How to Choose the Best Deep fryer commercial for Your Pizzeria

Share

A high-quality deep fryer commercial unit is more than just another piece of kitchen equipment; it's a strategic investment that can completely change your pizzeria's menu and bottom line. By adding perfectly fried appetizers, sides, and even desserts, you move beyond just pizza, seriously boosting your average ticket size and drawing in a much wider crowd.

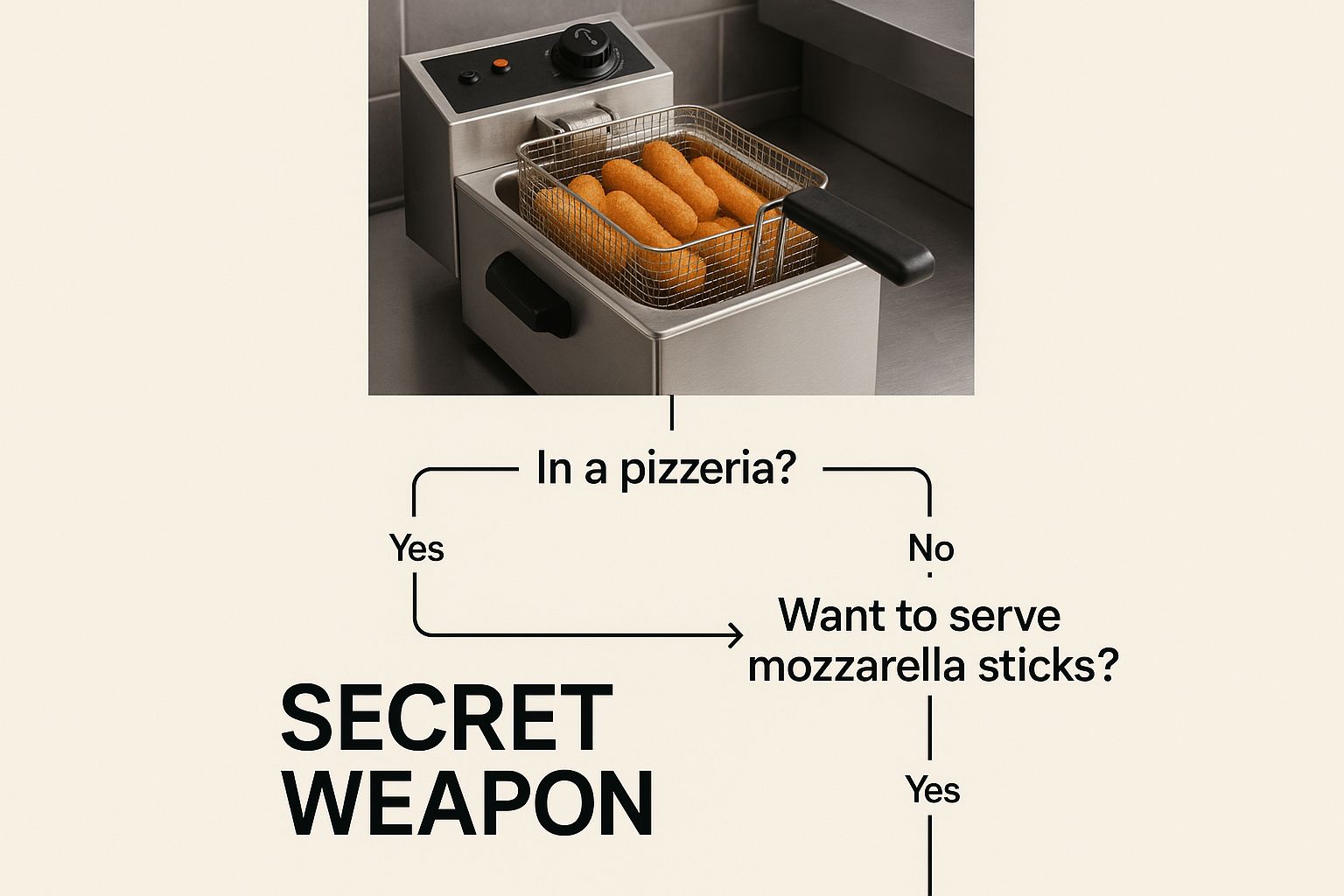

Why a Deep Fryer Is Your Pizzeria's Secret Weapon

Think about your core kitchen lineup. The pizza oven is obviously the star of the show, and the pizza prep table is where the magic begins. A commercial deep fryer is the essential supporting actor that makes the whole performance a hit. While your pizza prep table is busy crafting perfect pies, a fryer works right alongside it, helping you build a more complete and profitable menu.

