Understanding Commercial Kitchen Ventilation Requirements for Pizzerias

Share

Let's be clear: your commercial kitchen ventilation requirements aren't just a box to check on a safety list. They are, without a doubt, the single most critical safety and operational system in your entire pizzeria. These systems are legally required to pull dangerous heat, grease, and smoke out of your kitchen, keeping your staff and customers safe while protecting your entire investment from a catastrophic fire.

Why Your Pizza Oven Needs Proper Ventilation

Think of your commercial kitchen ventilation as the lungs of your pizzeria. Just like you need to exhale, your kitchen must have a way to get rid of the intense byproducts created by high-temperature pizza ovens. Without a powerful and effective system, your kitchen rapidly turns into a dangerous, suffocating, and deeply unpleasant place to work.

The main job of that big stainless steel exhaust hood is to capture a nasty mix of heat, smoke, and grease-filled vapor right at the source—your pizza oven. This isn't just about keeping things comfortable; it's about aggressive fire prevention. All the grease vaporizing from cooking pizzas—especially pies loaded with meat and extra cheese—can build up inside your ductwork, creating a serious and highly flammable fire hazard.

Understanding the Core Safety Mandates

The rules that govern kitchen ventilation aren't just arbitrary red tape. They’ve been written by national safety experts to prevent disasters. For any pizzeria owner, there are two rulebooks you absolutely have to know:

- NFPA 96: This is the Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations. Think of it as the bible for managing grease and preventing fires in your pizzeria's ventilation system.

- International Mechanical Code (IMC): This code gets into the nitty-gritty, providing the specific construction and installation standards for all the mechanical systems in your building, including your exhaust hoods and fans.

Don't see these codes as obstacles. They're your partners in building a safe, successful pizzeria. This focus on safety is a huge deal globally, and strict regulations are a major reason the commercial kitchen ventilation market is growing so fast. Following standards like NFPA 96 is mandatory for clearing out pollutants and stopping fires before they start.

Oven Type Dictates Ventilation Needs

The kind of pizza oven you're running is the most important factor in figuring out your ventilation setup. There’s no one-size-fits-all answer here.

For any gas-fired or wood-fired pizza oven, a Type I exhaust hood is always required. These ovens produce a massive amount of heat, smoke, and greasy particles that absolutely must be captured by a specialized, fire-rated hood system.

Even some high-volume electric pizza ovens, which typically produce fewer emissions, might still need a Type I hood. The final call almost always comes down to your local fire marshal, who will look at your cooking volume and your menu. An electric oven that’s cranking out hundreds of pepperoni pizzas a day has very different needs than one just used for a bit of cheese bread.

Ignoring these commercial kitchen ventilation requirements isn't just a simple code violation—it’s a direct and serious threat to the safety of your staff and the future of your pizzeria.

Decoding The Rules of Kitchen Ventilation

Navigating the world of commercial kitchen ventilation requirements can feel like trying to decipher a secret language. But to keep your pizzeria safe and legally sound, you have to know the rules of the road. Think of it less like jumping through hoops and more like following a proven safety blueprint for your business.

For any pizzeria owner, there are three main sets of codes that all work together to govern your entire ventilation system. Getting a handle on these three pillars—NFPA 96, the International Mechanical Code (IMC), and your local codes—is the key to a smooth opening and a safe, headache-free operation for years to come.

NFPA 96: The Kitchen's Fire Safety Rulebook

First on the list is NFPA 96, which is short for the Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations. The simplest way to think of NFPA 96 is as your pizzeria’s dedicated fire safety rulebook. Its entire purpose is to manage the grease and flammable vapors that come off your cooking equipment to prevent fires before they can start.

This is absolutely critical for a pizzeria. High-heat pizza ovens, especially when you're cooking up greasy toppings like pepperoni and sausage, produce a surprising amount of grease-laden vapor. NFPA 96 lays out exactly how your hood, ducts, and exhaust fan must be built and maintained to handle all that grease safely.

