Commercial Kitchen Layout Design: A Complete Guide for Pizzerias

Share

A killer commercial kitchen layout design is so much more than just arranging equipment. It's the literal blueprint for your pizzeria's profitability. This plan dictates your speed of service, your staff's sanity, and even the quality of your pizza. It's the difference between success and struggle.

Your Pizzeria's Blueprint for Success

Long before the first order comes in, the success of your pizzeria is already being baked into its design. A thoughtful layout isn't just a floor plan; it's a high-performance system built for speed, safety, and peak performance. It's your silent partner working for you during the chaos of a Friday night dinner rush.

I like to think of a kitchen as an ecosystem where every single piece has to work in perfect harmony. The whole point is to create a logical flow that cuts down on wasted steps and maximizes output. For a pizzeria, that flow is everything.

The Foundation of Pizzeria Efficiency

At the heart of any great pizza joint is a workflow that just makes sense. The journey of an order—from dough to oven to box—should feel like a straight line, not a tangled mess of people crossing paths. This is where you get into strategic zoning, creating dedicated areas for each stage of production.

A poorly planned kitchen is just chaos waiting to happen. Staff members bump into each other, ingredients are a marathon away, and precious seconds are lost on every single pie. Those seconds add up fast, leading to longer wait times, unhappy customers, and a team that’s completely burned out.

A well-designed kitchen can boost productivity by as much as 50%. It’s not just about telling your team to work harder; it’s about giving them an environment where they can work smarter, safer, and faster.

This one principle separates the struggling kitchens from the streamlined, money-making machines.

Why Your Pizza Prep Table Is the Command Center

For any pizzeria, the pizza prep table is the command center of the entire operation. Full stop. It's where raw ingredients become the final product, and the placement of this one piece of equipment can make or break your entire workflow.

An effective layout puts everything your pizza makers need within arm's reach:

- Refrigerated Toppings: Cold rails keep cheese, pepperoni, and veggies at safe temps and ready to go.

- Dough Storage: The dough press or sheeter should be right there. No wasted steps fetching the base for the next order.

- Sauce and Spices: Everything needed to build the pizza has to be organized on or around that prep table.

When you position the prep table correctly, you create an ergonomic "triangle" between the dough station, the prep area, and the pizza oven. This simple geometry minimizes movement, reduces physical strain on your staff, and shaves critical time off every single order. While this guide is all about pizzerias, you can find great broader principles for efficient commercial spaces in resources detailing creative coffee shop design ideas.

Ultimately, a superior commercial kitchen layout for a pizzeria is built around this central hub. It ensures a seamless production line that keeps up with customer demand and fuels your restaurant’s growth.

Designing Your Pizzeria's Production Zones

An efficient pizzeria isn't just a kitchen; it’s a production line. The real secret to a smooth operation is a smart commercial kitchen layout design built around dedicated zones. When you map out a logical workflow—from ingredient delivery to the final hand-off—you slash bottlenecks and eliminate wasted steps.

An efficient pizzeria isn't just a kitchen; it’s a production line. The real secret to a smooth operation is a smart commercial kitchen layout design built around dedicated zones. When you map out a logical workflow—from ingredient delivery to the final hand-off—you slash bottlenecks and eliminate wasted steps.

Think of it as creating a one-way street for your pizza. This approach doesn't just get pies out the door faster; it also cuts down on staff fatigue and, critically, prevents cross-contamination.

The Foundation: Receiving and Storage

Everything starts at your back door. This receiving zone has to be clean, bright, and right next to your storage. You can't have a delivery driver hauling supplies through the middle of the kitchen during a dinner rush. It's chaotic and a major safety hazard.

Your dry storage racks, walk-in cooler, and freezers need to be as close to that receiving door as possible. This simple placement makes a huge difference when your team is unloading heavy boxes of cheese, flour, and produce, making stock-takes faster and less of a workout.

- Dry Storage: This is for your flour, sugar, canned goods, and spices. Keep it on sturdy, organized shelves and label everything. No excuses.

- Cold Storage: Your walk-in and reach-in fridges are for the perishables—cheese, meats, fresh veggies. Organization here is non-negotiable for both food safety and speed.

