Top Pizza Prep Tables for Restaurant Success: Choose the Best

Share

Picking the right prep tables for restaurant kitchens is one of those strategic decisions that can make or break your speed, efficiency, and food quality. For a pizzeria, this isn't just a stainless steel counter; it's the command center of your entire operation. A dedicated pizza prep table takes a frantic, chaotic process and turns it into a smooth, streamlined workflow, making sure every single ingredient is fresh, safe, and right where you need it.

Why Your Pizza Kitchen Needs the Right Prep Table

Imagine trying to build a car on a tiny workbench with your tools scattered all over the garage. It would be frustratingly slow, and the final product would probably show it. That's exactly what running a pizzeria without a proper pizza prep table feels like during a Friday night rush. These specialized workstations are engineered to solve the real-world problems of high-volume pizza making.

A standard work counter just can't keep up. A true pizza prep table is a workhorse that masterfully combines three critical functions into one unit: refrigerated ingredient storage, a sanitary work surface, and under-counter cold storage for dough and backup toppings. This smart consolidation is the key to efficiency, transforming what would be a dozen steps across the kitchen into one fluid motion.

The Foundation of Speed and Consistency

At its core, a dedicated pizza prep table is all about creating a highly organized and ergonomic assembly line. When all your toppings—from pepperoni and mushrooms to different cheese blends—are held at the perfect temperature just inches from your hands, your team can build pizzas faster and more consistently. It’s that simple.

This setup drastically cuts down on the wasted time spent walking between the walk-in, a separate prep counter, and the oven. Every second you save during peak hours translates directly into more pizzas out the door and more revenue in the bank. It also helps guarantee that every pizza gets the same love, improving product consistency and keeping your customers happy.

For a pizzeria, the prep table isn't just another piece of equipment; it's the heart of your production line. A well-organized station can slash ticket times by up to 30% during busy periods, directly boosting your throughput and profitability.

Enhancing Food Safety and Reducing Waste

Beyond pure speed, these tables are absolutely vital for food safety. The integrated, refrigerated rails are designed to keep temperature-sensitive ingredients like meats and cheeses out of the dreaded "danger zone" (40°F to 140°F), where bacteria can multiply in a hurry. This isn't just a nice-to-have; it's a non-negotiable for passing health inspections and protecting your customers.

This constant, correct temperature control also delivers a serious financial benefit. It extends the shelf life of your ingredients and minimizes spoilage, which means less food waste and more money staying in your pocket. Investing in the right pizza prep tables for your restaurant isn't just an expense; it’s an investment in a more organized, profitable, and less stressful kitchen.

Understanding Refrigeration in Pizza Prep Tables

The refrigeration system is the heart and soul of any modern pizza prep table. It’s not just a cooler; it's the guardian of your most valuable assets—your ingredients. Think of it as your kitchen’s own highly specialized climate control, creating a consistently cold zone that’s absolutely critical for quality, safety, and keeping the health inspector happy.

Without a bulletproof system, even the most beautiful, high-quality ingredients can turn into a liability in a hurry. We’re not just talking about keeping things cool. We’re talking about maintaining a precise temperature range, even when your kitchen feels like a sauna and your crew is slamming lids open and shut during the dinner rush. A top-tier refrigeration unit is the unsung hero that slashes spoilage, minimizes costly food waste, and, most importantly, protects your customers from foodborne illness.

The demand for these units is skyrocketing for a reason. Pizzerias are getting smarter and more efficient. In fact, the global market for refrigerated prep tables is projected to climb from an estimated US$ 7.67 billion in 2024 to a whopping US$ 10.30 billion by 2031. That growth tells you everything you need to know about how essential these tables have become. You can dig into the numbers in this market research on refrigerated prep tables.

Forced-Air vs Cold-Wall Systems

When you start looking at prep tables for restaurant use, you'll mainly run into two types of refrigeration tech: forced-air and cold-wall. Knowing the difference here is key to picking the right tool for your pizzeria's real-world needs.

