The Ultimate Guide to Pizza Prep Tables Commercial for Your Pizzeria

Share

A commercial pizza prep table is the operational core of any high-volume pizzeria. Think of it as a dedicated, refrigerated command center for building pizzas quickly and safely. It cleverly combines a tough work surface with built-in, chilled compartments for toppings and ingredients, making sure everything stays fresh and right where you need it. For a busy pizza shop, this piece of equipment is the essential tool for keeping up speed, consistency, and food safety when the dinner rush hits.

The Heartbeat of an Efficient Pizzeria

Imagine the chaos of a Friday night rush. Orders are pouring in, tickets are stacking up, and your kitchen staff is scrambling. In a poorly organized pizzeria, a pizza maker might have to dart between a random countertop, a reach-in cooler for the cheese, and another one for the veggies. Each extra step adds precious seconds, and those seconds snowball into minutes of lost time, leading to inconsistent pizzas and unhappy customers.

Now, picture a different scene. Your pizza maker is planted at a single station, the stainless steel surface cool and ready. Stretched dough lands on a deep cutting board. With a simple reach, they grab chilled mozzarella, pepperoni, and perfectly sliced mushrooms from refrigerated pans sitting directly in front of them. The workflow is fluid, ergonomic, and incredibly fast.

This seamless operation isn’t just a happy accident; it’s the direct result of a well-chosen prep tables commercial setup designed specifically for pizza. More than just a slab of stainless steel, a great pizza prep table is the central hub of your entire production line. It's where raw ingredients are transformed into your signature product with maximum efficiency.

Why Your Pizza Prep Table Matters

Investing in the right prep table isn't just an expense—it's a strategic decision that directly boosts your pizzeria's bottom line. It’s an asset that pays you back in several critical ways.

- Boosted Speed and Output: By keeping all your essential pizza toppings organized and chilled at the point of assembly, you slash wasted motion and seriously speed up production.

- Guaranteed Pizza Consistency: An organized station means every pizza maker is pulling from the same fresh ingredients, leading to a consistent product that keeps customers coming back for more.

- Unyielding Food Safety: Integrated refrigeration keeps perishable toppings like cheese and meats well within the crucial food-safe temperature zone (below 41°F), preventing spoilage and keeping the health inspector happy.

A great pizza prep table isn't just about convenience; it's a foundational tool for building a reputation based on quality, speed, and safety. It empowers your team to work smarter, not harder.

The global demand for these specialized units has been surging for a reason. The market for pizza prep tables was valued at around USD 1.75 billion in 2024 and is projected to grow significantly. This growth just underscores how essential these tables have become for modern pizzerias trying to keep up with customer demand.

In this guide, we'll walk you through everything you need to know about selecting, using, and maintaining the perfect prep tables commercial for your pizzeria. From understanding the core components to mastering maintenance, you’ll have the knowledge you need to build a faster, safer, and more profitable kitchen. For a broader look at what your kitchen needs, check out our guide on commercial food prep equipment.

Getting to Know Your Pizza Prep Table's Anatomy

To make a smart buy on a prep table commercial, you need to know what you're looking at. A pizza prep table isn't just one big appliance; it's a whole system of parts working together for speed, toughness, and food safety. Getting a handle on these components and why they're important is the first step to picking a unit that will become the workhorse of your pizzeria.

A pizza prep table has three main zones: the refrigerated rail where your toppings hang out, the cutting board where the magic happens, and the refrigerated base where you stash your backup dough boxes and bulk ingredients. Each zone has features that will make or break your kitchen's flow, from how fresh your pepperoni stays to how long the table itself will last.

The Refrigerated Rail: Your Freshness Lifeline

The refrigerated rail is the heart of your station. It’s where you keep your pans of cheese, veggies, meats, and sauce. Its one job is to keep all those perishable pizza toppings safely below 41°F (5°C), even when you're slammed during a Friday night rush. How it achieves this is a pretty big deal.

You'll generally run into two types of cooling systems for these rails:

- Forced-Air Cooling: This is the more common setup. It uses fans to blow cold air directly over and around the food pans. It's fantastic at keeping temperatures steady and bounces back quickly when the lid is opened and closed a hundred times an hour. This makes it perfect for high-volume pizzerias.

