The Ultimate Commercial Ice and Water Dispenser Pizzeria Guide

Share

Let’s be honest, for a pizzeria, a commercial ice and water dispenser isn't just an appliance. It's a workhorse, a silent partner that can boost your beverage sales and bring some much-needed calm to your kitchen workflow, especially around the pizza prep table. This single machine delivers a constant, clean supply of ice and water, and that has a ripple effect on everything from the quality of your drinks to your staff's sanity and, ultimately, your bottom line.

Why Your Pizzeria's Success Depends on the Right Ice Dispenser

In the pizza business, we all know the profit margins are razor-thin and often hiding in the details. While the perfect cheese pull and a crispy crust get all the credit, that ice machine humming in the corner is one of the unsung heroes driving your success. It’s not just about keeping sodas cold; it’s a strategic piece of equipment that shapes the customer experience and your kitchen's rhythm from open to close.

The quality of your ice is the quality of your drinks. It’s that simple. Cloudy, bad-tasting ice from unfiltered water can completely wreck the flavor of a craft soda or iced tea, and that directly hurts your high-margin beverage sales. A dependable commercial ice and water dispenser guarantees every single drink goes out with clean, clear, consistently shaped ice. This protects the integrity of your beverage program—which, for many pizzerias, is a massive profit center.

Beyond the Beverage Station

Thinking an ice machine is only for the soda fountain is a rookie mistake. Its usefulness extends deep into the heart of your kitchen, especially around the pizza prep table. A reliable source of ice is non-negotiable for a bunch of back-of-house tasks that are crucial for consistency and food safety.

For starters, ice is a key player in:

- Controlling Dough Temperature: A lot of killer pizza dough recipes demand cold water to slow down the yeast activation during mixing. This is what gives the dough that perfect texture. An integrated water dispenser at the prep station gives you chilled water right when you need it.

- Rapidly Cooling Sauces: Ice baths are the professional standard for a reason. They're the fastest and safest way to cool down big batches of marinara, bringing them through the temperature "danger zone" to stop bacteria from growing.

- Stocking Pizza Prep Table Inserts: If your pizza prep table includes cold wells for toppings like veggies, meats, and cheese, you know that keeping them at a safe, fresh temperature requires a mountain of ice. It’s a small detail that makes a huge difference in food safety and quality.

Streamlining Operations for a Better Bottom Line

When the dinner rush hits, every second is gold. A well-placed dispenser means your staff isn't trekking across the kitchen to manually scoop ice from a distant, open-bin machine—a process that’s both a time-waster and a huge sanitation risk. Touchless or lever-operated dispensers are a game-changer for reducing cross-contamination and helping your team move faster.

A well-chosen commercial ice and water dispenser isn't an expense; it's an investment in efficiency, safety, and customer satisfaction. It reduces labor, minimizes waste, and maximizes the profitability of your high-margin beverage menu.

By centralizing where your team gets ice and water, especially near the pizza prep table, you empower them to bang out drink orders faster, keep the prep stations running without a hitch, and maintain a higher level of hygiene. This one equipment upgrade translates directly into a smoother workflow, happier employees, and a healthier bottom line for your pizzeria.

Choosing the Right Ice Style and Dispenser for Your Layout

Picking out a commercial ice and water dispenser is a lot like choosing the right oven for your pizzeria. Just as different ovens create different crusts, your choice here shapes both the customer experience and your kitchen's efficiency. The decision hinges on your layout, your workflow, and the kind of drinks you want to serve.

Before you even think about ice types, think about placement. Where you put this machine can either streamline your entire operation or create frustrating bottlenecks, especially during a hectic Friday night rush. You need to map out where ice is needed most and pick a model that supports that specific workflow, whether it's for back-of-house prep or a front-of-house beverage station.

Match the Dispenser Model to Your Pizzeria's Space

The physical footprint of your pizzeria will immediately narrow down your options. The three main styles—countertop, undercounter, and freestanding—each solve a different spatial puzzle.

-

Countertop Dispensers: These compact units are the obvious choice for self-service beverage stations in your dining area. They give customers easy access, freeing up your staff from constantly filling drinks. Their smaller size is a lifesaver for pizzerias with limited front-of-house space.

-

Undercounter Dispensers: Tucked neatly beneath a standard-height counter, these are the unsung heroes of staff efficiency. Placing one near the pizza prep table or behind the service counter gives your team instant access to ice for drinks and food prep without eating up valuable floor space.