This one piece of equipment can turn your pizzeria into a one-stop shop for a full meal, not just the main course.

Adding a fryer diversifies your menu in an instant. Suddenly, you can offer those crowd-pleasing appetizers that are not only fast to cook but also carry some seriously high-profit margins.

- Classic Appetizers: Crispy mozzarella sticks, golden-brown onion rings, and spicy jalapeño poppers are no-brainers that customers already love and look for.

- Wings and Tenders: Offering chicken wings with a variety of sauces can attract a whole new group of diners who might not have been in the mood for pizza.

- Specialty Items: You can even get creative with things like fried ravioli, calamari, or sweet desserts like zeppoles, setting your menu apart from every other pizza joint in town.

This infographic really drives home how a deep fryer becomes a pivotal tool in a pizzeria's kitchen.

As you can see, this isn't just about frying things. It's about strategically building a more robust and profitable menu from the ground up, all starting from the workflow you've established at your pizza prep table.

Expanding Your Revenue Streams

The financial impact of adding a deep fryer is huge. Appetizers and sides have a knack for dramatically increasing the average check size. A table that was just going to order a couple of pizzas might easily add an order of wings and fries, boosting that single sale by 25-40%. This isn't just a small bump; it’s a fundamental shift in your revenue potential.

The growing demand for fried foods makes this a smart move. The global market for commercial deep fryers was valued at around USD 0.504 billion in 2025 and is expected to hit USD 0.94 billion by 2034, growing at a steady clip of about 7.21% each year. This trend shows that the public's love for fried favorites isn't going anywhere. You can learn more about the commercial deep fryer market growth and what it means for your business.

By integrating a deep fryer, you're not just adding equipment; you're adding entire categories to your menu. This allows you to capture more spending from each customer and improve your overall profit margins on every single order that leaves your kitchen. It's a powerful tool for growth that works perfectly in sync with your pizza prep table and oven.

Choosing Your Fryer Type: Gas vs. Electric Models

Picking the right commercial deep fryer for your pizzeria is a bigger decision than you might think. It's not just about finding a model that fits next to your pizza prep table. This is a strategic choice that digs right into your kitchen’s workflow, your monthly utility bills, and even how crispy your mozzarella sticks turn out.

Think of it like choosing between a classic deck oven and a modern conveyor oven. Both get the job done, but how they do it—and what it costs you—are worlds apart. The first fork in the road is deciding between gas and electric power. Let's break down what that really means for your pizzeria during a Friday night rush.

The Power and Speed of Gas Fryers

Gas fryers are the undisputed heavyweights in most commercial kitchens. Hooked up to a natural gas or propane line, they are absolute beasts when it comes to heating up oil fast. More importantly, they bounce back to temperature almost instantly after you drop in a basket of frozen wings.

This rapid temperature recovery is their superpower. Imagine you’ve just pulled a big order of fries and another ticket immediately prints for more. A gas fryer gets that oil back up to the perfect 350°F in a flash, preventing that next batch from getting greasy and soggy. That’s how you get a consistently crispy product, order after order.

- Heats Up Fast: Gets to cooking temperature quicker at the start of the day, so you’re ready to go sooner.

- Recovers Quickly: Absolutely essential for maintaining quality during high-volume rushes.

- Lower Running Costs: In most places, natural gas is a lot cheaper than electricity, which you'll see on your monthly utility bill.

The trade-off? Gas fryers need professional installation for the gas line and a proper ventilation hood, which adds to the upfront cost. To see some models that are a great fit for a pizza shop, you can cook like a pro with these commercial gas deep fryers.

The Simplicity and Efficiency of Electric Fryers

Electric commercial deep fryers play a different game, one focused on convenience and pinpoint efficiency. Installation is often as simple as plugging it in. Because their heating elements sit directly in the oil, almost all the energy you're paying for goes straight into heating, with less heat escaping into your already-hot kitchen.

This efficiency makes them a smart pick for kitchens where running a gas line is impossible or just too expensive. And while they've historically been a bit slower on temperature recovery, modern high-end electric models have closed that gap considerably.

For pizzerias adding a fryer for the first time, electric models are often the way to go. Their plug-and-play setup and efficient energy use offer a practical path to expanding your menu without needing a major kitchen renovation, making them an easy addition near your pizza prep table.

