Essential Commercial Kitchen Equipment Checklist for Pizzerias

Share

Opening a pizzeria is a dream built on the perfect crust, the richest sauce, and bubbling, golden cheese. But turning that dream into a profitable reality depends less on romance and more on the cold, hard steel of your kitchen. The right equipment is the engine of your operation, the silent partner that dictates your speed, consistency, and ultimately, your success. This is more than a simple shopping list; it's a comprehensive commercial kitchen equipment checklist designed to be the strategic blueprint for building a high-functioning pizzeria kitchen from the ground up.

We will break down your future kitchen station by station, moving from the foundational dough mixer to the heart of the line, the pizza prep table. For each critical piece of equipment, we'll go beyond basic descriptions to offer practical insights into specifications, layout considerations, and brand reliability. You'll learn not just what to buy, but why a specific feature can prevent service bottlenecks or how a particular configuration can optimize your workflow.

This guide is for entrepreneurs who understand that a great pizza starts long before it hits the oven. It's about creating a symphony of efficiency where every component, from the refrigeration system preserving your fresh ingredients to the mighty oven that delivers the final product, works in perfect harmony. For those opting for a traditional wood-fired approach, understanding the best wood for pizza ovens is just as crucial for achieving that authentic flavor and cooking efficiency as selecting the right deck oven. Let’s build the kitchen that will power your pizzeria's success.

1. Commercial Convection Oven

A commercial convection oven is the workhorse of any high-volume kitchen, especially in pizzerias and Italian restaurants where consistent results are non-negotiable. Unlike conventional ovens that rely on radiant heat, a convection oven uses powerful internal fans to circulate hot air. This technology eliminates hot spots, ensuring everything from a sheet pan of roasted vegetables for toppings to garlic knots cooks evenly and efficiently.

This forced air circulation significantly speeds up cooking times, a critical advantage during a busy dinner rush. For a pizzeria, this means faster pre-baking of crusts or quick-roasting toppings like peppers and onions. Beyond speed, the even heat distribution is perfect for achieving that uniformly golden-brown, crispy finish on breadsticks, calzones, and other baked goods that complement your pizza menu. It’s an indispensable part of any complete commercial kitchen equipment checklist.

Why It's Essential for Pizzerias

While a dedicated pizza oven is paramount, a convection oven handles the high-volume baking and roasting tasks that support your main attraction. Its versatility allows you to expand your menu with perfectly baked appetizers, chicken wings, and desserts, all produced with reliable consistency.

Key Benefit: The primary advantage of a convection oven is its ability to reduce cooking times by up to 30% while cooking at lower temperatures, saving both time and energy costs. For example, a dish that takes 30 minutes in a conventional oven might be perfectly cooked in just 20-22 minutes in a convection model.

