Essential Equipment for Food Truck Kitchens for Pizza

Share

Building a killer pizza food truck isn't just about a secret family sauce recipe. It’s about engineering a high-speed, high-quality pizzeria that just happens to be on wheels. The right equipment for your food truck kitchen is the engine that drives your service speed, pizza quality, and ultimately, your profits. Let's break down the essential gear that will form the backbone of your mobile operation.

Your Blueprint For A Mobile Pizzeria

Stop thinking about your food truck kitchen as a random collection of appliances. Instead, picture it as a single, finely-tuned machine built for one job: cranking out amazing pizza, fast. Every single piece of gear, from that glorious oven down to the humble pizza prep table, has to play nice together in a space that’s just a few hundred square feet. This means your workflow isn't just important—it's everything.

Sure, the pizza oven is the heart of the operation, but its performance is completely tied to what’s happening just a few feet away at the pizza prep table. That station is your command center, where dough, sauce, and toppings all come together. If you choose the wrong prep table, you create an instant bottleneck that even the most powerful oven can't fix.

Matching Equipment To Your Volume

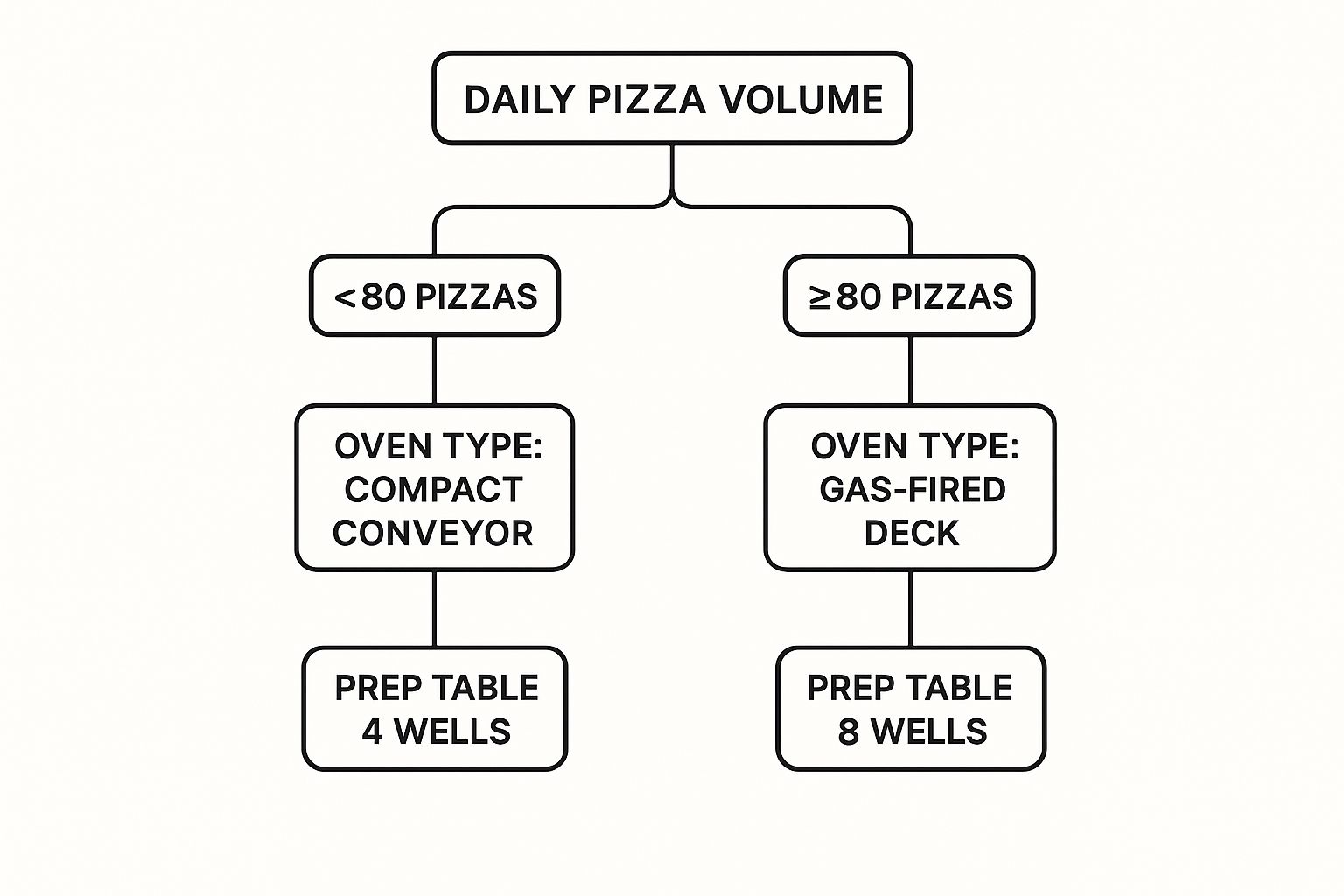

So, how much gear do you really need? The single most important factor is your projected daily sales volume. A setup designed for a quiet lunch spot will completely fall apart during a high-volume festival rush. On the flip side, oversized equipment is just a waste of precious space and cash.

This chart is your cheat sheet, showing exactly how your daily pizza goals should dictate your core equipment choices.

As you can see, there’s a direct line connecting the type of oven you need to the size of the pizza prep table that can support it. This ensures your workflow can scale right alongside customer demand.

The goal is to create a seamless path from raw ingredients to finished pizza. A well-designed layout minimizes unnecessary steps, prevents cross-contamination, and allows your team to move efficiently during the busiest service hours.

When you're mapping out your mobile pizzeria, don't forget the truck itself. You might need specialized cargo trailer transport services just to get your built-out kitchen to its home base. Nailing these equipment relationships is the first step. This strategic thinking ensures every last square inch of your truck is optimized to make you money.

