Food safety training for employees: A practical guide for pizzerias

Share

A solid food safety training for employees plan is more than just a manual; it’s a living program that teaches your kitchen crew the critical habits needed to prevent foodborne illness. This means getting everyone to master personal hygiene, temperature control, avoiding cross-contamination, and following cleaning protocols to the letter. Ultimately, it’s about making sure every single pizza that leaves your kitchen is safe.

Why Pizzerias Need a Specialized Food Safety Plan

A pizza kitchen has its own unique beat, a rhythm and a set of challenges that generic food safety guides just don't get.

Just think about the heart of your operation: the pizza prep table. It's a high-speed, high-risk zone where dozens of toppings with different temperature needs, raw dough, and ready-to-eat ingredients all come together. This environment requires a whole lot more than just basic handwashing knowledge. You need a specialized food safety plan built from the ground up for the realities of slinging pies.

Standard protocols often miss the mark. They don't account for the constant handling of raw dough, the rapid-fire restocking of refrigerated topping rails during a dinner rush, or the specific cleaning needs of a spiral dough mixer. A specialized training program tackles these pizzeria-specific risks head-on.

Moving Beyond Basic Compliance

Look, investing in a tailored program is about more than just checking a box to pass your next health inspection. It's a non-negotiable strategy for protecting your brand's reputation and earning the trust of your customers. One food safety slip-up can do damage that’s impossible to undo. Think of your training as a direct contributor to your bottom line—it cuts down on waste from spoiled toppings and keeps your operation running like a well-oiled machine.

A robust food safety plan isn't an expense; it's an investment in your pizzeria's longevity and success. It shows your team and your customers that you prioritize their well-being above all else.

The global numbers on foodborne illness are staggering. Every year, contaminated food is responsible for sickening an estimated 600 million people and causing 420,000 deaths worldwide. And while most pizzerias offer some kind of training, a global survey found that nearly 75% of these programs just cover the bare minimum legal requirements. They fail to bring in real-world scenarios from their own kitchens.

The Core Pillars of Pizzeria Safety

To be truly effective, a training program for a pizza joint has to be built on a few core pillars that speak directly to its unique workflow. These pillars are what create a proactive safety culture, not just a reactive one.

- Pizza Prep Table Management: This means specific rules for temperature monitoring, keeping ingredients separate, and dedicated utensil use at the busiest station in your kitchen.

- Dough Handling Protocols: Clear procedures for handling raw dough to prevent any cross-contamination with cooked or ready-to-eat ingredients.

- Allergen Awareness: Training your crew on how to manage common allergens like gluten, dairy, and nuts, especially when dealing with custom pizza orders.

- Equipment Sanitation: Detailed cleaning schedules for your specialized gear, like the pizza oven, dough sheeters, and peels.

Nailing these fundamentals is the first step. To go deeper, you can also learn more about how a system like HACCP provides a structured approach to food safety in our comprehensive guide. When you focus on these areas, you create a training program that actually connects with the daily tasks of your pizza makers, making safety a natural part of their routine.

Building Your Pizzeria's Core Training Modules

A solid food safety program isn't just a binder on a shelf—it's built from clear, repeatable training that actually makes sense in a busy pizzeria. You need to zero in on the real-world risks that pop up when you're handling dough, managing a dozen different toppings, and moving at the speed a dinner rush demands. These core modules are the bedrock of your team's knowledge.

This is about building muscle memory, not just checking a box. The goal is to make safe practices so automatic that your team doesn't even think about them, especially when the Friday night chaos hits and shortcuts start to look tempting.

Mastering Personal Hygiene Beyond Handwashing

Everyone gets the handwashing part, but real personal hygiene in a pizza kitchen goes way deeper. It's about creating an unbreakable barrier between your team and the pizza they're making, starting the second they clock in.