- A forced-air system (also called air-cooled) uses fans to actively blow cold air all around the unit, from the top ingredient rail down to the storage base. It's like having central air conditioning for your toppings, creating a uniform blanket of cold that ensures every pan of pepperoni is held at the same safe temperature as the pan of mushrooms next to it.

- A cold-wall system, on the other hand, works more passively. It relies on refrigerant lines that are literally built into the walls of the table. While these are often quieter and can be more energy-efficient when idle, they can sometimes lead to inconsistent temperatures across the rail. For a high-volume pizza joint, the rock-solid consistency of a forced-air system is almost always the smarter bet.

Key Takeaway: Forced-air systems give you much more even cooling, which is a lifesaver in a busy pizzeria where ingredient pans are constantly being opened. This consistency fights off dangerous hot spots and makes sure every topping stays safely chilled.

Temperature Recovery and Why It Matters

Here’s one of the most important, yet most frequently ignored, specs on a pizza prep table: temperature recovery time. This is the stopwatch test—it measures how fast the refrigeration system can muscle the temperature back down to its set point after a lid or drawer has been opened.

Picture a slammed Friday night. Your prep table is getting hammered. Every single time a lid is lifted, precious cold air spills out and warm kitchen air rushes in. A unit with a slow recovery time will struggle to keep up, letting your ingredients slowly and dangerously creep into the temperature danger zone.

A powerful compressor paired with an efficient forced-air system is what gives you that lightning-fast recovery. This is the feature that ensures your cheese, veggies, and meats stay crisp, fresh, and safely below 40°F, even when you’re cranking out pizzas at full speed. Faster recovery directly translates to better food quality and unwavering compliance with health codes. If you're weighing your options, our complete guide on the commercial pizza prep table offers more in-depth comparisons.

The Financial Impact of ENERGY STAR Ratings

Finally, let’s talk money. Don't ever underestimate the long-term savings of choosing an energy-efficient model. A pizza prep table is a serious piece of equipment that runs 24/7, making it one of the biggest vampires on your utility bill. An ENERGY STAR certified unit isn't just a feel-good choice; it's a smart business investment that will pay for itself over and over.

These models are engineered from the ground up to sip energy without sacrificing an ounce of performance:

- High-efficiency compressors: They simply work less hard to maintain cold temperatures, which means they pull less power from the wall.

- Better insulation: Think of it like a high-end thermos. Better foam insulation keeps more cold air trapped inside, so the compressor doesn't have to kick on as often.

- Improved gaskets: A tight seal around doors and lids is crucial. High-quality gaskets prevent cold air leaks, which are a notorious source of wasted energy.

Choosing an ENERGY STAR model can easily shave hundreds of dollars off your electricity costs each year for just a single table. It’s one of those rare decisions that’s a win for your bottom line and a win for the environment.

Finding the Perfect Size and Layout for Your Pizzeria

Choosing the right prep tables for restaurant use is a lot like planning a city's road system before you pour the first ounce of asphalt. Go too small, and you’re guaranteed to create frustrating traffic jams during your busiest rushes. But if you go too big, you’ve just installed a massive, space-hogging monument that eats up precious square footage.

Getting the fit right is about more than just measuring a wall. It’s about understanding the unique rhythm and flow of your pizzeria. The goal is to build a "pizza highway" where your crew can move with purpose, turning out perfect pies without constantly bumping into each other. This decision affects everything from team morale to how many customers you can serve on a hectic Friday night.

How to Measure for the Right Table Size

First things first, grab your tape measure. But remember, the numbers you jot down are only half the battle. You have to account for both the physical space and the operational flow of your pizzeria.

Start by measuring the exact footprint where you plan to put the table. But don't stop there. You need to think about clearance:

- Breathing Room: Always leave at least 3-6 inches of space behind and on the sides of the unit. The refrigeration compressor is the heart of the table, and it needs to breathe to work efficiently and avoid burning out.

- Aisle Space: Make sure there's a minimum of 36 inches of clear walking space in front of the table. This gives your staff enough room to open doors and pull out drawers without creating a roadblock.