Choosing the Right Pizza Oven

Your pizza oven is the heart and soul of your mobile pizzeria. It's the engine driving your entire operation, dictating how many pies you can sling, the style of pizza you can master, and how quickly you can serve a hungry crowd during that chaotic lunch rush. Getting this choice right is absolutely fundamental to making it on the road.

This isn't like picking an oven for a brick-and-mortar spot. In a food truck, you're in a constant battle with limited space, weight restrictions, and the never-ending demand for reliable power. The perfect oven for a restaurant could be a disastrous choice for a mobile kitchen.

Gas-Fired Deck Ovens: The All-Around Performer

Think of a gas-fired deck oven as the trusty workhorse of the pizza world. These ovens use stone or ceramic "decks" heated by powerful gas burners below, producing that classic, crisp crust perfect for New York-style slices. They're fantastic at holding their heat, which means they stay hot even when you're constantly opening and closing the door.

For a food truck, their biggest win is fuel efficiency. They run on propane, which means they won't demand a massive, power-guzzling generator to keep them fired up. This is a huge deal when you're mapping out your truck's electrical system.

Propane is the lifeblood of most food truck kitchens. A gas oven dramatically reduces the strain on your generator, which is one of the biggest operational headaches you'll face.

The flip side? They have a serious physical footprint and weigh a ton. You'll need to work hand-in-hand with your truck builder to make sure the vehicle's frame can handle the load and that you have the proper ventilation installed to meet fire codes.

Compact Conveyor Ovens: Speed and Consistency

If your game is all about speed and churning out perfectly identical pizzas every single time, then a compact conveyor oven is your champion. This machine operates like a slow-motion toaster, pulling pizzas through a heated chamber on a conveyor belt. The result? A perfectly, evenly cooked pizza every time, with zero need for a skilled cook to rotate and watch over it.

This is a game-changer for high-volume events or for operations with less-experienced staff. Speed is the only thing that matters, and these ovens deliver. They are also dead simple to operate.