The demand for these machines is huge, especially in North America where the restaurant scene is so vibrant. The commercial segment of the deep fryer market is a big part of why the entire market was valued at around USD 573.63 million in 2024. And it's not slowing down—forecasts show it growing to USD 723.90 million by 2033, a clear sign that more and more kitchens are adding fried foods to their menus.

Commercial Deep Fryer Comparison for Pizzerias

Deciding between gas, electric, countertop, or floor models can be tough. This table breaks down the key factors to help you match the right fryer to your pizzeria's specific needs, from your kitchen's layout to how many orders of wings you expect to sell on game day.

| Fryer Type | Best For | Key Advantage | Consideration |

|---|---|---|---|

| Gas Fryer | High-volume pizzerias with steady appetizer sales. | Unbeatable temperature recovery for back-to-back orders. | Requires professional gas line installation and ventilation. |

| Electric Fryer | Kitchens without gas access or those with lower-volume needs. | Easy plug-and-play installation and high energy efficiency. | Slower temperature recovery compared to gas models. |

| Countertop Fryer | Small kitchens or pizzerias just starting to offer fried items. | Space-saving design, can fit on a pizza prep table. | Limited capacity; not suitable for high-volume service. |

| Floor Fryer | Busy restaurants planning for high sales of fried foods. | Large oil capacity to handle a constant stream of orders. | Takes up significant floor space and requires more oil. |

Ultimately, your choice should be a practical one. A high-powered gas floor fryer is overkill if you only sell a few orders of fries an hour, while a small electric countertop model will quickly become a bottleneck in a busy restaurant.

Countertop vs. Floor Models

Your final choice comes down to size and volume. A countertop deep fryer is a fantastic solution for pizzerias tight on space or just dipping their toes into the fried appetizer game. It can sit right on a work table or even a stainless steel pizza prep table, uses less oil, and is perfect for a small, focused menu.

On the other hand, a floor model deep fryer is built for war. If you know you're going to be selling a ton of wings, fries, and jalapeño poppers, a floor model with its large oil tank and multiple baskets is the only way to keep your kitchen from grinding to a halt during the dinner rush. Base this decision on a realistic look at your sales projections and the actual square footage you have to work with.

Critical Features for a Pizzeria Fryer

Once you've settled on gas versus electric, the real fun begins. Now we get into the details that separate a basic hot oil tank from a true money-making machine for your pizzeria. It’s not just about heating oil anymore. The right features are make-or-break in a fast-paced kitchen, where every second counts and you're juggling orders from the pizza prep table to the oven and the fryer all at once.

Think of these features as the performance upgrades for your kitchen. They're designed to slash your oil costs, make sure every mozzarella stick comes out perfectly golden brown, and free up your staff to focus on the pizzas that are the lifeblood of your business.

The Financial Power of Oil Filtration

If there's one feature I tell every pizzeria owner to invest in, it's a built-in oil filtration system. It might feel like a luxury add-on, but trust me, it's one of the most powerful cost-saving tools you can have. Frying oil is a huge recurring expense, and a good filtration system can extend the life of your oil by up to 50%.

Imagine a system that works like a high-tech coffee filter for your fryer. At the end of the night, instead of your crew dealing with a messy, dangerous, and time-consuming manual filtering process, they just flip a switch. The fryer automatically drains the hot oil, runs it through a filter that catches all those tiny burnt particles of breading and food, and pumps clean, fresh oil right back into the tank. It's ready to go for the next shift.

This simple routine pays off in a few huge ways:

- Massive Cost Savings: Using oil longer means buying it less often. This directly cuts down your supply costs, and the savings add up fast.

- Consistent Food Quality: Clean oil just makes better-tasting food. Your fried calamari and onion rings will taste fresh, not like the ghosts of yesterday's lunch rush.

- Improved Staff Efficiency: Automating this messy job frees up valuable labor time that your team can spend on other end-of-night cleaning and prep, like restocking the pizza prep table.

Understanding Burner Styles: Open-Pot vs. Tube

The way a fryer heats its oil makes a massive difference, especially when it comes to the dreaded task of cleaning it. The two main designs you'll run into are open-pot and tube-type fryers.

An open-pot fryer has its heating elements on the outside of the fry tank. This leaves the inside of the pot completely smooth and unobstructed. Why does that matter? It's incredibly easy to clean. There are no nooks or crannies for grease and sediment to hide. This design is perfect for lightly breaded items like french fries.

