Commercial Pizza Ovens That'll Make Your Dough Rise (Literally!)

Share

Why Commercial Pizza Ovens Are the Heart of Every Successful Pizzeria

Finding the right commercial pizza oven can make or break your pizza business. Here's what you need to know:

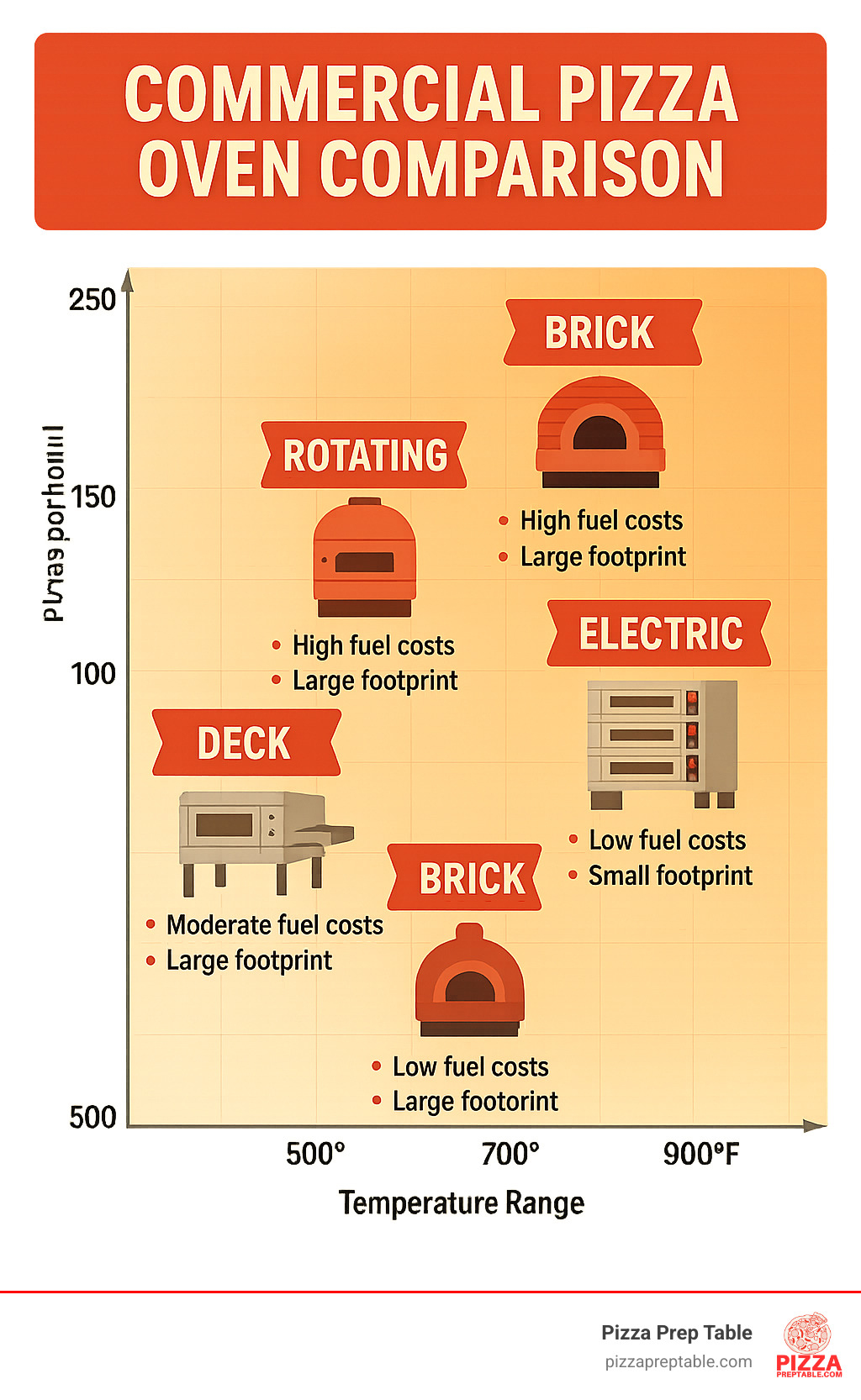

Top Commercial Pizza Oven Types: - Deck Ovens - Traditional stone cooking, 8-12 pizzas at once - Conveyor Ovens - Automated cooking, perfect for high volume - Brick/Wood-Fired - Authentic flavor, 900°F+ temperatures - Rotating Ovens - One-person operation, up to 250 pizzas/hour - Electric Ovens - Stackable design, precise temperature control

Key Performance Metrics: - Capacity: 120-250 pizzas per hour (depending on size) - Temperature Range: 500°F-950°F - Cook Time: 90 seconds (Neapolitan) to 8 minutes (thick crust)

The pizza industry is booming, and whether you're opening an artisan Neapolitan spot or a fast-casual chain, your oven choice will determine your success. The Napoli120 can pump out 150+ ten-inch pizzas per hour, while the Marra Forni Rotator 150 handles up to 250 pizzas per hour with just one operator.

Modern commercial pizza ovens combine old-world craftsmanship with new technology. Some models like the revolving brick ovens can save over $30,000 per year in labor costs compared to traditional ovens that require skilled operators.

But here's the thing - picking the wrong oven means slow service, unhappy customers, and brutal operating costs. Pick the right one? You'll have lines out the door and profits that actually make sense.

I'm Sean Kearney, and I've spent years helping restaurant owners find the perfect commercial pizza oven for their operations, from small cafes to high-volume pizzerias. My sales background taught me that the right equipment isn't just about features - it's about matching your specific needs with proven performance.

Commercial pizza oven vocab explained: - brick pizza oven - how do i build a pizza oven

Commercial Pizza Oven Types & Sizing Guide