The Starting Point: Dough Preparation

With your ingredients properly stored, the first real step is making the dough. Let's be honest, the dough prep zone is a flour-dusted mess by nature. It's smart to give this area a bit of separation to keep that flour cloud from settling over everything else.

This station is home to your big commercial mixer, a tough work table for balling up dough, and any dough presses or sheeters you use. Position it logically between your dry storage (for easy access to flour) and the cooler where the dough will proof. Keeping these things close creates a neat little loop for your prep cook.

I once walked into a kitchen where the dough mixer was on the opposite side from the flour storage. I watched a cook lug a 50-pound bag of flour across the busiest part of the kitchen. It’s a recipe for spills, delays, and back injuries.

A smart layout clusters these elements together. This is a great time to review a guide on essential commercial food prep equipment to make sure you have the right tools from the start.

Grand Central Station: Topping and Assembly

This is where the magic happens and where every second counts. Your topping and assembly zone is anchored by the most important piece of gear in the whole place: the pizza prep table. This station is the command center, bridging the gap between a proofed dough ball and a trip to the oven.

A well-set-up pizza prep table gives the pizzaiolo everything they need within arm's reach. We're talking refrigerated rails packed with toppings, under-counter refrigeration for backup supplies, and a wide cutting board for assembly. The flow should feel natural: dough comes in from one side, gets sauced and topped, and moves off the other side, straight to the oven.

The relationship between the prep table and the oven is critical. They must be next to each other. Every extra step a cook takes carrying a pizza is wasted time that adds up to serious delays over hundreds of orders.

The Finishing Touches: Cooking and Warewashing

The cooking zone is pretty straightforward—it’s dominated by your pizza oven. This area needs proper ventilation and fire suppression systems to meet local codes. Just as important is a "landing zone," which is just a heat-proof counter where hot pizzas can be placed for cutting and boxing.

Finally, the warewashing station, or dish pit, should be the last stop in the kitchen's flow. Keep it far away from food prep and cooking areas to stop dirty dishes from contaminating clean surfaces. A three-compartment sink and a commercial dishwasher are the standard here. A good layout ensures dirty dishes go in one way and clean dishes come out another, ready to be stored and reused.

This kind of detailed planning directly impacts your bottom line. A well-designed kitchen can boost productivity by up to 50% just by improving workflow. On the flip side, the U.S. Bureau of Labor Statistics reported 93,800 nonfatal injuries in full-service restaurants in one year, many of them cuts and burns made worse by cramped, poorly designed spaces. By zoning your pizzeria correctly from day one, you build a safer, faster, and more profitable business.

The Pizza Prep Table: Your Kitchen's Command Center

In any pizzeria worth its salt, the pizza prep table is the undisputed heart of the entire operation. It’s not just a hunk of stainless steel; it’s the command center where raw ingredients become delicious, finished pies. The placement, size, and features of this table can either create a seamless, high-speed production line or a chaotic bottleneck that grinds every order to a halt. A truly commercial kitchen layout design for a pizzeria is built around this single, critical station.

The first decision you'll make is choosing the right table, and it starts with size. This isn't a "one size fits all" situation. The size you need is directly tied to your menu's complexity and your projected sales volume. A small slice shop with a handful of toppings might get by with a compact 44-inch unit. But if you're a high-volume restaurant with dozens of topping combinations, you’ll need a much larger 93-inch workstation to keep up during a rush without constant restocking.

Selecting the Right Features for Your Workflow

Beyond just the physical footprint, the features of your pizza prep table are what really dictate its day-to-day usefulness. The refrigeration system is a huge one. Most good tables have refrigerated wells—we call them "rails"—on top to keep toppings cold and within arm's reach, plus under-counter refrigerated cabinets for backup storage.

The cutting board surface also matters more than you might think. A deep, full-length poly cutting board gives your pizza makers plenty of room to stretch dough and assemble pies without feeling cramped. Trust me, a worn or undersized board can slow down the whole process and create a lot of frustration for your crew.

A well-equipped prep table acts as a self-contained workstation. When everything a pizzaiolo needs is within a one-step radius, they can enter a state of "flow," building pizzas with incredible speed and consistency. This ergonomic efficiency is the goal.

Thinking through these details is what separates a smooth operation from a clumsy one. For a deeper dive into different models and what they offer, you can explore this guide that explains everything about restaurant kitchen prep tables and their specific features.