- Cold-Wall Cooling: This system is a bit different, relying on refrigerant lines built right into the walls around the pan rail. It’s usually quieter and more energy-efficient, but it can sometimes have a tough time keeping up if your crew is constantly leaving the lid open during a busy pizza rush.

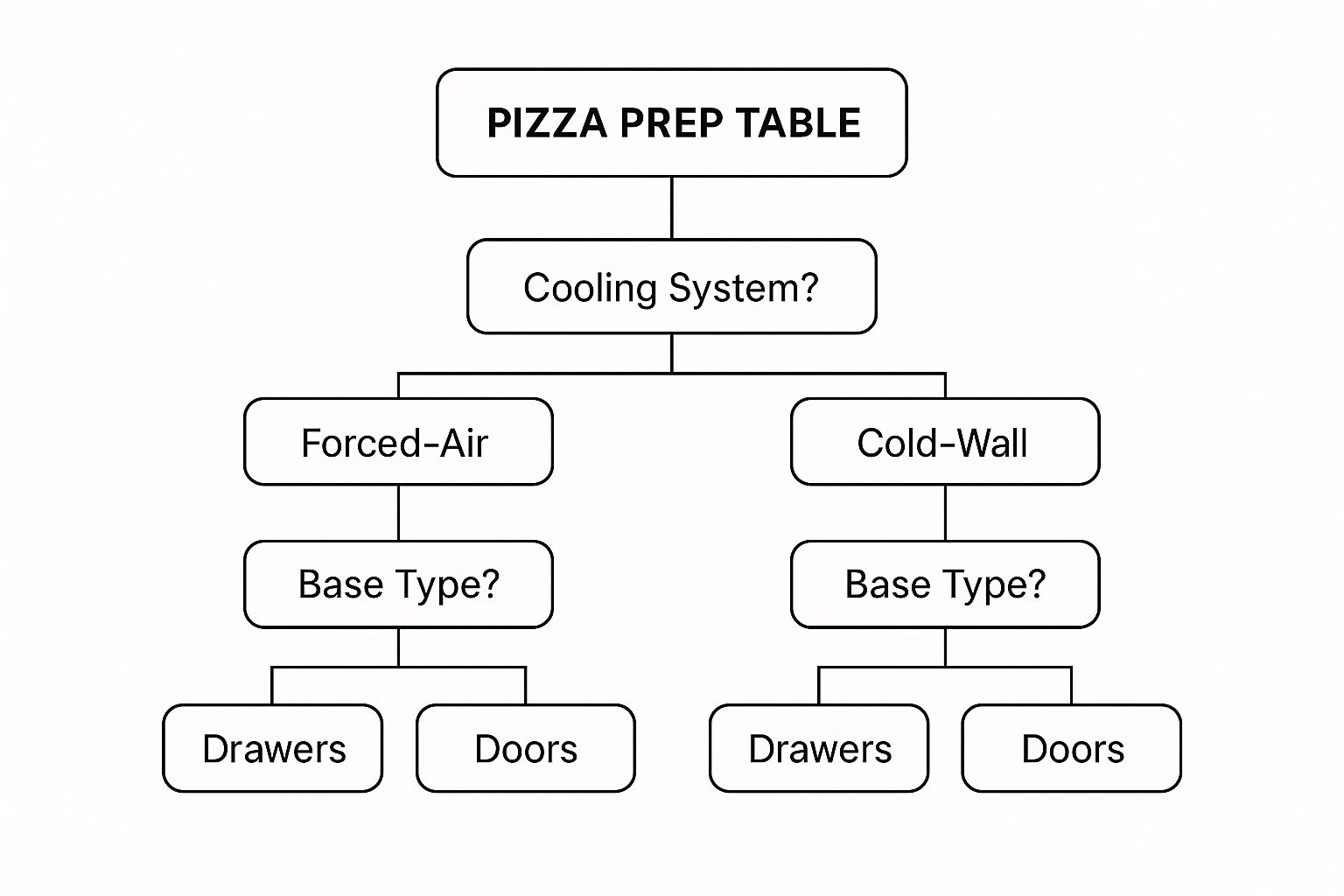

This decision tree helps visualize how your first big choices, like the cooling system and base type, set you on a path to the right table for your pizza shop.