-

Freestanding Dispensers: As the largest and highest-capacity models, freestanding units are built for serious volume. These are best suited for large kitchens or dedicated beverage areas where staff will be filling hundreds of cups a day.

Placing an undercounter model right on your prep line is a classic pro move. It puts ice within arm's reach for quickly cooling down a batch of sauce, making cold-water dough, or refilling the cold wells on your pizza prep table. It's that kind of smart integration that creates a smooth, productive workflow.

Selecting the Perfect Ice for Your Drinks

Once you've zeroed in on the right dispenser model, the next decision is the ice itself. This isn't just about frozen water; the shape and size of the ice dramatically affect drink quality, taste, and even your profit margins.

The right ice type can increase beverage displacement, meaning you use less soda per cup while still delivering a satisfying, chilled drink. This small detail can significantly boost the profitability of your beverage program over time.

For instance, big, slow-melting cubes are fantastic for preserving the bold flavor of craft sodas, while softer, chewable ice is a customer favorite that can set you apart. Let's break down the most common options for a pizzeria setting.

Here's a quick-glance table comparing common ice types to help you choose the best fit for your drinks and operational needs.

Comparing Ice Types for Pizzeria Beverages

| Ice Type | Best For | Melting Speed | Drink Displacement |

|---|---|---|---|

| Full Cube | Sodas, Iced Tea, Cocktails | Slow | Moderate |

| Half Cube | High-Volume Beverage Service | Medium | High |

| Nugget Ice | Smoothies, Soft Drinks, Healthcare | Fast | Very High |

This table gives you the basics, but the real story is in how each ice type performs in a cup.

Full cube ice is a classic for a reason. Its large surface area means it melts slowly, chilling drinks without watering them down too quickly. This makes it perfect for preserving the carbonation and flavor of fountain sodas that go hand-in-hand with a hot slice of pizza.

Half cube ice is the versatile workhorse. It packs more tightly into a glass, which increases drink displacement and cools beverages faster than full cubes. This makes it a smart, cost-effective choice for busy pizzerias looking to manage syrup costs without sacrificing drink quality.

And then there's nugget ice. This soft, chewable ice is a customer favorite and cools drinks almost instantly. Because it displaces so much liquid, it's highly profitable for beverage service. A commercial ice and water dispenser that produces nugget ice can become a defining feature of your drink station, creating a memorable experience that keeps people coming back.

Sizing Your Dispenser for the Friday Night Rush

Picking the right size for your commercial ice and water dispenser is one of the most important calls you'll make. It’s a classic balancing act. Go too small, and you’ll find yourself in the middle of a Friday night rush frantically buying bags of ice—a frustrating and expensive emergency that throws your whole kitchen off-kilter.

On the flip side, an oversized machine is just as bad for business. It doesn’t just hit you with a higher price tag upfront; it also guzzles more energy and water than you need, quietly inflating your utility bills for years to come. The sweet spot is that "Goldilo_cks" size: a machine that churns out enough ice to handle your busiest shifts without wasting a dime during the slow periods.

Production Rate vs. Bin Capacity

To get the sizing right, you have to understand two numbers that sound similar but do very different jobs: daily production rate and bin storage capacity. Getting this right is key to keeping your pizzeria stocked.

- Daily Production Rate: This is the total amount of ice, in pounds, the machine can make over a 24-hour period in perfect conditions (think 70°F air and 50°F water).

- Bin Storage Capacity: This is simply how much ice the machine’s built-in storage bin can hold at one time. Once it’s full, the machine takes a break until you use some ice.

Think of it like this: the production rate is how fast your oven can bake pizzas, and the bin capacity is how many finished pies you can hold on the warming rack. You need a fast oven and a big enough rack to survive the dinner rush. A machine that can produce 400 lbs of ice per day but only holds 80 lbs in its bin gives you a fantastic head start on a busy shift.

Calculating Your Pizzeria's Ice Needs

There's an old industry rule of thumb that says to plan for 1.5 lbs of ice per customer. But for a pizzeria, that formula just doesn’t cut it. It completely ignores all the ice you’re using in the back of the house. A much better approach is to map out every single spot where ice gets used.