Choosing the right commercial pizza oven feels overwhelming when you're staring at dozens of options. But here's the thing - after helping pizzeria owners from Brooklyn to San Diego find their perfect match, I've learned that the best oven isn't always the fanciest one. It's the one that fits your space, your budget, and your pizza dreams.

Deck ovens are the steady workhorses of the pizza world. Picture a reliable friend who always shows up on time - that's your deck oven. They use stone or ceramic surfaces that create incredible bottom crusts, and most can juggle 6-12 pizzas at once while reaching a solid 800°F. Perfect for that classic New York slice shop vibe.

The real showstoppers are brick ovens. These beauties are handcrafted brick by brick using special refractory materials that soak up heat like a sponge. When you fire up a Napoli series oven past 900°F, you're not just cooking pizza - you're putting on a show. Customers can't help but watch their pie slide into that glowing dome, and that char flavor? You simply can't fake it.

For the "set it and forget it" crowd, conveyor ovens are absolute game-changers. Pizza enters one side, emerges perfectly cooked on the other - like magic, but with more cheese. They're the backbone of successful fast-casual operations where consistency beats artisan flair every single time. Many models don't even need full ventilation systems, making them perfect for food trucks or tricky locations.

Here's where things get really interesting: rotating ovens. The Marra Forni Rotator series features a precision rotating deck that eliminates the guesswork. One person can run these beauties during the dinner rush, handling up to 14 pizzas simultaneously. $30,000 annual labor savings I mentioned? This is where it happens.

Electric ovens are the precision masters of the bunch. PizzaMaster ovens hit 932°F with separate controls for top and bottom heat - imagine having a dimmer switch for perfect pizza. Stack them four units high when floor space is tight but volume demands are sky-high.