Key Data & Performance Metrics

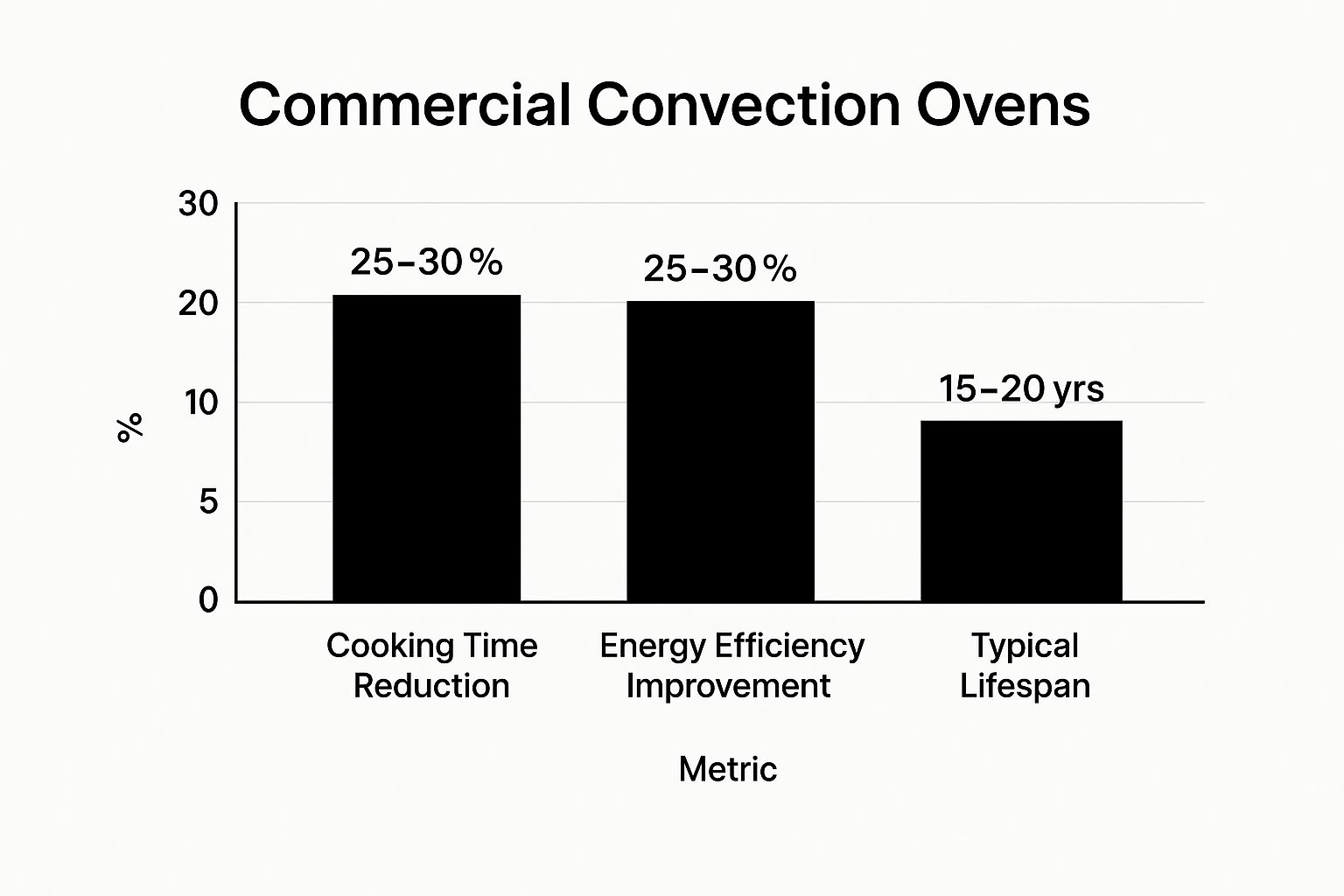

The following chart illustrates the core performance benefits that make commercial convection ovens a smart long-term investment.

The data clearly shows that investing in a quality convection oven leads to significant operational savings in both time and energy, alongside a durable lifespan that ensures a strong return on investment.

Implementation Tips

- Temperature Adjustment: As a rule, reduce the recipe temperature by 25°F (around 15°C) when converting from a conventional oven.

- Pan Rotation: Even with fans, rotating pans halfway through the cooking cycle guarantees the most uniform results.

- Airflow is Key: Use low-sided baking sheets and avoid overcrowding the oven. This allows the hot air to circulate freely around the food.

- Maintenance Schedule: Clean the fans and interior weekly to prevent grease buildup, which can impair performance and become a fire hazard.

For operations that need even faster cooking for specific menu items, combination units can be a powerful solution. To explore these options further, learn more about commercial convection microwave ovens for restaurants.

2. Commercial Refrigerator/Freezer System

Reliable refrigeration isn't just a convenience; it's the foundation of food safety and inventory management in any commercial kitchen. Commercial refrigerator and freezer systems are engineered for the relentless demands of a professional setting, featuring powerful compressors, durable construction, and precise temperature controls to keep ingredients safe and fresh. Unlike residential units, they are built to recover quickly from frequent door openings, a constant in a busy pizzeria.

These systems are available in various configurations, from large walk-in coolers for bulk dough and produce to reach-in units for daily supplies. For pizzerias, specialized pizza prep tables combine refrigerated ingredient wells on top with under-counter cold storage below. This design keeps cheese, sauces, and toppings within arm's reach, streamlining the assembly line and maintaining critical temperature safety during service. Having a dependable refrigeration system is a core component of any well-planned commercial kitchen equipment checklist.

