A Guide to Pizza Prep Tables

Share

Every great pizza has a secret origin story, and it doesn't start in the oven. It starts on the pizza prep table. This is the operational heart of any pizzeria worth its salt, the central hub where ingredients, assembly, and workflow all come together.

Think of it as a strategic asset. A well-chosen table makes every pizza order a smooth, repeatable process. The wrong one? It just creates chaos during a dinner rush.

The Foundation of an Efficient Pizzeria

Your pizza prep table isn't just a counter; it's the kitchen's command center. It’s where your team transforms raw ingredients into perfectly crafted pies ready for the heat. This one piece of equipment sets the entire pace and rhythm of your pizzeria's operation.

An organized station with refrigerated rails keeps essential toppings like mozzarella, pepperoni, and mushrooms perfectly chilled and always within arm's reach. Meanwhile, the under-counter storage gives you instant access to dough and other bulk ingredients. This setup isn’t just about making things easy—it’s about building an efficient system that guarantees every single pizza meets your high standards.

Why Your Pizza Prep Table Is a Strategic Asset

A pizzeria's success rides on its ability to pump out a high volume of consistent, quality pizzas—fast. The right pizza prep table is absolutely fundamental to making that happen. It gives your team the power to deliver by providing:

- Speed and Efficiency: With every topping, sauce, and cheese organized in one spot, your crew isn't wasting time running around. This minimizes movement and dramatically speeds up the pizza assembly process.

- Product Consistency: When ingredients are held at their optimal temperatures and laid out logically, it becomes second nature to make every pizza to the exact same standard.

- Enhanced Food Safety: Integrated refrigeration is a non-negotiable for pizzerias. It keeps perishable toppings safely chilled, cutting down the risk of spoilage and helping you ace every health inspection.

This isn't just an observation; the market reflects this growing importance. The pizza prep tables market recently hit USD 1.75 billion and is on track to hit USD 4.92 billion by 2033. That growth is fueled by pizzerias realizing they need specialized equipment to compete.

The Centerpiece of Your Pizzeria's Workflow

An efficient pizzeria relies on specialized equipment to produce consistently great food. It's what allows you to create those picture-perfect pies customers rave about—just look at these visual examples of delicious pizzas.

Ultimately, your choice of pizza prep table touches every single aspect of production. Making a smart, informed decision is one of the first and most important steps toward building a successful pizza business that's built to last. You can dive deeper into commercial food prep equipment in our detailed guide.

Getting to Know Your Pizza Prep Table

Let's be honest, not just any old prep table can handle the chaos of a Friday night pizza rush. A real pizza prep table is a purpose-built beast, engineered with specific features to keep your assembly line humming along smoothly and safely. Getting to know its anatomy is the first step toward picking a model that feels like a trusted teammate, not a piece of equipment you're constantly fighting.

At its heart, a pizza prep table is a brilliant combination of three key elements: a refrigerated ingredient rail, a tough-as-nails work surface, and cold storage right underneath. This all-in-one design means every single component—from your sauce and cheese to the dough itself—is kept at the perfect temperature and is always within arm's reach.

The Refrigerated Topping Rail

This is the signature feature of any pizza prep table, the thing that makes it instantly recognizable. The "topping rail" is that row of recessed pans on top, holding all your must-have ingredients like pepperoni, mushrooms, onions, and mozzarella. A quality rail uses a forced-air refrigeration system that blankets your toppings in a consistent layer of cold air, keeping them food-safe even when the lids are open during a crazy-busy service.

Think of a properly working topping rail as your first line of defense against foodborne illness. It absolutely must keep ingredients below 41°F (5°C) to meet health codes and stop bacteria in its tracks. This ensures every topping is as fresh and safe as it can be.

This forced-air method is worlds better than a simple cold-wall design, which often leads to hot spots and uneven cooling. Also, look for models with insulated lids. They’re a huge help in maintaining temperature and cutting down on your energy bill when the rail isn't in active use.

Under-Counter Storage: Doors vs. Drawers

Right below the main work surface, you'll need to choose between refrigerated doors or drawers. This decision really shapes your pizzeria's workflow, especially when it comes to managing your dough.