- Pro: Unmatched consistency. Every pizza comes out the same, which cuts down on costly mistakes.

- Con: They just don't have that authentic, hearth-baked character that true pizza lovers look for.

- Pro: Blazing-fast cooking times let you serve the maximum number of customers.

- Con: Can be pricier and require more maintenance than their deck oven cousins.

Wood-Fired Ovens: The Artisan's Choice

For the ultimate in authenticity and flavor, nothing—and I mean nothing—beats a wood-fired oven. These gorgeous, dome-shaped beauties can hit scorching temperatures over 900°F, capable of cooking a perfect Neapolitan-style pizza in as little as 90 seconds. The intense, dry heat creates that signature "leopard-spotted" crust that's impossible to get any other way.

This oven isn't just a cooking tool; it's a statement piece. It screams to your customers that you are dead serious about traditional, artisan pizza. The open flame also adds a bit of theater that naturally draws a crowd.

But the trade-offs are huge for a mobile setup. Wood-fired ovens are incredibly heavy, take a long time to heat up, and require a constant supply of quality hardwood. You also need a skilled operator who can manage the fire and cook pies in a very demanding environment. For those truly dedicated to the craft, however, there is no substitute. To learn more about how different oven types impact your final product, you can find helpful information in the ultimate guide to choosing the best pizza oven.

Optimizing Workflow with Pizza Prep Tables

If the oven is the heart of your pizza food truck, then the pizza prep table is its central nervous system. This is command central—the spot where dough, sauce, cheese, and toppings all come together in a blur of activity. Picking the right one from all the equipment for your food truck kitchen creates a smooth, efficient workflow. The wrong one? It’s an instant bottleneck that will absolutely sink you during a dinner rush.

For any serious mobile pizzeria, a refrigerated pizza prep table isn't just a nice-to-have; it's a non-negotiable workhorse. This single piece of gear combines a tough cutting board workspace, chilled wells for toppings, and under-counter cold storage for extra dough and ingredients. It's an entire assembly line packed into just a few precious square feet.

Key Features of a Food Truck Pizza Prep Table

Not all pizza prep tables are built the same, especially when they have to survive the constant vibrations and temperature swings inside a truck. When you’re shopping for a unit, you need to focus on the features that directly affect your speed, food safety, and long-term durability.

Your first big decision is the number of refrigerated topping wells, often called pans or inserts. A small truck with a simple menu might get by just fine with a 4-well setup. But if you’re offering tons of custom toppings, an 8 or 12-well table is what you need to keep everything chilled and within easy reach.

Next up is the cutting board. Its depth is a bigger deal than you might think. A deeper board (usually 19 inches or more) gives you plenty of room to stretch dough and build a large pizza without toppings spilling everywhere. A shallow board will have you feeling cramped and inefficient, slowing down your entire process.

A well-designed pizza prep table creates an ergonomic "golden triangle" for your pizza maker. Dough from the under-counter fridge, toppings from the wells, and the cutting board surface should all be accessible with minimal twisting or reaching.

Finally, take a hard look at the under-counter storage. This refrigerated cabinet is where you'll stash backup topping pans, proofed dough trays, and blocks of cheese. Make sure its capacity can handle your projected sales for a busy service, so you aren't caught scrambling to a separate fridge for restocks.

Sizing and Certification: Your Most Important Choices

Choosing the right size pizza prep table is a critical balancing act. A 48-inch table is nice and compact for tight spaces, but a 72-inch or even a 93-inch model provides a massive workspace that can easily support a two-person prep team. Meticulously measure your truck's layout and leave enough clearance for people to move around before you commit to a size.

But maybe the most critical feature of all is the NSF certification. This seal is your proof that the unit is built for commercial use, with materials and a design that are easy to clean and sanitize. Running a truck without NSF-certified equipment is a surefire way to fail a health inspection. Also, look for insulated lids over the topping wells; this simple feature helps maintain safe food temperatures and reduces the strain on your compressor, which saves energy. You can get a more detailed look at the specifications of a commercial pizza prep table in our guide here.

