Essential Food Safety Guidelines for Pizza Restaurants

Share

Excellent food safety isn't just about passing inspections; it's the very foundation of customer trust and the key to your pizzeria's longevity. For a pizza restaurant, this means getting a specific set of rules right—from the temperature of your walk-in cooler to how you organize your pizza prep table. It's about ensuring every single slice you serve is both delicious and safe.

Why Food Safety Is Your Pizzeria's Foundation

The success of your pizzeria is built on far more than a great dough recipe. It’s built on the trust your customers place in you every time they order a pie. A single oversight—a topping left out too long on the prep line, a contaminated pizza cutter—can shatter that trust in an instant. The fallout affects not just a customer's health but your restaurant's reputation and its future.

Think of food safety not as a tedious list of rules, but as the essential framework supporting your entire operation. It's the invisible ingredient in every pizza you sell.

The consequences of getting this wrong are severe. The global impact of food safety lapses is staggering; every year, an estimated 600 million people fall ill from contaminated food. These illnesses lead to about 420,000 deaths annually, with children being especially vulnerable.

The Core Pillars of Pizzeria Safety

To truly nail food safety in a pizza restaurant, you have to understand the entire journey your ingredients take. This starts before they even hit your kitchen, with things like a complete guide to labelling for food products that covers critical details like allergens and expiration dates for your cheese, meats, and sauces.

Once those ingredients are in your hands, your focus must shift to a few core pillars that protect both your customers and your business. We've broken them down here to give you a clear roadmap for your pizzeria.

The Core Pillars of Pizza Restaurant Food Safety

| Safety Pillar | Key Objective | Critical Focus for Pizza Prep |

|---|---|---|

| Precise Temperature Control | Keep ingredients out of the "danger zone" where bacteria multiply rapidly. | Maintaining 33°F-41°F in the pizza prep table's ingredient rail. |

| Cross-Contamination Prevention | Stop harmful bacteria from spreading between ingredients, surfaces, and tools. | Using separate cutting boards and utensils for raw sausage and ready-to-eat toppings like cheese. |

| Flawless Staff Hygiene | Ensure every team member follows strict personal cleanliness protocols. | Proper handwashing techniques and correct use of gloves before topping a pizza. |

| Effective Staff Training | Build a team that understands why safety rules exist and follows them consistently. | Regular training on allergen handling, temperature logging for the prep table, and cleaning schedules. |

| Regulatory Compliance | Meet or exceed all local health department codes and regulations. | Passing health inspections with flying colors by making pizza safety a daily habit. |

These pillars aren't just separate tasks; they work together to create a culture of safety that permeates every aspect of your pizza kitchen.

Mastering these food safety guidelines isn't just about passing a health inspection. It's about demonstrating a commitment to quality and care that builds a loyal customer base and secures your pizzeria’s success for years to come.

Throughout this guide, we will break down each of these pillars with a sharp focus on the unique challenges and opportunities inside a pizza kitchen. We’ll provide actionable steps for everything from organizing your pizza prep table to training your staff, making it crystal clear why impeccable food safety is the most critical investment you can make.

Mastering Temperature Control from Dough to Door

In the controlled chaos of a pizza kitchen, temperature is your silent partner. Get it right, and you serve up perfect, safe pizzas every time. Get it wrong, and you're flirting with a food safety disaster. The golden rule is simple: keep your ingredients out of the Temperature Danger Zone, that risky range between 40°F and 140°F (5°C and 60°C). In this zone, bacteria can double in as little as 20 minutes.

In the controlled chaos of a pizza kitchen, temperature is your silent partner. Get it right, and you serve up perfect, safe pizzas every time. Get it wrong, and you're flirting with a food safety disaster. The golden rule is simple: keep your ingredients out of the Temperature Danger Zone, that risky range between 40°F and 140°F (5°C and 60°C). In this zone, bacteria can double in as little as 20 minutes.