-

Doors: These are your go-to for bulk storage. The wide-open cabinet space is perfect for stashing big boxes of cheese, buckets of sauce, and other large, awkwardly shaped ingredients. Doors offer the most flexibility for items of all sizes.

-

Drawers: They are absolutely perfect for dough. Refrigerated drawers are designed to hold dough boxes like a glove. This setup is a dream for proofing and organization, letting your crew grab the next dough ball in a flash without letting all the cold air out of the cabinet.

For most pizzerias, a combination unit that has both doors and drawers offers the best of both worlds. You get that dedicated, organized space for your dough while still having flexible bulk storage for everything else you need.

Choosing the Right Work Surface

The main stage where every pizza masterpiece is built is the work surface, or cutting board. The material you pick here impacts everything from how the dough handles to how easy cleanup is at the end of the night.

Polyethylene is the undisputed industry standard, and for good reason. This durable plastic is non-porous, a breeze to clean, and it won't destroy your knives. It's also relatively cheap to replace when it eventually gets scored up from years of heavy use.

Marble or granite looks fantastic, but it's really better suited for pastry or chocolate work. While it stays naturally cool, which can be nice for some doughs, it's also porous, incredibly heavy, and can chip or crack under the intense pressure of a high-volume pizzeria. When it comes to pizza, a deep polyethylene board gives you the durability and practicality you need for the daily grind.

How to Choose the Right Size and Layout

Picking the right size for your pizza prep table isn't just about making sure it fits in the room. It’s about designing the very heartbeat of your pizzeria's workflow. The right dimensions can turn a chaotic Friday night rush into a smooth, efficient operation. Get it wrong, and you've created a bottleneck that costs you time and money.

Before you even think about looking at models, grab a tape measure. Seriously. You need to map out your kitchen's entire footprint, noting where your ovens, mixers, and walk-in are located. Most importantly, you have to consider how your team moves. Your staff needs to be able to hustle around the table without bumping into each other, especially when the orders are flying in.

Matching Table Size to Pizzeria Volume

The real question you should be asking is, "How many pizzas can we realistically crank out per hour on this thing?" The answer to that is directly tied to the table's width.

Standard models usually come in 48-inch, 60-inch, or 93-inch widths. Each size is built to handle a different level of pizza production. A wider table doesn't just give you more room to stretch dough; it holds more ingredient pans in its refrigerated rail, which means fewer trips to the walk-in.

