How to Choose the Best Stainless Steel Pizza Prep Table

Share

A stainless steel prep table is the operational heart of any high-volume pizza kitchen. It’s the durable, hygienic surface where everything happens—from stretching dough to building your signature pies. Think of it less like a table and more like the central command station where your speed, consistency, and food safety all come together.

The Unsung Hero of Your Pizza Kitchen

Every great pizza starts its journey long before it feels the blistering heat of the oven. Its story begins on the cool, clean surface of a prep table. In a busy pizzeria, this piece of equipment isn't just furniture; it’s the bedrock of your entire workflow. The right table has a direct impact on your service speed, the consistency of your product, and the safety of every single ingredient you handle.

I like to think of a stainless steel prep table as a perfectly seasoned pizza stone. Just as that stone is fundamental for a crisp, delicious crust, your prep table is the essential platform that makes operational excellence possible. It's where raw ingredients get transformed into the final product your customers line up for.

Why Your Pizza Prep Table Choice Matters

Picking out a prep table is about more than just finding something that fits in your kitchen. This is a critical investment, one that pays you back every single day through better efficiency and rock-solid reliability. A poorly chosen table creates bottlenecks, compromises hygiene, and can bring your entire pizza assembly line to a grinding halt. On the flip side, the right one acts as a force multiplier for your pizza-making team.

So, what separates a merely adequate table from one that truly elevates your pizza-making game? It boils down to a few core factors:

- Material Grade: The type of stainless steel used dictates its ability to resist corrosion from acidic ingredients like tomato sauce and pickled peppers.

- Refrigeration Integration: Having chilled toppings within arm's reach is a game-changer for food safety and speed, especially when the dinner rush hits.

- Size and Ergonomics: The table's dimensions have to support a logical workflow, allowing your pizza makers to move efficiently without feeling cramped.

A well-designed pizza prep station is the cornerstone of kitchen efficiency. It streamlines movement, keeps toppings organized, and provides a sanitary workspace—all non-negotiable elements in a successful pizzeria.

Ultimately, this guide is designed to help you look past the price tag and understand the features that will actually make a difference in your day-to-day pizza operations. We'll break down everything from durable construction to smart design, making sure you select a stainless steel prep table that serves as a lasting asset for your pizzeria. Making the right choice here will empower your team, protect your ingredients, and help you crank out consistently excellent pizzas, day in and day out.

Decoding the Anatomy of a Pizza Prep Table

What really separates a workhorse stainless steel prep table from a mere metal shelf? It's all in the anatomy—the specific parts and pieces chosen to survive the non-stop punishment of a busy pizzeria. Think about the constant scraping of pizza peels and the acidic splatter of tomato sauce. Every single detail matters.

Once you understand these details, you can see past the price tag and figure out a table’s real, long-term value. A well-built table isn’t just a surface; it’s a carefully engineered tool built for durability, hygiene, and flat-out pizza-making speed. Let's break down the essential elements that define a high-quality unit.

The Critical Choice of Stainless Steel Grade

Not all stainless steel is created equal, and for a pizza kitchen, this is a massive distinction. The grade of the steel determines how well it fights off corrosion and how long it will last. It’s like choosing between a standard car tire and a heavy-duty, all-weather one; both get the job done, but only one is built for the absolute toughest conditions of a pizzeria.

You'll mainly run into two grades: 304 and 430.

- 304-Grade Stainless Steel: This is the premium choice for any pizza prep surface. It has more chromium and nickel, giving it superior resistance to rust and corrosion. This is a huge deal in a pizzeria where acidic items like tomato sauce, olives, and pickled peppers are constantly sitting on the worksurface.

- 430-Grade Stainless Steel: This is the more budget-friendly option. It's still plenty durable, but it lacks the hardcore corrosion resistance of 304-grade. You'll often find it used for the legs, undershelves, or backsplashes where it's less likely to have prolonged contact with acidic toppings.

For the main worksurface of your pizza prep table, 304-grade is the undisputed champion. It’s your best defense against the pitting and staining that can ruin a table and compromise food safety over time.

