How to Choose the Right Pizza Prep Table Dimensions for Your Kitchen

Share

Why Pizza Prep Table Dimensions Are Critical for Your Kitchen's Success

Understanding Standard Pizza Prep Table Dimensions

When you're shopping for a pizza prep table, the pizza prep table dimensions you see on spec sheets represent the exterior measurements that determine how much real estate the unit will claim in your kitchen. These aren't just numbers on paper – they directly impact whether your kitchen flows like a well-oiled machine or feels like a cramped obstacle course.

The three key exterior dimensions are width, depth, and height. Width is where you'll see the most dramatic variation, ranging from compact 44-inch single-door units that fit perfectly in food trucks to massive 119-inch behemoths designed for pizza chains cranking out hundreds of pies daily. Depth stays fairly consistent across the industry at 31 to 33.1 inches, while height typically ranges from 39 to 42.8 inches to keep your cutting surface at a comfortable working level.

Getting these measurements right is crucial for your Commercial Food Prep Equipment selection. You need to make sure your chosen unit can actually make it through your doorways during delivery (trust me, I've seen that nightmare scenario), has proper ventilation clearance, and leaves enough aisle space for your staff to work without bumping into each other during the dinner rush.

Common Widths: From Compact to High-Volume

Pizza prep table widths follow predictable patterns that match up with door configurations and storage needs. Think of it like shoe sizes – there are standard measurements that work for most situations.

Compact single-door models at 44-48 inches are the perfect fit for smaller operations. The EFI CPDW2-44VC is a great example, offering 10-13 cubic feet of storage and space for 6 standard 1/3-size pans in the refrigerated rail. These units shine in food trucks, small cafes, or pizzerias where every square inch of kitchen space counts.

Mid-size two-door units spanning 67-72 inches hit the sweet spot for many pizzeria owners. The EFI CPDW2-67VC measures exactly 67 inches wide and delivers 20 cubic feet of capacity, while the PeakCold IM72PP2 stretches to 71 inches with 16.9 cubic feet of storage. These workhorses typically accommodate 9-12 pans and handle moderate-volume operations beautifully.

Large three-door giants at 93-119 inches are built for serious pizza production. The Atosa MPF8203GR at 93 inches wide provides an impressive 28.4 cubic feet of storage and holds 12 pans comfortably. Some manufacturers push even further with 119-inch models for the highest-volume operations.

Choosing between established brands like True Food Prep Tables and value-focused options from Atosa USA often comes down to your specific width requirements and budget. For a detailed breakdown of two-door options, our 2-Door Pizza Prep Fridges Reviewed guide covers all the key players.

Standard Depth and Height Considerations

While width gets most of the attention, depth and height dimensions are more standardized across the industry – but they're just as important for creating a kitchen that actually works for your team.

Depth measurements cluster tightly between 31 and 33 inches across most models. The Tzanet PICL2HC measures 31.5 inches deep, while EFI models stretch to 33.1 inches deep. This consistent depth accommodates the refrigerated rail, cutting board, and internal storage without making your unit stick out too far into precious aisle space.

Height ranges from 39 to 42.8 inches, which positions the cutting board at a comfortable working level for most staff members. The Omcan FMA 39592 sits at a compact 39 inches, while the PeakCold IM72PP2 reaches 42.8 inches tall. Getting this right prevents your team from developing back problems during long prep sessions.

When planning your kitchen layout, a 33-inch deep unit needs at least 42-48 inches of aisle clearance behind it for staff to work comfortably. Height considerations include any overhead ventilation systems or shelving that might interfere with your prep table's operation.

For comprehensive guidance on balancing all these dimensional factors, check out our detailed guide on Picking The Perfect Kitchen Prepping Table, which covers the nuances beyond basic measurements.

Decoding Functional Dimensions: Beyond the Exterior Footprint

Here's what really matters: how much usable space you actually get from your pizza prep table. Exterior measurements tell you if it'll fit in your kitchen, but functional dimensions determine whether your staff can work efficiently or if they'll be bumping into each other all night.

