Your Guide to Commercial Kitchen Equipment for Pizzerias

Share

When you're dreaming of opening a pizzeria, what do you picture? Probably the perfect cheese pull, the crispy-chewy crust, and a line of happy customers. But to get there, you need the right tools. Your success, from crafting that perfect dough to serving a beautifully baked pie, literally hangs on having dependable commercial kitchen equipment. This gear is the engine of your entire operation.

Building Your Pizzeria's Equipment Foundation

Getting a pizzeria off the ground is an incredible feeling, but your vision only comes to life with the right machinery in your corner. Don't think of your equipment as a random shopping list. Instead, see it as an interconnected system built for one single purpose: making exceptional pizza, fast.

Every piece has a job to do. A weakness in one area—like a slow oven or an undersized mixer—creates bottlenecks that can bring your entire service to a screeching halt on a busy Friday night.

Setting up a solid equipment foundation means making critical business investments. The initial cost for quality gear isn't small, but it pays you back every single day through reliability, speed, and consistency. This isn't just a hunch; the global market for this equipment was valued at around USD 13.8 billion and is expected to climb to USD 22.4 billion. That steady growth tells you one thing: serious pizzeria operators are continuously investing in their kitchen's infrastructure.

The Core Trio of Pizzeria Equipment

For any pizzeria, three types of commercial kitchen equipment are completely non-negotiable. They form the operational backbone of your business, and they directly control both your product quality and your kitchen's workflow.

- Pizza Ovens: This is where the magic happens. The oven you choose—whether it's a classic deck, a high-volume conveyor, or a versatile convection—defines the very character of your pizza. It's the difference between a crispy, hearth-baked crust and a perfectly uniform, evenly cooked pie.

- Dough Mixers: Great pizza starts with consistent dough. A commercial-grade mixer is the only way to guarantee every single batch has that perfect texture and elasticity. Trying to do this by hand at scale is a recipe for disaster.

- Pizza Prep Tables: This is the command center for your entire production line. It's a specialized workstation that brilliantly combines refrigerated storage for all your toppings with a durable surface for assembly, keeping everything an arm's length away.

A well-chosen pizza prep table is so much more than a countertop; it's an ergonomic hub that dictates the pace and organization of your entire pizza-making process. It’s where speed meets food safety.

To give you a clearer picture, here’s how these essential pieces fit together.

Essential Equipment for a Pizzeria Kitchen

This table breaks down the core equipment categories that are absolutely crucial for any pizzeria's success, highlighting their main job and how they impact your day-to-day operations.

| Equipment Category | Primary Function in a Pizzeria | Impact on Workflow |

|---|---|---|

| Pizza Oven | Baking the final product | Dictates cooking time, throughput, and final pizza style. The oven is the ultimate bottleneck or the key to high volume. |

| Dough Mixer | Preparing consistent pizza dough | Ensures every pizza has the same base texture. A powerful mixer prevents delays and staff fatigue from hand-mixing. |

| Pizza Prep Table | Assembling pizzas efficiently | Centralizes topping storage and prep space. A good table drastically cuts down movement and assembly time per pizza. |

Understanding how these core pieces function together is the first step toward building a kitchen that runs like a well-oiled machine. While other tools are certainly important, this trio represents the foundational investment for any aspiring pizzeria owner. To get even more granular, you can dive deeper into the world of commercial food prep equipment in our guide and start making more informed choices for your business.

The Pizza Prep Table: Your Kitchen's Command Center

If the pizza oven is the heart of your pizzeria, the prep table is its brain and central nervous system. This single piece of commercial kitchen equipment orchestrates the entire assembly line, turning a scattered collection of ingredients into a perfect pizza, ready for the fire. It’s so much more than a countertop—it's an ergonomic powerhouse built for speed, consistency, and food safety.

Think of it like a pit stop in a Formula 1 race. Every tool and component is exactly where the crew needs it, allowing for lightning-fast execution without a single wasted motion. That's what a great prep table does for your kitchen staff, keeping chilled toppings, sauce, and dough within immediate reach.

This all-in-one approach is what separates the pros from the amateurs. Without it, your staff would be running between a standard worktop and various fridges, bleeding precious seconds on every single order. On a busy night, those seconds add up to minutes, leading to longer ticket times and unhappy customers.

