The Pizzeria Owner's 60 Inch Pizza Prep Table Guide

Share

A 60-inch pizza prep table is one of those commercial kitchen workhorses. It’s a workstation that cleverly merges a refrigerated storage base with a food prep surface right on top, designed to make building pizzas, sandwiches, or salads a seamless process. While it's a versatile beast, its spacious layout makes it a strategic powerhouse for pizzerias, giving you plenty of room for stretching dough while keeping chilled toppings just inches away.

Why a Prep Table Is Your Pizzeria's Secret Weapon

Picture a Friday night at your pizzeria. It’s controlled chaos. Orders are flooding in, and your team is firing on all cylinders. The line between a smooth, profitable rush and a stressful, chaotic one often comes down to a single piece of equipment: the prep station. This is where a 60-inch pizza prep table becomes your kitchen’s command center.

This specific size just seems to hit that perfect sweet spot for most pizzerias. It provides a massive work surface for building multiple pies at once and offers generous refrigerated storage for every last topping on your menu. The moment you switch from a disjointed prep area to a streamlined production line like this, the difference is immediate.

A well-organized prep station is the heart of an efficient pizzeria. It transforms a series of individual tasks into a single, fluid motion, directly impacting speed, consistency, and profitability.

With everything from dough balls and sauce to mozzarella and pepperoni right there within arm's reach, your chefs can operate like pilots in a finely tuned cockpit. The whole setup is engineered to slash order times, cut down on costly mistakes, and dramatically boost your kitchen's output when you need it most.

The Strategic Value of the 60 Inch Model

Putting a 60-inch pizza prep table in your kitchen isn't just an operational upgrade; it's a smart strategic move. This piece of equipment is a core part of a thriving market, which tells you just how critical it is in modern kitchens. In fact, the food prep tables market, which includes these popular 60-inch models, was valued at USD 1.18 billion in 2023 and is expected to climb to USD 1.62 billion by 2029. That growth is all about the demand for efficient, high-volume gear in places that live and die by speed and customization. You can explore more on the food prep tables market trends on Arizton.com.

This investment pays you back in several key areas of your pizzeria:

- Boosted Efficiency: It minimizes all that wasted running around, letting your staff build more pizzas in less time.

- Improved Consistency: With ingredients perfectly organized, every single pizza gets the right amount of toppings, guaranteeing a consistent product for your customers.

- Enhanced Food Safety: All your perishable ingredients are kept at a constant, food-safe temperature, which cuts down on spoilage and waste.

- Maximized Output: It empowers your team to handle the heaviest rushes without ever sacrificing quality or speed.

At the end of the day, this unit isn't just a stainless steel table. It's a foundational asset that drives your kitchen's efficiency and directly supports your business's growth.

Decoding The Features That Boost Pizza Production

Not all prep tables are created equal, especially when you throw them into the chaos of a busy pizzeria. A generic table might work just fine for slapping together a few simple sandwiches, but pizza production is a different beast entirely. It demands specific features that can make or break your kitchen's rhythm.

A well-designed 60-inch pizza prep table isn't just a cold box with a cutting board; it's a complete pizza-building cockpit where every component is engineered for speed and consistency.

The magic really starts with the refrigerated rail. This isn't just a place to keep toppings cold—it's the heart of your menu. With enough room for up to 24 pans, you can have every single topping, from classic pepperoni to gourmet artichoke hearts, perfectly chilled and just a quick grab away. This kind of immediate access slashes wasted motion, letting your team build complex orders without ever having to leave their station.