A tube-type fryer, on the other hand, has tubes running directly through the oil inside the tank, with the gas burners firing inside them. This design is a bit more efficient at transferring heat and is fantastic for heavily breaded items like fried chicken or mozzarella sticks. The sediment has space to fall down between the tubes into the cold zone. The trade-off is that cleaning around all those tubes is a much bigger chore.

For most pizzerias that are cranking out a mix of appetizers, an open-pot fryer with a solid cold zone is usually the most practical choice. It hits that sweet spot between great performance and the daily cleaning demands of a busy kitchen.

Essential Features for Consistency and Efficiency

Beyond filtration and burner types, a few other features can seriously level up your kitchen's workflow and the quality of your fried food.

First, a cold zone is non-negotiable. This is an area at the very bottom of the fry pot, below the heating elements, where the oil temperature is much lower. Crumbs and bits of breading naturally fall into this cooler zone, which keeps them from burning and making the rest of your oil taste nasty. A good cold zone is vital for extending oil life and keeping your food tasting great.

Next up are programmable controls. These are a game-changer for consistency. You can set precise cooking times and temperatures for everything on your menu. A cook just has to select the "wings" or "mozzarella sticks" button, drop the basket, and the fryer does the rest. Every single order comes out perfectly cooked, with no guesswork involved.

Finally, if you have the budget, consider automated basket lifts. This feature automatically pulls the baskets out of the hot oil the second the cooking cycle is done. It’s the ultimate defense against overcooking during a chaotic rush and lets your crew focus on other tasks—like boxing up those pizzas—without having to babysit the fryer.

Optimizing Your Kitchen Workflow and Safety

Where you park your new deep fryer commercial unit can completely make or break the rhythm of your kitchen. A thoughtless placement creates frustrating bottlenecks and traffic jams, but a strategic spot can make your whole operation run like a well-oiled machine. This is about more than just finding an empty corner; it’s about designing a workflow that supports your pizza line, not competes with it.

The goal is to build a dedicated frying station that works in harmony with your pizza production. A well-placed fryer cuts down on the steps your cooks need to take, dramatically lowers the risk of accidents, and prevents dangerous cross-contamination between raw and cooked foods.

Designing the Perfect Frying Station

Think of your kitchen like a highway system during rush hour. The path from the pizza prep table to the oven is one lane, and the route from the freezer to the fryer is another. If those lanes cross awkwardly, you get gridlock.

Ideally, your fryer should be right next to your main cooking line but have a bit of separation from where the pizzas are actually being built on the pizza prep table. This creates a logical flow where one cook can knock out appetizers without ever getting in the pizza maker's way.

Here’s a simple way to think about the layout:

- Ingredient Flow: The freezer or fridge holding your wings, fries, and mozzarella sticks should be just a step or two away from the fryer.

- Cooking Zone: The fryer itself needs to be under a proper ventilation hood, with a stainless steel landing table right next to it for baskets.

- Finishing and Plating: A small station next to the landing table for seasoning, saucing, and plating completes the loop.

This setup lets a cook grab, fry, and plate an order in a few efficient steps. It keeps movement to a minimum and productivity high, preventing the chaos of a cook running back and forth with dripping baskets.

A dedicated frying station isn't a luxury; it's a necessity for any pizzeria doing serious volume. It compartmentalizes tasks, reduces kitchen accidents by over 25%, and ensures your fried food quality stays consistent, even when the order screen is lighting up.

Non-Negotiable Safety Protocols

Let's be blunt: a commercial deep fryer holds gallons of oil heated to over 350°F. This makes safety your absolute, number-one priority. Ignoring safety protocols isn't just risky; it's a direct path to a kitchen fire, one of the most common and devastating disasters a restaurant can face.

First on the list is ventilation. Your fryer absolutely must be installed under a Type 1 commercial hood that has an integrated fire suppression system. In almost every jurisdiction, this is the law. The vent hood pulls greasy, hot air out of the kitchen, while the suppression system is your first line of defense if things go wrong. For a deep dive into the specifics, our guide on commercial kitchen ventilation requirements is a must-read.

Beyond the hardware, your people are your best defense. Staff training is critical. Your team needs to be drilled on how to safely operate the fryer, filter the oil, and—most importantly—how to react in an emergency. This means knowing exactly where the Class K fire extinguishers are and how to use them properly. To get everyone on the same page, investing in a comprehensive guide to food handler certification for your staff is one of the smartest moves you can make. A well-trained employee is the best safety feature you can have.