The Big Picture Impact of Smart Equipment

Investing in the right pizza prep table and other quality equipment is more than just a startup cost; it's a strategic move that keeps you competitive. The food truck industry's incredible growth is being driven by operators who are adopting better, more efficient kitchen technology.

The global food truck market is projected to hit about $5.8 billion by 2025, with a strong compound annual growth rate (CAGR) of 6.4% expected through 2035. This boom is fueled by operators using smart equipment to meet the rising demand for quality food served fast. By choosing gear that maximizes your workflow, you position your mobile pizzeria to grab a piece of that expanding market.

Mastering Cold Storage and Dough Management

Anyone can throw toppings on dough, but consistent, high-quality pizza hinges on something far less glamorous than a fiery oven: precise temperature control. Both your fresh ingredients and your carefully fermented dough are incredibly sensitive. This is where your cold storage strategy becomes a cornerstone of your equipment for food truck kitchens, making sure every single pizza tastes just as amazing as the last.

In a food truck, you're fighting a constant battle against brutal temperature swings, road vibrations, and a laughable amount of space. Your standard home fridge won't last a week. You need commercial-grade gear designed to handle the abuse of the road and the intense heat of a mobile kitchen.

Under-Counter Refrigerators The Space-Saving Heroes

In the world of food truck kitchens, under-counter refrigerators are the undisputed champs. They slide neatly beneath your pizza prep tables and work surfaces, transforming what would be dead space into functional, cooled storage. This integration is absolutely key to keeping your workflow smooth and efficient, putting backup ingredients just an arm's length away.

When you're shopping for one, look for models built with heavy-duty compressors and a tough construction that can take a beating from constant motion. Doors with strong magnetic gaskets are non-negotiable; they keep the cold air locked in, even when the truck is rattling down the highway. This isn't just about convenience—it's about survival.

The "danger zone" for food is between 40°F and 140°F, where bacteria can multiply like crazy. A reliable commercial refrigerator is your first line of defense against foodborne illness, a risk that gets magnified in the challenging environment of a food truck.

Compact Freezers and Dough Management

While your pizza prep table and under-counter units handle the day-to-day ingredients, a compact chest or upright freezer is your secret weapon for bulk items. Think frozen meats, big blocks of cheese, and specialty toppings. A dedicated freezer lets you buy in larger quantities to lower your food costs over time, but more importantly, it gives you a stable, long-term storage environment you can count on.

Now let's talk dough. Perfect pizza dough demands a controlled proofing process. While some operators get by proofing at room temperature, a dedicated dough-proofing cabinet or a retarder offers consistency you just can't get otherwise. These units maintain the perfect temperature and humidity, letting your dough develop those complex flavors slowly and predictably. It means you have perfectly proofed dough ready for every service, every time.

When organizing your cold storage to keep the health inspector happy, follow these simple rules:

- Top-Down Organization: Always store ready-to-eat foods like veggies and cheese on the top shelves.

- Raw Meat Placement: Raw meats belong on the lowest shelf, period. This prevents their juices from dripping down and contaminating everything else.

- Clear Labeling: Every single container needs a clear label with the item name and the date it was stored. No exceptions.

Calculating Your Refrigeration Needs

So, how much cold storage do you actually need? Start by mapping out your pizza menu and making a realistic estimate of your daily sales. Calculate the total volume of perishable ingredients you'll need to hold for a busy service, and then add a little buffer for those unexpected rushes.

Think about your prep schedule, too. If you prep ingredients for two days at a time, you'll need double the storage space compared to someone who preps daily. And remember, every health department requires food trucks to operate from a licensed commissary kitchen. This off-site space is perfect for deep cleaning and can supplement your onboard storage, so you don't have to cram everything into the truck itself. Plan this out carefully, and you'll ensure your ingredients stay fresh, your dough is perfect, and your mobile pizzeria is set up for success from day one.