Once you know your physical limits, it’s time to think about your pizza volume. Are you a small corner shop making 50 pizzas a night, or a high-volume powerhouse cranking out hundreds?

- Compact Units (48-60 inches): These are perfect for smaller pizzerias, food trucks, or kitchens with a straightforward menu. They're a fantastic choice when space is at a premium but you still need dedicated, refrigerated prep space.

- Mid-Size Units (67-72 inches): These are the workhorses for most busy pizzerias. They strike a great balance between prep surface area and ingredient storage without completely taking over your kitchen.

- Large Units (93 inches and up): These are reserved for high-volume operations where multiple cooks are hitting the line at the same time. These massive workstations can support a huge variety of toppings for a complex and diverse pizza menu.

Standard Top vs Mega Top Designs

After you've locked down the length, your next choice is the rail configuration: standard top or mega top. This decision directly impacts how many toppings you can keep chilled and ready to go.

A standard top pizza prep table is the classic setup, typically holding two rows of 1/3-size food pans. It’s a time-tested, effective design that works perfectly for most traditional pizzerias.

A mega top design kicks things up a notch by adding a third row, which increases your pan capacity by about 50%. This is a total game-changer for pizzerias with a ton of topping options—think gourmet ingredients, multiple cheese blends, and a variety of sauces. The only trade-off is that the extra row makes your cutting board a little less deep, but the easy access to more ingredients is often well worth it.

Choosing between these two really comes down to your menu's complexity. If you offer a dozen or so standard toppings, a standard top is all you need. If you pride yourself on a list of 30+ custom toppings, the mega top will be your new best friend.

Doors vs Drawers for Undercounter Storage

The final piece of the layout puzzle is deciding what’s happening below the work surface. Do you need doors or drawers? This isn’t just about looks; it’s a critical decision for organization and speed.

- Doors: These offer flexible, open-cabinet storage. They're perfect for stashing bulky items like big bags of flour, large sauce containers, or boxes of backup cheese. It's bulk storage at its simplest.

- Drawers: These provide far better organization for portioned items. They are ideal for holding pre-portioned dough balls, pans of extra toppings, or separated cheeses. Drawers give you faster, more ergonomic access, as staff can quickly grab what they need without bending over and rummaging inside a dark cabinet.

Many modern prep tables for restaurant kitchens now offer a combination of both, giving you a mix of drawers for organized items and a door for bulk goods. This hybrid approach often delivers the best of both worlds. The demand for this kind of multifunctionality is a major force in the market. In 2023, restaurants were the top buyers of food prep tables, focusing on compact, efficient units that make the most of their space. You can dig into more food prep table market trends to see how the industry is evolving.

By carefully thinking through these size and layout factors, you can build the most effective pizza assembly line for your team.

Decoding Materials and Must-Have Features

The materials and build quality of a prep table for restaurant kitchens are what separate a true workhorse from a wobbly liability. A well-built table is the unsung hero of a chaotic pizzeria, standing strong night after night. A flimsy one, on the other hand, quickly becomes a maintenance nightmare.

Knowing what to look for goes way beyond the price tag. It's about investing in a piece of equipment that’s durable, safe for your food, and designed to make your team's life easier. Let’s break down the components that really matter for a pizza operation.

The Gold Standard: Stainless Steel

When you're looking at the body of a pizza prep table, you need to know that not all stainless steel is created equal. The industry benchmark, and what you should always insist on, is 304-grade stainless steel. Think of it as the heavyweight champion of kitchen metals. It has more chromium and nickel, giving it a serious defense against rust and corrosion.

This is a huge deal in a pizzeria. Your table is constantly fighting a battle against acidic tomato sauce, briny olives, and harsh cleaning chemicals. A cheaper, lower-grade steel like 430-grade might look the part initially, but it won't be long before it starts showing rust spots and pitting. That's not just ugly—it's a sanitation risk. Sticking with 304-grade for food zones isn't just a good idea; it's a must for longevity and passing health inspections.

A prep table made from 304-grade stainless steel isn't just a purchase; it's a long-term asset. Its resistance to corrosion means it will maintain a hygienic, easy-to-clean surface for years, safeguarding both your food quality and your kitchen's inspection record.