Worksurface Design and Integrated Features

Beyond the steel itself, the design of the worksurface directly impacts your kitchen’s flow. The layout should feel less like a countertop and more like a pizza-building cockpit, with everything you need organized and right there. What you choose here comes down entirely to how you operate.

A basic flat top stainless steel prep table gives you a massive, uninterrupted canvas. This is perfect for jobs that need a lot of space, like kneading and stretching large batches of dough. It’s a simple, versatile solution for the first steps of pizza making.

But for the assembly line, an integrated refrigerated rail is a total game-changer. These units have chilled compartments built right into the worksurface, keeping toppings like pepperoni, mushrooms, and cheese perfectly organized and at safe temperatures. This setup cuts down on movement, reduces cross-contamination risks, and seriously speeds up the pizza-building process during a chaotic dinner rush.

A table with an integrated refrigerated rail transforms your prep area from a passive surface into an active, high-efficiency pizza workstation. It’s the fastest way to bridge the gap between your walk-in cooler and the pizza oven.

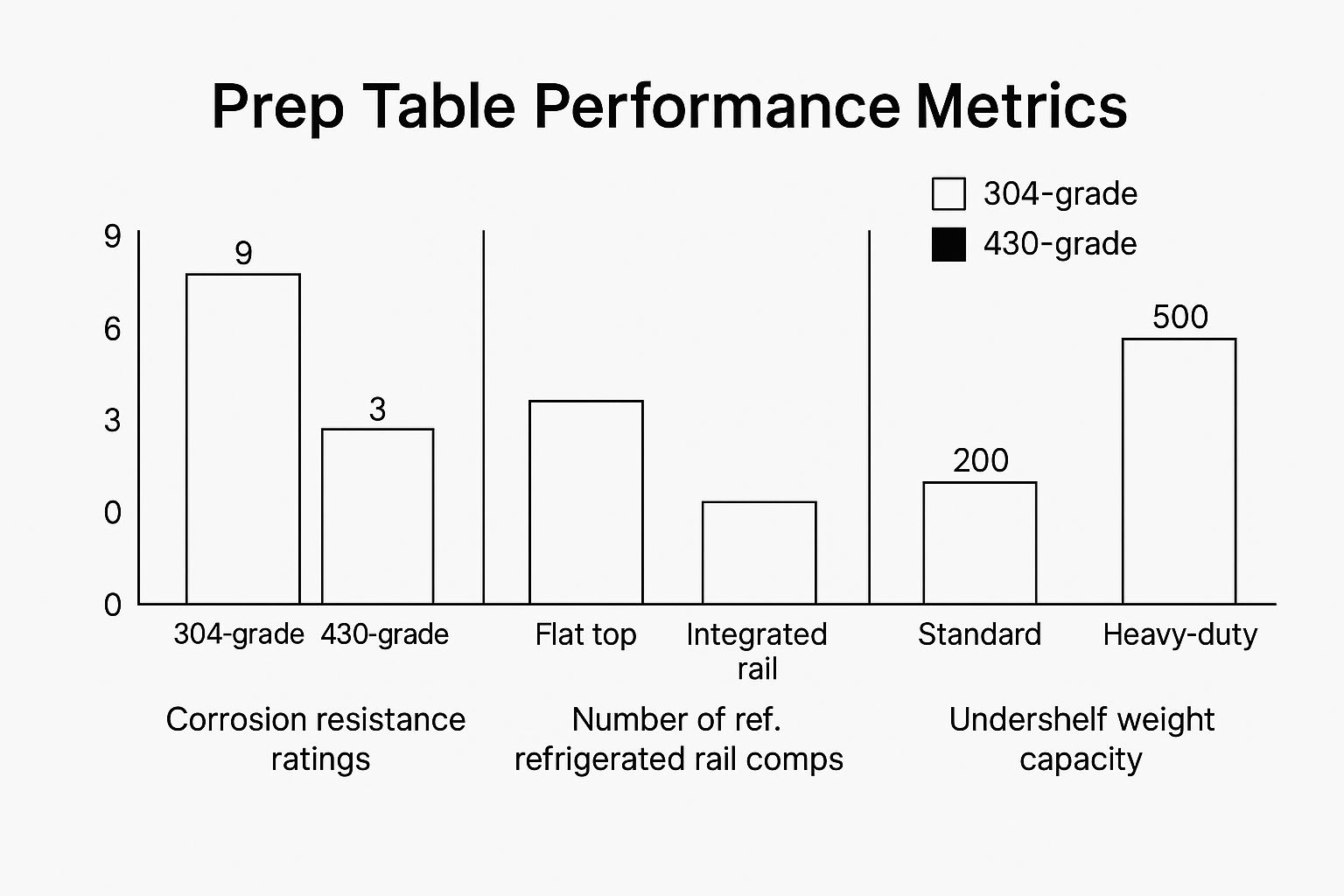

The chart below shows how key performance metrics change based on the features you choose for your prep table.

As you can see, going with a 304-grade steel table with integrated features and a heavy-duty frame provides a massive upgrade in performance and functionality for any pizzeria.

Essential Structural Components

Finally, the support structure of a prep table is just as critical as its surface. These are the features that provide the stability, mobility, and utility you need in a fast-paced pizzeria.

- Heavy-Duty Undershelves: Look for undershelves with a high weight capacity, often rated for 500 lbs or more. This is crucial for storing heavy items like bulk flour bags, stacked dough boxes, or big containers of pizza sauce without the shelf bowing or warping.

- Welded Backsplashes: A backsplash is more than just a trim piece. A welded, 4- to 6-inch backsplash shields your walls from splashes and spills, making cleanup way faster. It also stops sauce and moisture from getting into wall cracks, which can lead to mold.

- Smooth-Rolling Casters: Mobility is everything in a pizzeria. High-quality casters, especially with locking mechanisms, let you easily move the table for deep cleaning or to reconfigure your kitchen layout. Without them, a heavy table becomes a permanent, immovable fixture you have to clean around.

Why Refrigeration is a Non-Negotiable Feature for Pizza Prep