Why It's Essential for Pizzerias

For a pizzeria, refrigeration is mission-critical. Bulk cheese, tubs of sauce, fresh dough, and prepped vegetables all require strict temperature control to prevent spoilage and ensure food safety. A high-quality pizza prep table is a specialized form of this system that directly boosts efficiency, allowing staff to build pizzas quickly without leaving their station, which is vital for maintaining ticket times during peak hours.

Key Benefit: The primary advantage is maintaining consistent, food-safe temperatures despite constant use. For example, a quality pizza prep table's refrigerated rail keeps toppings below 41°F (5°C) even during a dinner rush, protecting thousands of dollars in inventory and preventing the risk of foodborne illness.

Key Data & Performance Metrics

Investing in a robust refrigeration system from a reputable brand like True Manufacturing, Traulsen, or Beverage-Air is crucial for operational stability. These units are designed for longevity and efficiency in high-demand environments.

| Metric | Typical Performance | Impact on Pizzeria Operations |

|---|---|---|

| Temperature Holding | ±2°F of setpoint | Prevents spoilage; ensures health code compliance. |

| Recovery Time | 5-10 minutes | Maintains food safety during busy service periods. |

| Energy Efficiency | ENERGY STAR certified | Lowers long-term utility costs significantly. |

| Typical Lifespan | 10-15+ years | Provides a strong return on a major capital investment. |

This data underscores the importance of choosing commercial-grade equipment. The initial cost is offset by reduced food waste, lower energy bills, and dependable performance that prevents costly downtime.

Implementation Tips

- FIFO System: Strictly organize all ingredients using the "First-In, First-Out" method. Place new inventory behind existing stock to ensure older items are used first, minimizing waste.

- Optimal Capacity: Keep refrigerators and freezers around 80% full. This allows for proper air circulation while being full enough to help maintain cold temperatures efficiently.

- Door Alarms: Install alarms on walk-in and reach-in doors to alert staff if a door is left ajar, preventing catastrophic temperature loss and food spoilage.

- Maintenance Schedule: Have a professional service the compressors and clean the coils every six months. Clogged coils force the system to work harder, increasing energy use and leading to premature failure.

For kitchens that need both freezing and refrigeration in one place, dual-temperature units offer a space-saving solution. To learn more about selecting the right model, explore this guide to choosing a commercial refrigerator for your restaurant.

3. Commercial Gas Range with Griddle

A commercial gas range with an integrated griddle is the powerhouse of the cook line, serving as the primary station for a wide variety of cooking methods. This single piece of equipment combines multiple high-BTU open burners for sautéing, boiling, and simmering with a flat-top griddle for searing and frying. This versatility is crucial for maximizing space and efficiency in any fast-paced kitchen, from a bustling pizzeria to a high-volume diner.

For a pizza-focused restaurant, the open burners are essential for preparing signature pasta sauces, soups, and sautéed pizza toppings like mushrooms and onions. The griddle side provides the perfect surface for grilling chicken or steak for specialty pizzas, toasting sandwich bread for subs, or even offering a popular breakfast menu. This multi-functionality makes it a core component of any comprehensive commercial kitchen equipment checklist.

Why It's Essential for Pizzerias

While the pizza oven handles the main event, the gas range is where all the supporting flavors are born. It allows you to create a diverse and profitable menu beyond pizza. From crafting complex marinara sauces on the burners to perfectly searing philly cheesesteak ingredients on the griddle for a specialty pie, its value is in its sheer flexibility and raw power.

Key Benefit: The main advantage is consolidating two critical cooking functions into one footprint. This saves valuable floor space and allows a single chef to manage multiple cooking processes simultaneously, drastically improving workflow efficiency during peak hours.

Key Data & Performance Metrics

The chart below highlights the key operational benefits of investing in a quality commercial gas range and griddle combination unit.

This data underscores how the equipment’s design directly translates to an expanded menu potential and a more efficient kitchen layout, backed by a durable build designed for long-term commercial use.

Implementation Tips

- Season the Griddle: Before first use and regularly thereafter, season the griddle surface with oil and heat to create a non-stick patina. This is vital for preparing toppings like steak or chicken.

- Match Cookware to Burner: Use pots and pans that are appropriately sized for the burners to ensure efficient heat transfer and prevent wasted energy.

