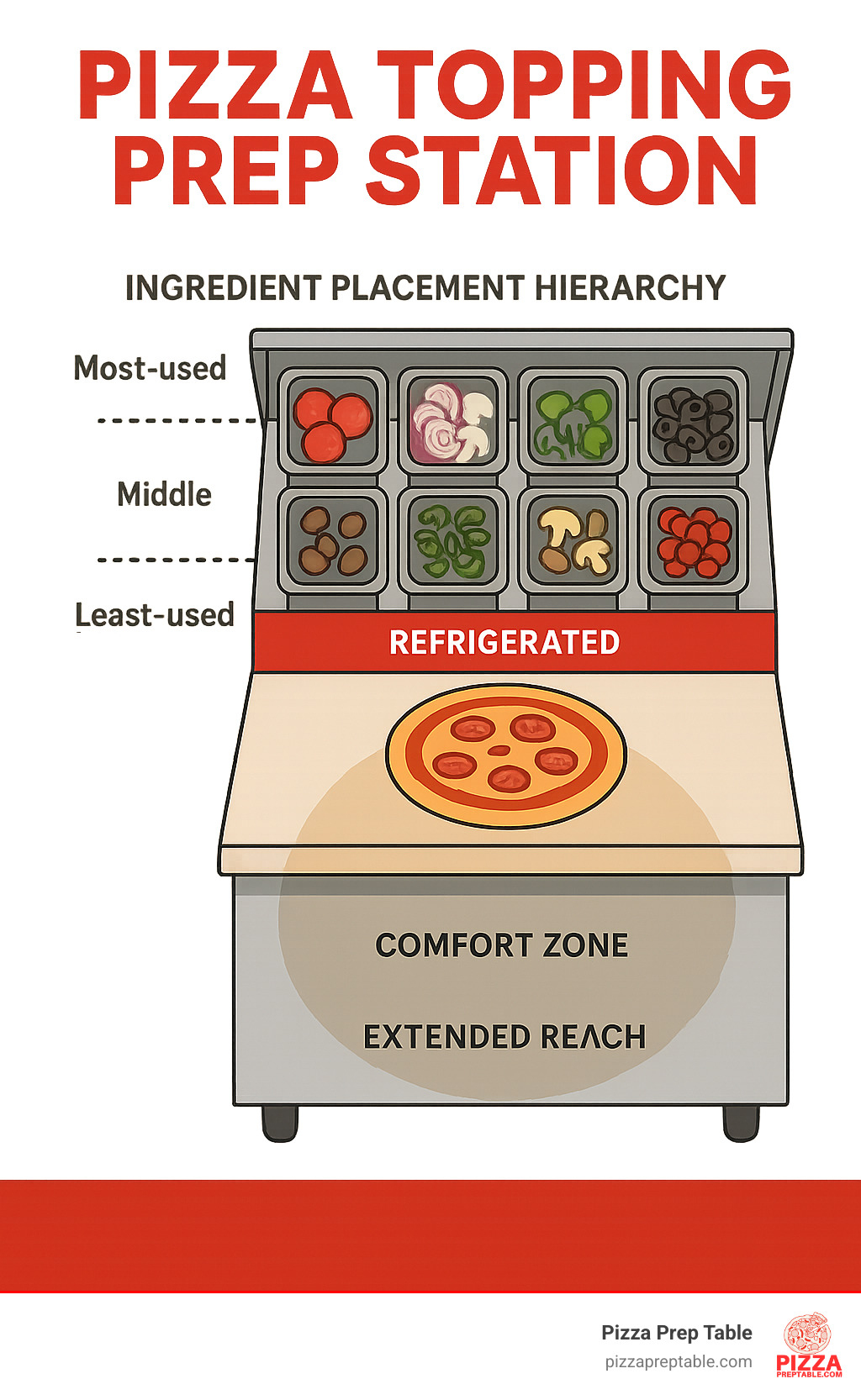

Position your most-used toppings in the center pans where they're easiest to reach. This simple change reduces staff fatigue during long shifts and speeds up pizza assembly. Less popular toppings can go in the outer positions where they're still accessible but don't slow down your workflow.

Temperature monitoring should become second nature, even with modern units that maintain consistent temperatures automatically. A quick check with an infrared thermometer catches any issues early and ensures compliance during health inspections.

For comprehensive guidance on maintaining all types of commercial equipment, visit our detailed guide on restaurant kitchen prep tables.