Anatomy of a Pizza Prep Table

At its core, a pizza prep table is a three-part system working in perfect harmony. Each component is engineered to solve a specific problem in the pizza-making workflow.

- Refrigerated Topping Rail: This is the row of chilled pans right at the top of the unit. It holds high-use ingredients like pepperoni, mushrooms, and cheese at a safe temperature while keeping them open and accessible. A deep, angled rail makes it even easier for your crew to see and grab toppings in a flash.

- Durable Work Surface: This is your main assembly area, usually made from a tough, food-safe material like high-density polyethylene. The cutting board is wide enough to handle your largest pizza and is designed to be easily removed for deep cleaning.

- Cold Base Storage: Below the work surface sits a refrigerated cabinet. This is the perfect spot for backup pans of toppings, bulk cheese, sauce, and—most importantly—trays of proofed pizza dough, holding them at the ideal temperature until they're ready to be stretched.

Choosing the right prep table is a decision that directly impacts your kitchen’s output and your bottom line. It’s an investment in workflow optimization that pays for itself through reduced labor, faster service, and consistent product quality.

The market for this specialized equipment continues to boom, which just shows how critical it is in modern pizzerias. In fact, the global commercial cooking equipment market was valued at over USD 36 billion and is expected to climb to more than USD 54 billion. This growth is fueled by demand for efficient appliances that boost kitchen productivity. You can get the full story on this market's trajectory in this detailed industry report from Fortune Business Insights.

Standard vs. Mega Top: What's the Difference?

When you start shopping for a pizza prep table, you’ll see two main styles: standard-top and mega-top. The right choice for you comes down to the complexity of your menu.

A standard-top pizza prep table is the classic design. It features two rows of food pans in the refrigerated rail, which is perfect for pizzerias with a focused menu of traditional toppings.

A mega-top unit, on the other hand, is built for variety. It adds a third row of pans, boosting your topping capacity by about 30-50%. This is the go-to for restaurants offering a wide array of specialty pizzas, as it lets you hold more ingredients without needing a second unit.

Key Features to Look For

Beyond the basic style, a few key features will determine if a prep table is the right fit for your pizzeria's unique needs.

- Size and Capacity: Prep tables are measured by their width, commonly ranging from 44 inches for small spots to over 93 inches for high-volume operations. Measure your kitchen space carefully, but don't forget to consider your projected output. A table that’s too small will create a major bottleneck during your busiest hours.

- Refrigeration Power: Look for a system with a powerful, efficient compressor. The goal is to hold consistent, food-safe temperatures (below 40°F or 4°C) in both the rail and the base, even when the lids are open constantly during a dinner rush.

- Work Surface Material: While most units come with polyethylene cutting boards, some high-end models offer a marble or granite work surface. Marble is naturally cool and non-stick, making it a fantastic surface for handling dough, but it requires more care and cash. Stainless steel is another option, valued for its durability and how easy it is to sanitize, though dough can sometimes stick to it.

Mastering the Bake with Essential Cooking Equipment

While an organized pizza prep table acts as your mission control, it's the heavy-duty cooking equipment that turns all that careful prep into a final product people will crave. These machines are the real heart of your pizzeria's kitchen, directly shaping the taste, texture, and soul of every pie you send out the door.