Choosing the right features from the get-go saves a lot of headaches down the road. Here's a quick comparison of what to look for.

Pizza Prep Table Feature Comparison

| Feature | Benefit for Pizzeria Workflow | Consideration |

|---|---|---|

| Refrigerated Rail Size | Holds more toppings, reducing restock trips during peak hours. | Larger rails mean a larger overall unit footprint. Match it to your menu complexity. |

| Deep Cutting Board | Provides ample space (19"+) for stretching large pizza doughs. | A deeper board can make reaching the back of the rail slightly harder for shorter staff. |

| Undercounter Storage | Keeps bulk backups (cheese, dough) cold and immediately accessible. | Drawers are faster for pre-portioned items; doors are better for bulky containers. |

| Ergonomic Height | Reduces staff fatigue and strain during long shifts. | Standard heights work for most, but adjustable leg options offer more flexibility. |

Ultimately, each feature should serve one purpose: to make your team's job faster and easier.

Strategic Placement for Maximum Speed

Once you've picked your table, where you put it is the next make-or-break decision. The sweet spot creates an ergonomic "work triangle" between three key points: the dough station (mixer/sheeter), the pizza prep table, and the oven. This trio needs to be in a tight, logical sequence to kill any wasted motion.

Your cook should be able to turn from the dough sheeter, slap the dough on the prep table, build the pizza, and then pivot to slide it into the oven—all in just a few steps. Any extra distance they have to travel between these stations is time bleeding out of your ticket times. Over a busy night, those lost seconds pile up into serious delays and fewer pizzas out the door.