Think of it as maintaining a strict "temperature chain of custody" for your pizza toppings. Every single link—from the delivery truck to your customer's pizza box—has to be secure. This means obsessing over the temperatures in your walk-in, your pizza prep table, and your oven. A single weak link can break the whole chain, which is why strict temperature management is absolutely non-negotiable.

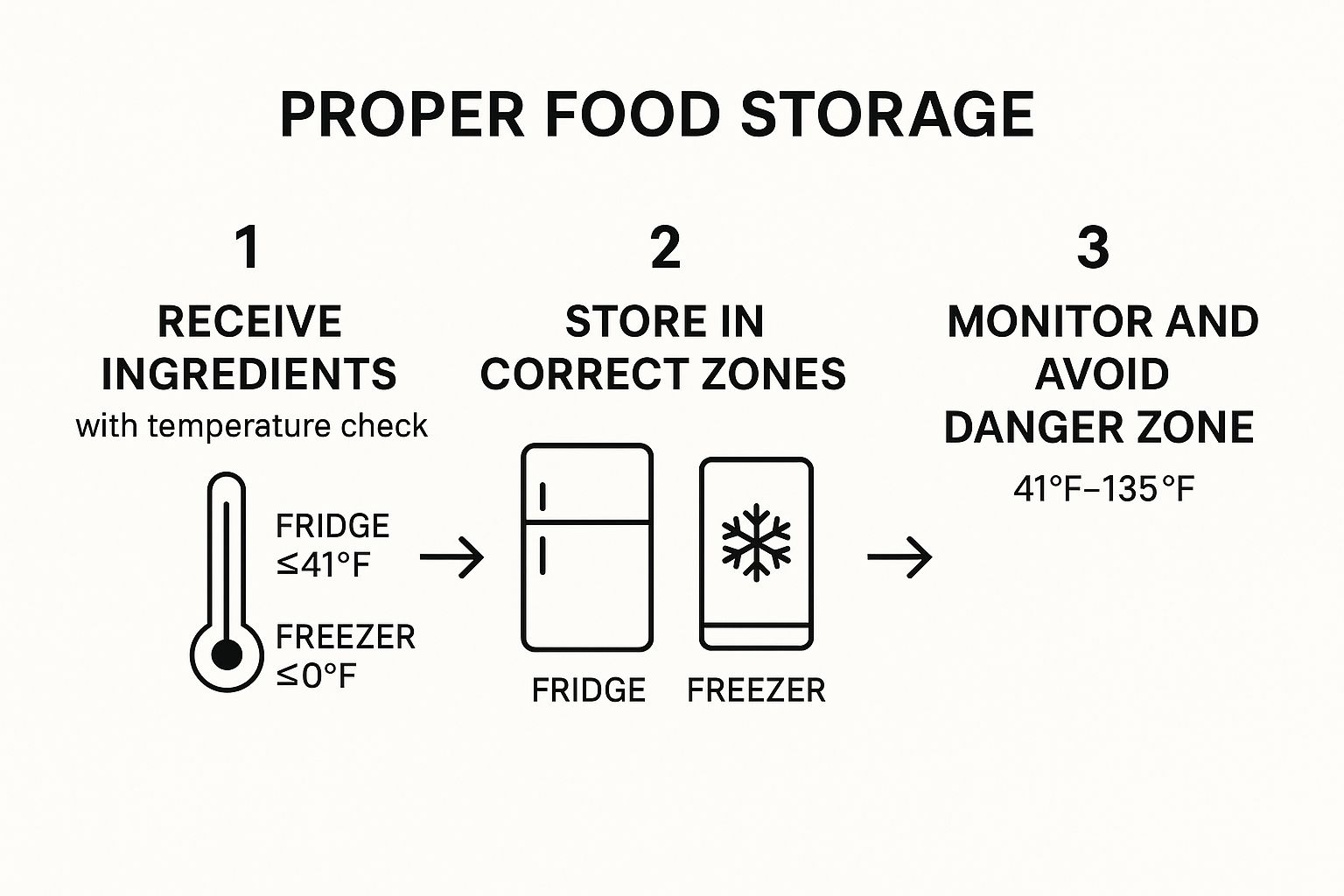

This all starts the moment a delivery arrives. Your team needs to be trained to whip out a calibrated food thermometer and check every shipment of time-temperature control for safety (TCS) foods—that's your cheese, meats, and sauces. If it’s not at or below 41°F (5°C), it doesn't come in the door.