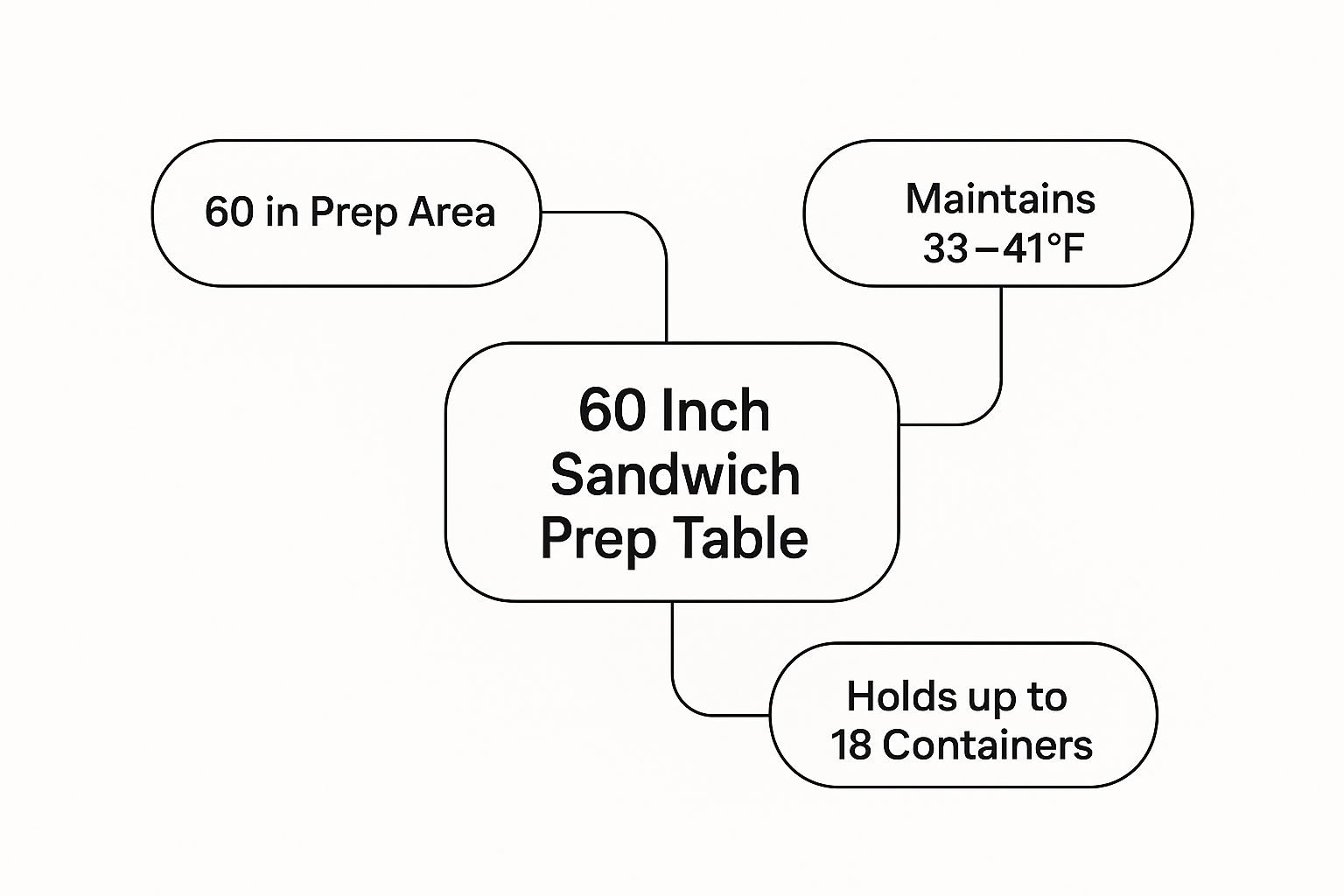

This image really breaks down the core specs that make this unit a pizzeria powerhouse.

You can see how the generous prep area, massive container capacity, and precise temperature control all come together to create the ideal workspace.

The Workspace And Storage Dynamic

Next up is the cutting board, which in a pizzeria is more of a "dough-stretching deck." The depth of this surface is absolutely critical. A deeper board gives you the real estate you need to stretch out large pizza doughs without the edges hanging off—a small detail that's crucial for keeping things clean and sanitary.

Underneath that workspace, you've got your undercounter refrigerated storage, which acts as your immediate backup supply. This is where you face a key operational decision: doors or drawers?

- Door Configurations: These are perfect for storing bulky items. Think large dough trays, massive blocks of mozzarella, and gallon jugs of sauce. They're great for things you need to restock less often but are essential to have on hand.

- Drawer Configurations: Drawers are the champions of organization for smaller, pre-portioned items. They’re perfect for holding backup containers of sliced veggies or meats, which means faster, more organized refills right in the middle of a rush.