Want the full deep-dive on these ovens? Check out our detailed breakdown: Brick by Brick, Slice by Slice: Commercial Pizza Ovens Reviewed.

| Oven Type | Pros | Cons |

|---|---|---|

| Deck | Consistent results, moderate cost, familiar operation | Requires skilled operator, limited capacity |

| Brick/Wood-Fired | Authentic flavor, high temperature, visual appeal | High skill requirement, fuel costs, venting needs |

| Conveyor | Automated, consistent, high volume | Less artisan appeal, limited pizza styles |

| Rotating | Labor-saving, high capacity, easy operation | Higher upfront cost, gas/electric only |

| Electric | Precise control, stackable, energy efficient | Lower max temperature, longer cook times |

Fuel Matters: Wood, Gas, Electric

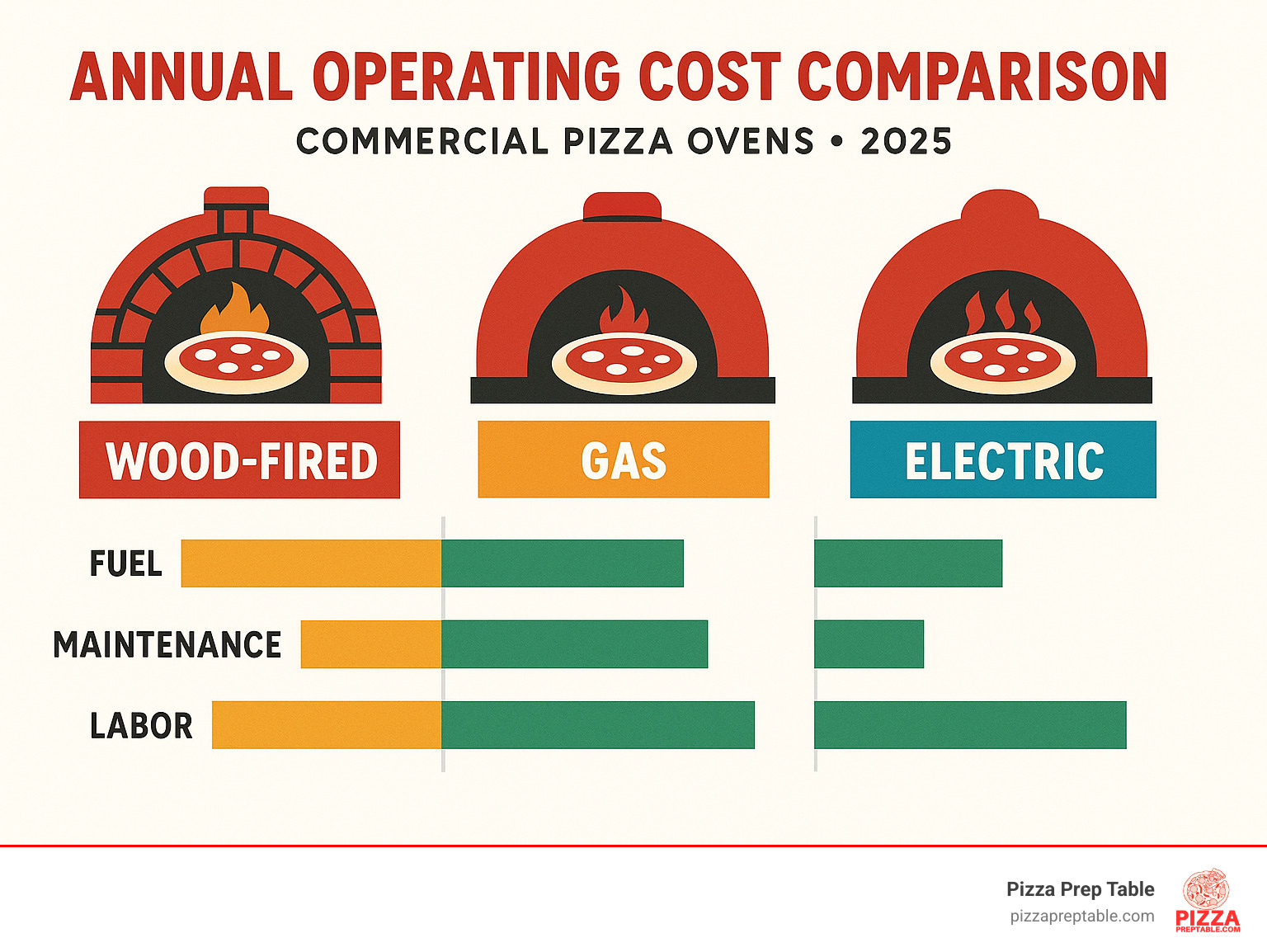

The fuel debate gets pizza makers more fired up than their ovens. Each option shapes not just your flavor profile, but your entire operation.