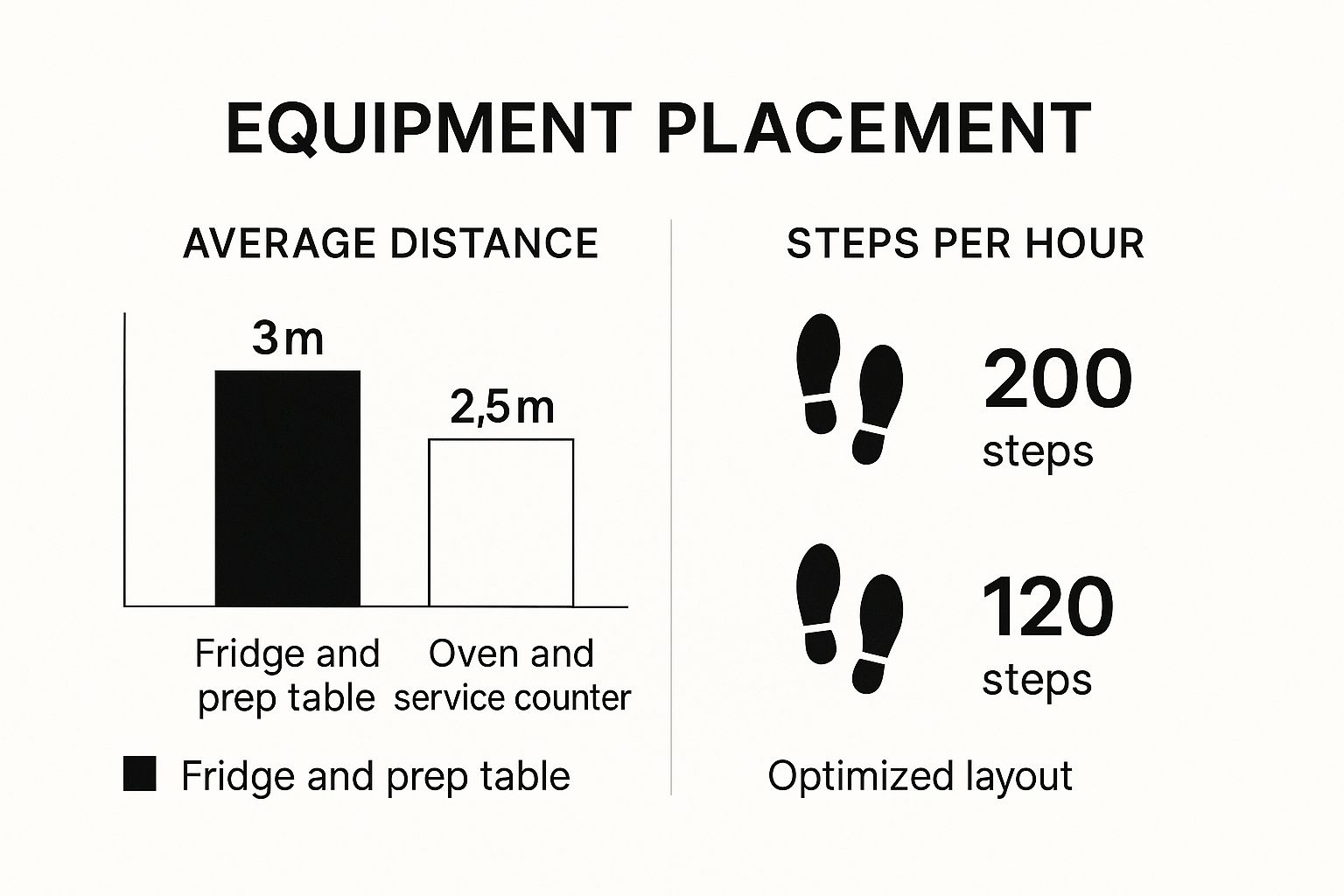

This visual shows just how much small placement changes can impact staff movement and boost efficiency.

The numbers don't lie. An optimized layout that shortens travel distances can slash the number of steps a cook takes per hour by nearly 40%. That translates directly to less fatigue and faster tickets. It’s that simple.

Organizing the Prep Table for Peak Performance

Finally, how you organize everything on and around the prep table is just as crucial as its physical location. A well-organized station ensures every topping, sauce, and dough ball is intuitively placed to keep your pizza makers in constant motion.

Think like an assembly line. The workflow should move in one clean direction, usually left-to-right (or right-to-left, depending on your kitchen's flow).

- Start: Dough arrives at one end of the table.

- Middle: Sauces and cheeses go on first, followed by your most popular toppings. These should be in the most accessible part of the refrigerated rail.

- End: The finished pizza comes off the other end, ready for the oven.

This assembly line method minimizes crossed arms and confusion, which is especially important when you have multiple cooks working the line. Your under-counter refrigeration should be just as logical. Keep backup pans of high-use items like cheese and pepperoni stored directly below their counterparts in the top rail. This makes mid-service restocking a quick, seamless task instead of a frantic search party. By focusing on these granular details, you turn your pizza prep table from a simple counter into a powerful engine for productivity and profit.

Mapping Your Workflow and Equipment Placement

Alright, you've got your zones blocked out. Now comes the real art of commercial kitchen layout design: digging into the details of movement and access. A truly great kitchen feels intuitive, and that happens when every single piece of equipment has a perfect spot.

The whole point is to design a space where every step is deliberate. You want to eliminate wasted motion, making your team faster, safer, and ultimately more productive.

When it comes to pizzerias, this usually boils down to two main layout styles: the assembly line and the island. Each has its own rhythm and works best for different spaces and service volumes. The right choice depends entirely on how your team will actually build pizzas during a chaotic Friday night rush.

Choosing Your Pizzeria's Layout Style

The assembly line layout is the undisputed champion for high-volume pizzerias. It’s exactly what it sounds like: equipment and stations are arranged in a logical, linear sequence. This is the ultimate setup for raw speed and consistency, as each pizza moves methodically down the line from one task to the next.

Just picture the flow. Dough comes out of the cooler to the sheeter, then glides onto the pizza prep table for saucing and topping, and finally slides right into the oven. It's a straightforward path that's incredibly efficient and super easy for new hires to master.

On the other hand, you have the island layout. This style centers a key function—often cooking or prep—in the middle of the kitchen, with other stations orbiting around it. For a pizzeria, this could be a large, central prep table where multiple cooks work side-by-side, or maybe the pizza ovens themselves become the island focal point. It's a fantastic design for fostering communication and flexibility, but be warned: it eats up more floor space and can create traffic jams if not planned carefully.

Strategic Placement of Key Pizzeria Equipment

With a layout style in mind, it's time to start placing your core equipment. This isn't just a game of Tetris; it's about choreographing a dance where every move is efficient.