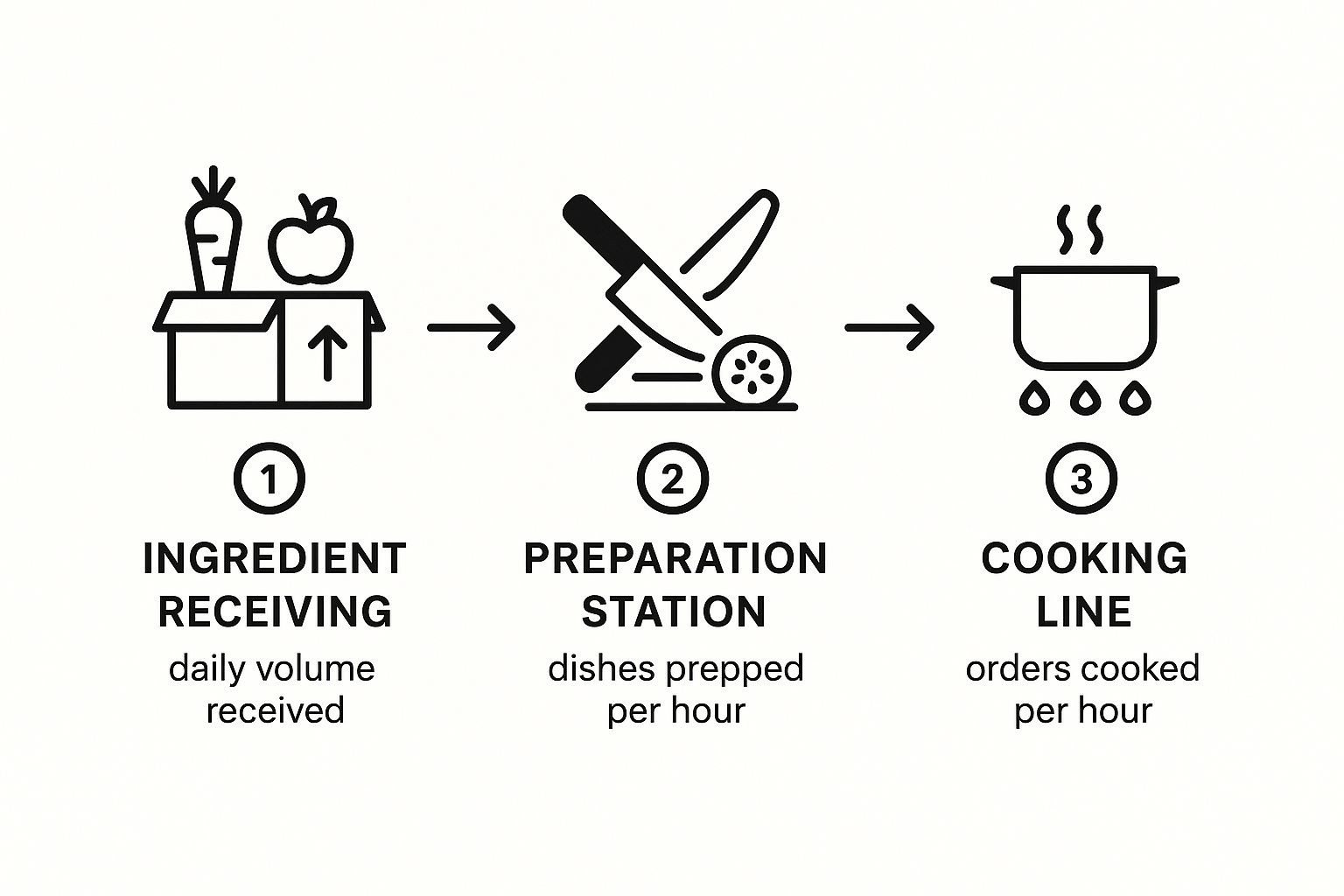

The journey from a stack of raw ingredients to a perfectly cooked pizza is a streamlined process in any high-volume pizzeria. The infographic below maps out a typical workflow, starting with receiving goods, moving to the pizza prep table, and finally hitting the cooking station. It shows how each stage needs to handle a specific volume of work.

This visual makes one thing crystal clear: your cooking line absolutely has to keep up with what your prep station is putting out. If it can't, you'll create expensive bottlenecks right when you can least afford them—during your busiest hours.

Choosing Your Pizzeria's Powerhouse: The Oven

The oven is, without a doubt, the most critical piece of commercial kitchen equipment you will purchase. It doesn’t just cook the pizza; it gives it a personality. Your oven choice dictates your baking style, how many pizzas you can pump out per hour, and even how much you'll spend on energy. In the world of commercial pizza ovens, there are three main contenders.

- Deck Ovens: This is the traditionalist's choice. These ovens use stone or ceramic "decks" to bake pizzas directly on the surface, creating that authentic, hearth-baked crust with a beautiful char and crispness. They take a bit more skill to master but give you incredible control over the final product.

- Conveyor Ovens: The speed demon of the pizza world. You place a pizza on a conveyor belt, and it moves through a heated chamber at a set speed and temperature. This method is all about consistency and high volume with minimal labor, which is why it's a favorite for chains and delivery-heavy shops.

- Convection Ovens: The versatile workhorse. Using fans to circulate hot air, these ovens cook food quickly and evenly. While not a pizza specialist like a deck or conveyor, they're fantastic for pizzerias that also serve other baked items like wings, breadsticks, or pasta dishes.