Choosing between doors and drawers isn't just about storage; it's about designing your workflow. Doors offer flexible bulk space, while drawers provide rapid, organized access to smaller items, directly influencing your kitchen's speed.

To give you a clearer picture of how these features directly benefit a high-volume pizza kitchen, let's break them down.

Key Feature Breakdown for Pizzeria Prep Tables

| Feature | Standard Specification | Benefit for Pizza Prep |

|---|---|---|

| Refrigerated Rail | 16-24 pan capacity | Holds every topping imaginable, eliminating trips to the walk-in and speeding up assembly. |

| Cutting Board Depth | 12-19 inches | Provides ample space to stretch large pizza doughs without mess or contamination. |

| Undercounter Storage | 15-20 cubic feet | Keeps bulk backups like dough trays and sauce containers chilled and ready for restocking. |

| Temperature Control | 33°F - 41°F Range | Ensures all ingredients, from cheese to meats, are held at food-safe temperatures. |

Each of these elements—the high-capacity rail, the deep cutting board, and the versatile undercounter storage—directly translates into a more efficient pizza-making process. They work in concert to create a seamless flow from raw dough to a fully topped pie that’s ready for the oven.

To make an informed decision on specific features, it's also helpful to consult a general appliance selection guide that covers broader considerations for kitchen equipment. Understanding these components ensures you pick a unit that doesn’t just fit in your kitchen but actively boosts its productivity and output.

What's Going On Inside Your Prep Table's Refrigeration System?

Let's be honest, keeping your pizza toppings fresh and safe isn't just good practice—it's the bedrock of your reputation. The refrigeration system humming away inside your 60 inch pizza prep table is the silent hero, working around the clock to protect every last ingredient, from delicate basil to shredded mozzarella. This is the tech that makes the prep table a true pizzeria powerhouse.

Most modern units run on a forced-air refrigeration system. Don't think of it as just a cold box. Picture it more like a system that generates a constant, gentle cold breeze. This breeze circulates throughout the entire cabinet and, crucially, around every single food pan in the top rail. This design is brilliant because it eliminates warm spots, ensuring every topping stays at a consistent and safe temperature.

This consistent cooling is what allows you to hit the gold standard for food safety: holding ingredients between 33°F and 41°F. This specific range is the "safe zone" where bacterial growth slows to a crawl, preserving the quality and integrity of your toppings. A reliable system means you can serve with confidence, knowing your ingredients are just as fresh at the end of a dinner rush as they were at the start.

Efficiency and Long-Term Savings

Beyond just keeping things cold, the technology inside these systems has a huge impact on your bottom line. Modern prep tables are engineered for efficiency, and that translates directly into lower monthly utility bills. Two key pieces of hardware are driving this: the compressor and the type of refrigerant used.

- Energy-Efficient Compressors: Newer compressors are designed to be more powerful while sipping less energy. They cool the unit down faster and don't have to kick on as often to maintain the right temperature.

- Eco-Friendly Refrigerants: Many of today's tables use R290 refrigerant, a natural hydrocarbon. It's not only way better for the environment, but it's also more thermodynamically efficient, which means lower energy bills for you.

Think of an efficient refrigeration system as a long-term investment. The upfront cost might be a little higher, but the savings on your energy bills will deliver a significant return over the life of the unit.

The market for this equipment shows just how important it is. The refrigerated prep tables market was valued at around USD 3.2 billion in 2024 and is expected to keep growing. This growth is fueled by demand for units just like the 60-inch model, which perfectly blends workspace with precise temperature control to boost workflow and food safety.

By understanding the mechanics behind the cold, you can choose a unit based not just on its size, but on its performance, reliability, and how much it'll cost you to run over the years. After all, a great refrigeration system is one of the most important features of prep sandwich refrigerators that keep your ingredients fresh and your customers happy.

Integrating the Prep Table into Your Kitchen Workflow

Buying the right 60 inch pizza prep table is only half the battle. Figuring out where to put it is what really unlocks its magic. I've seen kitchens where a top-of-the-line unit actually slows things down because it was shoehorned into the wrong spot, creating a massive bottleneck. Strategic placement, on the other hand, transforms it from just another piece of steel into the true command center of your production line.