What the infographic really shows is that how you operate your pizzeria—whether you prioritize speed, energy savings, or storage access—is what determines the best setup for your kitchen.

The Workspace and Storage: Your Pizza-Making Base

Just below the rail is your main workspace: the cutting board. When you're making pizza, the depth of this board is a deal-breaker. A sandwich prep table might get away with a narrow board, but a pizza prep table needs a deep one, often 19 inches or more. You need that space to handle large pizza skins without them flopping over the edge. Most boards these days are made of high-density polyethylene, which is a non-porous material that’s a breeze to clean and won't dull your knives.

Underneath the workspace, you’ve got the refrigerated base for your bulk cold storage. Your choice here boils down to doors versus drawers.

Doors are fantastic for storing bigger, awkward items like cases of cheese, dough boxes, or giant tubs of sauce. Drawers, on the other hand, are perfect for organizing smaller, portioned ingredients, which can make your workflow much faster and cleaner.

A lot of pizzeria owners end up choosing a combination unit. It really gives them the best of both worlds and the flexibility to store items of all shapes and sizes, which is key to keeping the kitchen running like a well-oiled machine.

The Unseen Engine and Durable Body

The two parts that get overlooked the most, yet are arguably the most important, are the condenser coil and the material the unit is built from. The condenser is the engine of your whole refrigeration system. It works by pushing heat out of the refrigerant, but if it gets clogged with flour, dust, and grease, the compressor has to work way harder. Trust me, a dirty condenser is the number one killer of pizza prep tables, leading to sky-high energy bills and costly repair calls.

Finally, any prep table commercial worth its salt should be made of stainless steel. But not all stainless steel is created equal. You want to look for units built from 300-series stainless steel for any area that touches food and 400-series for the outside. This combination ensures the table can stand up to corrosion and the daily beating of a commercial pizzeria, protecting your investment for years to come.

How to Select the Perfect Commercial Prep Table for Your Pizzeria

Choosing the right prep table commercial for your pizzeria is a make-or-break decision. It’s one of those choices that quietly shapes every single shift. Get it right, and the table feels like a natural extension of your crew. Get it wrong, and you've just installed a permanent bottleneck in your pizza line.

This is more than a simple purchase; it's a strategic investment in your kitchen's speed, consistency, and sanity. To nail it, you have to think like a kitchen strategist. It all starts with asking a few core questions about how your pizzeria actually operates day in and day out.

Answering the Three Core Questions for Your Pizzeria

Before you even glance at a single model, hit the pause button. Take a hard look at your specific needs, because every pizzeria has its own rhythm. Your prep table has to match it.

-

What Size Fits My Space and Volume? This is the most practical place to start. Your new table has to physically fit into your kitchen layout without causing traffic jams. Common sizes like 48", 60", and 93" models each have their place. A 48" unit might be perfect for a small café that added pizzas to the menu, but a bustling pizzeria cranking out pies all night will need a 60" or larger table to keep up.

-

How Many Pizzas Do I Make During Peak Hours? Think about your busiest hour on a Friday night. That's the real test. If you’re pushing out 50+ pizzas an hour, you need a prep table that can hold enough toppings to survive the rush. A smaller table means your team is constantly stopping to run to the walk-in, killing their momentum and slowing down ticket times.

-

What Does My Pizza Menu Require? Finally, consider your menu's complexity. Are you a classic cheese and pepperoni shop? Or are you a gourmet spot with two dozen fresh vegetable and meat toppings? The more ingredients you offer, the more pan slots you'll need in that refrigerated rail. It's that simple.

Standard Top vs Mega Top: Which Is Right for Your Pizzeria?

Once you've got a handle on size and volume, the next big decision is the refrigerated rail's configuration. This choice ties directly back to your pizza menu and breaks down into two main options: the standard top or the mega top.

A standard top prep table usually comes with two rows of food pans. This setup offers a solid amount of storage for the most common pizza toppings and gives you a good balance of ingredient capacity and a nice, open workspace on the cutting board.

On the other hand, a mega top unit squeezes in a third row of pans. This simple change boosts your topping capacity by 30% or more compared to a standard top of the same width. For pizzerias with huge, topping-heavy menus, this is an absolute game-changer.