In a modern pizzeria, a refrigerated stainless steel prep table isn't just a nice-to-have piece of equipment—it's the engine of your entire operation. It turns a simple work surface into an efficient, food-safe assembly line where every topping is perfectly chilled and within arm's reach.

Think of it this way: a non-refrigerated table is just a staging area. A refrigerated unit is a fully equipped pizza assembly station with every ingredient ready to go.

This integrated design is an absolute game-changer during the dinner rush. Instead of pizza makers constantly running back and forth to a walk-in cooler, they have everything they need right in front of them. This cuts ticket times dramatically, reduces kitchen chaos, and ensures every pizza is built with ingredients held at a consistent, safe temperature.

Ultimately, this setup directly protects your product quality and your bottom line. When toppings sit in the "temperature danger zone" (40°F to 140°F), their quality plummets. Refrigeration protects your inventory, reduces spoilage, and guarantees that the pepperoni on the hundredth pizza of the night is just as fresh as the first.

Understanding Refrigeration Styles for Pizzerias

Not all refrigerated prep tables are created equal. The right model for your pizzeria really depends on your menu's complexity, your kitchen's volume, and just how many toppings you need to keep on hand. Each style is built to support a different kind of pizza-making workflow.

The two most common designs you'll run into are standard refrigerated prep tables and their bigger siblings, the mega-top units.

- Standard Refrigerated Tables: These are the workhorses of countless pizzerias. They typically feature a refrigerated rail with two rows of food pans, which is plenty of space for core pizza toppings like cheese, pepperoni, and mushrooms. This design strikes a great balance between topping storage and dough-stretching workspace.

- Mega-Top Refrigerated Tables: Just as the name implies, mega-top units are built for high-volume pizzerias with extensive menus. They usually have a third row of pans in the rail, offering up to 50% more topping capacity than standard models. This is perfect for shops famous for their "build-your-own" options with tons of fresh ingredients.

A refrigerated prep table is your first line of defense in food safety. By keeping ingredients consistently below 40°F, you eliminate guesswork and create a system that protects both your customers and your pizzeria's reputation.

Choosing between these styles comes down to a simple calculation of your needs. A small shop with a classic menu might thrive with a standard model, while a bustling restaurant will need the capacity of a mega-top to keep the pizza line moving. For a deeper look, our guide on choosing a refrigerated sandwich prep table offers insights that apply directly to pizza operations, too.