Your training needs to get specific. Don't just say "wear gloves." Explain when to wear them. A new pair is non-negotiable after handling raw sausage, taking out the trash, or even touching a phone. Train your team to change gloves instinctively between tasks, especially when moving from raw ingredients to ready-to-eat items on the pizza prep table.

Here's a critical point to hammer home: Gloves are not a substitute for clean hands. They are an extra layer of protection. Hands must be washed thoroughly before putting on a new pair of gloves, every single time.

Preventing Cross-Contamination at the Pizza Prep Table

The pizza prep table is ground zero for potential cross-contamination. It’s where raw meats, fresh veggies, different cheeses, and cooked items are all within inches of each other. A single slip-up here can have serious consequences, especially when you factor in allergies.

Your training on cross-contamination has to be laser-focused on this workstation. Make these points non-negotiable:

- Dedicated Utensils: Use separate, color-coded tongs and spoons for each topping category—one for meats, another for veggies, one for cheese. This simple visual cue is surprisingly effective at preventing accidental mixing.

- Allergen Management: If you serve gluten-free crusts, you need an iron-clad process. That means a designated prep area, clean utensils, a separate pizza cutter, and fresh gloves to keep gluten from contaminating the order.

- Smart Ingredient Segregation: Teach your crew how to arrange toppings in the prep rail to minimize risk. For example, raw meats like sausage should never be placed directly next to or above ready-to-eat vegetables like onions or peppers.

Demystifying Time and Temperature Control

We’ve all heard of the "temperature danger zone"—that sweet spot for bacteria between 41°F and 135°F (5°C and 57°C). In a pizzeria, this concept becomes critical at the prep line and in storage. Your job is to make this abstract idea feel tangible and urgent.

Explain that toppings like pepperoni, mushrooms, and cheese can enter this zone in minutes if left out. The refrigerated rail of a pizza prep table is designed to keep them cold, but it isn't magic—it needs constant monitoring. Train your team to use a calibrated food thermometer to check the temperature of ingredients in the rail at the start of every shift and a few times throughout the day. If an item creeps above 41°F, it's a safety problem that has to be fixed immediately.

Practical Cleaning and Sanitation Schedules

A clean pizzeria is a safe pizzeria. It's that simple. Your cleaning and sanitation training should lay out a clear, non-negotiable schedule for every single piece of equipment, from the giant dough mixer down to the humble pizza peel. Break it down into daily, weekly, and monthly tasks so it feels manageable instead of overwhelming.

This module has to specify the right chemicals and procedures for each job. For instance, food contact surfaces like the pizza prep table and cutting boards must be washed, rinsed, and sanitized—in that exact order. It's vital your team understands the difference. For a detailed guide, you can explore our breakdown of the three main types of sanitizer solutions and how to use them correctly in a commercial kitchen.

Your training program isn't just about internal rules; it's about meeting a global standard. Certifications like ServSafe are common in the U.S., with over 80% of restaurants requiring them. Proven methodologies like HACCP are credited with cutting contamination risk by as much as 80% when done right. Still, a global survey found that fewer than 20% of food businesses offer professional development for supervisors, showing a huge gap in building a strong food safety culture from the top down. You can learn more about these food safety training findings in the full report.

These four modules form the foundation of a robust food safety culture in your pizzeria. Below is a quick checklist to help you structure your training content, ensuring you cover the key points with practical, pizzeria-specific examples.

Pizza Restaurant Training Module Checklist

| Module | Key Learning Objectives | Pizza Prep Table Application |

|---|---|---|

| Personal Hygiene | Understand proper handwashing techniques, glove use protocols, and when to stay home sick. | Changing gloves between handling raw sausage and ready-to-eat peppers. Washing hands before stocking the prep rail. |

| Cross-Contamination | Prevent the transfer of bacteria and allergens between foods, surfaces, and equipment. | Using separate, color-coded utensils for meats and veggies. Having a designated "allergy-safe" prep zone on the table. |

| Time & Temp Control | Keep foods out of the temperature danger zone (41°F-135°F). Monitor and log temperatures correctly. | Regularly checking ingredient temperatures in the prep rail with a thermometer. Ensuring the rail holds below 41°F. |

| Cleaning & Sanitation | Know the difference between cleaning and sanitizing. Follow daily, weekly, and monthly cleaning schedules. | Properly washing, rinsing, and sanitizing the cutting board and topping containers at the end of every shift. |

By building your training around these core concepts and applying them directly to the real-world environment of your pizza prep line, you're not just complying with regulations—you're building a team of food safety experts.