Organizing Your Cold Storage for Pizza Safety

Once those ingredients pass inspection, they need a proper home. Your walk-in cooler isn't just a big, cold box; it’s a critical control point for your pizzeria. How you organize it can make or break your food safety plan.

The First-In, First-Out (FIFO) method is your best friend here. It’s a simple concept: new stock always goes behind the old stock. This rotation ensures you’re using ingredients like dough, cheese, and toppings in the right order, slashing spoilage and waste. Of course, this only works if you label every single item with a "received" or "use-by" date.

Beyond that, the way you stack your shelves is immensely important. To prevent dangerous cross-contamination from drips, you need a clear hierarchy. Store your food top-to-bottom like this:

- Top Shelf: Ready-to-eat foods like cooked chicken toppings, pre-sliced veggies, and pepperoni.

- Middle Shelves: Raw seafood, whole cuts of pork and beef.

- Lower Shelves: Ground meats like sausage.

- Bottom Shelf: Raw poultry (chicken wings, raw chicken toppings).

This setup ensures that juices from raw meats can't possibly drip onto and contaminate foods that get little to no further cooking.

The Pizza Prep Table: The Active Cold Zone

The refrigerated rail on your pizza prep table is where the action happens—it's the frontline where cold ingredients meet the heat of the kitchen. Keeping toppings like pepperoni, mushrooms, and cheese below that 41°F (5°C) threshold is a constant battle. Good commercial food prep equipment is built for this fight, but only if you use it correctly.

A well-maintained pizza prep table is more than just a workstation; it is an active defense against bacterial growth. Its ability to hold toppings at a consistent, safe temperature during a busy service is fundamental to your kitchen’s food safety integrity.

To get the most out of your pizza prep table, keep the lids closed whenever you’re not grabbing ingredients. This simple habit traps the cold air where it belongs. You also have to resist the urge to overfill the pans; piling toppings high blocks airflow and stops the unit from keeping that top layer of food safely chilled.

Finally, the oven is your last line of defense. Cooking a pizza to the right internal temperature is what kills any lingering harmful bacteria. For any pie with raw meat toppings like sausage, the internal temperature must hit at least 165°F (74°C). Get in the habit of using a clean, calibrated thermometer to spot-check pizzas, especially in the thickest part under the cheese, to guarantee every single one is perfectly and safely cooked.

Your Pizza Prep Table: Cross-Contamination Ground Zero

The pizza prep table is the heart of your kitchen. It's where sauce, cheese, and toppings come together to create your signature pies. But this bustling hub of creativity is also a high-risk zone for cross-contamination.

Think of it as a busy intersection. When you have raw meats, fresh produce, and ready-to-eat dairy all in close proximity, you need clear rules of the road. Without them, collisions are inevitable. In a kitchen, those "collisions" happen when harmful bacteria from raw sausage jumps ship to shredded mozzarella—an ingredient that gets no further cooking. That single mistake can land a customer in the hospital.

To prevent this, you need to transform your prep table from a danger zone into a fortress of food safety. This takes more than a quick wipe-down. It demands a systematic approach to workflow, tool management, and sanitization that protects every single pizza you make.

A Traffic Light System for Pizza Toppings

A powerful way to get your team thinking about safety is to use a 'traffic light' system for your pizza toppings. It’s a simple mental model that helps everyone instantly recognize the risk level of each item and handle it the right way, even during a chaotic dinner rush.