Essential Supporting Tools and Sanitation

A high-powered oven and a slick pizza prep table are the stars of your mobile kitchen, no doubt. But they can't put on a show without a solid supporting cast. The smaller, everyday tools are the unsung heroes that keep your operation humming like a well-oiled machine, bridging the gap between your main stations to turn ingredients into pizzas with speed and precision.

Think of it like a theater production. While the audience is focused on the lead actors (your oven and pizza prep table), it’s the crew working behind the scenes that makes the performance flawless. If you skimp on these items, you're setting yourself up for service slowdowns, inconsistent pizzas, and frustrating bottlenecks right when the line starts to grow.

Equipping Your Dough and Pizza Prep Stations

Long before a pizza hits the prep table, the dough has to be mixed and portioned perfectly. This is where a commercial dough mixer becomes a critical piece of equipment for your food truck kitchen. The romance of mixing by hand fades pretty fast when you're facing down a dinner rush. A planetary mixer is the industry standard for a reason—it can handle dense pizza dough day in and day out without burning out.

Choosing the right size is always a balancing act in a food truck. You need to weigh your production needs against your precious, limited space. A 20-quart mixer is a really popular sweet spot for many trucks, giving you enough capacity for small to medium batches without eating up your entire prep counter.

Once that dough is ready, you need the right hand tools to wrangle it:

- Pizza Peels: You’ll need at least two kinds. A classic wooden peel is fantastic for launching raw pizzas into the oven; its slightly porous surface helps prevent the dough from sticking. For turning and pulling out cooked pies, a durable metal peel is your best friend.

- Dough Cutters and Scrapers: A simple bench scraper is one of the most valuable tools you'll own. It's perfect for dividing bulk dough into individual portions and for scraping stray flour off your pizza prep surfaces.

- Ingredient Bins: Get yourself some NSF-certified, clear polycarbonate bins with tight-fitting lids. They're essential for storing bulk stuff like flour, sugar, and cheese. Not only do they keep everything fresh and prevent cross-contamination, but they also let you see your inventory at a glance.

The Non-Negotiable Sanitation Hub

No piece of equipment matters more for passing your health inspection than your sink setup. This is not the place to get creative or cut corners. Every single health department in the country is going to require, at minimum, a three-compartment sink for washing, rinsing, and sanitizing, plus a totally separate handwashing station.

In the tight quarters of a food truck, sanitation isn't just a box to check—it's your first line of defense against foodborne illness. A proper sink setup is the bedrock of a safe, legal, and trustworthy mobile kitchen.

Your three-compartment sink has to be big enough to fully submerge your largest pizza pans and peels. Your handwashing sink needs both hot and cold running water and must be stocked with soap and paper towels at all times. This little corner of your truck is basically your command center for food safety. Beyond just having the sinks, keeping up with daily hygiene is everything. Following a comprehensive commercial kitchen cleaning checklist will make sure no critical task gets missed.

This focus on durable, certified gear is playing out across the entire industry. The global commercial kitchen equipment market is expected to jump from around $49.51 billion in 2025 to $82.24 billion by 2034. That growth shows a huge demand for efficient, reliable tools in all kitchens, big and small. It reinforces that putting your money into quality equipment isn't just an expense—it's a smart business move. You can see more on how equipment trends are shaping the business side of things in these insights on food truck profitability in 2025.

A Few More Things to Figure Out

Stepping into the world of mobile pizzerias means you'll have questions—a lot of them. Getting the right equipment for your food truck kitchen involves a ton of variables, from power grids and health codes to some tough budget decisions. This section tackles the most common questions new pizza truck operators face, giving you clear, straightforward answers to help you make smarter investments.

Think of this as your final checklist before you start writing checks. Getting these details right from the jump will save you from costly mistakes, failed inspections, and massive operational headaches down the road.