Mastering the Pizza Prep Table High-Risk Zone

Your pizza prep table isn't just a workspace; it's the high-traffic, high-risk command center of your entire operation. I like to think of it as a busy intersection where a dozen different ingredients, each with its own safety rules, have to coexist safely during a chaotic dinner rush.

Getting this zone right through dedicated food safety training for employees is non-negotiable. This isn't just theory from a textbook. It's about building practical, repeatable habits that turn your prep station into a fortress of food safety, from the first ticket of the day to the final cleanup.

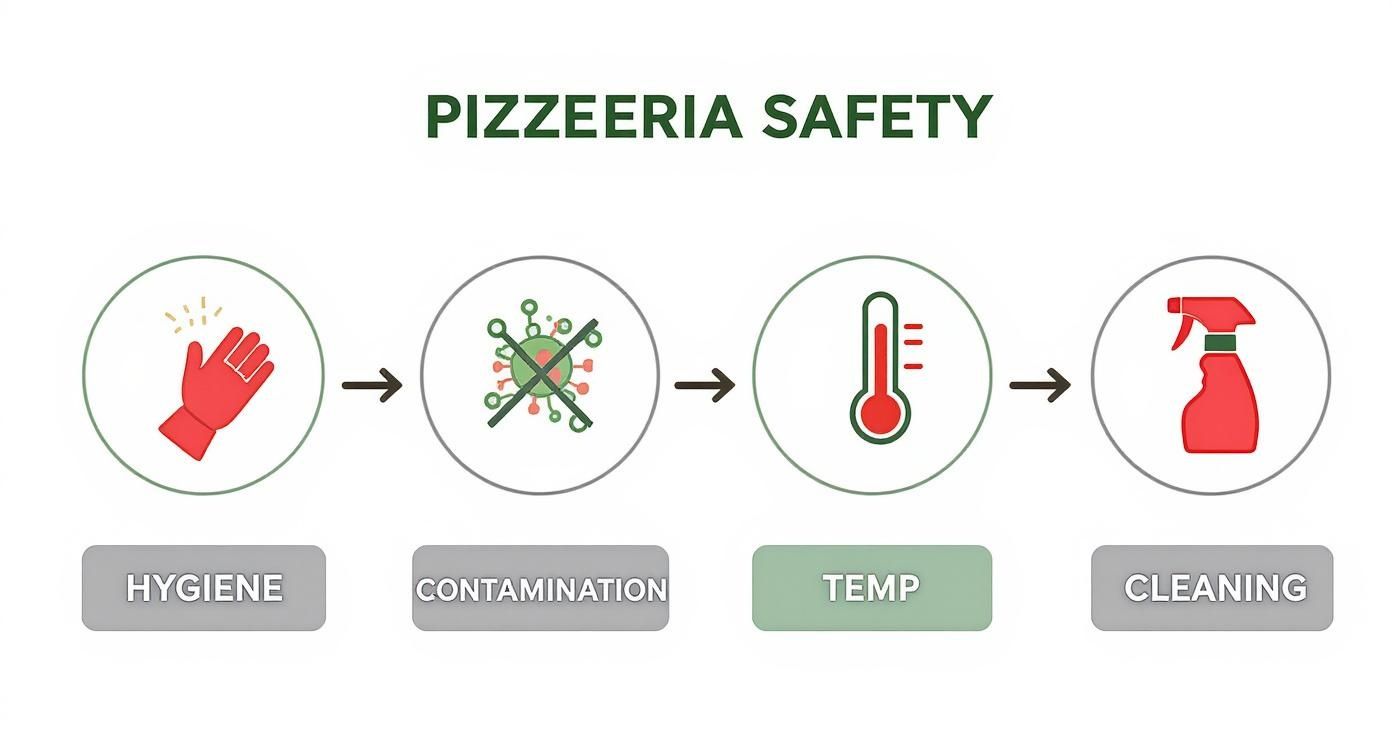

This simple workflow breaks down the four critical pillars of pizzeria safety: keeping yourself clean, stopping germs from spreading, watching your temperatures, and cleaning up the right way.

When you focus your training on these four interconnected areas, you're building a complete safety system that tackles the real-world risks we see in fast-paced pizzerias every single day.

Pre-Shift Setup: The Foundation for a Safe Day

A safe shift starts long before the first order ever hits the printer. The pre-shift setup is your team's chance to make sure that prep table is a safe place to work. This proactive check can head off major problems before they even have a chance to start.

First things first, check the temperature of the refrigerated rail. It absolutely must be holding every single ingredient at or below 41°F (5°C). Train your crew to use a calibrated thermometer to spot-check a few different topping containers. Never just trust the unit's digital display. An FDA study found that less than half of restaurants were consistently on top of their time and temperature controls, which makes this one simple check a powerful way to stay ahead of the curve.

Next, it's all about the strategic arrangement of your toppings. This simple step is one of your best defenses against cross-contamination.

- Raw Meats: Keep things like raw sausage or ground beef at one end of the rail, far away from anything that’s ready to eat.

- Ready-to-Eat Veggies: Group your vegetables—onions, peppers, mushrooms—together and keep them separated from any raw products.

- Allergen Zone: If you can, create a designated spot for common allergens like pineapple or anchovies to prevent any accidental contact.