Here’s how it works:

- Red Light (High Risk): This is for all your raw meats—uncooked sausage, ground beef, raw chicken. These items must be handled with dedicated utensils and extreme care to keep their juices from touching anything else on the prep table.

- Yellow Light (Caution): This category includes produce that needs a final prep step, like unwashed mushrooms or onions that still need slicing. They're less risky than raw meat but aren't ready-to-eat yet, so they must be kept separate from your "green light" items.

- Green Light (Ready-to-Eat): These are your low-risk, ready-to-eat toppings. Think shredded cheese, pepperoni, pre-cooked veggies, and sauces. These ingredients are good to go directly onto the pizza.

This process flow helps visualize how to manage ingredients from the moment they arrive, keeping them safe long before they even reach your pizza prep table.

The key takeaway here? Strict temperature control and organization from the very beginning are your first line of defense against problems at the pizza prep station.

Non-Negotiable Pizza Prep Table Protocols

Beyond organizing ingredients, you need to enforce strict protocols for every tool and surface. Your team has to understand that these rules aren't suggestions; they are non-negotiable parts of your pizzeria's food safety guidelines.

Start with your cutting boards. Using color-coded cutting boards is one of the easiest and most effective visual cues to prevent cross-contamination. A common, battle-tested system is:

- Red for raw meat

- Green for vegetables and fruits

- White for ready-to-eat items like cheese and pepperoni

A well-organized prep area with clear visual cues, like colored cutting boards, doesn't just prevent errors—it builds a safety-first mindset into your kitchen's muscle memory. It makes doing the right thing the easiest thing to do.

Utensils are another critical point. You absolutely need separate, clearly marked containers for scoops, spoons, and tongs dedicated to specific ingredient types, especially for raw meats. A spoon used for raw sausage should never find its way into the mushroom bin. For a deeper look at setting up your station, our guide on choosing a commercial pizza prep table has great insights on models designed to support these separated workflows.

Finally, lock down a rigorous cleaning schedule. Your prep table surfaces must be cleaned and sanitized at least every four hours of continuous use. Even more importantly, they need to be sanitized immediately after any potential contamination, like a splash of raw sausage juice. These cleaning protocols are vital; for instance, you can learn more about stopping dangerous pathogens from resources that explain E. Coli: How to Clean to Stop the Spread. By combining these strategies, your pizza prep table becomes a pillar of safety, not a liability.

Making Personal Hygiene Your First Line of Defense

Let's be real: exceptional food safety begins and ends with your team. You can have the most perfectly calibrated oven and a pizza prep table sanitized to within an inch of its life, but it all means nothing if the hands building the pizza are a source of contamination. Think of a pizza maker's hands as their most critical tool—and like any critical tool, they need to be impeccably maintained to create a safe masterpiece. This goes far beyond a simple "wash your hands" sign taped to the wall; it's about embedding a complete hygiene culture into your pizzeria.

A single slip-up in personal hygiene can have massive consequences. In fact, poor cleanliness is one of the most common culprits behind foodborne illness outbreaks in restaurants. Establishing and, more importantly, enforcing strict protocols is the single best way to protect your customers, your team, and the reputation you've worked so hard to build.

The Foundation: Handwashing and Glove Use

The most basic yet most powerful rule in any kitchen is proper handwashing. It takes only a few moments but is a formidable defense against spreading germs. Staff must wash their hands before starting their shift, after touching their face or hair, after handling raw meat, and, crucially, before putting on a new pair of gloves to make a pizza.

Speaking of gloves, they can create a dangerous false sense of security if not used correctly. They are a single-use barrier, not a permanent shield.

Here are the non-negotiable rules for glove use at the pizza prep station:

- Wash First: Hands must be thoroughly washed and dried before a new pair of gloves ever goes on.

- Change Often: Gloves need to be changed after handling raw meats, before touching ready-to-eat ingredients like cheese or pepperoni, or any time they become dirty or torn.