A key mandate from NFPA 96 is the non-negotiable schedule for professional cleaning. For most pizzerias, which are considered moderate-volume cooking operations, the entire system—from the hood right up to the fan on the roof—must be professionally cleaned semi-annually. This isn't a friendly suggestion; it's a core requirement for fire prevention.

IMC: The Building's Instruction Manual

Next up is the International Mechanical Code (IMC). If NFPA 96 is the fire safety rulebook, then the IMC is the building's instruction manual. This code gets into the nitty-gritty engineering and construction standards for how your ventilation system is installed within the larger building structure.

The IMC is all about the mechanical details. It dictates things like:

- The proper gauge of steel required for your ductwork.

- How ducts must be continuously welded and sealed to be completely leak-proof.

- Specific requirements for where your exhaust fan is placed and its clearance from any combustible materials.

For example, the IMC will tell you precisely how your exhaust ductwork has to be routed through the building to the roof and how far it must stick out from property lines or fresh air intakes. Following the IMC ensures your system isn't just safe, but also structurally sound and properly integrated into your restaurant.

Local Codes: The Final Authority

Finally, and most importantly, we have your local health and fire codes. While the NFPA and IMC provide the national framework, your local city or county officials are the ones with the final say. They are responsible for enforcing these codes and often have the power to add their own, sometimes stricter, requirements based on local conditions.

Your local fire marshal is the person who will walk through your pizzeria, inspect your setup, and ultimately give you the green light to open your doors. They can, and often do, make judgment calls that go above and beyond the national standards.

For instance, national codes might not explicitly say you need a hood over a small, countertop conveyor oven you use for appetizers. However, your local fire marshal might see that it's located near your main pizza prep line and producing more grease than anticipated. In that scenario, they have the full authority to require a Type I hood for that specific appliance to ensure total kitchen safety. Always, always talk to your local officials early in the planning process to avoid expensive surprises down the road.

Choosing The Right Hood For Your Pizza Oven

Now that we’ve covered the rules of the road, it’s time to pick the right equipment for your pizzeria's specific commercial kitchen ventilation requirements. This isn’t about grabbing the biggest, shiniest hood on the market. It's about making a smart match between your exhaust hood and the actual heat, smoke, and grease your pizza ovens produce.

The whole decision really boils down to one critical distinction: Type I versus Type II hoods.

Think of it like this: you wouldn't use regular street tires on a monster truck that hauls gravel up a mountain all day. In the same way, you can't use a light-duty hood for a heavy-duty pizza oven. They're built for entirely different jobs.

Type I Hoods: The Heavy-Duty Grease Fighters

A Type I hood is your front-line soldier in the battle against grease. It's an absolute must-have for any cooking appliance that churns out significant grease, smoke, and those flammable vapors that give fire marshals nightmares. For a pizzeria, that means any gas-fired, wood-fired, or conveyor oven falls squarely into this category.

These hoods are purpose-built for serious fire protection. Their most important features include:

- Baffle Filters: These aren't just simple screens. They are thick, maze-like metal filters designed to aggressively rip grease particles out of the air before they have a chance to get into your ductwork and create a fire hazard.

- Integrated Fire Suppression System: By law, Type I hoods must have a built-in fire suppression system. This includes nozzles aimed directly at your pizza ovens, ready to extinguish a fire the moment it starts.

For most pizza ovens, these features are completely non-negotiable. They are the single most important line of defense against a grease fire—the most common and dangerous threat in any pizzeria.

Type II Hoods: The Heat and Steam Movers

On the other end of the spectrum, you have the Type II hood, which you might also hear called a condensate hood. Its job is much simpler: remove things like steam, heat, and moisture from the air. You'll typically see a Type II hood hanging over a commercial dishwasher or a small electric oven used only for proofing bread.