Think about your kitchen in terms of footsteps. Every extra step a chef takes to grab dough, reach for toppings, or slide a finished pie into the oven is wasted time and energy. The goal is to create a seamless, almost dance-like flow that minimizes movement and cranks up productivity. This is where smart layout design stops being a "nice-to-have" and becomes critical to your restaurant's success.

Designing Your Pizzeria's Workflow Triangle

In real estate, it’s all about location, location, location. In a pizzeria, it’s all about the "pizza triangle"—the sacred, ergonomic layout connecting your dough station, prep table, and oven. Your 60-inch prep table needs to be the beating heart of this triangle, positioned to create the most intuitive path for your team. A good setup ensures that from the moment dough is stretched to the final bake, the whole process feels smooth and effortless.

Your prep table's location dictates the entire rhythm of your kitchen. A well-placed unit creates a fluid, assembly-line motion. A poorly placed one introduces friction and chaos, grinding your whole operation to a halt.

When you’re mapping out the kitchen floor, get practical. Walk the space. Pretend you're making a pizza. Can you open all the doors and drawers on the prep table without blocking a major walkway or smacking into the fryer? A few inches of miscalculation might seem minor on paper, but it can create a choke point that brings your kitchen to its knees during a dinner rush.

To nail your layout and create a seamless workflow, run through this simple checklist:

- Proximity to Oven: How quick is the trip from the prep table to the pizza oven? A fast, easy transfer is a must.

- Dough Station Access: Count the steps. How far is it from your dough sheeter or stretching area to the prep table? Fewer is better.

- Ventilation Clearance: Did you leave at least 3-6 inches of clearance around the back and sides? The compressor needs to breathe. Starve it of air, and you're asking for overheating and a premature breakdown.

- Power Source: Is there a dedicated electrical outlet right there? These units are power-hungry and need their own circuit. Never, ever use an extension cord.

- Team Movement: Can two chefs work side-by-side at the unit without constantly bumping into each other or other equipment?

Thinking through these details means you're not just installing a piece of hardware. You're integrating a strategic asset that will streamline every single part of your pizza-making process.

Choosing Materials That Withstand the Pizzeria Grind

In a busy pizzeria, your equipment takes a relentless beating day in and day out. Your 60-inch pizza prep table isn't just another piece of metal; it's a frontline soldier in the daily battle for efficiency. Picking a unit built with the right stuff is the difference between a long-term workhorse and a short-term headache.

Think of it like buying a pickup truck for a construction site. You wouldn't choose one with a flimsy frame, and the same logic applies here. Robust materials mean fewer breakdowns during a dinner rush, lower repair bills over the unit's lifespan, and consistent performance you can actually count on.

The Stainless Steel Showdown

Here's something a lot of people don't realize: not all stainless steel is created equal. This becomes critically important when you're dealing with acidic ingredients like tomato sauce day after day. The grade of steel used in your prep table is a dead giveaway of its durability.

- 304-Grade Stainless Steel: This is the undisputed champion for any surface that touches food, like the interior and top of your prep table. It has a higher nickel content, which gives it superior armor against corrosion from acids (hello, tomato sauce) and salts.

- 430-Grade Stainless Steel: You'll often find this on the exterior sides and back of a unit. It’s tough and more budget-friendly, but it's more likely to rust over time if you don't keep it perfectly dry and clean—a tough ask in a steamy kitchen.

For any pizzeria, insisting on a 304-grade stainless steel interior and worktop isn't just a good idea; it's non-negotiable. This one detail will dramatically extend the life of your table by stopping the pitting and corrosion that acidic ingredients are famous for causing.

The growing demand for these durable units tells a story. The global market for sandwich and salad prep tables was valued at around USD 1.2 billion in 2024 and is expected to hit USD 1.8 billion by 2033. This growth is all about kitchens needing tougher, more efficient solutions.

Details That Define Durability

Beyond the type of steel, it’s the little engineering details that separate a high-quality unit from the pack. When you’re evaluating a commercial pizza prep table, look closely at the parts that take the most abuse.

Heavy-duty, reinforced door hinges are a must. These doors will be yanked open and slammed shut hundreds of times a day. Flimsy hinges are one of the first things to fail.