Choosing the Right Cutting Board Surface

The cutting board is where the magic happens—it’s the stage for your entire pizza assembly line. The material you choose affects everything from how long your knives stay sharp to overall food safety. For most pizzerias, the most practical and popular choice is high-density polyethylene (HDPE).

This tough, plastic-based material is the go-to for a few key reasons:

- It’s Non-Porous: Unlike wood, it won't soak up bacteria, funky smells, or moisture, making it a breeze to keep sanitized.

- It’s Gentle on Knives: The surface has just enough "give" to keep your pizza cutters and knives from getting dull too quickly.

- It’s Durable: It can take a beating from constant scraping, chopping, and cleaning without cracking or splintering.

While some kitchens might experiment with other materials, the proven reliability and NSF-approved status of a thick, white polyethylene board make it the undisputed champ for pizza-making.

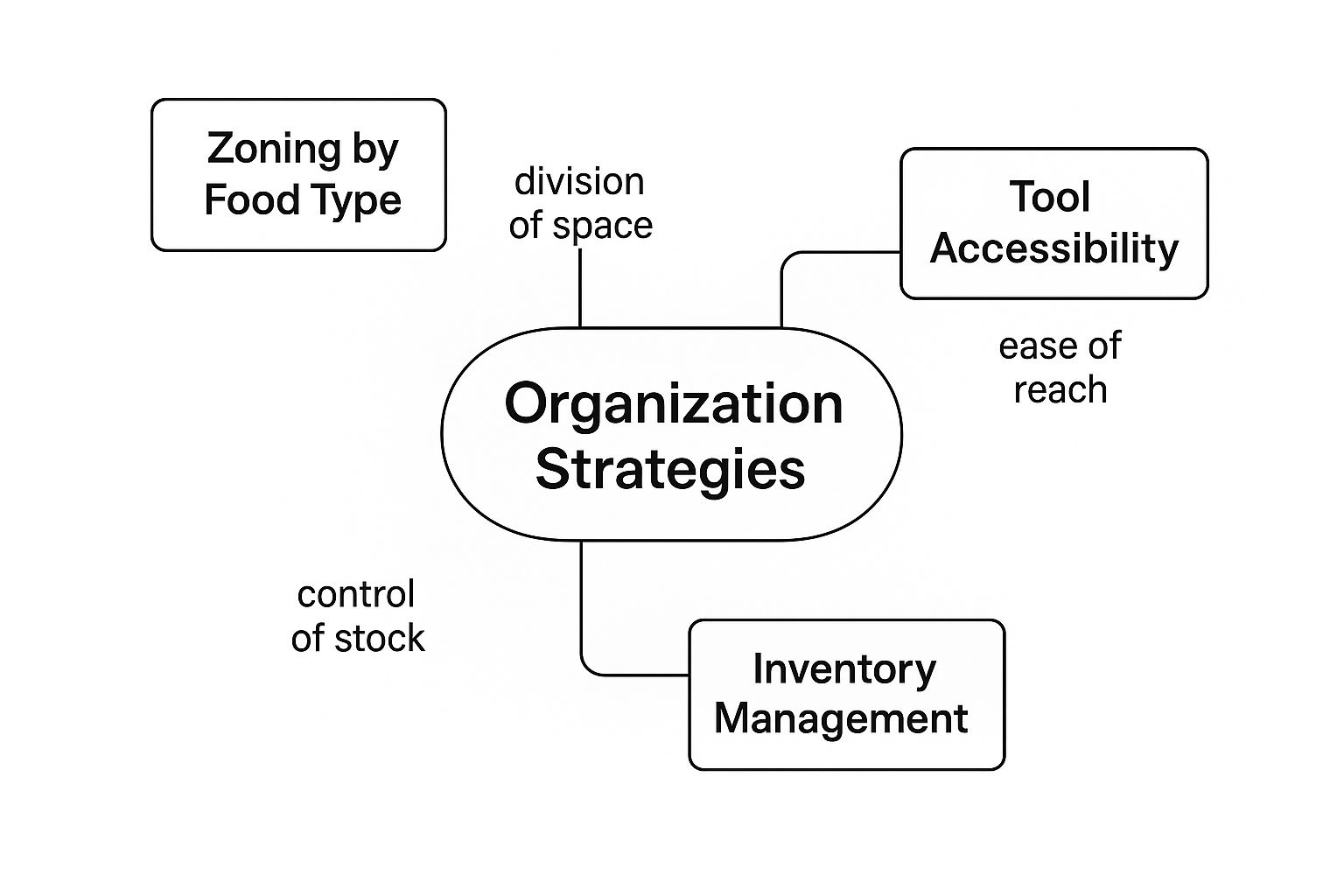

When choosing a prep table, it's about more than just the surface. You're selecting a tool that can transform your kitchen's organization.

This image really drives home how a great prep station creates zones for tools, ingredients, and workflow, turning chaos into a smooth, repeatable process.

To help you weigh your options, this table breaks down the key features that separate a standard unit from a premium one.

Pizza Prep Table Feature Comparison

| Feature | Standard Option | Premium Option | Benefit for Pizzerias |

|---|---|---|---|

| Insulated Lids | Thin, uninsulated metal or plastic lids. | Heavy-duty, foam-insulated lids. | Reduces compressor workload, saves on energy bills, and maintains food-safe temperatures. |

| Gaskets | Basic magnetic seals that may wear quickly. | High-quality, durable magnetic gaskets. | Creates a tight seal to prevent cold air leaks, ensuring food safety and energy efficiency. |

| Pan Rails | Fixed, integrated pan rails. | Removable stainless steel pan rails. | Simplifies daily cleaning, preventing grime and bacteria buildup in hard-to-reach areas. |

| Cutting Board | Standard-depth (10-12 inch) polyethylene. | Extra-deep (14-19 inch) polyethylene board. | Provides ample workspace for large pizzas, preventing ingredient spillage and mess. |