These hoods don't have the heavy-duty grease filters or fire suppression systems that their Type I cousins do. Because of this, they are only suitable for appliances that produce little to no grease. For the vast majority of pizzerias, a Type II hood just isn't going to cut it over the main pizza oven.

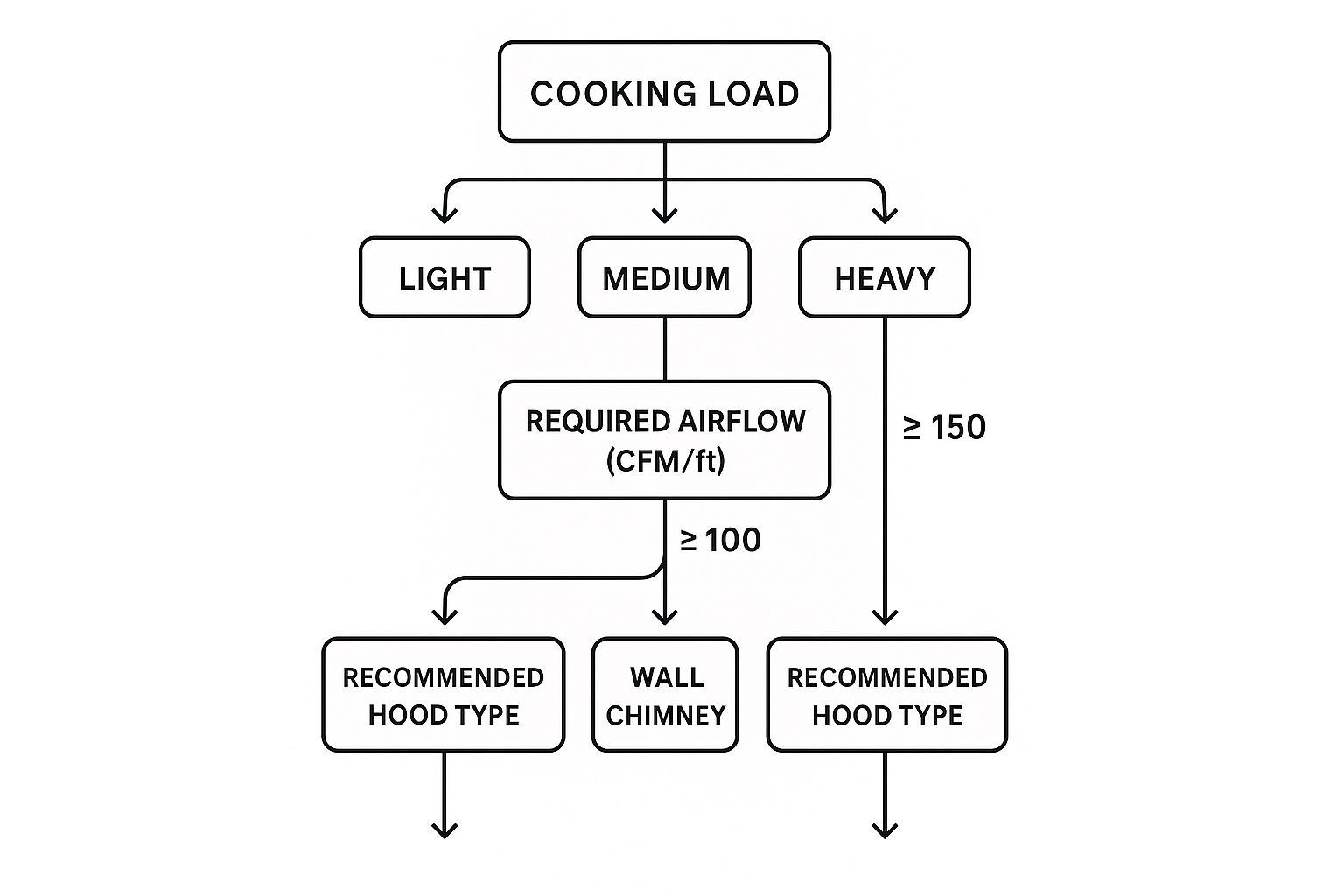

This decision tree helps visualize how the selection process works based on what you're cooking.