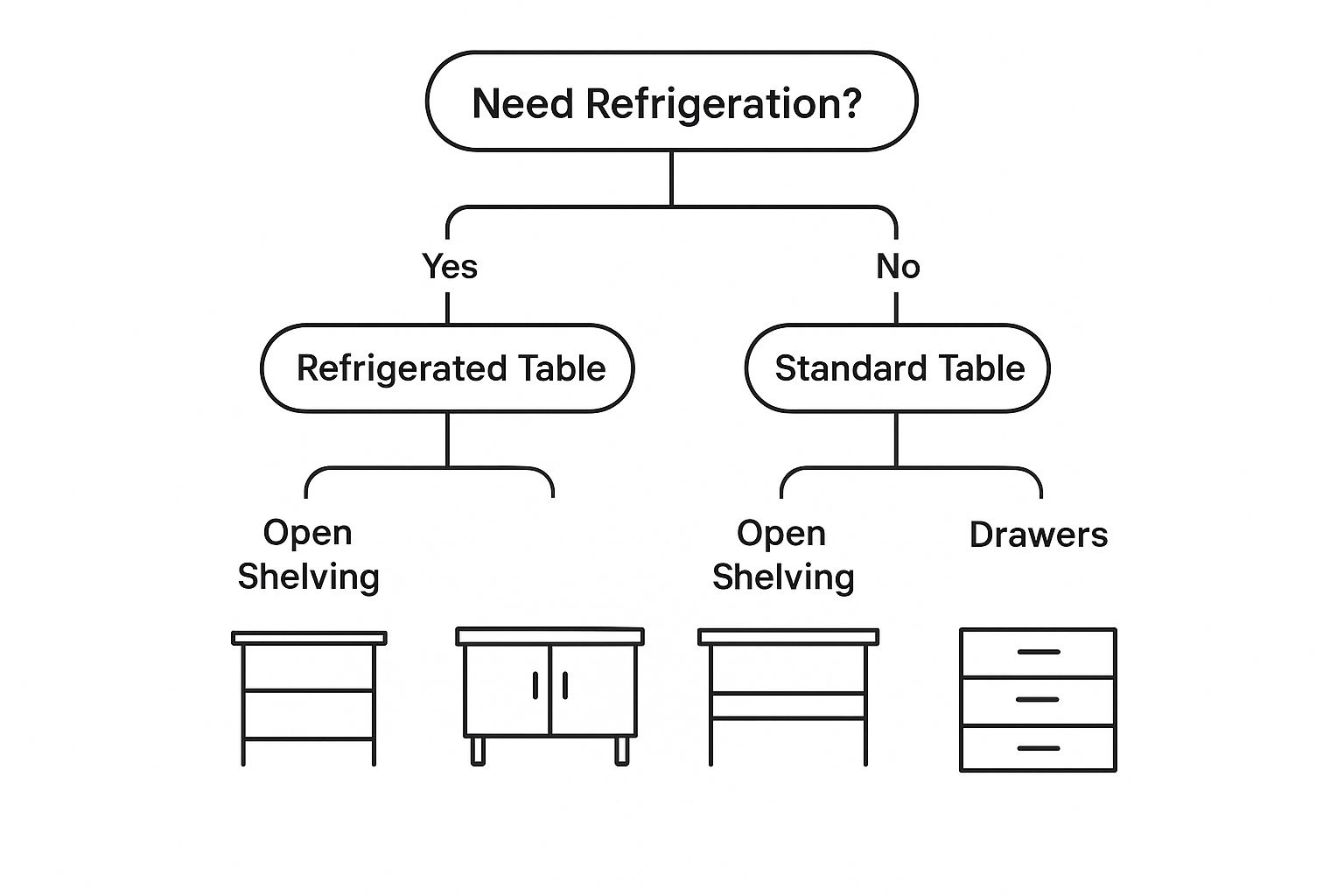

This simple decision tree gives you a great starting point for narrowing down your options, beginning with the most basic question: do you need refrigeration?

As you can see, the path immediately splits based on that cooling need. From there, you get into storage choices like shelves or drawers. It’s a logical way to think, ensuring you nail down the most critical function before getting lost in the details.

A Practical Size and Capacity Comparison

Seeing how table dimensions translate into real-world capacity makes the choice a lot clearer. If you want to get really deep into the weeds, you can learn more about how to choose the right pizza prep table dimensions for your kitchen in our dedicated guide. And don't forget to think outside the box—sometimes clever solutions like mobile stands and sliding stainless steel tables can be game-changers for tight or awkward spaces.

Your choice should balance your current needs with your future ambitions. If you plan to grow, investing in a slightly larger table now can save you the significant cost and disruption of an upgrade later.

Let's break down how table size lines up with ingredient capacity and your pizzeria's output.

Pizza Prep Table Size and Capacity Guide

Here’s a quick-glance table to help connect the dots between the width of the table, how many toppings it can hold, and what kind of pizzeria it’s best suited for.

| Table Width | Ingredient Pan Capacity (1/3 size) | Under-Counter Sections | Ideal for Pizzeria Volume |

|---|---|---|---|

| 44"–48" | 6–8 pans | 1 door | Low-volume, small shops, cafes, or food trucks. |

| 60"–72" | 8–12 pans | 2 doors or drawers | Medium-volume pizzerias, most common size. |

| 93" and Up | 12+ pans | 3+ doors or drawers | High-volume restaurants needing max output. |

Ultimately, choosing the right size is about finding that perfect sweet spot where your equipment empowers your team to work at their absolute best, no matter how busy it gets.

Why Materials and Build Quality Matter

Think of your pizza prep table as a long-term investment, not a disposable tool. Its whole job is to take a beating in a commercial kitchen, day in and day out. That's why you have to look past the price tag and really dig into the build quality—it's the only way to make sure your table will still be standing strong years from now.