- Clean While Warm: Scrape the griddle surface clean while it is still warm (but not hot) for the easiest removal of food debris and grease.

- Prioritize Ventilation: A powerful commercial hood system is non-negotiable. Gas ranges with griddles produce significant heat, smoke, and fumes that must be managed for safety and comfort.

4. Commercial Dishwasher System

A commercial dishwasher system is the backbone of sanitation and efficiency in any food service operation, especially for pizzerias where cheese and sauce can create challenging cleanup tasks. These high-temperature machines are engineered to wash, rinse, and sanitize large volumes of dishes, glassware, utensils, and even pizza pans in minutes. By using powerful water jets and maintaining specific high temperatures, they ensure all wares meet stringent health department standards for cleanliness, a critical component of any commercial kitchen equipment checklist.

The speed of a commercial dishwasher is its most significant operational advantage. In a busy pizzeria, the ability to turn tables quickly depends on having clean plates, glasses, and silverware ready for the next customer. A reliable system eliminates the bottleneck of manual washing, allowing staff to focus on food preparation and service, thereby improving workflow and maximizing revenue during peak hours.

Why It's Essential for Pizzerias

For a pizzeria, a commercial dishwasher is non-negotiable. It tackles tough, baked-on cheese and tomato sauce on pans, plates, and utensils with an efficiency that hand-washing cannot match. Furthermore, it guarantees that every item is properly sanitized, preventing cross-contamination and ensuring a safe dining experience for your customers.

Key Benefit: The core advantage is achieving guaranteed sanitation while dramatically reducing labor costs. A high-temperature dishwasher uses a final rinse of 180°F (82°C) or higher to kill bacteria, a standard that is nearly impossible and unsafe to achieve manually. This process ensures health code compliance and reduces the staff time dedicated to washing dishes.

Key Data & Performance Metrics

Investing in the right dishwasher system delivers measurable improvements in operational speed and hygiene. The chart below highlights the key performance metrics that make these systems indispensable.

The data confirms that a commercial dishwasher not only accelerates cleanup but also provides significant savings on labor and utilities, making it a sound financial investment for any pizzeria.

Implementation Tips

- Pre-Scrape and Rinse: Always pre-scrape heavy food debris, especially cheese and dough, into a compost or trash bin before loading. A quick pre-rinse will prevent the wash filters from clogging and improve cleaning performance.

- Proper Rack Loading: Do not overcrowd racks. Ensure plates, bowls, and pans are angled to allow water jets to reach all surfaces. Place utensils in designated baskets with handles down for best results.

- Monitor Temperatures: Regularly check the water temperature gauges to ensure the wash and final rinse cycles are meeting required sanitation levels.

- Daily Maintenance: At the end of each day, drain the machine, remove and clean the filter screens, and wipe down the interior to prevent grime and lime buildup.

Proper sanitation is a cornerstone of a successful restaurant, extending beyond just dishwashing. To ensure your entire operation is up to code, you can learn more about food safety guidelines for restaurants.

5. Commercial Hood Ventilation System

A commercial hood ventilation system is the lungs of a professional kitchen, an essential safety and compliance fixture that is absolutely non-negotiable. It is an exhaust system installed directly above cooking equipment, like pizza ovens and ranges, designed to capture and remove airborne grease, smoke, heat, and odors. This system keeps the kitchen air clean and safe while introducing fresh "make-up" air to maintain proper circulation and prevent negative pressure.

This process is critical for fire prevention, as it removes flammable grease particles from the air before they can accumulate on surfaces. For a pizzeria, which often operates high-temperature deck or conveyor ovens, a robust ventilation system is a primary line of defense. It also ensures a more comfortable and healthy working environment for staff, which is vital for productivity and morale. A properly installed hood is a cornerstone of any functional commercial kitchen equipment checklist.

Why It's Essential for Pizzerias

The intense heat and potential for grease-laden vapor from cheese and meat toppings make a Type I hood system (which handles grease) a requirement over most pizza ovens and cooking lines. It ensures your establishment meets local health and fire codes, preventing costly fines or shutdowns. Beyond compliance, it protects the significant investment you've made in your pizza ovens and other cooking equipment by preventing heat and grease damage to the surrounding structure.