Ultimately, investing in premium features pays for itself through energy savings, easier maintenance, and a more efficient kitchen workflow.

Features That Make a Real Difference

Beyond the big-ticket materials, it’s the smaller details that often separate a great prep table from a merely adequate one. These are the things that impact your daily grind.

Insulated Lids: A heavy, foam-insulated lid is your first line of defense for keeping toppings cold. It traps the cold air inside the rail, meaning the compressor doesn't have to work as hard. That saves you real money on your electricity bill. A flimsy, uninsulated lid is just an energy leak.

High-Quality Gaskets: The magnetic seal around the doors and drawers—the gasket—is absolutely critical. A tight seal keeps the cold air in. A cracked or worn-out gasket is like leaving your fridge door cracked open all day, leading to food safety problems and eye-watering energy costs.

Removable Pan Rails: Cleaning the ingredient rail is a daily chore, no way around it. Models with removable stainless steel pan rails make this job so much easier. You can lift the whole assembly out to wipe down the interior, stopping grime and bacteria from building up in those pesky, hard-to-reach corners. To see how these features come together in a pro setup, check out our guide on how to prep like a pizza pro with these topping stations.

Comparing the Top Pizza Prep Table Brands

Stepping into the market for commercial kitchen gear can feel like walking into a crowded room where everyone is yelling. Every brand insists they’re the best, but when you’re talking about prep tables for restaurant kitchens—especially pizzerias—a few names always seem to cut through the noise.

Let’s skip the boring feature lists and talk about these brands based on how they fit the unique needs of a pizzeria.

Choosing a brand is about more than just the price tag. It’s like hiring a key employee; you need a long-term partner that can handle your pizzeria’s daily grind, fit your budget, and grow with you. The good news is that you're investing in a booming market. The global demand for food prep tables was valued at around USD 1.18 billion in 2023 and is projected to climb to USD 1.62 billion by 2029. You can get more details on the food prep tables market on Arizton.com.