Let’s walk through a realistic estimate for a pizzeria with 50 seats, expecting to be packed on a Friday night:

- Customer Drinks: 50 seats x 1.5 lbs/person = 75 lbs

- Pizza Prep & Dough: Using chilled water for perfect dough consistency = 20 lbs

- Pizza Prep Table Inserts: Keeping those veggies and meats crisp and fresh = 40 lbs

- Staff & Kitchen Use: Cooling down sauces, staff drinks, etc. = 15 lbs

Total Estimated Peak Demand: Add it all up, and your pizzeria needs about 150 lbs of ice just to get through a single, slammed dinner service without breaking a sweat. In this scenario, a machine that produces 250-300 lbs per day with a bin that holds at least 80-90 lbs would be a safe, efficient choice.

This calculation ensures you have a big enough buffer in the bin to handle that initial wave of customers, while the machine’s production power works behind the scenes to replenish your supply all night. Getting this sizing right is becoming more critical as restaurant owners invest in gear they can rely on. The market for these dispensers is booming, projected to hit USD 8,148.1 million in the next decade, which just shows how central they are to a modern kitchen. You can explore more about this market growth and what it means for operators.

Navigating Installation and Kitchen Requirements

Picking out the right commercial ice and water dispenser is a big win, but a smooth installation is what really sets your pizzeria up for success. Thinking ahead about the technical stuff—plumbing, electrical, and drainage—is the difference between a seamless setup and a string of costly headaches. Getting these details right from the start ensures your machine runs like a dream, especially when it's tucked in next to a busy pizza prep table.

Before that shiny new unit even arrives, you need to do a proper site assessment. This isn't just about measuring floor space; it’s about mapping out every single connection your machine needs to come alive. One of the most common mistakes I see is failing to plan for a dedicated cold water line with its own shut-off valve. That connection is the lifeblood of your dispenser, and you’ll want it easily accessible for any future maintenance.

Plumbing and Electrical Essentials

Your dispenser's performance is directly tied to the quality of its connections. Think of it like making pizza dough—if your water temperature or yeast is off, the final product suffers. The same exact logic applies here.

Here are the non-negotiable hookups you'll need to have ready:

- Dedicated Water Line: Your machine needs a cold water line, usually a 1/4" or 3/8" connection. Sharing a line with a dishwasher or a sink is asking for trouble. It can cause pressure drops that mess with your ice production, especially when other equipment kicks on.

- Proper Drainage: Every ice machine creates wastewater from melt-off and condensation. A floor drain is the gold standard—simple and reliable. If a floor drain isn't an option, you’ll need to install a condensate pump to move that water to a suitable drain.

- Correct Electrical Circuit: A commercial ice and water dispenser is a heavy-duty appliance. It needs its own dedicated electrical circuit to avoid tripping breakers during your Friday night rush. Always check the manufacturer's specs for the exact voltage and amperage required.

To keep your machine happy and efficient, you absolutely need adequate water pressure. If you run into problems, it’s worth learning how to increase water pressure in your building. Consistent pressure is what leads to uniform ice cubes and a steady flow of water.

Air-Cooled vs. Water-Cooled: The Pizzeria Dilemma

In a hot pizzeria kitchen packed with ovens and grills, heat is your ice machine's mortal enemy. How your dispenser cools itself—its condenser type—is a critical decision you have to make. Your two main choices are air-cooled and water-cooled.

For the vast majority of pizzerias, an air-cooled condenser is the most practical and cost-effective choice. They are simpler to install and do not add to your water bill. However, their efficiency is entirely dependent on proper ventilation.

Water-cooled units are more efficient in super-hot kitchens, but they use a ton of water, making them more expensive to run and even prohibited in some areas. For a pizzeria, the real key to success is simply managing the airflow for an air-cooled unit.