Key Benefit: The primary advantage of a hood system is its role in fire safety and air quality. A properly maintained system can reduce the risk of a devastating grease fire by over 70%, while simultaneously improving indoor air quality to meet health standards and protect employees from respiratory issues.

Key Data & Performance Metrics

The performance of a ventilation system is measured in Cubic Feet per Minute (CFM), which indicates the volume of air it can move. The required CFM depends on the type of cooking equipment underneath it. For example, a high-temperature conveyor pizza oven may require a higher CFM rating than a standard range. Partnering with a professional is key to ensuring your system is sized correctly. Leading manufacturers include CaptiveAire Systems, Greenheck, and Accurex.

Investing in a quality system pays off through safety, compliance, and creating a better work environment. Its lifespan and effectiveness are directly tied to a strict maintenance schedule.

Implementation Tips

- Filter Cleaning: Grease filters are your first line of defense. They should be cleaned weekly, or even daily in very high-volume pizzerias, to maintain airflow and reduce fire risk.

- Professional Cleaning: Schedule a certified professional to clean the entire system, from the hood to the rooftop fan, every 3 to 6 months. This is often a requirement for insurance and fire code compliance.

- Balance Airflow: Ensure your make-up air unit is functioning correctly. An imbalanced system can create negative pressure, causing doors to be hard to open and exhaust fans to work inefficiently.

- Test Fire Suppression: Your hood's built-in fire suppression system (like an Ansul system) must be tested and certified regularly, typically semi-annually, by a qualified technician.

6. Commercial Food Prep Table with Refrigeration

A commercial food prep table with refrigeration, often called a pizza prep table, is the command center for assembly-line efficiency in any pizzeria. This dual-function unit combines a durable stainless steel work surface with under-counter refrigerated storage, allowing chefs to access chilled ingredients instantly without leaving their station. It is a cornerstone piece of equipment that directly impacts workflow, speed, and food safety.

The design typically features a refrigerated rail along the top to hold food pans filled with toppings like cheese, pepperoni, and vegetables, all kept at precise, food-safe temperatures. The refrigerated base provides bulk storage for dough, sauces, and extra ingredients. This setup minimizes movement, reduces prep time, and is a non-negotiable part of a complete commercial kitchen equipment checklist for any restaurant focused on made-to-order items.

Why It's Essential for Pizzerias

For a pizzeria, the prep table is where the magic happens. It’s the assembly station where a simple dough disc is transformed into a final product. Having all toppings perfectly organized and chilled within arm's reach is critical for maintaining speed and consistency during the chaotic dinner rush. This station prevents cross-contamination and ensures every ingredient remains fresh from the first pizza of the day to the last.

Key Benefit: The primary advantage is the massive boost in operational efficiency. By consolidating the prep surface and refrigerated storage, a pizza prep table can cut pizza assembly time by 50% or more compared to a system using separate work tables and reach-in refrigerators. This allows a single cook to assemble pizzas much faster, increasing output and revenue.

Key Data & Performance Metrics

The following table highlights the essential metrics that make a dedicated pizza prep table a critical investment for improving kitchen workflow and ensuring food safety compliance.

| Feature | Metric/Standard | Impact on Pizzeria Operations |

|---|---|---|

| Temperature Range | 33°F to 41°F (0.5°C to 5°C) | Food Safety: Crucial for keeping toppings out of the "danger zone." |

| Workflow Efficiency | Up to 50%+ reduction in assembly time | Speed & Output: Increases the number of pizzas made per hour. |

| Ingredient Waste | Up to 15-20% reduction | Cost Savings: Proper temperature control reduces spoilage. |

| Typical Lifespan | 10-15 years | ROI: A durable unit provides a strong return on investment. |

This data demonstrates that a high-quality prep table, from manufacturers like True Manufacturing or Turbo Air, is not just about convenience; it's a strategic tool for enhancing speed, safety, and profitability.

Implementation Tips

- Organize for Speed: Place the most frequently used ingredients, like cheese and pepperoni, in the most accessible pans in the rail.

- Prevent Cross-Contamination: Keep the cutting board and stainless steel surfaces sanitized, especially when switching between different types of pizzas (e.g., meat and vegetarian).

- Daily Temperature Logs: Monitor and log the temperatures of the refrigerated rail and base daily to ensure compliance with health codes.