As you can see, the heavier your cooking load, the more robust your ventilation solution needs to be.

To help you quickly identify the right hood for your setup, here's a simple guide.

Exhaust Hood Selection Guide For Pizza Ovens

This table breaks down the common pizza oven types and the ventilation they typically require, helping you make a quick and informed decision.

| Pizza Oven Type | Typical Use Case | Primary Emission | Required Hood Type | Reasoning |

|---|---|---|---|---|

| Wood-Fired / Coal-Fired | Artisan pizzerias, high-heat cooking | Heavy smoke, grease, solid fuel embers | Type I | Produces high levels of grease and combustible byproducts, making fire suppression essential. |

| Gas Deck / Conveyor | High-volume pizzerias, consistent output | Moderate to heavy grease, heat | Type I | The volume of pizzas and toppings like cheese and meat generate significant grease-laden vapors. |

| High-Power Electric | Busy shops, all-day operations | Moderate grease, heat | Type I | High production, especially with greasy toppings, crosses the threshold for requiring grease removal. |

| Small Electric (Ventless) | Cafes, low-volume use | Low heat, minimal grease | Ventless (Internal System) | Certified ventless ovens have built-in filtration and are approved for use without a traditional hood. |

| Electric (Light-Duty) | Baking bread, re-heating only | Heat, steam | Type II | Only acceptable if zero grease-producing food is ever cooked in the oven. |

This guide makes it clear: for nearly all commercial pizza production, a Type I hood is the only safe and compliant choice.

The Electric Oven Dilemma: When To Choose a Type I

This is where I see a lot of pizzeria owners get tripped up. What about a big, powerful electric pizza oven? They don't have a live flame or produce the same thick smoke as a wood-fired oven, so a Type II should be fine, right? Not so fast.

An electric oven can still generate a shocking amount of grease, especially if you're loading it up with pepperoni, sausage, and extra cheese all day.

The rule of thumb is this: the grease output from your food, not the oven's fuel source, is the deciding factor. An electric oven cooking hundreds of meat-heavy pizzas a day will almost certainly generate enough grease to require a Type I hood to keep an inspector happy.

This reality is why we're seeing more investment in high-quality ventilation. The USA commercial kitchen ventilation market is projected to grow at a CAGR of 4.3% between 2025 and 2035, driven by operators upgrading their systems to meet tough safety codes like NFPA 96. You can dig into the specifics by reviewing the full market analysis from Future Market Insights.

If you're ever in doubt, just call your local fire marshal. They have the final say and would much rather help you choose the correct hood beforehand than shut you down for a violation later. Picking one of the best commercial pizza ovens that'll make your dough rise is just the first step; ventilating it properly is what keeps your business safe and sound.

How Professionals Calculate Your Kitchen's Airflow

Let's pull back the curtain on one of the most technical parts of meeting commercial kitchen ventilation requirements: airflow, which we measure in CFM (Cubic Feet per Minute). Instead of getting lost in complicated formulas, just think of CFM as your kitchen's "breathing rate." The goal is a simple one: create a slightly negative pressure. You want your hood fan pulling more air out than is being supplied, which forces all that smoke and grease straight up into the hood, right where it belongs.

An HVAC pro doesn't just pick a number out of thin air. They perform a careful, deliberate calculation based on factors unique to your pizzeria. This ensures your system is perfectly sized—strong enough to clear the air without being an oversized, energy-guzzling monster.

The Key Factors in Airflow Calculation

The go-to method for most professionals is the "Linear Foot Method." It's a surprisingly straightforward approach that boils down to the size of your exhaust hood and what you're cooking under it.