Think of it this way - you wouldn't buy a car based only on its length and width. You'd want to know about legroom, trunk space, and how the controls are laid out. The same logic applies to pizza prep tables.

Functional dimensions include everything that affects your daily workflow: cutting board depth, how many ingredient pans you can access, door swing clearance, and whether your tall prep cook can work comfortably without hunching over. These measurements directly impact how many pizzas your team can crank out during the dinner rush.

A well-designed 67-inch table with smart functional dimensions can actually outperform a poorly configured 93-inch unit. That's why we focus so heavily on Efficient Pizza Prep Stations when helping customers choose equipment.

The All-Important Cutting Board: A Deeper Look at Pizza Prep Table Dimensions

The cutting board is where the magic happens - and where most pizzeria owners make their biggest mistake. Pizza prep table dimensions for cutting boards run much deeper than you'd expect: 14 to 19 inches compared to the measly 8-9 inches on sandwich prep tables.

Why so deep? Try stretching a 16-inch pizza dough on a 9-inch board and you'll understand quickly. You need that extra depth to work comfortably without sauce and toppings ending up on the floor. A 19-inch deep cutting board like those on certain Master-Bilt models gives you enough room to handle even large specialty pizzas without feeling cramped.

The width typically spans most of the unit's total width. A 67-inch table might have a 60-inch wide cutting board, while a 93-inch unit could feature an 85-inch board. This generous width becomes crucial during busy periods when multiple staff members need to work side-by-side.

Material matters too. Standard HDPE boards work fine for most operations, but composite materials like Richlite resist knife cuts better and last longer. Some high-end units feature removable boards, making deep cleaning much easier.

Here's a pro tip: measure your largest pizza size and add at least 3 inches on each side. That's your minimum cutting board depth requirement. Anything less and your staff will struggle during rush periods.

For more detailed guidance on optimizing your prep workspace, our Restaurant Kitchen Prep Tables Explained guide covers the finer points of cutting board selection.

Top Rail and Food Pan Capacity

The refrigerated rail above your cutting board holds your most-used ingredients - cheese, pepperoni, vegetables, and sauce. How many pans it holds and how they're configured can make or break your kitchen's efficiency.

Standard pan configurations use 1/3-size pans measuring roughly 12.75" x 6.9". A typical 67-inch unit holds 9 pans, while a 93-inch model accommodates 12 pans. Some "Mega Top" designs use smaller 1/6-size pans to give you more ingredient variety in the same space.

Pan depth is another consideration most people overlook. Standard 4-inch deep pans work for most operations, but busy pizzerias often benefit from 6-inch or even 8-inch deep pans. The catch? Not all cooling systems can handle deeper pans while maintaining proper temperatures. Liquid cooling systems using propylene glycol typically handle the deepest pans most effectively.

Randell leads the innovation here with their impressive capacity options. Their traditional narrow rail tables hold 6 to 15 (1/3-size) pans, dual-tier models accommodate 11 to 25 pans, and wide rail tables can hold 21 to 42 (1/6-size) pans. These dual-tier designs maximize ingredient accessibility without making the unit any bigger.

The raised, angled rail design common on pizza prep tables provides much better visibility and access compared to flat-top sandwich units. Your staff can see ingredients clearly and grab what they need without awkward reaching. This ergonomic advantage reduces prep time and prevents the back strain that comes from leaning over flat surfaces all day.

Want to optimize your topping organization? Our comprehensive Pizza Topping Stations guide covers advanced strategies for maximizing your rail space.

How Storage and Features Impact Overall Pizza Prep Table Dimensions

When you're shopping for a pizza prep table, the exterior measurements are just the beginning of the story. The real magic happens inside, where clever storage design and specialized features can transform how efficiently your kitchen operates. Understanding how these elements affect pizza prep table dimensions helps you choose a unit that works harder for your space.