True Manufacturing: The Unbeatable Workhorse

If you’ve been in a commercial kitchen, you’ve seen True. They are an absolute titan in the refrigeration world, and for good reason. Think of a True prep table as the unbeatable workhorse of your kitchen—it's built like a tank and engineered to just keep running, year after year, with almost no drama. Pizzeria owners who can't afford downtime often invest in True for its legendary durability.

Their pizza prep tables are famous for having powerful, oversized refrigeration systems. What this means for you is incredibly fast temperature recovery. During a brutal dinner rush when that lid is flying open and closed, a True table bounces back to a safe temperature almost instantly.

- Industry Reputation: Top-tier, hands down. Known for being bulletproof.

- Price Point: Premium. You're paying for that build quality and the peace of mind that comes with it.

- Best For: High-volume pizzerias that need equipment they can rely on, day in and day out, no questions asked.

Turbo Air: The Smart Innovator

Turbo Air has smartly carved out its own space by zeroing in on smart design and energy efficiency. If True is the gritty workhorse, then Turbo Air is the smart innovator, always adding clever features that actually make a difference in a real-world pizzeria.

Their standout feature has to be the self-cleaning condenser system. A small rotating brush automatically whisks away dust buildup from the coils. It’s a simple but brilliant idea that helps the unit maintain peak efficiency, trims your energy bills, and cuts down the risk of a compressor burnout—a massive headache for any busy pizzeria.

Turbo Air's focus on practical innovation sets it apart. Features like the self-cleaning condenser directly address major operational pain points, saving operators time on maintenance and money on utility costs.

Atosa: The Accessible Starter

For new pizzerias or any restaurant on a tighter budget, Atosa has become a go-to name. Atosa is the accessible starter brand. It delivers solid performance and all the essential features you need for making pizzas, but without that premium price tag. They've found a great sweet spot between quality and value.

Atosa's pizza prep tables use high-quality components you'd find in more expensive units, like Embraco compressors, and have a clean, functional design. While they might not have the decades-long reputation of a brand like True, they offer a reliable and affordable way to get professional-grade equipment into your pizzeria. It's a smart, practical choice for getting a new business off the ground.

Here’s a quick way to think about how these brands fit different pizzeria owners:

- True: For the seasoned operator who has been burned by cheap equipment before. They value longevity and will pay more upfront to avoid headaches and lower their long-term costs.

- Turbo Air: For the tech-savvy owner who geeks out on energy efficiency and loves smart features that make maintenance easier.

- Atosa: For the startup pizzeria or budget-conscious buyer who needs a dependable machine that gets the job done without breaking the bank.

At the end of the day, the "best" brand is simply the one that fits your operation, your budget, and your expectations for service.

Essential Maintenance to Protect Your Investment

Think of your pizza prep table as the engine of your kitchen. It runs hard, day in and day out. Just like you wouldn't drive a car without ever changing the oil, you can't run a prep table without consistent care. Proper maintenance isn't just a good idea—it's what separates a long-lasting, food-safe unit from one that's headed for a costly breakdown.

An actionable maintenance plan is your best defense against surprise repair bills and failed health inspections. By breaking down the work into simple daily, weekly, and monthly tasks, you can keep your prep table humming like it’s brand new. This isn't about adding more work; it's about protecting your investment and ensuring every pizza starts with the freshest, safest ingredients possible.

Your Daily Maintenance Checklist

These quick tasks should be part of your end-of-shift routine. They only take a few minutes but make a massive difference in hygiene and how well your table runs.

- Wipe Down All Surfaces: Grab a soft cloth and a mild detergent to clean every stainless steel surface, inside and out. A pro tip: always wipe in the direction of the steel's grain to prevent ugly scratches.

- Sanitize the Cutting Board: Scrape off any food debris, then give the cutting board a thorough wash and sanitization. This is your number one defense against cross-contamination.

- Clean Out Ingredient Pans: Pull all the ingredient pans from the rail. They need to be washed, sanitized, and completely dry before you refill them for the next service.

- Inspect and Wipe Door Gaskets: A quick wipe-down of the door and lid gaskets removes crumbs and spills. A clean gasket creates a tight seal, which is critical for keeping your energy bills down.