- The Four-Hour Rule: At a bare minimum, gloves must be changed after four hours of continuous use on the same task (e.g., portioning dough). This prevents the warm, moist environment inside the glove from becoming a breeding ground for bacteria.

Proper hygiene is a conscious, active process, not a passive one. Wearing gloves doesn't magically make hands clean; it's the disciplined cycle of washing, wearing, and changing that creates a truly safe barrier between your staff and the pizzas they serve.

Beyond the Hands: Uniforms and Personal Habits

Hygiene doesn't stop at the wrist. Contaminants are hitchhikers—they can travel on clothing, hair, and even jewelry, making comprehensive policies essential for maintaining the strictest food safety guidelines in your pizza restaurant.

A clean uniform is part of the job description. Staff should arrive in clean attire, and aprons need to be laundered regularly. Any soiled uniforms or aprons must be stored far away from food preparation areas to stop cross-contamination in its tracks.

On top of that, you need clear policies for the following:

- Hair Restraints: All pizza makers and kitchen staff must wear clean hats or other effective hair and beard restraints. No exceptions.

- Jewelry: All jewelry, except for a plain wedding band, should be removed before handling food. Rings and bracelets are notorious for trapping germs and can become a physical hazard if they fall onto a pizza.

- Designated Break Areas: Employees must never eat, drink, or smoke near food preparation zones. A dedicated break area keeps personal food and drinks well away from your pizza ingredients and prep surfaces.

When a Sick Employee Must Stay Home

One of the most critical—and sometimes most difficult—hygiene policies to enforce is a clear rule for when sick employees must stay home. An ill team member is a significant risk to everyone, customers and coworkers alike. It is a manager’s absolute responsibility to send a sick employee home.

Employees must be trained to report symptoms like vomiting, diarrhea, or jaundice to a manager immediately. Beyond general cleanliness, understanding specific pathogens is key. For instance, learning about Norovirus: What It Is, How It Spreads, and How to Stop It can drive home just how important this is. This virus is incredibly contagious and often spreads through hand-to-food contact, making a strict sick-leave policy a non-negotiable cornerstone of your defense.

Using Technology for Smarter Pizza Safety

Let’s be honest, those old-school paper logs and handwritten checklists are a huge pain. One of the single best upgrades any pizzeria can make is stepping away from the clipboard and embracing technology. It lets you automate, track, and verify your safety rules with a precision that paper just can't match, freeing up your team and seriously boosting compliance.

This isn’t just a nice-to-have; it’s where the entire industry is headed. The FDA is pushing this with its "New Era of Smarter Food Safety" initiative, encouraging a major shift to tech-based systems. We're already seeing this in action, with many restaurants adopting tools like wireless temperature monitors by 2025 to eliminate the human error that comes with manual logs. You can get a deeper look into how these restaurant food safety trends for 2025 are shaping the industry.

For a pizza restaurant, this means swapping out dated methods for smart, practical tools that work around the clock to protect your food.

Automating Critical Temperature Checks

Imagine if your walk-in cooler or pizza prep table could text you before a problem gets serious. That’s exactly what wireless temperature monitors do. You place these small sensors inside your fridges, freezers, and pizza prep table ingredient rails, and they quietly track the temperature day and night.

Instead of an employee having to open the rail lid and scribble down a temperature three times a day, these systems log it automatically every few minutes. If the temp in your ingredient rail starts creeping into the danger zone, you get an alert on your phone right away.

This is a game-changer for a pizzeria for a few reasons:

- Real-Time Alerts: You'll catch a failing prep table compressor or a walk-in door left ajar immediately, not hours later during a line check when you have to throw out hundreds of dollars in cheese and toppings.

- Accurate Records: The system creates perfect digital logs automatically. When the health inspector shows up, you have flawless documentation ready to go.

- Proactive Maintenance: You can spot temperature trends that show a refrigeration unit is struggling, letting you call for repairs before it dies on a busy Friday night.