Selecting an oven is really about matching the technology to your brand's identity. A classic Neapolitan pizzeria thrives on the artisan touch of a deck oven, while a high-traffic slice shop might depend on the relentless efficiency of a conveyor model.

Each type has its own set of pros and cons. Getting a handle on these differences is the key to making a smart investment. To really get into the nitty-gritty, check out this fantastic guide on the best commercial pizza ovens that'll make your dough rise, literally.

The Unsung Hero: The Commercial Dough Mixer

Long before a pizza gets anywhere near an oven, its journey starts in the dough mixer. You can't make great pizza without perfectly consistent dough, and trying to produce that by hand at scale is a recipe for disaster. This workhorse saves you a massive amount of time and labor, all while ensuring every single pizza base has the exact same texture and elasticity.

Just like with ovens, there are two main types of commercial mixers you'll find in most pizzerias, each designed for different doughs and production levels.

Planetary vs. Spiral Mixers

Deciding between a planetary and a spiral mixer really boils down to two things: how you make your dough and how much of it you need to make.

A planetary mixer is the jack-of-all-trades. The agitator spins on an offset shaft while the mixing bowl stays put, creating a motion that looks a lot like a planet orbiting the sun. They come with different attachments (dough hook, flat beater, wire whip), making them a great fit for kitchens that also mix sauces, cheese blends, or batters. The downside? They can be a little rough on pizza dough and are generally better for smaller batches.

A spiral mixer, on the other hand, is a true pizza dough specialist. In this machine, both the spiral-shaped hook and the bowl rotate at the same time. This action is much gentler on the dough, preventing it from getting over-kneaded or too warm. It develops the gluten structure perfectly, which leads to a superior crust. These mixers are built for heavy, dense doughs and are the top choice for high-volume pizzerias that are serious about their craft.

When you're looking at models, pay close attention to the motor power (horsepower) and bowl capacity (quarts). Your goal is to pick a mixer that can easily handle your biggest dough batch during your busiest shift, with a little room to spare for future growth. An undersized mixer will constantly strain its motor and become a major bottleneck for your entire operation.

Designing a High-Efficiency Pizzeria Kitchen

Having the best commercial kitchen equipment is a fantastic start, but it's only half the battle. How you arrange that equipment is what really separates a good pizzeria from a truly great one. An intelligent layout transforms a room full of stainless steel into a high-performance engine for your business, directly impacting your speed, your staff's sanity, and your bottom line.

Think of your kitchen less like a single room and more like a series of interconnected work zones. The real goal is to create a seamless, one-way street for production. A pizza should move from one station to the next with almost zero backtracking, just like a car moving down an assembly line. This simple concept is what keeps chaos at bay during a frantic dinner rush.

This focus on smarter infrastructure is an industry-wide trend. The U.S. commercial cooking equipment manufacturing market recently hit around USD 6.4 billion and is expected to climb to USD 6.7 billion. This isn't just growth for growth's sake; it shows that smart pizzeria operators are investing in more efficient kitchens. You can see the bigger picture by exploring detailed market size data on IBISWorld.

Mapping the Ideal Pizzeria Workflow

The perfect pizzeria layout simply follows the natural journey of a pizza, from raw ingredients to a hot, boxed meal ready for the customer. When you create dedicated zones for each stage, you eliminate frustrating bottlenecks and reduce the risk of cross-contamination.

- Cold Storage and Dough Prep: This is ground zero. Your walk-in cooler, freezer, and dough mixer need to be close to the delivery entrance. This lets you unload and store supplies quickly and prep huge batches of dough without tripping over the main cooking line.

- The Assembly Line (Pizza Prep Table): This is mission control. Your pizza prep table should be the central hub, acting as the bridge between cold storage and the hot line. Your team should be able to grab dough, sauce it, and add toppings without taking more than a step or two.

- The Cooking Station: Your ovens must be right next to the prep table. This isn't a suggestion; it's a necessity. The pizza maker should be able to slide a finished pie into the oven with a simple pivot. Placing ovens across the kitchen is one of the most common and costly layout mistakes.

- Finishing and Boxing: Once a pizza is out of the oven, it needs a dedicated spot for cutting, garnishing, and boxing. This station has to be near the pass-through window or pickup counter to get that perfect pizza to the customer as fast as possible.