- Use Correct Pan Sizes: Utilize a mix of food pan sizes (1/3, 1/6, 1/9) to organize toppings efficiently and minimize wasted space in the rail.

- Night Covers: Use the insulated night covers that come with the unit to maintain temperature and save energy overnight.

7. Commercial Stand Mixer

A commercial stand mixer is the muscle behind any serious baking or prep station, especially in pizzerias and Italian restaurants that pride themselves on fresh, house-made dough. Unlike their residential counterparts, these heavy-duty machines are engineered with powerful motors and robust gear-driven transmissions to handle large, dense batches of dough day in and day out without faltering. They are a cornerstone of any comprehensive commercial kitchen equipment checklist.

These mixers come with various attachments, such as a dough hook, flat beater, and wire whip, making them incredibly versatile. For a pizzeria, the primary function is kneading consistent, perfectly developed pizza dough in volumes that are impossible to manage by hand. Beyond dough, they can be used for mixing large batches of sauce, shredding cheese with a grater attachment, or preparing fillings for calzones and stromboli, consolidating multiple prep tasks into one efficient station.

Why It's Essential for Pizzerias

The quality of your pizza starts with the dough, and consistency is everything. A commercial stand mixer eliminates the variability of hand-kneading, ensuring every single dough ball has the same texture, elasticity, and hydration level. This leads to a predictable and high-quality crust, whether it's your first pie of the day or your last one during a chaotic dinner service. Many high-volume operations, like Panera Bread, rely on industrial Hobart mixers for their daily bread production, showcasing the machine’s reliability.

Key Benefit: The main advantage of a commercial mixer is its ability to produce large, consistent batches of dough, saving immense labor costs and time. A 60-quart mixer can prepare enough dough for over 100 pizzas in a single batch, a task that would take hours and multiple staff members to accomplish manually.

Key Data & Performance Metrics

Commercial stand mixers are defined by their capacity and power, which directly impact a kitchen's output.

- Planetary Mixers: The most common type, where the agitator moves in an orbital pattern around a stationary bowl.

- Capacities: Range from smaller 20-quart models suitable for cafes to massive 80-quart or larger units for high-volume pizzerias and commercial bakeries.

- Motor Power: Measured in horsepower (HP), typically ranging from 1/2 HP for smaller units to 3 HP or more for larger models designed for stiff doughs.

- Attachments: Standard attachments include a dough hook (for kneading), a flat beater (for mixing batters and sauces), and a wire whip (for meringues and creams).

Investing in a mixer with the right capacity and power is crucial for matching your production needs without straining the equipment.

Implementation Tips

- Respect Capacity Limits: Never overfill the bowl beyond the manufacturer's recommendations for your specific dough's absorption ratio. Overloading can strip gears and burn out the motor.

- Use the Right Attachment: Always use the dough hook for kneading. Using a flat beater for heavy dough will damage both the attachment and the mixer.

- Start Slow: Begin mixing on the lowest speed to incorporate ingredients, then gradually increase to the desired speed to prevent flour from flying out and to protect the motor.

- Immediate Cleanup: Clean attachments and the bowl immediately after use. Dried-on dough is extremely difficult to remove and can harbor bacteria.

For pizzerias that demand ultimate dough consistency, pairing a quality mixer with a reliable pizza prep table is the key to an efficient production line. To see how these pieces work together, you can explore our guide on the best commercial pizza prep tables.

8. Commercial Deep Fryer

A commercial deep fryer is a cornerstone of kitchens specializing in appetizers and side dishes, offering high-capacity frying with precise temperature control. Unlike domestic fryers, commercial models are built for continuous, high-volume operation, featuring rapid temperature recovery to handle back-to-back orders without a drop in quality. This ensures that every batch of french fries, mozzarella sticks, or fried calamari comes out consistently crispy and perfectly cooked.

This equipment is designed with powerful heating elements that bring oil to the ideal temperature quickly and maintain it, even when frozen food is added. For a pizzeria, a reliable deep fryer opens up a lucrative menu of appetizers that perfectly complement your main offerings. Its ability to produce popular, high-margin items efficiently makes it a vital component of any complete commercial kitchen equipment checklist.