Frequently Asked Questions About Pizza Topping Prep Stations

How do refrigerated and non-refrigerated stations differ?

The biggest difference comes down to automatic temperature control. Refrigerated pizza topping prep stations do all the work for you, keeping ingredients at that perfect 33-40°F range without you having to think about it. This means your toppings stay fresh and safe for hours, even during the busiest dinner rush.

Non-refrigerated stations require more hands-on management. You'll need to rely on ice baths, change out ingredients every few hours, or use the natural cooling properties of materials like granite. These work great for backyard pizza parties or food trucks where you're using ingredients quickly, but they're not practical for commercial operations.

The time factor is crucial here. While a refrigerated unit can safely hold your pepperoni and cheese for an entire shift, a non-refrigerated setup typically needs fresh ingredients every 2-4 hours depending on how hot your kitchen gets. For busy pizzerias, that's the difference between smooth service and constant trips to the walk-in cooler.

What size station fits my space and sales volume?

Here's where we get practical about matching your pizza topping prep station to your actual needs. If you're making 50-100 pizzas per day, a 44-inch unit like our Atosa model gives you plenty of workspace without overwhelming your kitchen. It's perfect for that cozy neighborhood pizzeria vibe.

Step up to 200-400 pizzas daily? You'll want something in the 67-72 inch range, like the True TPP-AT series. These units give you the pan capacity and workspace to handle dinner rushes without your staff bumping into each other.

Once you're cranking out 400+ pizzas per day, it's time to consider the big guns - 93+ inch units or those impressive dual-tier Randell systems. These are for serious high-volume operations where every second counts.

Don't forget about your menu complexity though. A simple pepperoni-and-cheese operation can work with fewer pans, while a gourmet place with 15 different toppings needs all the space they can get. My advice? Buy slightly bigger than you think you need - it's much cheaper than upgrading in two years when business picks up.

How often should I deep-clean the rail and base?

Commercial kitchens should treat their pizza topping prep station like the workhorse it is. Weekly deep cleaning of the rail keeps everything running smoothly - empty those pans, hit it with sanitizer, and let it air dry completely before restocking.

The base components need monthly attention. Check those coils, clean the drains, and inspect the gaskets. If you've got one of those self-cleaning condensers, you're in luck - they need less babying, but still deserve a monthly once-over.

Home users have it easier. Give your station a thorough cleaning after big pizza parties and once a month during regular use. The Ooni's removable containers make this especially simple - just pop them in the dishwasher and you're done.

The key is consistency. Regular maintenance prevents those expensive service calls and keeps your ingredients at perfect temperatures. Trust me, spending 30 minutes a week on cleaning beats explaining to customers why their pizza took so long because your station decided to take a break during the dinner rush.

Conclusion

Choosing the right pizza topping prep station is one of the smartest investments you can make for your kitchen. Whether you're flipping dough in your backyard or running a busy pizzeria, the right station becomes the heart of your operation.

We've seen how these stations transform workflows. The Ooni station turns weekend pizza parties into smooth, professional experiences. The Atosa budget models help new pizzerias compete with established shops. And those Randell dual-tier systems? They're the secret weapon behind many successful pizza chains.

The numbers don't lie - maintaining perfect 33-40°F temperatures automatically, cutting prep time by up to 40%, and saving up to 60% on energy costs with smart rail cooling systems. But beyond the statistics, it's about creating a workspace that makes sense. No more running back and forth to the walk-in cooler. No more scrambling to find ingredients during the dinner rush.

When you're ready to upgrade, think about your real needs. That compact 44-inch unit might be perfect now, but if you're growing fast, consider the 67-inch model. The extra capacity costs less than upgrading again in two years. And don't forget about construction quality - stainless steel construction and sealed rails might cost more upfront, but they save money and headaches down the road.

At PizzaPrepTable.com, we've helped thousands of pizza makers find their perfect match. From food trucks in Los Angeles to family pizzerias in Chicago, we understand that every operation is unique. That's why we offer financing options that work for real businesses, not just the ones with perfect credit.

The best part? Your investment pays for itself quickly. Better organization means faster service. Consistent temperatures mean less waste. Happy staff means lower turnover. And when customers see that professional setup, they know they're getting quality.

Ready to transform your pizza game? Visit us at PizzaPrepTable.com and let's find the pizza topping prep station that fits your space, your budget, and your dreams. Your future self will thank you every time you glide through a busy dinner rush with everything perfectly organized and within reach.