- Dough Mixer and Walk-In Cooler: Your mixer should live right next to your dry storage for easy access to flour. Just as critically, it needs to be a short trip to the walk-in cooler where your dough will proof. Forcing staff to lug heavy dough trays across a busy kitchen is a classic recipe for inefficiency and accidents.

- Pizza Ovens: The oven is the heart of your pizzeria. It absolutely must be positioned directly adjacent to the assembly or prep station. The person loading the oven should be able to do it with a simple pivot, not by taking several steps. This tiny detail saves an incredible amount of time over a full shift.

- Dishwasher: The warewashing station should be the final stop in the kitchen's circuit, tucked away from the main production line. You need a clear, one-way path for dirty dishes to come in and a separate path for clean ones to go out, preventing any cross-contamination with your pizza prep areas.

I once consulted for a pizzeria where the walk-in cooler was at the far end of the kitchen—a 30-foot walk from the prep line. The cooks were wasting nearly an hour per shift just walking back and forth. We reorganized the layout to bring the dough's journey down to just a few feet, and their ticket times dropped by almost 20%.

Smart storage is another piece of the puzzle. Using durable heavy-duty storage racks for bulk ingredients and equipment can dramatically improve organization and keep your workflow humming.

The Non-Negotiables You Can't Ignore

Beyond workflow, some equipment placement is simply dictated by safety and building codes. These are the things you have to plan for from day one, or you’ll face expensive and frustrating revisions down the road.

Ventilation and Fire Suppression Your pizza ovens, fryers, and griddles are all going to need a commercial ventilation hood. This isn’t a suggestion; it’s a legal requirement. The hood's size and placement will fundamentally determine where your primary cooking line can even go. Integrated fire suppression systems are also mandatory over most cooking equipment, and their installation has to be planned from the very beginning.

Utility Access Every piece of equipment has needs. Your dough mixer needs a high-voltage electrical outlet, your sinks need plumbing, and your gas-fired ovens demand a dedicated gas line. Mapping these utility connections onto your floor plan before construction starts is absolutely essential. Trust me, trying to add a floor drain or move a gas line after the concrete is poured is a costly nightmare you want to avoid.

This level of detailed planning is part of a bigger trend toward smarter, more efficient kitchens. In fact, the global commercial kitchen market is projected to grow by USD 1.00 billion between 2024 and 2028, largely driven by investments in optimized layouts and energy-efficient tech. By thinking through these details now, you're creating a commercial kitchen layout design that's not only fast but also safe, compliant, and built for the future.

Navigating Health Codes and Safety Regulations

A brilliant commercial kitchen layout design is completely worthless if it doesn't pass inspection. You can map out the most efficient workflow imaginable, but if it violates local health and safety codes, you’re staring down costly delays, expensive retrofits, and maybe even a failure to open.

Building compliance into your design from day one isn't just a good idea—it's non-negotiable.

Health inspectors have a sharp eye, and they scrutinize everything. They aren't just looking for general cleanliness; they’re checking for precise measurements and required placements that directly impact food safety. For a pizzeria, this scrutiny often starts with the flow around your pizza prep table.

What Health Inspectors Scrutinize Most

Inspectors live by a detailed checklist, and knowing their priorities is half the battle. They will physically measure the space between equipment to ensure there's enough room for thorough cleaning. A common rule of thumb is a minimum of 36 inches for main traffic aisles, but they'll also check the clearance behind and beside your cookline and prep stations.

They also zero in on the placement and number of sinks. You need dedicated sinks for specific jobs, and their locations are strictly mandated.

- Hand-Washing Sinks: These are required in prep areas and warewashing stations. An inspector will check that they are easily accessible to staff and not blocked by equipment or supplies.

- Three-Compartment Sink: This is your workhorse for washing, rinsing, and sanitizing dishes and equipment. It must be kept separate from food prep areas to prevent splash contamination.

- Food Prep Sink: If you're washing vegetables or other raw ingredients, you’ll need a dedicated sink for just that purpose, located far away from the warewashing chaos.

A common pitfall I’ve seen is overlooking these sink requirements until it's too late. Trying to add plumbing to a nearly-finished kitchen is a financial and logistical nightmare you don't want.

Fire Safety and Material Regulations

Fire safety is another massive component of any kitchen inspection, especially in pizzerias with high-temperature ovens. Your local fire marshal has specific rules about ventilation and fire suppression that are literally baked into the building codes.