Think of it like buying a house - two homes with identical square footage can feel completely different based on their layout and features. The same principle applies to pizza prep tables. Smart internal design can pack more usable storage into the same footprint, while poorly designed units waste precious space with thick insulation or awkward layouts.

Special features like granite countertops, backsplashes, and dual-tier rails add functionality but also impact your unit's overall footprint. The key is finding the sweet spot between these improvements and your available kitchen space. This is why we always emphasize the importance of Choosing The Perfect Pizza Preparation Refrigerator based on both external and internal specifications.

Interior Storage: Cubic Feet vs. Usable Space

Here's something that might surprise you: cubic feet ratings don't tell the whole story about usable storage space. Two units with identical exterior dimensions can have dramatically different internal capacity based on insulation thickness, compressor placement, and how cleverly the manufacturer designed the interior layout.

Let's look at some real examples. A 67-inch unit might offer anywhere from 16.3 to 20 cubic feet of storage. The Tzanet PICL2HC provides 16.3 cubic feet, while the EFI CPDW2-67VC offers 20 cubic feet in the same width category. That's nearly 4 cubic feet of difference - enough space for several extra ingredient containers or backup pans.

Large units show even more variation. The Atosa MPF8203GR 93-inch model provides 28.4 cubic feet of storage, while the similar-sized Migali C-PP93 offers 26 cubic feet. Both measure 93 inches wide, but internal design differences account for the 2.4 cubic foot variance.

Insulation quality plays a huge role in this equation. Thicker insulation improves energy efficiency but steals internal space. High-quality polyurethane insulation can maintain proper temperatures with less thickness, maximizing your usable storage within the same exterior dimensions. It's like having a well-insulated winter coat that keeps you warm without the bulk.

Compressor placement also affects your storage capacity. Front-breathing compressors allow for zero-clearance installation against walls but may slightly reduce internal capacity. Side-mounted or rear-breathing units might offer more internal space but require additional clearance for ventilation - a trade-off worth considering during your kitchen planning.

For guidance on maximizing storage efficiency in compact spaces, our Under-Counter Freezer Capacity Guide offers valuable insights that apply to pizza prep tables as well.

Doors vs. Drawers: Impact on Workflow

The choice between doors and drawers affects more than just storage - it changes how your staff moves through their daily prep routine. Each configuration has distinct advantages and impacts the space requirements around your pizza prep table.

Traditional swing doors provide maximum storage flexibility with adjustable shelves that can accommodate everything from 50-pound cheese blocks to gallon sauce containers. They're perfect for bulk storage and irregular-sized items. However, doors need clearance space for opening - typically 24 to 30 inches in front of the unit. This means your kitchen aisles need to be wider to accommodate door swing without blocking traffic flow.

Drawer systems offer a completely different approach. They provide organized storage for backup ingredient pans at comfortable waist height, eliminating the need to bend down and search through shelves. Drawers slide out smoothly and require less clearance space since they don't swing open. The downside? They typically offer less total storage volume than door configurations.

Combination units give you the best of both worlds. Many modern pizza prep tables feature two doors and one drawer, providing both bulk storage and organized pan storage. This setup lets you store cheese blocks and sauce containers behind doors while keeping backup topping pans in easily accessible drawers.

Workflow considerations make all the difference in busy kitchens. Drawers excel for frequently accessed backup pans that mirror the ingredients in your top rail. When your mozzarella pan runs low during the dinner rush, pulling out a fresh pan from a drawer is faster and more ergonomic than opening a door and searching shelves. Doors work better for less frequently used items and bulk storage that doesn't need constant access.

For detailed comparisons of drawer-based storage solutions, explore our guide on Under-Counter Freezer Drawers.

How Specialized Features Affect Your Table's Footprint

Specialized features can transform your pizza prep table from basic storage into a high-performance workstation. However, these upgrades often come with dimensional trade-offs that affect your kitchen layout. Understanding these impacts helps you decide which features justify the additional footprint.