This kind of thoughtful setup drastically cuts down the risk of dangerous pathogens hopping from one ingredient to another, which is a huge deal when the kitchen gets slammed.

In-Shift Habits for Constant Vigilance

Once service kicks off, food safety becomes all about consistent, disciplined habits. When the ticket machine is screaming, it's easy to want to cut corners. That's precisely when good training needs to take over as muscle memory.

One of the best in-shift rules I've ever seen implemented is "wipe-as-you-go." Spills of sauce, cheese, or toppings shouldn't sit there until closing. Train your team to keep sanitized cloths in a designated bucket and to frequently wipe down the cutting board and stainless-steel surfaces. It's a small action that prevents the buildup of food debris where bacteria love to grow.

Utensil discipline is another huge one. Every single topping container needs its own dedicated tongs or spoon. Sharing utensils is one of the fastest ways to cross-contaminate. Using the same tongs for raw sausage and then grabbing mushrooms is a major food safety foul.

Restocking the prep rail during a rush is a high-risk moment. Never, ever top off a partially empty container with new product. Always pull the old container, clean its slot in the rail, and drop in a fresh, full one. This "first-in, first-out" (FIFO) system is critical for both freshness and safety.

These in-shift behaviors need constant reinforcement. They are the active defenses protecting every single pizza that goes out your door.

End-of-Day Breakdown: The Final Defense

The end-of-day breakdown and sanitation process is your last line of defense against bacterial growth overnight. A rushed or sloppy cleaning job leaves your prep table vulnerable, creating risks for the next day's service before it even begins.

This process has to be methodical and complete. It's way more than just a quick wipe-down.

- Empty and Store: All leftover toppings have to come out of the prep rail. Each ingredient gets properly covered, labeled with today's date, and stored in the walk-in cooler.

- Wash, Rinse, Sanitize: The empty containers, their lids, and every utensil—tongs, spoons, cutting boards—must go through the full three-step cleaning process.