Three main variables drive the calculation:

- Hood Dimensions: The length of your exhaust hood is the starting point. It's simple logic: a longer hood has to move more air to effectively capture heat and smoke across its entire span.

- Appliance Type: Different pizza ovens create different amounts of heat and grease. A roaring wood-fired beast is a "heavy-duty" appliance, while a high-volume gas conveyor oven usually falls into the "medium-duty" category.

- Overhang: How far the hood juts out past your pizza oven is also critical. A generous overhang is your best friend for improving capture efficiency, which can influence the final CFM number.

By weaving these factors together, a professional can tailor a ventilation system to your exact setup. This covers everything from your main pizza oven down to any other heat-producing commercial kitchen equipment on your line.

A Simplified Pizzeria Example

Let's walk through a quick calculation for a typical pizzeria scenario. Imagine you're installing a gas-fired deck oven that needs a 10-foot-long Type I exhaust hood above it.

The IMC gives us a baseline CFM per linear foot based on the cooking intensity. For a medium-duty appliance like a gas pizza oven, the code might suggest a rate of 300 CFM per linear foot.

The calculation is pretty simple:

10 feet (Hood Length) x 300 CFM/foot (Duty Rating) = 3,000 CFMThis tells you that your exhaust fan needs to be powerful enough to pull 3,000 cubic feet of air out of your kitchen every single minute to keep things safe and clear.

This number gives you the foundational exhaust rate. Once this ideal airflow is calculated, pros use advanced techniques like clash detection and coordination to make sure the ductwork and other ventilation components fit perfectly with your building's existing plumbing and electrical systems, preventing expensive mistakes down the road.

Beyond the Basics: Modern Ventilation Technology

The world of kitchen ventilation is moving fast. We're seeing more demand-controlled systems that automatically adjust airflow based on how much cooking is actually happening, saving energy and money. IoT-enabled sensors are also becoming more common, ensuring peak efficiency.

While things like high installation costs and tricky regulations are still challenges, new tech like AI-powered air quality monitoring and advanced filtration are making kitchens safer and more efficient than ever.

Having a basic handle on these calculations helps you have a much more productive conversation with your HVAC contractor. You can make sure they've accounted for all your equipment—from the main oven to a small fryer—and you'll end up with a system that genuinely works for your pizzeria.

The Critical Role of Makeup Air in a Pizzeria

Exhausting smoke and grease is only half the battle when it comes to your commercial kitchen ventilation requirements. For every single cubic foot of air your powerful exhaust hood shoots outside, you have to bring a fresh cubic foot back in. This crucial job falls to the makeup air (MUA) unit.

Think about trying to suck the air out of a sealed plastic bottle. After a tiny puff, it becomes impossible because you’ve created a vacuum. Your pizzeria kitchen is no different. Without an MUA unit constantly feeding it fresh air, your exhaust fan creates negative pressure, which can lead to a whole cascade of serious, and sometimes dangerous, problems.

When Your Kitchen Can't Breathe

Without enough makeup air, you're essentially starving your kitchen of the air it needs to operate. This "air starvation" creates a vacuum effect that shows up in several ways, quickly turning your efficient pizzeria into a frustrating and hazardous place to work.

Here are the tell-tale signs of inadequate makeup air:

- Doors that are hard to open: If your staff or customers have to physically yank on the front door to get in, it’s a classic symptom of negative pressure pulling it shut from the inside.

- Pilot lights that keep going out: Your gas pizza ovens and water heaters can have their flames snuffed out as the building desperately tries to suck air down through their flue pipes.

- Weak exhaust hood performance: The hood simply can't capture smoke and grease if there isn't enough replacement air flowing toward it.

The single most dangerous consequence of poor makeup air is back-drafting. This is when toxic gases like carbon monoxide from your pizza ovens get pulled back into the kitchen instead of being safely vented outside. This creates a severe health risk for your entire team.