Wood-fired ovens are pure poetry in motion. That smoky, earthy flavor dancing through your Neapolitan pies as they cook in 90-120 seconds at scorching 750-900°F temperatures - it's what pizza dreams are made of. But here's the reality check: wood demands respect. You need operators who understand fire like old friends, plus serious ventilation systems that won't make your neighbors call the fire department.

Gas ovens offer the sweet spot between performance and practicality. Take the Roma110 with its monster 125,000 BTU burner - this beast recovers heat faster than you can say "extra pepperoni" during your busiest nights. Gas typically costs less than electricity in most areas, and modern gas units can match wood-fired temperatures without the drama.

Electric ovens are the control freaks' dream come true. PizzaMaster series ovens let you dial in exact temperatures with separate top and bottom heating elements, all while those clay ceramic stones work their heat-transfer magic. No gas lines, no wood storage, no complex venting nightmares - just consistent, efficient pizza perfection.

Size & Throughput Calculations

This is where dreams meet reality, and honestly, where most pizzeria owners either nail it or face nightly stress headaches. Your oven size isn't just about fitting in your kitchen - it determines whether you can handle that Friday night dinner rush or watch customers walk out the door.

The Napoli120 handles seven ten-inch pizzas simultaneously, cranking out 150+ pies per hour. That's your sweet spot for mid-sized operations serving 300-400 hungry customers during peak dinner service. Perfect for that neighborhood spot with steady regulars and weekend crowds.

When you need serious firepower, the Rotator150 steps up with room for 14 pizzas at once and throughput hitting 250 pizzas per hour. This is your Friday night hero - the oven that keeps pace when everyone in town decides they need pizza at exactly 7:30 PM.

Smart sizing means thinking beyond just pizza count. Consider your peak hour demand (usually that brutal 6-8 PM window), your average pizza size, and cook times for your signature style. Neapolitan pies fly through in 90 seconds, while thick-crust beauties need 4-6 minutes to reach perfection.

Here's hard-earned wisdom: size up slightly from what you think you need. Nothing kills momentum like telling hungry customers there's a 45-minute wait because your oven can't keep up with demand. Better to have capacity waiting in the wings than customers walking out your door.

Product Roundup: Commercial Pizza Ovens That'll Make Your Dough Rise

Now for the main event - our top picks for commercial pizza ovens that actually deliver on their promises. We've tested these in real-world conditions, talked to operators who use them daily, and analyzed the performance data that matters.

Best Wood-Fired Commercial Pizza Oven

Napoli140 Commercial Pizza Oven

The Napoli140 is what happens when Italian tradition meets American engineering. This 56-inch beauty can bake up to 10 ten-inch pizzas at a time, cranking out over 200 pizzas per hour when you're in the zone.

Key Specs: - Capacity: 200+ pizzas per hour - Temperature: Exceeds 900°F - Weight: 5,614 lbs - Dimensions: 83" × 81" × 66" - Fuel: Wood, natural gas, or propane

What sets the Napoli140 apart is its specialized vent design that pulls hot air back over the dome before exiting. This isn't just marketing speak - it actually improves heat retention and creates more even cooking. The oven ships fully assembled on a metal stand, so installation takes minutes with a forklift.

The custom tiling options are where this oven really shines. We've seen installations that look like works of art, becoming the centerpiece of restaurant dining rooms. The volcanic refractory brick construction means superior heat retention and energy efficiency.