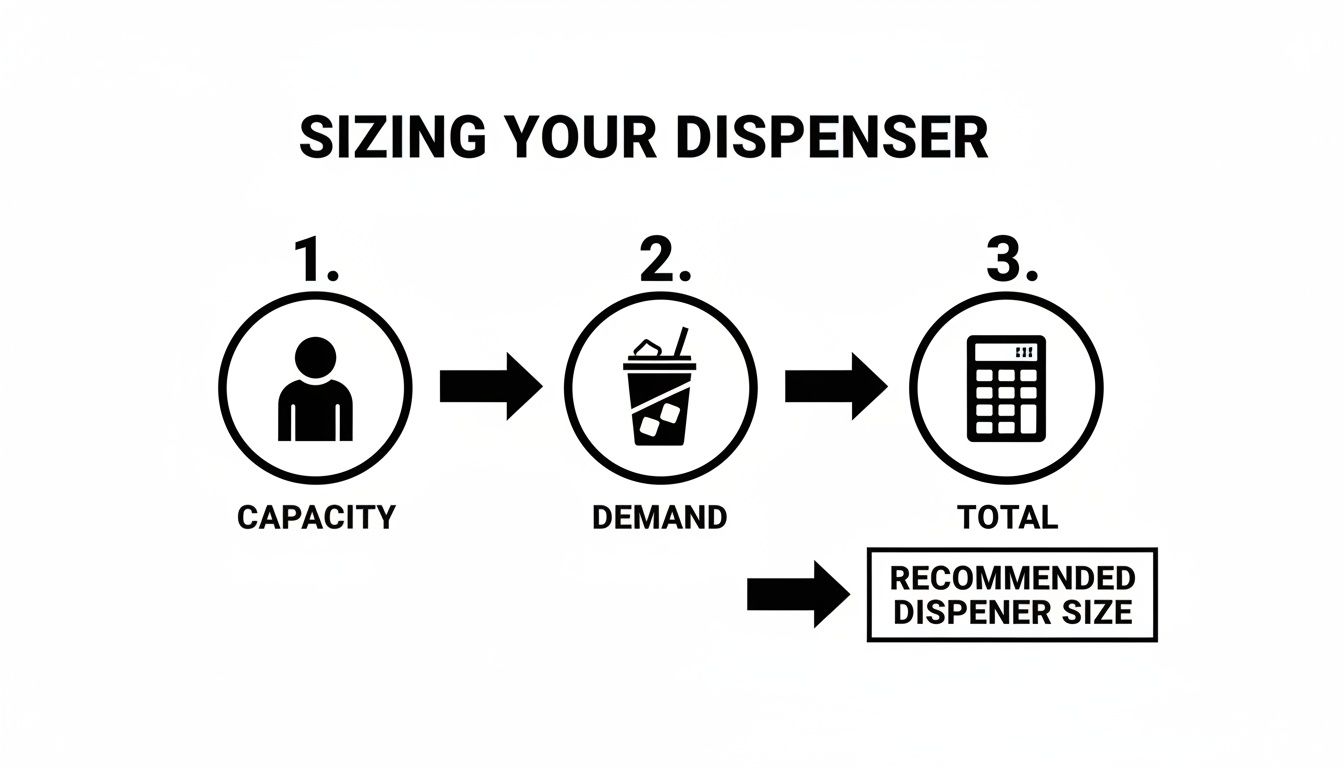

This flowchart shows how to properly size your dispenser based on capacity, peak demand, and your total ice needs.

As you can see, figuring out your total ice requirement is a multi-step process, not just a quick guess based on how many seats you have.

To get the most life and efficiency out of your air-cooled dispenser, you have to give it room to breathe. Most manufacturers recommend at least 6-8 inches of open space on all sides and on top. If you block the air vents, especially next to a hot pizza oven, you force the compressor to work way harder, which leads to higher energy bills and a much greater risk of a breakdown.

Why Water Filtration Is Your Secret Ingredient

Here's a little secret every seasoned pizzeria owner knows: the key to perfect, crystal-clear ice and fountain drinks that actually taste right isn't some fancy syrup. It's pure water. For any pizzeria, a good water filtration system isn't just an add-on for your commercial ice and water dispenser; it's a non-negotiable part of the setup. It’s the behind-the-scenes hero that has a massive impact on your beverage quality, how long your machine lasts, and even your pizza dough.

Think of unfiltered tap water like looking through a smudged window. It’s loaded with minerals, chlorine, and sediment that create cloudy, off-tasting ice and can affect the flavor of your pizza crust. This doesn’t just look bad—it actively messes with the carefully balanced flavors of your sodas and iced teas. The result is a disappointing drink for your customer and a hit to your high-margin beverage sales.

From Murky Ice to Pristine Purity

A high-quality water filter is the gatekeeper that traps all that gunk before it ever hits the ice-making mechanism. This one step is what separates cloudy, foul-smelling ice from the clean, crisp cubes that make a drink truly refreshing.