The choice between a standard and mega top is a direct reflection of your menu strategy. A mega top supports ingredient diversity and high-volume output, while a standard top is an efficient choice for more focused, streamlined menus.

To make it even clearer, let's look at them side-by-side.

Pizza Prep Table Comparison: Standard vs Mega Top

Deciding between a standard and mega top table really comes down to balancing your pizza menu's ambition with your kitchen's workflow. Here’s a quick breakdown to help you see which one fits your operation.

| Feature | Standard Top Pizza Prep Table | Mega Top Pizza Prep Table |

|---|---|---|

| Ingredient Capacity | Good for essential toppings (2 rows of pans) | Excellent for extensive menus (3 rows of pans) |

| Workspace | More open cutting board area | Slightly less depth on the cutting board |

| Ideal Use Case | Pizzerias with a focused menu | Pizzerias with diverse, gourmet toppings |

Ultimately, the mega top is for the pizzeria that never wants to say "no" to a topping request, while the standard top is for the operation that has perfected a classic, high-demand menu.

Of course, the table's material and build are just as crucial as its configuration. If you're planning a full kitchen build-out or renovation, getting expert advice from commercial construction services can ensure your new table is integrated perfectly into the workflow. Durability is also paramount. To dig deeper into what makes a workstation last, check out our guide on the benefits of a stainless steel prep table. This decision affects not just your workflow today, but your return on investment for years to come.

Fine-Tuning Your Pizza Workflow and Food Safety

Owning the perfect prep table commercial is a great first step, but the real magic happens in how you use it day in and day out. Think of the table as a high-performance engine; your workflow is the skilled driver that gets the most out of it. This is where your investment starts paying you back in speed, consistency, and most importantly, safety.

A well-organized station is what separates a chaotic pizzeria from a smooth-running machine during the dinner rush. By turning your prep table into a finely tuned system, you give your pizza makers the power to work faster, smarter, and safer. It’s how you guarantee every single pizza that leaves your kitchen is up to your standards.

Mastering Mise en Place for Peak Pizza-Making Speed

In the restaurant world, "mise en place" is everything. It literally means "everything in its place," and for a pizzeria, that philosophy begins at the refrigerated topping rail. A smart, strategic rail setup is the secret to shaving precious seconds off every pizza order—and those seconds add up fast during a busy shift.

Take a look at your most popular pizzas. What are the top three or four ingredients you use on nearly every single order? Those ingredients deserve the prime real estate on your topping rail, placed directly in front of your pizza maker for the easiest access.

- High-Volume Toppings First: Put your workhorse ingredients like mozzarella, pepperoni, and mushrooms in the most accessible pans. This simple move cuts down on reaching and wasted motion.

- Logical Grouping: Keep all your vegetables on one side and all your meats on the other. This isn't just for organization; it's a critical step in reducing the risk of cross-contamination.

- Ergonomics Matter: Position the pans so your team can scoop with a natural, fluid motion. Twisting and overextending leads to fatigue, which slows everyone down over a long night.

This kind of methodical setup helps your team build pizzas on muscle memory. It gets rid of hesitation and searching, letting them assemble orders with instinctual speed.

The Unbreakable Rules of Pizzeria Food Safety

Speed is great, but food safety is non-negotiable. Your prep table commercial is your front line of defense in protecting both your customers and your reputation. Following strict protocols isn't just about passing a health inspection; it's about building trust with every person who eats your pizza.

Temperature is king. The refrigerated compartments are designed to keep perishable ingredients in the "safe zone"—at or below 41°F (5°C). This is the magic number that stops harmful bacteria from growing.

Your refrigerated prep table does more than just keep toppings cool; it actively safeguards the health of your customers. Treating its temperature settings and storage procedures with absolute seriousness is fundamental to running a responsible pizzeria.

The industry gets it. The market for these refrigerated tables was valued at around USD 3.24 billion in 2023 and is only expected to grow, largely driven by rising hygiene standards and food safety laws.