Backsplashes might seem like a minor detail, but they affect both functionality and space planning. Units with backsplashes, like the Omcan model with its 6-inch backsplash, add height and may require additional clearance from overhead equipment like ventilation hoods or shelving. The benefit? Backsplashes protect your walls from sauce splashes and provide a more finished, professional appearance that health inspectors appreciate.

Granite countertops represent a premium upgrade that affects both performance and pizza prep table dimensions. The 80-inch Omcan PT-CN-0580 features granite work surfaces that maintain lower temperatures than stainless steel, which benefits dough handling by preventing sticking. However, granite adds weight and may slightly increase the unit's height profile compared to standard stainless steel tops.

Dual-tier rail designs maximize ingredient capacity without increasing the base footprint - a brilliant space-saving innovation. Randell's dual-tier systems can hold 11 to 25 (1/3-size) pans compared to 6-15 for traditional rails. This means dramatically improved ingredient accessibility in the same width, perfect for gourmet operations that need extensive topping variety.

Mega Top configurations take ingredient capacity to the extreme. Wide rail designs accommodate 21 to 42 (1/6-size) pans, providing incredible ingredient variety for specialty pizza operations. These systems increase the depth slightly but offer best topping selection for restaurants focusing on gourmet or build-your-own pizza concepts.

For comprehensive feature comparisons and buying guidance, The Ultimate Guide to Buying a Pizza Prep Table provides industry insights from equipment experts. You can also explore our reviews of Dukers Pizza Prep Tables for specific feature examples.

A Practical Checklist for Choosing Your Dimensions

Choosing the right pizza prep table dimensions feels overwhelming when you're staring at dozens of spec sheets and trying to imagine how each unit will fit in your kitchen. I've walked through this process with hundreds of pizzeria owners, and I always tell them the same thing: measure twice, buy once.

Your decision comes down to three key factors: available space, current volume needs, and future growth plans. Get any of these wrong, and you'll either be cramped from day one or kicking yourself when you outgrow your table in six months.

Start by grabbing a tape measure and honestly assessing your kitchen space. Don't just measure the spot where the table will sit - factor in door swing clearance, aisle space for your staff, and enough room for deliveries and maintenance. A 93-inch table might look perfect on paper, but if your team can't move around it comfortably, it becomes a bottleneck instead of a productivity booster.

Next, think about your daily pizza volume realistically. If you're making 75 pizzas a day now and hoping to hit 150 in two years, a 67-inch unit might serve you better than a 44-inch model that you'll outgrow quickly. For comprehensive kitchen planning strategies, our guide on Pizza Shop Design Ideas offers layout inspiration that can help you visualize your space better.

Comparing Popular Pizza Prep Table Dimensions

| Width | Typical Doors/Drawers | Approx. Pan Capacity (1/3 size) | Approx. Storage (cu. ft.) | Ideal For |