Weekly and Monthly Deep Cleaning

While daily wipe-downs handle the surface grime, the real secret to a long-lasting machine lies in deeper cleaning. These are the jobs that are easy to put off but are absolutely essential for preventing system failure. Neglecting them is one of the fastest ways to kill your prep tables for restaurant use.

A study of restaurant equipment failures revealed a stunning fact: over 50% of refrigeration service calls could be avoided with basic maintenance, especially regular condenser coil cleaning. In a pizzeria, this one task is your best defense against a burnt-out compressor.

For a more detailed schedule, including video tutorials and step-by-step instructions, check out our complete guide on essential maintenance to protect your investment.

Here’s a simple schedule to get you started:

- Check and Clean Condenser Coils (Monthly): In any pizza kitchen, a nasty mix of grease and flour dust loves to clog up condenser coils, forcing the compressor to work overtime. Make sure the unit is unplugged, then use a stiff brush or a vacuum to gently clean the coils.

- Clear Drain Lines (Monthly): Check that the condensation drain line is completely clear. If this line gets blocked, water will start pooling inside your unit, creating a major sanitation nightmare.

- Inspect Gaskets for Wear (Weekly): Here's a classic trick: the "dollar bill test." Close the door on a dollar bill. If you can pull it out with no resistance, the gasket is worn out and needs to be replaced. A bad seal wastes energy and puts your food in the temperature danger zone.

Got Questions About Pizza Prep Tables? We've Got Answers.

Jumping into the world of commercial kitchen equipment, especially for a pizzeria, brings up a ton of questions. Getting straight answers is the key to making a smart investment in your restaurant. Let's tackle some of the most common things people ask when buying and using pizza prep tables.

My goal here is to give you straightforward, no-nonsense answers so you can feel confident about your decision. Getting these details right ensures the prep table you choose will actually fit your kitchen's unique flow and make your life easier.

What’s the Real Difference Between a Pizza Prep Table and a Sandwich Prep Table?

It all comes down to one critical feature: the depth of the cutting board. A real-deal pizza prep table is built with a much deeper cutting board, usually somewhere between 16 and 19 inches. That extra space is absolutely essential for handling big pizza skins without sending your toppings all over the floor.

A sandwich or salad prep table, on the other hand, has a much skinnier board, typically around 10 inches deep. You’ll also notice that pizza tables often have a raised pan rail that angles the ingredient pans toward you, making it way easier to top pizzas in a hurry. Sandwich tables usually just have flat, recessed wells for their pans.

How Often Should I Be Cleaning the Condenser Coils?

In a standard commercial kitchen, cleaning the condenser coils every 90 days is a good rule of thumb. But pizzerias are a whole different ballgame. Your kitchen air is constantly filled with a fine mist of flour dust and grease particles.

Because of this unique environment, you really need to clean the coils on your pizza prep table every 30 to 60 days. When those coils get clogged, the compressor has to work overtime, jacking up your energy bills and dramatically increasing the risk of a premature system failure. Honestly, this is probably the single most important maintenance task you can do.

Are Drawers a Better Choice Than Doors for the Base?

The classic "drawers vs. doors" debate really boils down to what you plan to store and how your team works. Neither one is universally "better," but they're built for very different jobs in a pizzeria.

- Drawers are fantastic for organization and speed. They’re perfect for holding pans of pre-portioned dough balls, backup shredded cheese, or separated sauces. This setup gives you quick access without having to bend over and rummage through a dark cabinet.

- Doors offer more flexible, open storage. They're the better choice for bulky or awkwardly shaped items like large bags of flour, big ingredient containers, or boxes of supplies.

A lot of pizzerias find that a combination unit—one with both drawers and doors—gives them the best of both worlds: organized access for daily-use items and bulk storage for everything else.

Ready to build the perfect pizza assembly line for your kitchen? At Pizza Prep Table, we offer a wide selection of high-quality prep tables designed for the demands of a busy pizzeria. From compact units to large workstations, we have the right equipment to improve your workflow and protect your ingredients. Explore our collection and find your perfect fit today!