Streamlining Daily Operations with Digital Checklists

Beyond just temperatures, technology can bring that same level of order and accountability to every part of your safety plan. Digital checklist apps turn your cleaning schedules, opening duties, and training records into a simple, trackable process on a tablet or phone.

Technology transforms food safety from a memory-based task into an automated, verifiable system. It creates a digital trail of accountability that ensures critical protocols are followed consistently, even during the busiest pizza rush.

Think about the daily grind. With a digital app, a manager can assign tasks like "Sanitize Pizza Prep Table" or "Check Use-By Dates on Dough." An employee taps the task to mark it complete, and the system logs who did it and when. It creates an undeniable record of who is responsible for what.

This is incredibly powerful for pizzerias. You can create very specific checklists for:

- Pizza Prep Station Setup: Verifying that all your color-coded boards and separate topping scoops are in the right place.

- Dough Management: Ensuring your team is following FIFO principles for every batch of dough.

- Allergen Handling: Documenting that a station was fully sanitized after making a pizza with a known allergen, like a gluten-free crust.

By bringing these tools into your pizzeria, you’re not just ticking compliance boxes. You're building a smarter, more resilient safety culture that protects your business, empowers your team, and makes sure every single pizza you serve is as safe as it is delicious.

Making Food Safety a Gut Instinct, Not Just a Rule

Let’s be honest: slapping a poster on the wall with food safety rules is a start, but it’s not a strategy. True safety isn’t about checking a box; it’s about building a living, breathing culture where every single person on your pizza team feels a personal stake in getting it right. This means moving past a one-and-done orientation and creating a system of constant learning that actually sticks.

For a pizzeria, this training has to be specific. A new hire doesn’t just need to hear about the "temperature danger zone." They need to understand exactly why keeping the toppings in the pizza prep table's rail below 41°F is a non-negotiable part of their job. The real goal is to build deep understanding, not just demand that they memorize a bunch of rules.

A food safety culture is born when your team's mindset shifts from "What do I have to do?" to "What's the safest way to make this pizza?" It’s a powerful move from basic compliance to genuine ownership, and it all starts with effective, ongoing training.

What Your Pizzeria Team Absolutely Needs to Know

A solid training program gives your staff the confidence and knowledge to handle the real-world messes and mistakes that happen in a busy kitchen. Think of it as their blueprint for success, with each part designed to tackle the specific risks of a pizza-making environment.

Your training needs to hit these core topics hard:

- Pizza Prep Table Discipline: This calls for hands-on demos. Show them how to use color-coded utensils and cutting boards, how to arrange toppings to stop cross-contamination in its tracks, and exactly how often that prep area needs to be sanitized.

- Real-World Pathogen Scenarios: Don't just list scary-sounding bacteria. Create pizzeria scenarios that make the risk feel real. For example, "What are the first three things you do if raw sausage accidentally touches the shredded mozzarella?" This makes the danger of something like E. coli hit home.

- Allergen Awareness: This is non-negotiable. Train everyone on the exact process for handling allergy orders, from using a clean pizza cutter and a separate surface to clear, direct communication with the front-of-house team.

- Proper Temperature Logging: Teach them how to correctly use both digital and manual thermometers for every critical checkpoint—from checking a cheese delivery to monitoring the pizza prep table rail, and verifying the final cook temp of every pizza that leaves the oven.

This kind of targeted training ensures every employee, from the dishwasher to the lead pizza maker, understands the critical control points that are unique to your operation. For a deeper dive into organizing your workspace for safety, check out our guide on how to best use prep tables for restaurant efficiency.

Keeping Safety Training Fresh and Continuous

A single training session is useless if it’s forgotten in the middle of a chaotic Friday night rush. To make safety a genuine habit, you have to reinforce it constantly, weaving it into the natural rhythm of the pizzeria until it becomes second nature.

Here are a few practical ways to make training dynamic and effective:

- Daily Team Huddles: Before each shift, gather everyone for a quick, five-minute safety check-in. It could be a simple reminder about changing gloves after handling raw sausage, a pop quiz on cooking temperatures, or a public shout-out to someone who handled a safety issue perfectly the day before.