|---|---|---|---|---|

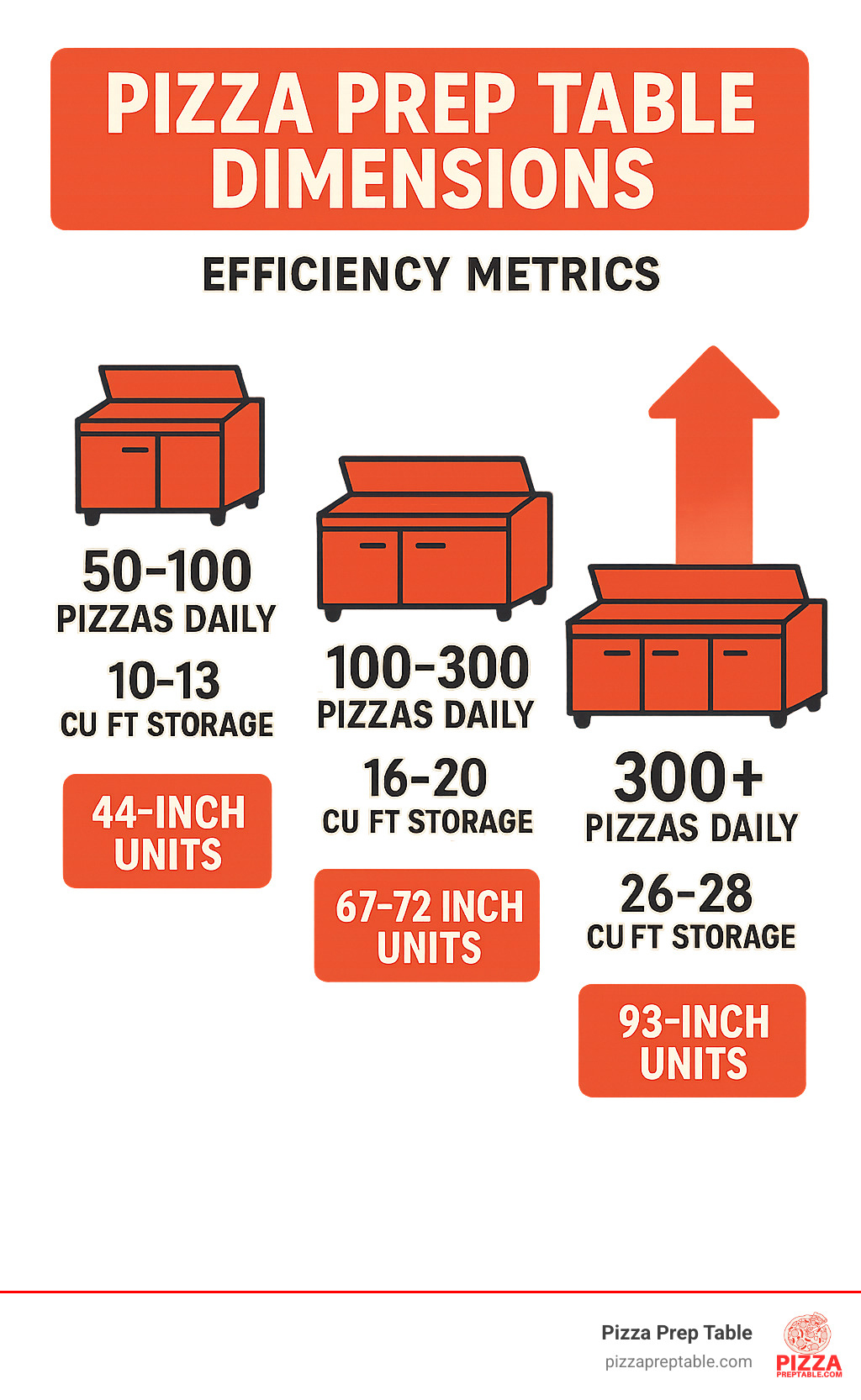

| 44" | 1 Door | 6 | 10-13 | Small cafes, food trucks |

| 67"-72" | 2 Doors | 9-12 | 16-20 | Mid-size pizzerias |

| 93" | 3 Doors | 12 | 26-28 | High-volume restaurants |

This comparison shows how pizza prep table dimensions scale with your operational needs. The jump from a single-door to three-door unit isn't just about width - you're getting double or triple the storage capacity and pan space.

Space planning goes beyond the unit's footprint. Add 6-12 inches on each side for comfortable access and cleaning. Behind the unit, you'll need 42-48 inches for door swing and staff movement - trust me, cramped aisles lead to accidents and frustrated employees. Above the unit, maintain 18-24 inches of clearance for ventilation access and any overhead equipment.

Volume assessment requires honest math. A 44-inch unit works beautifully for operations making 50-100 pizzas daily - think small cafes or food trucks. Bump that up to 100-300 pizzas daily, and you'll appreciate the extra storage and prep space of a 67-72 inch model. High-volume operations pushing 300+ pizzas daily need the serious capacity of a 93-inch unit.