To make the choice even clearer, let's break down the key differences between standard and mega-top prep tables. While both keep ingredients cold, their capacity and workflow advantages are designed for very different pizzeria demands.

Refrigerated Prep Table Feature Comparison

| Feature | Standard Refrigerated Prep Table | Mega-Top Refrigerated Prep Table |

|---|---|---|

| Topping Capacity | Typically holds two rows of food pans | Holds three rows of food pans |

| Best For | Pizzerias with classic, focused menus | High-volume kitchens with extensive topping options |

| Workspace | Offers a good balance of prep area and storage | Maximizes topping storage, sometimes at the expense of workspace |

| Footprint | Generally more compact for smaller kitchens | Often requires more depth to accommodate the third row |

| Ideal Use Case | Small to mid-size shops, classic pizza parlors | "Build-your-own" concepts, large chains, busy pizzerias |

This side-by-side comparison should help you visualize which style best fits your operational pace and menu complexity. Think about your busiest Friday night—would an extra row of toppings speed things up or just get in the way? Your answer points you to the right table.

Key Technical Considerations for Pizzerias

Beyond the number of pans, several technical details are crucial for making sure your refrigerated stainless steel prep table performs reliably under pressure. Ignoring these can lead to failed health inspections, wasted ingredients, and frustrating slowdowns on the pizza line.

First and foremost is NSF certification. The NSF (National Sanitation Foundation) mark is your guarantee that the equipment is designed and built in a way that promotes food safety. It ensures the unit is easy to clean, made from food-safe materials, and can reliably hold ingredients at the proper temperatures. For any commercial pizzeria, NSF certification is simply non-negotiable.

Another critical factor is the cooling capacity and system design. Your prep table needs to be powerful enough to keep toppings chilled even when the lids are open during a relentless dinner rush. Look for units with robust compressors and smart air circulation systems that distribute cold air evenly across all the food pans. This prevents hot spots and ensures toppings at the front are just as cold as those in the back. A poorly designed system can lead to some ingredients freezing while others creep into the danger zone.

Sizing Your Pizza Prep Station for Peak Workflow

Picking the right size for your stainless steel prep table is one of those decisions that can either make your pizzeria flow like a dream or create a constant traffic jam. A table that’s too small will have your chefs bumping elbows and juggling ingredients. Go too big, and you’ll choke off valuable floor space, disrupting the natural rhythm of your kitchen.

Think of it like designing a highway. You need just enough lanes to handle rush hour without causing backups, but building a ten-lane expressway when you only need three is a waste. The sweet spot is finding that perfect balance where your team can move in sync, especially when the ticket machine starts spitting out orders. This isn't just about length and width; it's about engineering a workflow that ramps up speed and dials down stress on the pizza line.

Measure Your Space for Movement

Before you even glance at table dimensions, grab your tape measure and get to know your kitchen floor. It's so easy to just focus on the table's footprint, but the real magic happens in the "negative space" around it—the pathways your staff needs to move safely and without hesitation.

I've seen so many operators make the classic mistake of forgetting about clearance. You have to account for the space needed for:

- Staff Movement: You need at least 36 inches of clearance in walkways. In a tight, fast-paced pizzeria, I always recommend shooting for 48 inches. That extra foot is the difference between a smooth pass and a collision when someone is carrying a hot pizza.

- Door and Drawer Swing: Measure the full swing of every refrigerator, oven, and cabinet door that opens into the prep area. A prep table that's just a few inches too close can make other equipment a pain to use.

- Cleaning Access: Your team needs to get behind and under the table for deep cleaning. Cramped spaces become grime traps that are impossible to sanitize properly, and that's a health inspector's nightmare.

Here's a rule of thumb I live by: Your kitchen's workspace isn't the tabletop—it's the entire operational zone around it. Sacrificing clearance for a bigger table almost always backfires, creating bottlenecks and safety issues.

Calculate Your Ideal Surface Area

Once you know your spatial boundaries, you can figure out the ideal worksurface. This isn't guesswork; it's a calculation based on the reality of your menu and how many pizza makers are on the line during your busiest shift.