- Deep Clean the Unit: The prep table itself needs a thorough cleaning and sanitizing. This includes the refrigerated rail, the gaskets around the doors, and all the stainless-steel surfaces.

This final step is also critical for taking care of your equipment. For more specific advice, our guide on the best way to clean a stainless steel refrigerator has detailed techniques that apply perfectly to your prep table. By leaving the station impeccably clean, you reset the safety standard for the next shift.

Putting Your Pizzeria Training Program into Action

A killer curriculum is one thing, but making it stick on the kitchen floor? That’s a whole different game. A well-designed food safety training for employees program only works when it’s consistently put into practice, turning abstract rules into automatic habits for your crew. This is your roadmap for rolling out the training, from a new hire’s first day to keeping your veteran pizza makers sharp and bought-in.

The goal here isn’t a single, forgettable training day. It’s about weaving food safety so deeply into your pizzeria's culture that it becomes a shared responsibility everyone takes seriously.

Onboarding New Hires The Right Way

That first week is your golden opportunity to set the standard. New employees are sponges—they’re eager to learn the ropes and make a good impression, so use this time to build a rock-solid foundation. A mix of theory and hands-on practice is always going to beat just handing them a manual.

Try a structured first-week schedule that introduces concepts gradually. For instance, Day One could be all about personal hygiene and a thorough kitchen tour. On Day Two, you can dive into cross-contamination with direct practice at the pizza prep table. This approach immediately connects the "why" behind a rule with the "how" of doing it right.

Your onboarding is the first and best chance you get to show that food safety isn't just a rule—it's a core value. The way you introduce these concepts will shape an employee's attitude for their entire time with you.

To really make it stick, the "shadow-and-show" technique is unbeatable. Have the new hire shadow a seasoned team member at the pizza prep table, watching how they work. Then, have the new person demonstrate those same tasks back. This active learning builds muscle memory for critical habits, like using separate tongs for meat and veggies or correctly restocking the topping rail.

Keeping Veteran Staff Engaged with Refresher Training

Let's be honest: food safety knowledge isn't permanent. Bad habits can creep back in, especially when the kitchen is slammed on a Friday night. That’s why ongoing refresher training is non-negotiable for preventing skill decay and reinforcing your high standards. But how do you keep these sessions from feeling like a chore for your experienced pizza crew?

Instead of boring, formal classroom sessions, try short, punchy "huddles" before a shift. You could focus on a single topic for the whole week, like temperature logging or handling allergen-aware orders. These quick, 5-minute reminders are much easier to digest and far more likely to be remembered during the rush.

Another great strategy is to make it interactive. For some really creative ideas, you can check out these branching safety training examples to build dynamic, scenario-based learning paths. Pose a real-world pizzeria problem, like, "A customer calls asking about gluten-free options. What are the exact steps you take at the pizza prep table?" Discuss the answers as a team. This gets people thinking critically instead of just nodding along.

The data backs this up in a big way. The effectiveness of food safety training is directly tied to improved employee knowledge and real-world practices. One major study found that employees who got refresher training were 25 times more likely to hit acceptable knowledge scores and an incredible 45 times more likely to achieve excellent scores. Even better, the odds of them demonstrating proper practices shot up by a factor of over 10.

Tracking and Assessing Knowledge

You can't manage what you don't measure. Figuring out who's been trained and whether they actually got it is critical to knowing if your program is working. The good news is this doesn't have to be a complicated, bureaucratic headache.

A few simple tools can make all the difference:

- Training Log: Keep a simple spreadsheet or checklist that tracks which employee has completed which training module and when. This is a lifesaver for accountability and for spotting who’s due for a refresher.

- Informal Quizzes: Short, friendly quizzes are a great, low-pressure way to see what’s sticking. You can even make it fun with a small prize for the high score, like a free pizza or getting first pick of shifts.

- On-the-Floor Observations: The real test is how people behave when they think no one is watching. Managers should make a habit of observing the team during service, offering immediate, constructive feedback on things like glove changes or cleaning procedures at the prep table.