A well-designed kitchen layout is a form of silent communication. It tells your staff exactly where to be and what to do, reducing the need for constant verbal direction and letting them focus purely on speed and quality.

Creating Efficient and Safe Work Zones

Zoning is about more than just a smooth workflow; it’s about safety. Keeping raw ingredient prep far from the cooking and finishing areas is your best defense against cross-contamination between raw dough and cooked food.

A key player in this strategy is the refrigerated chef base. By placing one of these units directly under your griddles or charbroilers, you can create a powerful, self-contained station for cooking toppings like sausage or sides like wings. This is a brilliant way to keep secondary orders from clogging up your primary pizza assembly line. If you're curious about how this could work for you, check out our guide on choosing a refrigerated chef base.

Ultimately, the goal is to design a space where every piece of commercial kitchen equipment supports a fluid, stress-free process. This thoughtful arrangement slashes ticket times, reduces staff stress, and helps ensure every pizza you send out is consistently perfect.

Protecting Your Investment with Smart Maintenance

Your commercial kitchen equipment is easily one of the biggest checks you'll write for your pizzeria. It’s the engine that drives every single order, and just like any high-performance machine, it needs consistent care to keep running at its peak. Skimping on maintenance isn't a risk; it's a guarantee you'll face costly emergency repairs, killer downtime during the dinner rush, and a much shorter life for your most valuable assets.

Think of smart maintenance as an insurance policy for your kitchen's sanity and your restaurant's bottom line. A well-maintained pizza prep table holds food-safe temperatures without breaking a sweat. A clean oven bakes a better, more consistent pizza. A healthy mixer churns out perfect dough, batch after batch. It’s simply not optional if you're serious about this business.

Your Pizza Prep Table Maintenance Plan

The pizza prep table is mission control for your entire pizza assembly line, making its upkeep absolutely critical. This single piece of equipment juggles refrigeration, food storage, and your main work surface, so its health directly impacts food safety and how fast you can get pies out the door. The secret to keeping this workhorse in top shape is a simple, repeatable checklist.

A proactive approach is what stops common failures in their tracks. We're talking about a struggling compressor or a torn door gasket—small issues that can quickly spiral into spoiled ingredients and a failed health inspection. Here’s a maintenance schedule you can put to work in your own pizzeria.

Regular maintenance isn’t just about stopping things from breaking. It’s about making sure every part, from the condenser coils to the door seals, is working efficiently. That saves you real money on energy bills and protects your food inventory from spoilage.

This schedule breaks down the essential tasks into daily, weekly, and monthly jobs, making it easy for any staff member to follow through.

Pizza Prep Table Maintenance Checklist

A simple schedule of essential maintenance tasks is the key to keeping your pizza prep table running efficiently and sanitarily day in and day out.

| Task | Frequency | Importance |

|---|---|---|

| Wipe Down All Surfaces | Daily | Crucial for preventing cross-contamination and keeping the workspace sanitary. This includes cutting boards, rails, and lids. |

| Check & Clean Gaskets | Weekly | Dirty or torn gaskets let cold air escape, forcing the compressor to work overtime. This means higher energy bills and potential food spoilage. |

| Clean Condenser Coils | Monthly | Dust and grease on the coils act like a blanket, keeping the unit from cooling properly. This is one of the top causes of refrigeration failure. |

| Inspect Thermostat Calibration | Monthly | An off-kilter thermostat can land your ingredients in the temperature danger zone. Regular checks make sure it's holding temp correctly. |

| Sanitize Drains and Lines | Monthly | Stops clogs and funky odors from building up due to condensation and small spills inside the unit. |

By turning these tasks into habits, you ensure your prep station remains the reliable heart of your kitchen instead of a ticking time bomb.

Expanding Maintenance to Other Core Equipment

While your pizza prep table needs daily love, don't forget about the other key players in your commercial kitchen equipment lineup. A complete maintenance plan ensures your whole workflow runs without a hitch.

For Your Ovens (Deck or Conveyor):

- Daily: Brush out any carbon buildup and leftover food bits from the cooking chamber or deck. This is non-negotiable for preventing burnt, off-flavors from ruining your pizzas.

- Weekly: Give the exterior surfaces a thorough cleaning and double-check that all controls and doors are working as they should.