First, think about your pizzas. If you're known for a monster 18-inch pie, you'll need more real estate than a shop that focuses on 12-inch personal pizzas. A great starting point is making sure the table's depth can handle your largest pizza peel without it hanging precariously over the edge.

Next, do a headcount for your rush hour. How many people are building pizzas at the same time?

- One-Person Station: A 48-inch or 60-inch table usually does the trick. It gives one pizza maker plenty of room to stretch dough, sauce, and top a pizza without feeling boxed in.

- Two-Person Station: To get two chefs working side-by-side without a turf war, you’ll want to look at a 72-inch or even a 93-inch table. This gives each person their own dedicated zone for making pizzas.

A wider table isn't just about adding space; it's about creating an assembly line. One chef can be stretching dough while the other is topping, which drastically boosts your output. For pizzerias looking to grow, a versatile 60-inch sandwich prep table can offer the perfect blend of size and refrigerated functionality for an expanding team.

Translate Capacity into Real-World Pizza Terms

Finally, let's talk about what the numbers on a spec sheet actually mean when you're in the weeds. The sheet might say a refrigerated rail holds twelve 1/6-size pans, but what does that really mean for your dinner rush?

It means having enough prepped pepperoni, mushrooms, and mozzarella to get through your busiest two hours without someone yelling, "I need more cheese!" The goal is to choose a stainless steel prep table that minimizes those frantic trips to the walk-in. A mega-top unit with 18 pan slots, for example, might hold enough toppings for the entire night.

Apply that same logic to the undershelf. Don't just look at the weight rating; picture what you'll be storing there. A heavy-duty shelf means you can stash three or four full dough boxes right below the worksurface. That saves your crew dozens of steps over a shift. Sizing your pizza station correctly is all about anticipating your needs so your pizza line flows without a hitch, from the first order to the last.

Keeping Your Investment in Top Shape

A quality stainless steel prep table isn't just another piece of equipment; it's a serious investment you expect to pay off for years, maybe even decades. What makes that happen? Good old-fashioned care. Taking care of your table turns it from a line item on an expense report into a true asset for your pizzeria.

The whole reason stainless steel rules the commercial kitchen is its non-porous surface. Picture a flawless sheet of glass. Unlike wood that can soak up bacteria in tiny cracks, stainless steel gives germs nowhere to hide. This slick, tough surface comes from a thin layer of chromium that reacts with the air, forming a natural shield against stains, rust, and bacteria.

But that shield isn't bulletproof. In a pizzeria, it's under constant attack from acidic tomato sauce, greasy cheese, and abrasive flour. If you let that stuff sit, it will weaken the steel's defenses. A clean table isn't just about looking good for the health inspector—it's a cornerstone of a safe, hygienic pizzeria.

Your Pizzeria's Daily Cleaning Playbook

Consistency is everything. A few minutes of proper cleaning at the end of every single shift is what stops small messes from becoming big, corrosive problems. This daily ritual is your number one defense.

- Clear and Scrape: Get rid of all the loose stuff—flour dust, dried cheese bits, and veggie scraps. A soft plastic or nylon scraper is your best friend here; it can lift off stubborn bits without scratching the surface.

- Wipe Down: Grab a soft cloth or sponge with warm water and a mild detergent. Always, always wipe in the direction of the steel's grain. This avoids creating tiny scratches that can trap food particles later.

- Rinse It All Off: Soap residue left behind is no good. It can build up and dull the finish. Rinse the entire surface with a clean, damp cloth to get rid of any leftover cleaner.

- Dry Immediately: This is the step everyone skips, but it's critical. Hard water leaves mineral spots that can eat away at the finish over time. Use a dry, soft towel to wipe the table completely dry. You'll restore its shine and protect that all-important chromium layer.

How to Handle Tough Pizzeria Messes

Beyond the daily wipe-down, you're going to face messes unique to a pizza shop. Dried-on tomato sauce and baked-on cheese can feel like they're welded to the table. But reaching for an aggressive scrubber is the worst thing you can do.

Never use steel wool, Brillo pads, or any other abrasive sponge on your stainless steel prep table. These will absolutely scratch the protective chromium layer, creating a perfect home for rust and bacteria to move in.