Daily and Nightly Safety Protocols

Great safety habits are built through daily repetition. Here are the essential procedures to weave into your pizzeria's routine:

-

Implement FIFO: Always, always follow the "First-In, First-Out" rule. When you restock the pans, put the new ingredients in the back and slide the older ones to the front. This one simple habit ensures you use the freshest product first and drastically cuts down on spoilage.

-

Nightly Storage is a Must: Never leave toppings out in the rail overnight. At the end of every shift, all pans must be pulled, covered tightly with plastic wrap, and stored in the refrigerated base or a walk-in cooler. This keeps ingredients from drying out and protects them from airborne contaminants.

-

Prevent Cross-Contamination: This is a big one. Use separate, dedicated scoops or tongs for each ingredient, especially between meats and vegetables. Clean and sanitize these utensils regularly throughout the shift to stop bacteria from hitching a ride.

Beyond the equipment itself, knowing how to master food safety in your restaurant is critical. When you combine an efficient workflow with rock-solid safety rules, your prep table becomes the reliable heart of a profitable and respected pizzeria.

Keep Your Investment Humming: Essential Pizza Prep Table Maintenance

Think of your commercial pizza prep table as the engine of your pizzeria. It’s a serious investment, and just like the engine in your delivery car, it needs regular care to keep running smoothly and avoid a catastrophic breakdown during the Friday night rush.

Protecting this piece of equipment isn't a chore; it’s one of the smartest things you can do for your bottom line. A few minutes of consistent maintenance can save you thousands in emergency repair bills and add years to your unit's life. Neglecting it is a recipe for disaster.

And these tables are only becoming more critical. The market for them was already valued at USD 1.18 billion in 2023 and is expected to hit USD 1.62 billion by 2029. That tells you just how central these workhorses are to modern pizzerias, making their upkeep more important than ever.

Your Daily Maintenance Checklist

Simple, daily habits are the bedrock of a long-lasting prep table. These tasks take just a few minutes at the beginning and end of each day but are your best defense against food safety issues and equipment failure.

- Sanitize All Surfaces: At the end of every single shift, give the cutting board, stainless steel surfaces, and topping rail a thorough cleaning. Use food-safe cleaners to get rid of all food debris. For some pro tips, check out our guide on the best way to clean a stainless steel refrigerator.

- Wipe Down Gaskets: Grab a damp cloth and wipe down the door and drawer gaskets. Crumbs and sticky residue will ruin the seal, forcing the compressor to work overtime and driving up your energy bill.

- Check the Temp: Make it a habit to glance at the thermometer. You need to see that the refrigerated base and rail are holding steady at or below 41°F (5°C). This isn't just a suggestion; it's a food safety absolute.

Weekly Deep Cleaning Routines

Once a week, you need to go a little deeper. This is where you tackle the grime that builds up after a busy week of slinging pies and prevent small issues from turning into big, expensive problems.

First, unplug the unit and pull out all the food pans and other contents. Get those pans and inserts into your three-compartment sink for a good washing, and let them air dry completely. Then, scrub the inside of the refrigerated base and the entire topping rail area, making sure to get into every corner to hunt down any hidden spills.

Think of this weekly clean-out as a system reset. It’s your chance to spot little things—a torn gasket, a slow drain—before they escalate into a frantic service call that shuts down your entire pizza make-line.

Critical Monthly Procedures

Your monthly tasks are less frequent but are arguably the most important for the health of your prep tables commercial. These steps directly impact how well your refrigeration system works and how long it lasts.

The single most important job is cleaning the condenser coil. Over time, these coils get absolutely caked with airborne flour, grease, and dust. A clogged coil is like putting a pillow over the compressor's face—it suffocates the system, causing it to overheat as it struggles to release heat. This is, without a doubt, the #1 cause of premature refrigeration failure in pizzerias.

How to Clean Your Condenser Coil:

- Disconnect Power: Always, always unplug the prep table from the wall before you start. No exceptions.

- Access the Coil: Find the condenser. It’s usually hiding behind a removable panel on the front or back.

- Brush and Vacuum: Use a stiff-bristled brush to gently loosen all the gunk on the coils. Follow that up with a vacuum cleaner to suck away all the debris.

Doing this 15-minute task every month ensures your pizza prep table runs efficiently, keeps your energy bills in check, and can prevent a multi-thousand-dollar compressor replacement. A clean machine is a reliable machine.