Fryer Maintenance and Smart Oil Management

A deep fryer commercial unit is a real workhorse in a pizzeria, but it's only as good as the care you give it. Think about it: just like your pizza oven needs regular attention to bake that perfect crust, your fryer needs a solid maintenance routine to pump out crispy, golden-brown appetizers day after day. Good habits aren't just about keeping things clean; they're a direct investment in your food quality, your equipment's lifespan, and your bottom line.

If you let it slide, you'll end up with greasy food, a smoky kitchen, and eventually, a call to the repair guy that's going to hurt. By setting up some simple daily, weekly, and monthly routines, you can protect your investment and keep it humming along for years. Even better, getting a handle on smart oil management will slash one of your biggest recurring supply costs.

Your Daily Cleaning Checklist

The bedrock of good fryer maintenance is what you do at the end of every single shift. Letting grease and old food particles sit in the oil overnight is the fastest way to ruin a batch of oil and create a miserable cleaning job for the next day. A few minutes of prevention makes a world of difference.

First thing's first: always turn the fryer off and let that oil cool down to a safe temperature before you do anything.

- Wipe Down Surfaces: Grab a food-safe degreaser and clean all the exterior surfaces. This prevents that sticky, grimy buildup that makes a kitchen look unprofessional.

- Clean the Baskets: Pull the fry baskets and give them a thorough wash with soap and hot water to get rid of any caked-on bits.

- Skim the Oil: Use a fine-mesh skimmer to fish out any floaties and larger food particles from the oil.

This whole process takes maybe five minutes, but it stops tiny messes from snowballing into big, greasy problems.

Mastering Smart Oil Management

Cooking oil is the lifeblood of your fryer, and learning how to manage it is one of the quickest ways to get your costs under control. Just dumping and refilling the vat every few days is like pouring cash right down the drain. The real goal is to extend the life of your oil without ever compromising the taste of your food.

The first step is filtering the oil, and you should be doing this every single day. Filtering gets rid of all those microscopic burnt crumbs and sediment that turn oil dark and give it that nasty, bitter flavor. If your fryer has a built-in filtration system, it’s as easy as flipping a switch. For manual filtering, you'll drain the cooled oil through a filter cone or machine into a clean stockpot, give the empty fry pot a good scrub, and then pour the filtered oil right back in.

Properly filtering your cooking oil every day can extend its usable life by up to 50%. This simple habit not only results in better-tasting food but also delivers significant savings on your operational costs over the course of a year.

Knowing When to Change Your Oil

Even with daily filtering, oil doesn’t last forever. Using it for too long will make everything from mozzarella sticks to wings taste off. You need to train your staff to recognize the warning signs of oil that's past its prime.

Here are the tell-tale signs it's time for a change:

- Dark Color: Fresh oil has a light, golden hue. If yours looks dark and murky, it’s done.

- Bad Smell: When oil goes bad, it gives off a sharp, rancid smell, even when it’s cool.

- Smoking: If you notice oil smoking at a lower temperature than it should, its smoke point has dropped. It needs to be replaced.

- Foaming: Seeing excessive foam bubble up on the surface when you drop food in is a dead giveaway that the oil has broken down.

Figuring out how to dispose of used oil is also a critical part of the job. All that grease needs somewhere to go, and our guide on grease trap sizing has the essential info you need to keep your plumbing clear and stay on the right side of local regulations. The deep fryer commercial market is huge—valued at around USD 583.92 million in 2024—which tells you just how many kitchens are tackling these same challenges. You can discover more insights about commercial fryer market trends to get a sense of the industry's scale.

Common Pizzeria Fryer Questions Answered

Even with the best plan, adding a deep fryer commercial unit to your pizzeria can stir up a lot of questions. From the daily grind to long-term strategy, getting straight answers is the key to making your new fryer a moneymaker, not a headache.

Think of this as your go-to guide for adding a fryer into your kitchen workflow, right alongside your pizza prep table and oven. We'll tackle the real-world stuff: oil management, choosing the right machine, and the critical safety features that let you fry with confidence.

How Often Should I Filter the Oil in My Fryer?

This is one of the most important questions I get, because the answer hits both your food quality and your wallet. The short answer is simple: you have to filter your fryer oil every single day.