What exactly is a good filter pulling out of your water?

- Chlorine: This is the stuff used to treat city water, and it leaves behind a distinct "pool water" taste and smell that completely clashes with beverage syrups.

- Sediment: We're talking about tiny particles of dirt, rust, and sand. They make ice look cloudy and unhygienic, and they can wreak havoc on your machine's internal parts.

- Minerals: Calcium and magnesium are the main culprits behind scale buildup, which is the number one enemy of any commercial ice machine.

An effective filtration system is really just preventative maintenance in disguise. By stopping scale before it can form, you’re protecting sensitive components like evaporator plates and sensors. This extends the life of your dispenser and helps you dodge expensive repair bills down the road.

This isn’t just my opinion; it’s an industry-wide focus. The market for commercial beverage dispensers, which absolutely relies on quality ice and filtration, is expected to grow by USD 242.9 million as more restaurants realize how critical quality and reliability are.

Meeting Health Codes With NSF Certification

Beyond making things taste better, water filtration is a straight-up public health issue. Local health departments have strict rules for food equipment, and believe it or not, ice is legally considered a food product. Using an uncertified filter or dispenser can get you hit with violations, fines, or even a forced shutdown.

This is exactly why choosing an NSF-certified model is so critical. This certification is your guarantee that the dispenser and its filtration system have been put through the wringer and tested to meet public health and safety standards. It’s the seal of approval that tells inspectors—and your customers—that your ice is clean, safe, and free from harmful contaminants.

A Simple Maintenance Schedule for Longevity

Keeping up with your filtration system is one of the easiest and most important things you can do for the long-term health of your dispenser. Once a filter gets clogged, it doesn’t just stop working; it chokes the water flow, forcing the machine to work harder and dramatically cutting down your ice production.

Here’s a simple schedule to stick to:

- Check Monthly: Just take a quick look at the filter. Can you see any discoloration or signs that it's getting clogged?

- Replace Every 6 Months: This is the standard advice for most commercial filters. If you’re a high-volume pizzeria, you might even need to change them more often.

- Follow Manufacturer Guidelines: Always check the specific instructions for your model. They know their machine best.

To make sure you're picking the right system for your specific water quality, it’s worth checking out a detailed comparison of various water filtration systems to see what technologies are out there. This small, routine task is your best defense against scale and ensures your investment keeps paying off day after day.

Understanding the True Cost of Your Ice Machine

A smart investment in a commercial ice and water dispenser goes way beyond the initial sticker price. To really get a handle on the financial impact for your pizzeria, you need to look at the total cost of ownership (TCO). This means thinking about every single expense that will hit your budget over the machine's entire life, not just the day you buy it.

The biggest ongoing costs, by far, are energy and water. An inefficient machine can quietly suck hundreds, or even thousands, of dollars from your profits each year through bloated utility bills. This is especially true in a hot pizzeria kitchen where all your refrigeration equipment, from the pizza prep table to the walk-in, is already working overtime.

Look Beyond the Purchase Price

When you're budgeting, it's natural to fixate on the upfront cost and gloss over the long-term expenses. But those recurring costs are what truly define whether you made a good investment. A cheaper machine might feel like a win today, but it can cost you a fortune down the road in poor energy efficiency and constant repair calls.

To get the full financial picture, you have to factor in these key ongoing expenses:

- Energy Consumption: This will be a major line item on your monthly bills. An inefficient model is a guaranteed way to overpay your electric company.

- Water Usage: It's not just the water that becomes ice. Some units, especially water-cooled models, use extra water for cooling, adding another layer to your utility costs.

- Maintenance and Cleaning: This isn't optional. Professional deep cleaning services are needed at least twice a year to keep you on the right side of the health department.

- Filter Replacements: Water filters are essential for protecting your machine and ensuring you serve clean, good-tasting ice. Expect to replace them every six months.

The Power of ENERGY STAR Certification

One of the smartest moves you can make to control long-term costs is choosing an ENERGY STAR® certified model. These machines are independently tested and proven to be more efficient than standard models, often using 10-20% less energy and at least 20% less water.

An ENERGY STAR certified commercial ice machine can save a business an average of $150 per year on utility bills. Over the machine's typical 7-10 year lifespan, those savings add up to well over $1,000.