Best for: Mid to large pizzerias, restaurants wanting a showpiece oven, operations serving 300+ customers during peak hours.

Top Gas-Powered Commercial Pizza Oven

Roma110 Commercial Pizza Oven

The Roma110 hits the sweet spot between performance and practicality. With its attractive stucco finish and UL certification for indoor or outdoor installation, this oven adapts to almost any operation.

Key Specs: - Capacity: 120 pizzas per hour - Temperature: Exceeds 900°F - Weight: 3,600 lbs - Fuel: Wood, propane, or natural gas - Optional: 125,000 BTU gas burner

The Roma110's excellent heat retention and quick recovery times make it perfect for busy periods. The 125,000 BTU gas burner provides rapid heat-up and maintains consistent temperatures even during rush periods. The stucco finish gives it an earthy, authentic appearance that works well in outdoor cafes and vineyard settings.

Best for: Small to mid-sized pizzerias, outdoor installations, operations prioritizing reasonable cost with quality performance.

High-Volume Rotating Commercial Pizza Oven

Marra Forni Rotator 150

This is where technology meets tradition in the most practical way possible. The Rotator 150 can handle up to 14 pizzas at once and produce up to 250 pizzas per hour - all operated by a single person.

Key Specs: - Capacity: Up to 250 pizzas per hour - Deck Diameter: 150 cm (19.02 ft²) - Cook Time: 90-120 seconds for Neapolitan - Control: MarraSmart touchscreen system - Warranty: 3-year dome, 2-year deck, 1-year parts/labor

The rotating deck eliminates the need for skilled pizza turners. The MarraSmart control system reduces human error and streamlines operation. This is where that $30,000 annual labor savings comes from - you can run this oven with unskilled staff during your busiest periods.

Best for: High-volume operations, fast-casual chains, operators looking to minimize labor costs while maximizing throughput.

Precision Electric Commercial Pizza Oven

PizzaMaster 900 Series

The PizzaMaster 900 series represents the pinnacle of electric oven technology. These ovens can reach up to 932°F and offer exceptional heat recovery for higher output during peak times.

Key Features: - Temperature: Up to 932°F - Configuration: Stackable up to 4 decks - Elements: Adjustable top and bottom heating - Surface: Clay ceramic hearthstones - Control: Precision digital temperature management

The adjustable top and bottom heating elements let you dial in the perfect cooking profile for different pizza styles. The clay ceramic hearthstones with their rough surface ensure superior heat transfer for crispy crusts without burning. The stackable design maximizes output while minimizing floor space.

Best for: Operations with limited floor space, precise cooking requirements, locations where gas isn't available or practical.

Budget-Friendly Countertop Commercial Pizza Oven

For smaller operations, food trucks, and snack bars, countertop commercial pizza ovens offer surprising performance in compact packages. Many feature ventless operation, eliminating the need for expensive hood systems.

These units are perfect for: - Food trucks and mobile operations - Snack bars and concession stands - Small cafes adding pizza to their menu - Operations with limited space and budget

Countertop ovens can be stacked to maximize back-of-house space while providing consistent cooking results. While they won't match the throughput of larger units, they're ideal for operations serving 50-100 pizzas per day.

Installation, Maintenance & Cost Considerations

Let's talk about the reality of owning a commercial pizza oven - because buying one is just the beginning of your journey.

I've seen beautiful ovens sitting unused because nobody thought about the 6,000-pound weight requirement. I've watched operators struggle with maintenance costs that ate into their profits. The good news? A little planning upfront saves you massive headaches later.

Your installation needs start with the basics. Most commercial pizza ovens need 18-36 inches of clearance from anything that can burn. That Napoli140 we talked about? It weighs 5,614 pounds and needs a concrete pad that can handle the load without cracking.