By combining a solid onboarding process, creative refresher sessions, and simple tracking methods, you turn your training program from a one-off event into a continuous cycle of learning and improvement. This is how you build a genuine food safety culture that protects your customers, your team, and your reputation with every single pizza that goes out the door.

Nail Your Next Health Inspection with Smart Compliance & Modern Tools

Think of your food safety training program as your best defense when a health inspector walks through the door. It’s more than just a binder on a shelf. Well-kept training logs and checklists you actually use every day show an inspector that safety is baked into your pizzeria's culture, not just a performance you put on when they arrive.

This paper trail is your proof. It provides concrete evidence that your team has the knowledge to handle food safely, especially around a high-risk area like the pizza prep table. It can be the one thing that turns a good inspection into a great one.

What Health Inspectors Look for at the Pizza Station

Health inspectors are pros at spotting risks, and the pizza prep table is often their first stop. They know it's a hot zone where raw meats, fresh veggies, and ready-to-eat cheeses all come together, making it a critical control point for foodborne illness.

Your training needs to get your team ready for this scrutiny. Here's what inspectors will zero in on:

- Temperature Logs: The first thing they'll ask for are your daily temp logs for the prep table's refrigerated rail. If they're missing, incomplete, or look like they were filled out five minutes ago, that's a huge red flag.

- Ingredient Temperatures: Expect them to pull out their own calibrated thermometer. They’ll spot-check the temperature of your pepperoni, cheese, and sausage to make sure everything is holding at or below 41°F (5°C).

- Cross-Contamination Risks: They'll scan your setup with a critical eye. Are raw meats stored properly away from vegetables? Are there dedicated tongs and spoons for each ingredient to prevent allergens and bacteria from mixing?

- Sanitizer Solution: That red bucket of sanitizer isn't just for show. They'll dip a test strip into your solution to verify its concentration is strong enough to actually kill germs on contact.

After the prep station, they're usually heading straight for the walk-in cooler to check your food storage, labeling, and dating. Be ready.

Elevating Safety with Modern Tools

Meeting the health code is the minimum. Today's technology gives you powerful—and surprisingly affordable—ways to build an even safer pizzeria. A few smart tools can automate critical tasks, make training stick, and cut down on human error when the dinner rush gets chaotic.

One of the best upgrades you can make is a digital temperature monitoring system. These systems use small wireless sensors you place inside your pizza prep rail and walk-in coolers to track temperatures 24/7. If a cooler starts to warm up into the danger zone, you get an alert sent straight to your phone. It's the difference between catching a problem early and losing thousands of dollars in spoiled toppings.

Technology shifts food safety from a manual chore that's easy to forget into an automated, reliable system. It gives you the power to spot issues in real-time, long before they can threaten your customers or your business.

QR codes are another simple but brilliant tool. You can create and print QR codes that link directly to specific training videos or checklists. Stick one on the dough mixer, and a new hire can scan it to watch a quick video on the correct cleaning procedure. This brings training right to the station where it's needed most. Some businesses are even exploring things like augmented reality safety programs in the workplace to provide interactive instructions right on the equipment itself.

Implementing Daily Safety Checks

To make all this training stick, you have to turn it into a daily habit. A pre-shift safety checklist and a daily temperature log are non-negotiable. These tools reinforce what your team has learned and build a culture of accountability. Plus, they create the documentation you need to ace that next inspection.

This checklist is a fantastic starting point for your pizza prep station. It covers the core opening and closing duties that keep this critical area safe, clean, and compliant from open to close.