Instead, be patient and use a gentler touch for those stubborn stains:

- For Dried Tomato Sauce: The acid in tomatoes is a real enemy to stainless steel if left to sit. Mix up a paste of baking soda and water, spread it on the stain, and let it sit for 15-20 minutes. Then, gently scrub it off with a soft nylon brush.

- For Melted and Hardened Cheese: Soak a towel in hot water, wring it out, and lay it over the cheese for a few minutes. The heat and moisture will soften it right up, making it easy to lift off with a plastic scraper.

- For Stubborn Flour Dust: A damp cloth usually does the trick. But for that caked-on flour that gets into corners, a soft-bristled brush can help break it loose before you wipe the surface clean.

For more detailed tips on keeping all your stainless steel gear looking brand new, check out our guide on the best way to clean a stainless steel refrigerator—the same principles apply.

Durability Clues to Look For When Buying

Long-term value also starts with how the table is built in the first place. When you're shopping for a pizza prep table, keep an eye out for a few key markers of durability. A truly solid stainless steel prep table will have fully welded corners.

This means the seams are literally fused together into one solid piece. It creates a much stronger and more sanitary joint that won't trap grime. Cheaper tables often use screws or other fasteners, which can loosen up over time and create tiny gaps that are a paradise for bacteria. A fully welded frame is a clear signal of top-tier craftsmanship that's built to handle the chaos of a busy pizzeria.

Got Questions About Your Pizza Prep Table? We've Got Answers.

Picking the right stainless steel prep table brings up a lot of questions. It's a big investment for your pizzeria, after all. To help you feel confident in your choice, I’ve rounded up some of the most common questions I hear from pizzeria owners, reinforcing what we've covered in this guide.

What's the Best Stainless Steel Grade for a Pizza Prep Table?

This is one I get all the time, and the answer is simple: for any surface that touches food, especially something acidic like tomato sauce, 304-grade stainless steel is the only way to go. It's the undisputed champ for a reason.

Its higher nickel and chromium content gives it superior armor against rust and corrosion. Sure, you might see 430-grade steel used for legs or undershelves to keep costs down, but it just can't stand up to the daily abuse of a primary worksurface in a busy pizzeria. Investing in a 304-grade top is non-negotiable for hygiene and making your table last.

Think of 304-grade steel as your table's built-in defense system. It actively fights off the corrosive effects of daily pizza-making spills, ensuring your investment remains sanitary and professional-looking for years to come.

How Much Clearance Space Does My Pizza Prep Table Really Need?

This is a critical one. Forgetting to plan for the space around the table is one of the most common—and costly—mistakes I see in pizzeria design. It directly impacts your workflow and, more importantly, your team's safety.

- Walkways: You need at least 36 inches of clearance for staff to move around without bumping into each other. In high-traffic zones, bump that up to 48 inches to keep things flowing smoothly, especially when carrying hot pizzas.

- Equipment Doors: Get out your tape measure. Check the full swing of nearby refrigerator, oven, and cabinet doors to make sure they can open all the way without getting blocked.

- Cleaning Access: Don't jam the table against a wall. Leave enough room behind and around it so your team can get in there for daily wipe-downs and deep cleaning.

Can I Just Grab Steel Wool to Clean My Pizza Prep Table?

Absolutely not. Please, don't do it. Using abrasive scrubbers like steel wool or a Brillo pad is the fastest way to permanently ruin your prep table's surface.

Those scrubbers will literally scratch off the protective chromium layer, creating microscopic grooves. What loves to live in those tiny crevices? Bacteria. And what starts to form there? Rust.

When you're dealing with tough, baked-on cheese or dried sauce, reach for a soft nylon brush or a plastic scraper. A little patience goes a long way—let a paste of baking soda and water sit on the spot, or use a hot, damp cloth to soften the gunk before gently wiping it away. This keeps the steel's surface smooth, non-porous, and easy to sanitize, which is the whole point of using it in your pizzeria.

Ready to build the heart of your pizzeria? Pizza Prep Table offers a curated selection of high-quality, NSF-certified refrigerated prep tables designed for the demands of a busy pizza kitchen. Find the perfect size and style to boost your efficiency and food safety. Explore our collection today.