Answering Your Top Pizza Prep Table Questions

Once you’ve got a handle on the basics of choosing and maintaining a prep table commercial, the real-world questions start popping up. What about the power bill? Am I following the health code? Can I just use a sandwich table instead? These are the details that separate a good pizzeria from a great one.

Think of this as your go-to FAQ for those moments when you need a straight, practical answer. Getting these things right is what keeps your operation running smoothly and safely.

How Much Electricity Does a Pizza Prep Table Use?

This is a big one for any pizzeria owner keeping an eye on overhead. The truth is, the exact electricity usage of a commercial pizza prep table depends on a few things: its size, the compressor's efficiency, how hot your kitchen gets, and how often your staff opens it.

As a ballpark figure, a standard 60-inch pizza prep unit will likely use between 8 to 12 kWh of electricity per day. To keep that number as low as possible, always look for the ENERGY STAR certification. These models are independently proven to be at least 20% more efficient than their standard counterparts, which adds up to real savings on your utility bill.

You can also slash energy use with a few smart habits. Make sure the door gaskets are clean and create a tight seal—any escaping cold air means the compressor works overtime. Cleaning the condenser coils regularly is another huge win, as it allows the unit to shed heat efficiently. Little things, like keeping the unit away from the pizza oven and closing the rail lids when not in use, make a surprisingly big difference.

What Are the Health Code Requirements for a Pizza Prep Table?

When it comes to health codes for prep tables commercial, it all boils down to one critical thing: keeping food at a safe temperature to stop harmful bacteria from growing. This is absolutely non-negotiable for any pizzeria.

The single most important rule is that your prep table's refrigerated rail must keep all your perishable toppings at or below 41°F (5°C). That temperature is the line in the sand between safe food and the "danger zone."

Health departments want to see proof that your equipment is up to the task. That's why they often require equipment to be NSF (National Sanitation Foundation) certified. An NSF stamp on your prep table is your assurance—and theirs—that it meets strict public health standards for pizzerias.

Beyond temperature, the cutting board has to be made of a non-porous material like high-density polyethylene, which won’t harbor bacteria. It needs to be kept clean and free of deep cuts where germs can hide. And, of course, daily sanitizing of every surface that touches food is mandatory.

Can I Use a Sandwich Prep Table for Making Pizzas?

You technically can, but you really, really shouldn't. Trying to make a pizza on a sandwich prep table is a recipe for frustration and a massive workflow bottleneck that will slow down your entire line. No serious pizzeria would even consider it.

The main difference is the depth of the cutting board. A true pizza prep table has a deep board, usually 19 inches or more, specifically designed to handle large, round pizza dough. A sandwich prep table, on the other hand, typically has a board that's only 8 to 12 inches deep.

This means your pizza maker has to do this awkward shuffle—stretching and saucing the dough on a separate counter, then moving it to the narrow board for toppings. It’s a broken workflow that kills speed and increases the chance of mistakes and cross-contamination. For the speed and ergonomic flow you need in a competitive pizza kitchen, investing in a purpose-built pizza prep table is essential.

How Often Should I Clean the Condenser Coils?

Listen up, because this is the most important maintenance task you can do to protect your investment. For most pizzerias, cleaning the condenser coils every 90 days is a solid routine.

However, if your kitchen is full of airborne flour and grease—which is pretty much every pizza shop—you need to bump that up to monthly. When coils get clogged, they act like a winter coat, trapping heat and forcing the compressor to run nonstop. This spikes your energy bill, weakens the unit's cooling power, and is the #1 cause of expensive, premature system failure.

Cleaning them is simple and takes about 15 minutes. Just unplug the unit, get to the coils (usually behind a front or back panel), and use a stiff brush to knock off all the gunk. Follow up with a vacuum to suck up the debris. This tiny, regular task can literally save you thousands of dollars in repairs and add years to the life of your machine.

Ready to build a faster, more efficient pizzeria? The right Pizza Prep Table is the heart of your operation. At Pizza Prep Table, we offer a huge selection of top-quality units from brands like Atosa, True, and Dukers, all designed to meet the demands of a busy kitchen. Explore our equipment and find the perfect fit for your restaurant at https://pizzapreptable.com.