Why It's Essential for Pizzerias

While your pizza oven is the star, a commercial deep fryer allows you to build out a profitable and popular appetizer menu. Items like chicken wings, onion rings, and breaded ravioli are customer favorites that can significantly increase average ticket sizes. A high-quality fryer ensures these sides are executed to the same standard as your signature pizzas, enhancing the overall dining experience.

Key Benefit: The primary advantage is its rapid recovery time, which ensures consistent product quality during peak hours. A good fryer can return to its set temperature within seconds of a new basket being submerged, preventing greasy, undercooked food and guaranteeing a crispy finish every time.

Key Brands & Models

The following brands are industry leaders known for reliability, performance, and advanced features like built-in filtration systems.

- Frymaster: A Welbilt brand, often considered the gold standard for performance and oil efficiency.

- Pitco Frialator: Known for durable construction and a wide range of models suited for different kitchen sizes.

- Vulcan Equipment: Offers powerful and energy-efficient fryers that are built to last in demanding environments.

- Imperial Commercial Cooking Equipment: Provides reliable, no-frills fryers that offer excellent value and consistent results.

Investing in a model with an integrated oil filtration system can significantly extend the life of your cooking oil, leading to substantial cost savings over time.

Implementation Tips

- Daily Filtration: Filter your cooking oil at the end of every day. This removes food particles and sediment, preserving oil quality and improving food taste.

- Temperature Discipline: Constantly monitor your oil temperature. Frying at the wrong temperature can lead to greasy food and pose a safety risk.

- Correct Oil Choice: Use the right type of oil for your needs. High-smoke-point oils like canola, peanut, or a specialized frying blend are essential for high-heat cooking.

- Vat Cleaning: Implement a regular "boil out" schedule to deep clean the fry pots and prevent carbon and grease buildup, which can taint oil flavor and become a fire hazard.

Proper oil management is crucial for both food quality and operational costs. For more detailed guidance, you can get insights on commercial fryer oil storage tips to maximize its lifespan and safety.

Commercial Kitchen Equipment Comparison Matrix

| Equipment | Core Features/Characteristics ✨ | User Experience/Quality ★★★★✩ | Value Proposition 💰 | Target Audience 👥 | Unique Selling Points 🏆 | Price Points 💰 |

|---|---|---|---|---|---|---|

| Commercial Convection Oven | Fan-forced airflow, digital controls, steam injection | Faster, even cooking; energy-efficient | Speeds kitchen workflow, consistent large-scale baking | Pizzerias, bakeries, restaurants | Reduces cooking time by 25-30%; multi-rack use | $3,000 - $15,000+ |

| Commercial Refrigerator/Freezer | Stainless steel, digital temp monitoring, self-closing doors | Reliable temp control; large capacity | Ensures food safety & storage efficiency | Pizzerias, sandwich shops, restaurants | ENERGY STAR models; HACCP compliance support | $2,000 - $50,000+ |

| Commercial Gas Range with Griddle | High-BTU burners, flat griddle, cast iron grates | Instant heat, versatile cooking | High heat output, lowers operating costs | Pizzerias, food trucks, diners | Combines burners and griddle; precise control | Variable; includes installation costs |

| Commercial Dishwasher System | High-temp cycles, rapid wash, chemical dispensing | Fast sanitization, consistent cleanliness | Reduces labor, meets health codes | Pizzerias, catering, hospitals | Energy & water efficient; NSF certified | $3,000 - $50,000+ |

| Commercial Hood Ventilation | Grease filters, variable fans, fire suppression integration | Improves air quality, reduces kitchen heat | Essential for safety & compliance | All pizzerias & commercial kitchens | NFPA 96 compliance; fire suppression ready | $10,000 - $100,000+ |

| Commercial Food Prep Table | Refrigerated storage, stainless surface, ingredient rails | Keeps ingredients cold during prep, organized prep | Maximizes space and efficiency | Pizza kitchens, sandwich shops, salad bars | NSF certified; customizable sizes | Mid-range |

| Commercial Stand Mixer | Powerful motors, multiple speeds, interchangeable tools | Handles large batches; consistent mixing | Reduces prep labor, versatile for baking | Pizzerias, bakeries, restaurants | Large capacity; variety of attachments | $1,500 - $15,000+ |

| Commercial Deep Fryer | Digital temp controls, oil filtration, safety features | Fast, consistent frying | High-volume frying with efficient oil use | Fried food restaurants, pizzerias | Auto shut-off; cool zone tech | Mid to high range |