Getting this balance right isn't just a best practice; it's a non-negotiable safety requirement. Most codes mandate that your makeup air system must replace at least 80% to 90% of the air your exhaust hood removes.

Protecting Your Pizza Prep Table from the Elements

Just having an MUA unit isn't enough—where and how it delivers that air is just as important. Simply dumping raw, untreated outside air into your kitchen can create a whole new set of problems, especially for a pizzeria where dough quality and ingredient consistency are everything.

Imagine you're running a pizzeria in a cold climate. If your MUA unit is just pumping in freezing winter air, you're not just making your staff miserable. You're creating drafts that can wreak havoc on your entire operation, especially around your sensitive pizza prep tables.

A blast of cold air blowing across your pizza prep line can:

- Shock your pizza dough: Cold temperatures can stop the proofing process in its tracks, leaving you with a dense, tough crust.

- Cool down ingredients: Toppings and sauces sitting on the prep table's rail can quickly fall below safe temperature zones.

- Affect the final bake: A cold pizza base hitting a hot oven can cook unevenly, ruining the final product.

To prevent this disaster, pizzerias in colder regions absolutely must install a heated (or tempered) MUA unit. These systems warm the incoming air to a comfortable room temperature before releasing it, protecting both your employees and your pizza. A professional will also strategically place the air diffusers to avoid creating disruptive drafts over sensitive areas like your pizza prep table, ensuring your workflow stays smooth and your pizzas come out perfect every time.

Your Essential Ventilation Maintenance Checklist

Viewing your ventilation system's upkeep as just another expense is a massive misstep. A better way to think about it is like vital insurance—a smart, proactive strategy that shields your pizzeria from devastating fires, eye-watering non-compliance fines, and expensive equipment failures. This isn't just about mopping up grease; it's about the very safety and integrity of your kitchen.

A system that’s properly cared for runs like a dream, sipping energy instead of guzzling it. More importantly, it’s your number one defense against the constant threat of a grease fire. The key is to lock in a consistent maintenance schedule and document every single task. That logbook is your proof of compliance and your ticket to a safer kitchen.

The Weekly Walk-Through

These are the quick but crucial jobs that stop tiny issues from snowballing into full-blown hazards. I recommend carving out a specific time each week, maybe during a slower period, to knock these out.

- Clean Hood Filters: This is, without a doubt, your most important weekly task. Whether you soak them in hot, soapy water or run them through a high-temp dishwasher, clean filters are non-negotiable. They ensure proper airflow and are the front line in preventing grease from invading your ductwork. Clogged filters? That’s a fire waiting to happen.

- Wipe Down Interior/Exterior of Hood: Give all the accessible surfaces of the hood canopy a good cleaning. This gets rid of that sticky grease film that can drip onto food or, even worse, act as fuel for a fire.

Monthly Inspections and Checks

Once a month, you’ll need to peek a little deeper under the hood, so to speak. These checks focus on the mechanical bits and pieces, making sure they’re in solid working order to prevent a surprise breakdown during a chaotic dinner rush.

- Inspect Fan Belts: Check the exhaust fan belt for any signs of cracking, fraying, or just looking tired and worn out. A snapped belt means your entire exhaust system shuts down instantly.

- Check the Makeup Air Unit: Make sure the MUA unit is humming along correctly and that its filters are clean. A choked-up MUA filter starves your kitchen of fresh air, forcing your exhaust hood to work overtime.

- Verify Hinge Kit Functionality: If you have a rooftop fan, confirm that the hinge kit swings open smoothly. A seized hinge makes the professional cleaning crew’s job difficult and dangerous.

Keeping a detailed maintenance log is not optional; it’s proof of diligence. A simple binder or digital file recording dates, tasks performed, and who completed them can be your best friend during a surprise visit from a fire marshal or health inspector.

Semi-Annual Professional Cleaning

This is the big one, and it's mandated by NFPA 96 for a very good reason. Twice a year, you are required to bring in a certified professional for a top-to-bottom cleaning of the entire ventilation system.