- Role-Playing Scenarios: Walk through common pizzeria mistakes. Have your team act out how they would respond to a customer asking about a gluten allergy or what they should do if they see a coworker forget to wash their hands after touching their phone.

- Visual Cues and Fun Quizzes: Use posters with simple, clear graphics right at the pizza prep station and handwashing sinks. Tossing in occasional, friendly pop quizzes—maybe with a free slice of pizza as a prize—keeps knowledge top-of-mind and adds a little positive reinforcement.

Ultimately, your goal is to build a "see something, say something" environment. When training is continuous and empowering, your team will feel confident enough to gently correct a coworker or even stop the line to prevent a potential mistake. That's when you know you've succeeded—when your entire team becomes an active part of your pizzeria's food safety defense system.

Common Questions About Pizza Restaurant Safety

Even with the best systems and training in place, the real world of a busy pizzeria kitchen always throws a few curveballs. These day-to-day questions are where food safety theory meets reality. Getting the answers right turns rules on a checklist into habits that protect your customers and your business.

Let's break down some of the most common—and critical—questions that pop up in pizzerias.

How Often Should I Sanitize My Pizza Prep Table?

Think of your prep table as prime real estate for bacteria. It needs to be cleaned and sanitized at least every four hours if you're using it continuously. That’s the bare minimum.

The real answer? You sanitize it immediately anytime there's a risk of cross-contamination. A splash of raw sausage juice, an accidental spill of an allergen, or switching from prepping a meat lover's to a veggie pizza—all of these trigger an immediate need to clean and sanitize. This is why having color-coded zones and dedicated utensils isn't just a fancy idea; it's your best defense.

What Is the Safest Way to Store Pizza Dough?

The only safe way is to store your dough in sealed, food-grade containers and get it into the refrigerator, which should be holding at or below 40°F (4°C). This cold temperature dramatically slows down yeast activity, but more importantly, it stops harmful bacteria from multiplying.

Always, always label every dough container with the date it was made and live by the First-In, First-Out (FIFO) rule. If you proof dough at room temperature, remember that it can't be in the Temperature Danger Zone (40°F to 140°F) for more than two hours total. That clock is ticking from the moment you mix it to the second before it hits the oven.

A rookie mistake is forgetting that all the little moments dough spends out of the fridge add up. Five minutes here, ten minutes there—it all counts towards that two-hour limit. Diligent temperature tracking is non-negotiable.

Can We Use the Same Pizza Cutter All Shift?

Absolutely not. A pizza cutter is one of the most critical food-contact surfaces in your kitchen, and using the same one all day is a recipe for disaster. It’s a direct line for transferring germs and allergens from one pizza to the next.

The best practice is simple: have a rotation of clean, sanitized cutters ready to go. The second a cutter is used on a pizza with a meat topping, it must be taken out of service to be washed and sanitized before it touches a plain cheese or veggie pizza. This is crucial for preventing cross-contact, especially for guests with allergies or dietary restrictions.

What Is the Correct Internal Temperature for a Cooked Pizza?

Your oven might be cranked up for that perfect, crispy crust, but the real number that matters for safety is the final internal temperature of the pizza. It needs to reach at least 165°F (74°C). This is especially vital for any pizza with raw meat toppings like sausage, chicken, or ground beef.

Hitting that temperature is the final kill step that guarantees any potentially dangerous bacteria have been destroyed. Get in the habit of using a clean, sanitized food thermometer to spot-check the center of the pizza, right under the toppings, to confirm it’s safe before you slice and serve.

At Pizza Prep Table, we know that having the right equipment is the foundation of your entire food safety plan. Our NSF-compliant refrigerated prep tables are built to maintain precise temperatures, create organized workflows, and help you nail the strictest health guidelines with confidence. Check out our selection of top-tier equipment to build a safer, smarter pizzeria today at https://pizzapreptable.com.