Pizza Station Daily Safety Checklist

| Task (Opening) | Check | Task (Closing) | Check |

|---|---|---|---|

| Check prep rail temp (must be ≤ 41°F) | ☐ | Discard all toppings from rail | ☐ |

| Verify sanitizer bucket solution is at correct concentration | ☐ | Wipe down & sanitize entire prep surface and cutting board | ☐ |

| Stock rail with fresh, dated ingredients using FIFO | ☐ | Clean and sanitize all utensils (tongs, spoons, etc.) | ☐ |

| Ensure separate, clean utensils are in each topping bin | ☐ | Cover and properly store any bulk backup ingredients | ☐ |

| Wipe down entire prep station surface with sanitizer | ☐ | Sweep and mop the floor around the prep station | ☐ |

| Check handwashing sink is stocked (soap, paper towels) | ☐ | Empty trash receptacles near the station | ☐ |

Making checklists like this a part of your daily rhythm turns abstract safety rules into concrete actions your team can own. It’s the simplest way to ensure standards are met every single shift.

Got Questions About Pizzeria Food Safety? We've Got Answers.

When you're running a busy pizzeria, putting a solid food safety training for employees program in place can bring up a lot of real-world questions. Let's tackle some of the most common ones I hear from owners and managers who are deep in the trenches.

How Often Should I Be Retraining My Pizza Chefs?

Think of it as a constant conversation, not a once-a-year lecture. The best approach is to hold quick, informal refresher sessions every quarter and a more thorough, sit-down review once a year. This keeps safety from becoming an afterthought.

I always tell managers to use real events as training opportunities. Did you get a lower-than-expected health inspection score? Did a supplier issue a recall on mushrooms? Use that moment to huddle up the team and focus on high-risk zones like the pizza prep table. These frequent reminders stick far better than a single session that gets forgotten by next month.

What's the Single Biggest Food Safety Risk at a Pizza Station?

If I had to pick just one thing, it's the temperature of the pizza prep rail. Every other safety rule is important, but nothing beats strict time and temperature control for your toppings. That refrigerated unit has one job: keep everything below 41°F (5°C) to stop bacteria from throwing a party.

Your team needs to be obsessed with this. Train them to constantly monitor the temperature. Emphasize that perishable toppings—sausage, cheese, cut veggies—can't just hang out at room temperature. This one habit is your most powerful weapon against foodborne illness in a pizzeria.

A ServSafe certification is an excellent starting point for any food handler. However, it should be seen as the foundation, not the entire structure. Real-world, hands-on training that addresses your specific kitchen layout, menu, and equipment—especially your pizza prep table—is what turns theoretical knowledge into practical, life-saving habits.

Is Getting My Staff a ServSafe Certification Online Good Enough?

Online certifications like ServSafe are fantastic for building a solid baseline. They teach the "what" and "why" of food safety, and frankly, they're often a legal necessity. But they are absolutely not a complete solution.

You have to connect that textbook knowledge to your actual pizzeria. That means hands-on training covering your unique layout, your specific dough mixers, and your menu. The combination of formal certification and practical, in-house training is what creates a food safety culture that truly protects your customers and your business.

What's the Best Way to Train Staff on Handling Allergens?

Don't just tack allergen training on at the end of a session—give it the spotlight it deserves. Your team needs crystal-clear, actionable steps to prevent cross-contact, and the pizza prep table is ground zero for this.

- Dedicated Tools: Teach everyone to grab a clean, designated pizza cutter and use separate prep surfaces for gluten-free or other allergy-sensitive orders. No exceptions.

- Glove Discipline: Make changing gloves after handling common allergens like cheese, nuts, or seafood a non-negotiable rule.

- Clear Communication: Your crew needs to know how to communicate clearly with each other and with customers about how an allergy-safe order is being handled.

A simple visual chart of the most common allergens found in your toppings, posted right at the pizza prep station, can be a game-changer during a busy rush.

A well-trained team is the foundation of a safe kitchen, and the right equipment makes their job easier. Pizza Prep Table provides high-quality, NSF-compliant refrigeration solutions designed to maintain precise temperatures and streamline your workflow. Explore our selection of pizza prep tables and commercial kitchen equipment to build a safer, more efficient pizzeria at https://pizzapreptable.com.