This service isn't just a quick wipe-down. It includes:

- Scraping and cleaning the interior of all ductwork, from the hood collar right up to the fan.

- A thorough deep clean of the exhaust fan blades and its housing.

- Verifying that the entire system is free of hazardous grease buildup.

When they’re finished, the cleaning company will put a service sticker on the hood showing the date they were there. Trust me, that’s one of the first things an inspector will look for. To ensure ongoing compliance and peak performance, implementing regular safety audits for your ventilation system is as crucial as routine maintenance.

This rigorous schedule also has a direct effect on the performance of all your kitchen equipment, including the specialized prep tables for your restaurant that depend on a stable, comfortable kitchen environment to keep ingredients at safe temperatures. Consistent maintenance ensures your whole operation, from exhaust to prep, runs like a well-oiled (and safe) machine.

Common Pizza Kitchen Ventilation Questions

Even after you've got a handle on the core codes and equipment, there are always those specific, nagging questions that pop up during the design phase of a pizzeria. I've heard them all over the years. These are some of the most common ones I get from pizzeria owners, with straightforward answers to help you navigate the finer points.

Do I Need a Hood Over My Pizza Prep Table?

For a standard refrigerated pizza prep table? Almost always, no. That piece of equipment is designed for one thing: keeping ingredients cold while you assemble pies. It doesn't produce the heat, smoke, or grease that triggers the need for mechanical ventilation.

But—and this is a big but—the second you put any kind of cooking appliance on or near that prep table, the game changes completely. Say you add a small countertop fryer for wings or a finishing oven to get that perfect cheese melt. That specific appliance now absolutely needs its own hood to keep the fire marshal happy.

Here's the rule of thumb I always tell my clients: ventilation follows the heat and grease. If an item on your line is cooking and creating those emissions, it needs a hood. If it’s strictly for cold prep, you’re usually in the clear.

My Electric Oven Vendor Said I Don't Need a Hood. Is That True?

I'd tell you to be very, very careful with that advice. While it's true that some specialized electric ovens are certified as "ventless," and many electric models produce far less grease than their gas or wood-fired cousins, the vendor's opinion doesn't hold up with the authorities.

Ultimately, the person with the final say is your local fire marshal or building inspector. They aren't just looking at the oven; they're looking at your entire operation. They’ll consider things like:

- Your total cooking volume: Are you a small shop making a few dozen pizzas a night, or a high-volume spot slinging hundreds?

- Your menu's ingredients: A pizzeria that specializes in meat-lover's pies loaded with pepperoni, sausage, and extra cheese is putting out way more grease than a place focused on simple margherita pizzas.

Before you make any final decisions, get written approval from your local authority to skip the hood. I can't stress this enough. Taking this one step can save you from a world of hurt, including massive fines and being forced to shut down until you're in compliance.

How Often Must a Hood System Be Cleaned?

For the majority of pizzerias, which NFPA 96 classifies as operating with moderate-volume cooking, you're required to have a professional "hood-to-fan" cleaning semi-annually, or every six months.

And this isn’t just a quick wipe-down of the filters. We’re talking about a comprehensive service where certified pros clean the entire system—the hood itself, all the connecting ductwork, and the exhaust fan on your roof.

If you’re running an exceptionally busy shop, like a pizzeria that’s open 24/7, you'll likely need to bump that schedule up to quarterly. And make sure you keep a detailed logbook of every cleaning service. It’s mandatory, and it’s the first thing an inspector will ask to see.

Ready to create the perfect prep line for your pizzeria? Pizza Prep Table offers a wide selection of high-quality refrigerated pizza prep tables and all the essential commercial kitchen equipment to build an efficient, safe, and productive workspace. Explore our durable and NSF-compliant solutions at https://pizzapreptable.com and start building your dream kitchen today.