Final Thoughts

Embarking on the journey of opening or upgrading a commercial kitchen, especially for a specialized operation like a pizzeria, is a monumental task. The sheer volume of decisions can feel overwhelming, but building your kitchen from a well-researched commercial kitchen equipment checklist transforms a daunting challenge into a strategic, manageable process. This guide was designed to move beyond a simple list of items and provide a foundational understanding of how each piece of equipment functions as part of a larger, cohesive system. From the raw power of your pizza oven to the critical workflow of a refrigerated pizza prep table, every choice directly impacts your efficiency, product quality, and ultimately, your profitability.

The core principle to remember is that equipment is not just an expense; it is a long-term investment in your operational backbone. A cheap, undersized ventilation hood might save you money upfront, but it will create a hazardous, uncomfortable, and inefficient work environment down the line. Similarly, choosing a standard refrigerator instead of a specialized pizza prep table creates bottlenecks, compromises ingredient freshness, and slows down your entire production line during a Friday night rush. Each piece of equipment detailed in this checklist, from the workhorse stand mixer to the high-temperature dishwasher, serves a specific, vital role in the complex dance of a professional kitchen.

Key Takeaways for Strategic Equipment Selection

As you move forward, keep these core principles at the forefront of your planning. They are the difference between a kitchen that works for you and a kitchen you have to work against.

- Workflow is King: Your equipment layout must follow the logical flow of food, from receiving and storage to prep, cooking, and plating. For a pizzeria, this means a direct line from your walk-in cooler to your dough mixer, then to your refrigerated prep station, and finally to the oven. Analyze every step to eliminate wasted motion.

- Match Specs to Menu: Don't overbuy or underbuy. A small café doesn't need a 100-quart mixer, but a high-volume pizzeria will be crippled by a 20-quart model. Let your menu's complexity, your peak volume projections, and your signature items dictate the size, power, and features of the equipment you purchase. The BTUs of your range, the deck size of your oven, and the pan capacity of your pizza prep table are all critical data points.

- Prioritize the "Big Three": For most food service operations, especially pizzerias, your success hinges on three critical areas: refrigeration, ventilation, and cooking. A failure in any of these systems can shut down your entire operation. Allocate a significant portion of your budget to high-quality, reliable brands for your walk-in cooler, hood system, and primary pizza oven.

Your Actionable Next Steps

With this comprehensive checklist in hand, your path forward is much clearer. Here is how you can translate this knowledge into concrete action:

- Finalize Your Menu: Before you buy a single piece of equipment, lock in your core menu. This will be your ultimate guide for all purchasing decisions.

- Create a Scaled Floor Plan: Use graph paper or simple design software to draw your kitchen space to scale. Begin placing your major equipment pieces, paying close attention to workflow, clearance requirements, and utility hookups (gas, water, electric).

- Build a Tiered Budget: Create a budget with three columns for each item on your checklist: "Ideal" (new, top-tier brands), "Mid-Range" (new, value-oriented brands or certified used), and "Minimum Viable" (reliable used equipment). This gives you flexibility as you start sourcing and pricing.

- Consult the Professionals: Don't go it alone. Share your floor plan and equipment list with a licensed general contractor, a commercial kitchen designer, and your local health department inspector. Their feedback is invaluable and can save you from costly mistakes.

Ultimately, mastering your commercial kitchen equipment checklist is about more than just buying stainless steel. It’s about building the heart of your business, an engine designed for consistency, speed, and quality. It’s the foundation upon which you will create thousands of signature dishes, delight your customers, and build a lasting, successful culinary brand.

Finding the right equipment is the most critical step in building an efficient pizzeria kitchen, and a purpose-built prep station is the undisputed centerpiece of your workflow. For a system designed by pizza professionals for pizza professionals, explore the options at Pizza Prep Table. Their specialized units integrate refrigerated pan rails and durable cutting boards to streamline your assembly process, ensuring every pizza is built for perfection. Discover the right fit for your kitchen at Pizza Prep Table today.