It’s a lot like buying a work truck. You could grab a light-duty model to save a few bucks, and it might handle some easy jobs. But put it through the wringer every day, and it's going to fall apart. A well-built pizza prep table is engineered with materials that can handle the relentless pace of a pizzeria.

This isn’t just a hunch; it’s a massive industry trend. The global food service equipment market, already valued at USD 39,071.4 million, is growing because kitchens everywhere are demanding tools that are both efficient and built to last. It just proves how critical it is to invest in quality from the get-go. You can check out the full report on the growth of the food service equipment market on grandviewresearch.com.

The Stainless Steel Standard

In a commercial kitchen, stainless steel is king. But here’s the thing—not all stainless steel is the same. Knowing the difference between the grades is probably the most important thing when you're picking out a prep table that won't let you down.

- 304-Grade Stainless Steel: This is the good stuff, the premium choice you want for any surface that touches food, like your tabletop and topping rail. It has more chromium and nickel, which gives it top-tier protection against rust and corrosion from salt, acidic stuff like tomato sauce, and all the cleaning chemicals you'll be using.

- 430-Grade Stainless Steel: You'll often find this on the exterior sides and back of a unit because it's easier on the budget. It’s still tough, but with less nickel, it's more likely to rust over time. That’s why you want to keep it away from direct food contact.

For any high-volume pizzeria, a 304-grade stainless steel top isn't just a nice feature—it's non-negotiable. It's your single best defense against the pitting and corrosion that can wreck food safety and force you into a costly replacement.

Beyond the Metal Frame

While the steel grade gets most of the attention, it's the little details that often tell you the real story about a prep table's quality. These are the parts that you'll interact with every day, and they are just as critical for performance and longevity.

Take the cutting board, for example. It needs to be made from a thick, high-density polyethylene. This material is tough enough to fight off deep knife grooves where bacteria can multiply, but it won’t dull your pizza cutters after a week. Just as important, it has to be easy to pop off for a good, deep cleaning.

Then you've got the lid and door gaskets. A flimsy, poorly insulated lid is going to bleed cold air, forcing the compressor to work overtime and sending your energy bills through the roof. And the gaskets—those rubber seals around the doors—need to be flexible and create an airtight seal. Once they get brittle or cracked, you’re just wasting energy and putting your ingredients at risk from temperature swings. Paying attention to these "minor" parts is what ensures your investment is truly built to last.

Navigating Health Codes and Safety Certifications

When you buy a commercial pizza prep table, you're investing in more than just stainless steel and a compressor; you're investing in compliance. Following health codes isn’t just a good idea—it’s a non-negotiable part of the business that protects your customers, your reputation, and your bottom line from fines or even shutdowns.

Think of safety certifications as the universal language that tells a health inspector, "this equipment is built for the job." It’s a huge deal in the commercial kitchen world. The global market for food prep tables hit USD 1.18 billion and is climbing, partly because food safety rules are getting stricter everywhere. This growth tells you just how seriously the industry takes compliance, and you should too. You can get more details on this growing market and its drivers on arizton.com.

Decoding the NSF Mark

When you spot the NSF (National Sanitation Foundation) mark on a pizza prep table, you're looking at a serious seal of approval. It’s not just a sticker; it’s a guarantee that the table's design, materials, and construction meet tough public health standards. An NSF-certified table is your proof that the equipment is ready for a professional food environment.

So, what does that NSF logo actually mean for your day-to-day operations?

- Safe Materials: Any surface that touches food is non-toxic, won't absorb liquids, and is built to resist corrosion from things like tomato sauce.

- Easy to Clean: The unit is designed with smooth surfaces, rounded corners, and no hidden cracks where bacteria can throw a party. This makes daily sanitation fast and effective.

- Built to Last: It's constructed to handle the chaos of a busy kitchen without falling apart or developing unsafe cracks or chips.

Health inspectors are trained to look for the NSF logo. When they see it, it’s an instant signal that your equipment is designed to support the strict food safety guidelines for restaurants they’re there to enforce.

Understanding UL Electrical Safety

Now, for any pizza prep table with refrigeration, there’s another critical certification you need to look for: UL (Underwriters Laboratories). While NSF is laser-focused on sanitation, UL is all about electrical safety. A UL listing means the unit's wiring, compressor, and other electrical parts have been put through the wringer to prevent fires, shocks, and other nasty surprises.