For Your Dough Mixer:

- After Each Use: Clean the bowl, hook, and any other attachments right away. If you let the dough harden, you're signing up for a much tougher cleaning job later.

- Monthly: Take a look at the safety guard and check any lubrication points (if your model has them) to ensure it’s running smoothly and safely.

Finally, remember that a clean environment is just as vital as clean equipment. Beyond wiping down surfaces and caring for your machines, keeping pests out is a must for food safety and the longevity of your kitchen. Learning about effective strategies to deal with kitchen ants and other pests will help ensure your entire space stays pristine. A disciplined approach to both equipment care and general sanitation is what truly protects your investment and your reputation.

Frequently Asked Questions About Pizzeria Equipment

Jumping into the pizzeria business means you're going to have a ton of questions, especially when it's time to pick out, install, and take care of your commercial kitchen equipment. Getting good, straight answers is the only way to make decisions you won't regret later. This FAQ is all about tackling the most common things pizzeria owners ask, with direct advice to help you move forward.

Think of your equipment not as a random collection of machines, but as a complete system. It all has to work together to churn out a consistent, high-quality pizza every single time. From the mixer that brings your signature dough to life to the prep table where your masterpieces are assembled, every single piece has a job to do.

What Is the Most Important Piece of Pizzeria Equipment?

If you ask a dozen seasoned pizza pros, you'll likely get a dozen different answers, but one piece of equipment comes up over and over again: the pizza prep table. It’s the undisputed command center of your entire assembly line. A smart prep table keeps your refrigerated toppings, dough, and a cutting board all in one spot, which dramatically cuts down on wasted steps and gets pizzas out the door faster.

The reason it’s so critical comes down to workflow. A slow oven bakes one pizza slowly. But a disorganized, messy prep station? That slows down every single pizza that goes into that oven. It creates a massive bottleneck that sends ripples of chaos through your entire service.

How Much Space Do I Need for a Pizza Prep Table?

Figuring out the right size for your prep table comes down to two things: how much floor space you actually have and how many pizzas you plan on slinging. You can find compact models around 44 inches wide, perfect for a small cafe or food truck, all the way up to massive 93-inch units built for high-volume shops.

Here's how to get it right:

- Get Out the Tape Measure: Don't guess. Physically measure the spot where the table will live. Make sure to leave at least 3-4 inches of breathing room on the back and sides so the condenser can get proper airflow.

- Be Honest About Your Output: That 44-inch table might seem fine when you're dreaming of making 50 pizzas a night. But what happens when you’re slammed and need to push out 200? You'll want a 72-inch or 93-inch model to keep your team from bumping elbows.

- Think About Your Menu: Offering a boatload of toppings? Look into a "mega-top" model. These tables have an extra row for food pans, giving you about 30% more topping capacity without taking up much more floor space.

Should I Choose a Marble or Stainless Steel Work Surface?

This is a classic debate for pizza prep tables, and the right answer depends on your dough-handling philosophy and your budget.

- Marble Tops are the gold standard for artisan pizzerias. Marble is naturally cool to the touch, which is a huge advantage for keeping dough from getting sticky and tough to work with. It's the best surface for hand-stretching, but it comes with a higher price tag and needs TLC to avoid stains and chips.

- Stainless Steel Tops are the workhorses of the industry. They're incredibly tough, a breeze to sanitize, and much easier on the wallet. The only real downside is that dough can sometimes stick, but that's nothing a light dusting of flour can't fix.

Your choice of work surface is a small detail that says a lot about your pizzeria's identity. Marble sends a message of traditional, hands-on dough artistry. Stainless steel screams durability, speed, and no-nonsense sanitation.

Of course, having the right equipment is only part of the puzzle. The success of your pizzeria also depends heavily on its online reputation and what customers are saying about you. You can learn more about effective Restaurant Online Reputation Management and how to build a brand that people trust. A great physical setup paired with a strong digital presence is a recipe for success that's hard to beat.

At Pizza Prep Table, we live and breathe this stuff. We specialize in providing the high-quality, reliable equipment your pizzeria needs to not just survive, but thrive. From compact prep tables to huge workstations, our handpicked selection from top brands like Atosa, True, and Dukers means you get the performance and durability your kitchen deserves. Explore our full range of pizzeria equipment and find the perfect foundation for your business at https://pizzapreptable.com.