Growth planning saves money long-term. Consider where you'll be in 3-5 years, not just today. It's almost always more cost-effective to buy a slightly larger unit initially than to replace a smaller one as your business grows. I've seen too many successful pizzerias have to sell their perfectly good 44-inch table after a year because they simply outgrew it.

Frequently Asked Questions about Pizza Prep Table Dimensions

What is the main difference in dimensions between a pizza prep table and a sandwich prep table?

The biggest difference is in the cutting board depth - and it's a game-changer for pizza operations. Pizza prep table dimensions include cutting boards that are 14 to 19 inches deep, while sandwich prep tables typically have much shallower 8 to 9-inch boards.

This extra depth isn't just a nice-to-have feature. When you're stretching dough for a large pizza or spreading sauce across an 18-inch pie, you need that workspace. I've seen too many pizzerias try to make do with sandwich prep tables, only to watch ingredients constantly spill onto the floor during busy periods.

The refrigerated rail design is also different. Pizza prep tables feature raised, angled rails that improve ingredient visibility and access compared to the flat-top design of sandwich units. This means the overall height may be slightly greater, and the units often have deeper overall dimensions to accommodate the larger work surface.

How much clearance does a pizza prep table need for ventilation?

This is one of the most important questions for kitchen planning, and the answer depends entirely on your unit's cooling system design. Front-breathing units are a kitchen designer's best friend - they can often be installed with zero clearance on the sides and back, allowing you to maximize every square inch of your kitchen space.

Rear or side-breathing units need more breathing room - typically 3 to 6 inches of clearance for proper airflow. Skimping on this clearance might seem like a good way to save space, but it's a costly mistake that can void warranties and cause premature equipment failure.

Don't forget about the top clearance either. You'll want at least 18 to 24 inches above the unit for service access and heat dissipation from the condenser. Always consult the product's spec sheet before installation - it's much easier to plan correctly from the start than to move equipment later.

Can I get a pizza prep table in a custom size?

While most pizzerias use standard sizes like 44", 67", or 93", some manufacturers do offer custom solutions for unique kitchen layouts. Randell, for example, provides custom configurations for specific operational needs when standard sizes just won't work.

However, here's the reality: standard sizes are your best bet for most operations. They're more cost-effective, readily available, and much easier to service. Custom units often require longer lead times, higher upfront costs, and may have limited parts availability down the road.

Before going the custom route, I'd strongly recommend working with a kitchen design professional to explore standard size options. You'd be surprised how often creative layout solutions can accommodate standard equipment more efficiently than custom sizing. Sometimes what looks like a space problem is actually a layout opportunity in disguise.

Conclusion

Selecting the right pizza prep table dimensions isn't just about finding a unit that fits in your kitchen - it's about creating a foundation for your pizzeria's success. After helping hundreds of restaurant owners steer this decision, I've learned that the most successful operations take time to carefully measure their space, honestly assess their volume needs, and think ahead to future growth.

Exterior dimensions tell only part of the story. The real magic happens when you consider functional dimensions like cutting board depth, pan capacity, and storage configuration. A 67-inch unit with a 19-inch cutting board and smart internal layout can outperform a larger table with poor ergonomics. It's about working smarter, not just bigger.

At PizzaPrepTable.com, we've seen every type of kitchen imaginable - from cramped food trucks that need compact 44-inch units to busy pizzerias where 93-inch three-door models become the command center of the operation. What matters most is finding the right fit for your specific needs, not just copying what works for someone else.

The investment in properly sized equipment pays real dividends. Your staff will move more efficiently during rush periods. Your energy costs will stay manageable. Most importantly, you'll have the workspace needed to maintain consistent food quality even when orders are flying in.

Don't let poor dimensional planning become the bottleneck that limits your kitchen's potential. Whether you're just starting out or ready to upgrade, we offer financing options that make it easier to invest in the right dimensions from day one rather than compromising with undersized equipment.

Explore our complete collection of the best pizza tables for sale to find the perfect fit for your kitchen and find how the right pizza prep table dimensions can transform your entire pizza preparation process.