This focus on efficiency is a huge market trend. The global ice and water dispenser market, valued at USD 2.5 billion, is projected to hit USD 4.8 billion, largely because savvy owners are choosing energy-efficient models for their lower operating costs. You can explore a detailed analysis of the growing ice and water dispenser market to see where the industry is headed.

Factoring in Leasing and Financing Options

For many pizzeria owners, dropping thousands on a high-quality dispenser all at once is a big ask. This is where financing options like leasing become incredibly valuable. Leasing lets you get top-of-the-line equipment for a predictable, low monthly payment instead of a massive upfront hit to your cash flow.

It’s a smart way to manage your budget while still getting access to the best, most efficient technology. You can learn more by reading our complete guide on ice machine leasing options for pizzerias. By understanding the full financial commitment—from purchase to utilities to maintenance—you can choose an ice and water dispenser that delivers real, sustainable value for years to come.

Your Top Questions Answered

When you're outfitting a pizzeria, an ice and water dispenser is a bigger deal than most people think. It's a serious investment, and you need it to perform flawlessly, especially when the dinner rush hits. You've got questions, and we've got answers—not generic tips, but real-world advice for a fast-paced kitchen where every piece of gear has to earn its keep.

Getting these details right from the start is one of the smartest things you can do. It'll save you a mountain of headaches, not to mention time and money, down the road.

How Often Should I Clean My Commercial Ice Dispenser?

This is, without a doubt, the most important question. The cleanliness of your ice machine is directly tied to food safety and the machine's lifespan. A consistent cleaning schedule is non-negotiable if you want to prevent the slime, mold, and scale buildup that leads to health code violations and expensive repairs.

In a pizzeria, with flour dust and yeast floating in the air, you have to be even more vigilant. A simple, tiered schedule is the best way to stay on top of it.

- Daily Wipe-Downs: At the end of every shift, have your staff wipe down the dispenser's exterior. This includes the levers or touchless sensors and the drip tray. It’s a small step that prevents sticky soda residue and grime from becoming a bigger problem.

- Weekly Sanitizing: Once a week, you need to empty the ice bin completely. Sanitize all the interior surfaces with an approved cleaning solution. This is what kills bacteria and stops that nasty biofilm from forming inside the storage area.

- Semi-Annual Deep Cleans: Twice a year, it's time for a professional-level deep clean. You can hire a pro or do it yourself if you're comfortable. This means descaling and sanitizing the entire ice-making system, from the water lines right through to the evaporator. To get this right, you need the right products. Our guide on ice machine cleaners and sanitizers will help you choose the best ones for your machine.

Can I Just Use a Standard Water Line for My Dispenser?

Absolutely not. This is a common but critical mistake that will cause you nothing but trouble. A commercial ice and water dispenser is a high-demand appliance and needs its own dedicated, cold water line with a separate shut-off valve. If you try to tap into a line shared with a dishwasher or a sink, you're creating a battle for water pressure.

Think of it like this: if your three-deck pizza oven had to share a gas line with the deep fryer, you'd never get consistent temperatures. The same principle applies here. When another appliance kicks on, it can cause the water pressure to drop, leading to smaller, misshapen ice cubes or slower production.

For your machine to work as it should, the water line needs to provide a steady pressure between 20 and 80 PSI. Anything outside that range will strain the machine's components. A dedicated line with an easy-to-reach shut-off valve also makes routine maintenance and filter changes a whole lot safer and simpler.

What Is the Real Lifespan of a Commercial Ice Machine?

Manufacturers might make big promises, but in the real world, a well-maintained commercial ice machine will last you about 7 to 10 years. The key phrase there is "well-maintained." How long your specific machine lasts is almost entirely up to you.

The two biggest factors are water quality and how often you clean it. A machine running on hard, unfiltered water is going to die an early death from aggressive scale buildup choking its internal parts. Likewise, a unit that only gets cleaned when someone remembers will inevitably fail sooner.

If you want to push your machine toward that 10-year mark and get the most out of your investment, you have to be proactive. Stick to that cleaning schedule like glue, install a high-quality water filtration system, and make sure the machine has enough space around it for proper ventilation to keep it from overheating.

Ready to find the perfect workhorse for your pizzeria? The experts at Pizza Prep Table can help you select a commercial ice and water dispenser that fits your space, budget, and peak demand. Explore our selection of reliable, high-performance ice machines today at https://pizzapreptable.com.