Every pizza oven, fryer, or griddle must be situated under a properly sized commercial ventilation hood with an integrated fire suppression system. This isn’t a DIY job; it requires professional installation and regular inspections. The location of this hood will dictate the placement of your entire cooking line, so it has to be one of the very first things you plan in your commercial kitchen layout design.

An inspector once told me the easiest way to fail an inspection is to ignore material choice. They look at everything from the coving on the floor to the finish on the walls. Choosing non-porous, easy-to-clean surfaces isn't a suggestion; it's a requirement.

Floors must be durable, and walls behind cooking equipment often need to be stainless steel or another non-combustible material. Beyond the big stuff, the smaller details matter, too. For instance, using the right non-slip restaurant mats is crucial for preventing slip-and-fall hazards in a fast-paced kitchen. These are the details that ensure you operate both legally and safely. To get a better handle on your responsibilities, review these food safety guidelines for restaurants that cover a wide range of critical topics.

Integrating Accessibility Standards

Finally, a truly safe kitchen is one that’s accessible to every employee. The Americans with Disabilities Act (ADA) sets clear standards for workplace accessibility, including things like minimum aisle widths and ensuring workstations can accommodate employees with disabilities.

Building these standards into your design from the get-go isn't just about compliance—it's about creating a more inclusive and functional work environment for your entire team.

Common Pizzeria Layout Questions Answered

When you’re staring at a blank floor plan for your new pizzeria, a million questions start to bubble up. It's totally normal. After helping countless owners design their kitchens, I've noticed the same handful of questions pop up time and time again.

Let's dive into some of the most common sticking points and get you some clear, battle-tested answers.

"How Much Space Do I Really Need Between Equipment?"

This is always one of the first questions, and while your local building code gives you the bare minimum, real-world efficiency demands more.

For main walkways—the superhighways of your kitchen—you should shoot for 36 to 48 inches of clearance. This isn't just about meeting code; it's about function. It gives two people enough room to pass each other without doing that awkward shuffle, and more importantly, it lets you wheel a cart through to restock your pizza prep station during a chaotic dinner rush. Skimp on this, and you create instant bottlenecks.

"How Do I Choose the Right Size Pizza Prep Table?"

This question is huge, and getting it wrong is a classic rookie mistake. The answer depends entirely on your menu's complexity and your projected sales. Don't just cram the biggest table you can afford into the space. Be smarter than that.

- For Slice Shops & Limited Menus: A nimble 44-inch to 60-inch unit is often your best bet. It holds all your core toppings without eating up precious floor space in a tight kitchen.

- For High-Volume Restaurants: If you're planning a massive menu with a dozen or more toppings and expect lines out the door, you need a bigger command center. We're talking something in the 72-inch to 93-inch range. Go smaller, and your team will spend half the night running back and forth to the walk-in to restock the topping rail, killing your ticket times.

Think of your pizza prep table as the heart of the operation. Its size needs to match the intensity of the service it's going to face.

"Can My Pizza Oven Go Directly on Any Floor?"

Absolutely not. I can't stress this enough—this is a massive safety and compliance issue. Your powerful deck or conveyor oven generates an incredible amount of heat. Because of this, it almost always needs to sit on a non-combustible floor, which usually means a concrete slab.

Pro Tip: Most local fire marshals also require specific fire-resistant wall coverings, like stainless steel, extending at least 18 inches around the oven. Never, ever guess. Get your fire marshal on-site early to confirm the requirements before you finalize your oven's location.

Ignoring this can get your project shut down by a failed inspection or, far worse, lead to a fire. It’s a foundational piece of your design puzzle that has to be solved right at the start. It's no surprise that the market for professional kitchen design services is booming—it was valued at around USD 16.83 billion in 2023. Getting this expertise on your side is critical. You can see more about how this market is growing by reviewing the latest industry research.

Getting these details right from day one saves a world of pain, costly changes, and operational friction down the road. A well-planned kitchen isn't just an expense; it's a direct investment in your pizzeria's speed, safety, and profitability.

Ready to build the heart of your pizzeria? Pizza Prep Table offers a massive selection of high-quality refrigerated prep tables to anchor your perfect workflow. Find the ideal model for your volume and menu at https://pizzapreptable.com.