What Are The Power Requirements For A Pizza Oven?

Power is one of the most critical—and often underestimated—parts of planning any food truck. While most of your gear, like refrigerated pizza prep tables and smaller appliances, will run on standard 110V-120V electricity drawn from a generator, your pizza oven is the real energy hog.

The overwhelming choice for mobile kitchens is a gas or propane-fired oven. It's not even a close contest. These units are incredibly popular because they require very little electricity, usually just a tiny bit to power digital controls or internal fans. This dramatically reduces the strain on your generator, which is exactly what you want.

A fully electric pizza oven, on the other hand, is a massive power consumer. It would demand an enormous, expensive generator and specialized, heavy-duty wiring, making it impractical and often prohibitively costly for most mobile setups.

Always, always, always review the manufacturer's specs for both electrical (amps/volts) and gas (BTUs) requirements before you buy anything. Work closely with your truck builder to ensure your power and propane systems are not only sufficient but also installed safely to prevent fires or leaks.

How Do I Ensure My Equipment Is Health Code Compliant?

Health code compliance is the absolute bedrock of your business. It's completely non-negotiable. Your number one rule should be to only purchase equipment that is NSF certified or has a similar, recognized food-safe certification. This stamp is your assurance that the gear, especially your pizza prep table, is built with materials and a design approved for commercial cleaning and sanitation.

But an NSF sticker alone isn't enough. Before you purchase a single piece of equipment, you must contact the local health departments for every single city, county, or jurisdiction you plan to operate in. I can't stress this enough—regulations can vary wildly from one town to the next.

They will give you specific food truck regulations covering everything you need to know, including:

- The required size and setup for your three-compartment sink.

- The necessity of a completely separate handwashing station.

- Strict temperature standards for all refrigerated storage like your pizza prep table.

- Mandatory fire safety clearances around all your cooking equipment.

Should I Buy New Or Used Equipment?

This is the big budget question every new owner has to wrestle with. New equipment offers the peace of mind that comes with a manufacturer's warranty, the latest energy-efficient features, and proven reliability—but it all comes at a premium price.

Used equipment, on the other hand, can offer huge initial savings, freeing up capital for other startup costs. However, this route comes with considerable risk. If you're even thinking about buying used, you absolutely must inspect the item in person before any money changes hands.

For refrigerators and pizza prep tables, check that they hold their temperature consistently. For ovens, verify that the thermostats are accurate and that all safety features are working correctly. A smart hybrid approach is often the best strategy for a new pizza truck.

- Invest in New: Your pizza oven and pizza prep table are your money-makers. Buying these new, with a full warranty, is a wise investment that protects the core of your business.

- Shop Used for Support Gear: Look for quality used refrigeration, mixers, and sinks to keep your startup costs in check. Buying from a reputable restaurant supply dealer who services and stands by their used inventory is a much safer bet than a private sale on Craigslist.

What Size Pizza Prep Table Do I Need?

Choosing the right size for your pizza prep table is a balancing act between your menu, your projected sales, and the actual physical layout of your truck. A standard 48-inch to 60-inch refrigerated pizza prep table is a popular choice that works for many trucks, offering a good mix of workspace and topping storage.

If your menu is super limited—say, just cheese and pepperoni—you might be able to get by with a smaller, more compact unit. But if you plan to offer a wide variety of custom toppings, a 72-inch or even a 93-inch model may be necessary to prevent workflow jams and keep your line moving during a rush.

Before you decide, measure your available space meticulously, always leaving enough room for your team to move past each other comfortably. Trust me, it's almost always better to have slightly more prep space than you think you need rather than finding out you don't have enough during a chaotic, high-volume service.

At Pizza Prep Table, we specialize in helping mobile pizzeria entrepreneurs find the perfect equipment to build their dream on wheels. From compact pizza prep tables for tight spaces to high-capacity units for high-volume service, we have the NSF-certified gear to get you started right. Explore our selection and get a personalized recommendation today.