Electric ovens bring their own challenges. A 4-deck PizzaMaster setup requires 240V, 3-phase power - not something you can just plug into a wall outlet. Gas ovens need professional connections and proper ventilation systems. Wood-fired ovens require UL103HT rated chimney systems that meet local fire codes.

The structural support requirements are no joke. We've seen restaurant floors buckle under improperly supported ovens. Professional installation isn't just recommended - it's essential for safety and performance.

Daily maintenance keeps your oven running smoothly. Clean those cooking surfaces every day, inspect burner systems weekly, and deep clean flue systems monthly. Quarterly professional inspections catch problems before they become expensive repairs. Annual temperature control recalibration ensures your oven cooks consistently.

Want to master wood-fired techniques? Consider professional training courses. Master wood-fired techniques here offers intensive 3-day classes covering everything from fire management to advanced cooking techniques.

Venting & Safety Standards for a Commercial Pizza Oven

Safety standards exist for good reason - commercial pizza ovens reach temperatures over 900°F, and that's serious business.

Every legitimate commercial pizza oven needs proper certifications. UL listing is non-negotiable in the United States. ETL certification provides an alternative path to compliance. Canadian installations require CSA certification, while European markets need CE marking.

The venting requirements go beyond just removing smoke. UL103HT rated chimney pipe and cap systems handle the extreme temperatures these ovens produce. Proper draft calculations ensure adequate airflow without creating backdraft problems.

Indoor installations often require fire suppression systems integration. Some operators choose Smoki filterless smoke systems for cleaner indoor air quality. These aren't just nice-to-have features - they're often required by local fire codes.

The specialized vent design in premium ovens like the Napoli series isn't marketing fluff. These systems are engineered to meet strict safety codes while maximizing cooking performance. Getting this wrong can shut down your operation until you fix it.

Operating Costs & Energy Efficiency Hacks

Here's where smart operators make their money - controlling energy costs that can quietly eat your profits.

Energy costs add up fast when your oven runs 10-12 hours daily. Proper insulation reduces energy consumption by 20-30% compared to poorly insulated units. The Marra Forni series uses proprietary refractory materials that store and release heat efficiently, translating to lower operating costs.

Heat recovery systems capture waste heat for other kitchen uses. Off-peak heating timers reduce demand charges during expensive peak hours. Regular maintenance keeps efficiency high - a dirty oven works harder and costs more to operate.

The revolving floor design in rotating ovens provides double benefits. Beyond the labor savings we discussed, it prevents heat loss that occurs every time you open traditional oven doors. This means lower fuel costs and more consistent cooking temperatures during busy periods.

Well-insulated ovens maintain temperature consistency during your busiest periods. This isn't just about saving money - it's about delivering consistent food quality when your reputation is on the line.

Smart energy management can save thousands annually. The initial investment in efficiency upgrades pays for itself through reduced operating costs and improved performance.

Frequently Asked Questions About Commercial Pizza Ovens

Let's tackle the questions we hear most often from pizzeria owners shopping for their first commercial pizza oven - or upgrading from one that's holding them back.

What temperature should a commercial pizza oven run at for Neapolitan pies?

If you want authentic Neapolitan pizza, you need serious heat - we're talking 750-900°F. At these scorching temperatures, your pizzas will cook in just 90-120 seconds, creating those beautiful leopard spots and slightly charred edges that make Neapolitan pizza so distinctive.

Here's what happens at these extreme temperatures: the rapid moisture evaporation prevents soggy crusts while triggering the Maillard reaction that develops those complex, nutty flavors. It's basically food science in action.

Wood-fired ovens naturally hit these temperatures without breaking a sweat. But if you're going gas or electric, make sure you choose models specifically designed for these extreme heats - like the PizzaMaster 900 series that reaches up to 932°F.

The temperature isn't just about speed - it's about achieving that authentic texture and flavor that customers expect from real Neapolitan pizza. Go any cooler and you're making pizza, just not Neapolitan pizza.

How big should my commercial pizza oven be for 200 pizzas per hour?