A UL certification isn't just a friendly suggestion; it's often a hard requirement for commercial insurance policies and local building codes. Firing up non-certified electrical gear can void your coverage and put your entire business on the line.

When you're sizing up a new refrigerated prep table, make sure you see both logos: the NSF mark for sanitation and the UL mark (or ETL, which is a similar certification) for electrical safety. Together, they confirm that your unit is not only safe for making food but also safe to plug in and run, day in and day out. Do your homework here, and you’ll have an investment that's compliant, insurable, and ready for inspection from day one.

Common Questions About Pizza Prep Tables

When you’re about to invest in a new pizza prep table, you’re bound to have a few questions. That’s a good thing. Getting clear, practical answers is the best way to protect your investment, nail your food safety, and keep the kitchen humming.

We've gathered some of the most common questions we hear from pizzeria owners just like you. Each answer is designed to be straightforward and actionable, giving you the confidence to handle the day-to-day realities of running a pizzeria.

What Is the Ideal Temperature for Topping Rails?

This one is non-negotiable. Your refrigerated topping rail needs to hold all your perishable ingredients at or below 41°F (5°C). Period.

This isn't just a suggestion—it's the universal standard for preventing harmful bacteria from growing in high-risk toppings like cheese, meats, and pre-cut vegetables. A quality pizza prep table with a forced-air refrigeration system is built to lock in this temperature, even when you’re slinging pizzas with the lids wide open during a dinner rush.

Pro Tip: Always use a calibrated, independent thermometer to double-check the temperature every single day. The table's built-in display is a great guide, but a second thermometer placed right in a pan gives you the true reading. That’s exactly what a health inspector will want to see.

How Should I Clean and Maintain My Pizza Prep Table?

Think of proper cleaning and maintenance as cheap insurance for your pizza prep table. A simple, consistent routine is what keeps your unit running smoothly for years and helps you avoid those dreaded emergency repair calls.

Daily Cleaning Routine:

- Sanitize Surfaces: At the end of every shift, wipe down all the stainless steel surfaces and the cutting board with a food-safe sanitizer. No exceptions.

- Clear Debris: Get all the food scraps out of the topping rail and the under-counter storage. This prevents funky smells and keeps pests away.

- Wipe Down Gaskets: Give the door seals a quick wipe with a damp cloth. Any residue left behind can stop the door from sealing tightly.

Weekly & Monthly Tasks:

- Deep Clean: Once a week, it’s time to empty the unit completely and give the interior a thorough cleaning, getting into all the shelves and corners.

- Inspect Seals: Every month, take a close look at the door and lid gaskets. If you see any cracks or tears, get them replaced. Damaged seals leak cold air, forcing the compressor to work overtime and driving up your energy bill.

- Check Condenser Coils: Every month or two, inspect the condenser coils. If they look dusty or greasy, follow the manufacturer’s instructions to carefully clean them. This is one of the single best things you can do to ensure efficient cooling.

Is It Better to Buy a New or Used Pizza Prep Table?

Ah, the classic new vs. used debate. The right answer really comes down to a trade-off between your budget, how much risk you're willing to take, and what you value in the long run.

A new pizza prep table is all about peace of mind. It comes with a full manufacturer's warranty, so if anything goes wrong early on, you’re covered. You also get the latest energy-efficient tech, which can chip away at your utility bills over the years. Best of all, you know its entire history—no mysteries, no hidden abuse.

On the flip side, a used pizza prep table can offer some serious upfront savings, which can be a lifesaver for a new pizzeria on a shoestring budget. But this route comes with risks. You're usually on your own with no warranty, and you have no idea how well the previous owner took care of it. An unexpected repair bill could easily wipe out all the money you saved initially. If you do go with a used unit, try to buy it from a reputable dealer who has inspected and refurbished it first.

Ready to find the perfect pizza prep table for your pizzeria? Pizza Prep Table offers a wide selection of new and used models from top brands, complete with financing options and free freight to get you started. Explore our collection at https://pizzapreptable.com and build the efficient kitchen your business deserves.