Daily filtration isn't optional for a busy pizzeria. Throughout a shift, tiny bits of breading, batter, and food break off and swim around in the hot oil. If you leave them overnight, they burn. That turns your oil dark, makes it smoke, and gives everything you cook a nasty, bitter flavor.

Filtering the oil at the end of every single shift gets rid of all that gunk. This keeps your oil cleaner for way longer, making sure your mozzarella sticks and wings taste fresh every time. More importantly, this simple habit can extend the life of your cooking oil by up to 50%. That’s a huge saving on one of your most expensive supplies.

What Type of Oil Works Best for Pizzeria Appetizers?

Choosing the right cooking oil is a balancing act between cost, flavor, and how well it performs under pressure. For most of the classic pizzeria appetizers—fries, onion rings, breaded cheese sticks—you need an oil with a high smoke point and a neutral taste.

The smoke point is just the temperature where an oil starts to break down and smoke. Since most frying happens between 350°F and 375°F, you need an oil that can handle the heat without complaining.

Here are the top choices I see in successful pizzerias:

- Canola Oil: This is the crowd favorite for a reason. It's affordable, has a high smoke point (around 400°F), and a clean, neutral flavor that lets your food be the star.

- Peanut Oil: A classic for a reason, peanut oil has a super high smoke point (around 450°F) and adds a subtle, nutty flavor that a lot of customers love. The catch? It's pricier and you have to be mindful of nut allergies.

- Blended Vegetable Oil: Most food suppliers sell commercial-grade frying oils that are a mix of soybean, corn, and canola. These blends are engineered for stability and a long life in a commercial deep fryer, making them a super reliable and budget-friendly choice.

Steer clear of oils with low smoke points, like extra virgin olive oil or butter. They’ll just burn, ruining both your oil and your food.

My advice for a new pizzeria? Start with a high-quality canola or a blended vegetable oil. They give you the best mix of performance and value, so you can turn out consistently crispy, delicious appetizers without blowing your budget.

Can I Start with a Countertop Fryer or Do I Need a Floor Model?

This really comes down to two things: how much space you have in your kitchen and how many orders of wings you think you'll sell on a Friday night. Getting this right from the start saves a lot of frustration later.

A countertop deep fryer is a fantastic starting point if you're just dipping your toes into fried foods. They’re perfect for kitchens where floor space is gold, since they can sit on any sturdy prep table. They use less oil, which means lower startup costs, and they’re generally a bit easier to clean. If you only plan on selling a few appetizer orders an hour, a countertop model is a smart, low-risk way to get started.

But, if you're planning for fried items like wings and mozzarella sticks to be a big draw on your menu, a floor model deep fryer is the smarter long-term move. A floor model is built for war. It can handle a relentless dinner rush without breaking a sweat. Its bigger oil capacity and powerful burners mean the temperature bounces back fast, which is absolutely critical for cooking order after order without the food getting greasy and soggy.

Think of it like this: a countertop unit is your small dough mixer for making a few personal pizzas. A floor model is the 60-quart beast you need to get through a Friday night rush. Pick the tool that’s built for the job you expect it to do.

What Are the Most Important Safety Features I Should Look For?

When you’re working with gallons of oil heated to over 350°F, safety can't just be a footnote. Modern commercial fryers have some essential safety features that protect your staff, your kitchen, and your business.

Don't even consider a fryer without these features:

- High-Temperature Limit Switch: This is the big one. It’s a sensor that automatically kills the heat if the oil gets too hot (usually around 400°F). It's your first line of defense against a fire.

- Automatic Shut-Off: Many fryers will shut themselves down if they’re left on and unattended for too long, or if the oil level drops to a dangerous point.

- Integrated Filtration System: While we talk about filtration for saving money, it’s also a massive safety feature. A built-in system means your staff doesn't have to manually handle large buckets of scalding hot oil, which dramatically cuts down the risk of spills and serious burns.

And remember, safety goes beyond the fryer itself. Your deep fryer commercial unit absolutely must be installed under a proper commercial ventilation hood that has an up-to-date fire suppression system. Combine that with regular training for your team on how to use the fryer safely and what to do in an emergency, and you create a kitchen where everyone can work with confidence.

At Pizza Prep Table, we get it—the right equipment is the backbone of a great pizzeria. From heavy-duty floor fryers to space-saving countertop models, we’ve hand-picked a collection of commercial deep fryers to help you build out your menu and grow your business. Check out our collection and find the perfect fryer for your kitchen today.

Find your ideal commercial deep fryer at https://pizzapreptable.com.