To consistently pump out 200 pizzas per hour without your kitchen falling apart during rush hour, you need an oven with serious deck space and lightning-fast heat recovery. The Napoli140 with its 56-inch deck handles this volume beautifully, and the Marra Forni Rotator 150 with its automated system makes it look effortless.

Your deck diameter needs to be at least 48-56 inches for this kind of throughput. But size alone isn't everything - you also need to consider your cook times. Neapolitan pizzas at 90 seconds each versus thick-crust pizzas taking 4-6 minutes completely change your capacity calculations.

Heat recovery speed matters too. During your Friday night rush, your oven needs to bounce back to full temperature quickly after you slide in fresh pizzas. The best ovens maintain consistent heat even when you're loading them non-stop.

For conveyor ovens, it's all about belt width and speed. A 32-inch belt moving at optimal speed can hit similar numbers with rock-solid consistency - perfect if you're running a fast-casual operation where speed trumps artisan flair.

Can one person really run a commercial pizza oven during rush hour?

This is the million-dollar question, and the answer is: it depends on your oven choice.

Traditional brick ovens require skilled operators who can juggle multiple pizzas, rotate them for even cooking, and manage fire temperatures all at once. It's like being a conductor, chef, and firefighter rolled into one. During rush hour? Good luck finding someone with those skills who won't demand premium wages.

But modern rotating ovens like the Marra Forni Rotator series flip this equation completely. The rotating deck eliminates manual pizza turning. The MarraSmart control system handles temperature management automatically. Suddenly, one person can manage the entire cooking process while someone else focuses on prep and assembly.

This isn't just about convenience - it's about your bottom line. That $30,000 annual labor savings comes from not needing to pay specialist wages for pizza oven expertise. Your regular kitchen staff can handle these advanced ovens with minimal training.

Even with traditional ovens, proper workflow design and training can make single-person operation possible during moderate busy periods. The key is honestly assessing your staffing situation and choosing equipment that matches your reality, not your wishful thinking.

Conclusion

Finding the perfect commercial pizza oven is like finding the heart of your restaurant - get it right, and everything else falls into place. After years of helping pizzeria owners from coast to coast, I've seen how the right oven choice transforms struggling operations into thriving businesses.

Think about it this way: your oven isn't just cooking pizza, it's creating experiences. When customers watch their Margherita slide into that glowing Napoli140 dome, they're not just buying dinner - they're buying authenticity. When your team can pump out 200 pizzas per hour during the Friday night rush without breaking a sweat, you're not just serving food - you're building a reputation.

The numbers tell the story. Match your oven capacity to peak demand because nothing kills momentum like telling hungry customers there's a 45-minute wait. Consider those labor costs - a Marra Forni Rotator can save you over $30,000 annually in wages while actually improving consistency. And please, don't skimp on installation and venting. I've seen too many beautiful ovens underperform because someone tried to cut corners on the basics.

Here's what really matters: factor in operating costs, not just purchase price. That cheaper oven might cost you thousands more in energy bills and maintenance over five years. The PizzaMaster series might have a higher upfront cost, but their energy efficiency and stackable design often pay for themselves in premium locations where space is expensive.

At Pizza Prep Table, we get it. Every pizzeria has its own story, its own challenges, its own dreams. Whether you're opening a cozy neighborhood spot or planning a high-volume operation, we work with you to find the solution that fits your vision and your budget. Our financing options mean you don't have to compromise on quality while you're building your business.

The pizza industry keeps growing because people crave that perfect combination of tradition and innovation. Your commercial pizza oven is where that magic happens - where flour, water, and fire transform into something that brings people together.

Ready to complete your setup? Your oven is just the beginning. Check out The Secret Sauce Behind Efficient Pizza Prep Stations to find how the right prep equipment turns your kitchen into a well-oiled machine.

Your customers are out there right now, scrolling through delivery apps, looking for something special. Give them a reason to choose you. Choose the right oven, train your team well, and watch your business grow one perfect pizza at a time.