Also, keep an eye out for self-closing doors. This isn't just a neat trick; it’s a feature that saves you money on energy bills and reduces wear and tear on the compressor by making sure cold air isn't constantly escaping. These small, thoughtful features add up to a more reliable and long-lasting machine that can truly handle the pizzeria grind.

Essential Maintenance to Keep Your Prep Table Running

Dropping a chunk of change on a new 60 inch pizza prep table is just the first step. Protecting that investment means getting serious about a proactive maintenance routine. This isn't about busywork; it's about preventing those gut-wrenching emergency repair bills, sailing through health inspections, and getting years of faithful service from your equipment.

Think of it as a simple wellness plan for your kitchen's MVP. A little attention now saves you from a world of hurt down the road.

Daily, Weekly, and Monthly Maintenance Checklist

The easiest way to make maintenance happen is to build it right into your crew's closing duties. A simple checklist turns these crucial tasks into a habit, protecting both your ingredients and your hardware.

Daily Tasks (End of Shift):

- Wipe Down Surfaces: Hit all the interior and exterior stainless steel surfaces with a food-safe cleaner. No exceptions.

- Sanitize the Cutting Board: Pull that polyethylene cutting board, then wash and sanitize it. This is your number one defense against cross-contamination.

- Clean Door Gaskets: Grab a cloth with mild soap and water and wipe down the rubber door gaskets. Food gunk kills the seal, wastes energy, and makes your compressor work way too hard.

Weekly Tasks:

- Deep Clean the Interior: Empty out the refrigerated cabinet and give all the shelves and interior walls a proper scrub.

- Check Gasket Seals: Really look at the door gaskets. Are there any rips, tears, or spots where they've gone hard and brittle? A bad gasket is an open invitation for cold air to escape.

The single most important task for preventing compressor failure is cleaning the condenser coil. A clogged coil suffocates the refrigeration system, leading to overheating and costly breakdowns.

Monthly Task:

- Clean the Condenser Coil: This one is non-negotiable. Unplug the unit. Find the condenser coil—it's usually behind a grille on the front or back. Use a stiff brush and a vacuum to gently get rid of all the dust, flour, and grease that's built up.

Simple Troubleshooting for Common Issues

Even with the best maintenance plan, little things can still pop up. Here’s how you can tackle common headaches before they turn into service-stopping disasters.

- Temperature Swings: If the unit isn't holding its temperature, start with the simple stuff. Are the doors closing all the way? Are the gaskets making a tight seal? Is the condenser coil clean? You'd be surprised how often a blocked coil is the culprit.

- Frost Buildup: Seeing excessive frost is a big red flag for an air leak. Your first suspect should always be the door gaskets. It could also mean your staff is holding the doors open for too long during a rush.

By making this straightforward maintenance and troubleshooting part of your kitchen's culture, you ensure your 60 inch prep table stays the reliable workhorse it was designed to be, day in and day out.

Common Questions About Pizza Prep Tables Answered

Investing in a cornerstone piece of equipment like a 60 inch pizza prep table is a big decision, and it’s smart to have a few final questions. Getting straight answers is the key to making a confident purchase that will anchor your kitchen’s workflow for years.

One of the most common questions I hear is about the real difference between a standard sandwich prep table and one built for pizza. It all comes down to the cutting board. Pizza tables boast an extra-deep board, often 19 inches or more, giving you the real estate you need to stretch large doughs without making a mess. Standard sandwich tables have much shallower boards, which just doesn't cut it for serious pizza assembly.

Electrical Needs And Financial Planning

Another frequent concern is the electrical setup. Good news: nearly all 60-inch pizza prep tables run on a standard 120V supply and use a common NEMA 5-15P plug. The critical part, though, is that the unit must be plugged into its own dedicated circuit. Never, ever use an extension cord—it can cause a voltage drop and burn out your compressor.

When you’re planning for a significant investment, it helps to see the numbers clearly. A handy tool like an equipment loan calculator can give you a solid idea of financing options and what your monthly payments might look like.

The most common maintenance mistake is neglecting the condenser coil. A monthly cleaning is the single best thing you can do to prevent compressor failure and ensure the long-term health of your investment.

Finally, owners always ask if they can stick the prep table right next to a hot pizza oven. My advice is simple: don’t do it. High ambient heat forces the compressor to work overtime, which leads to sky-high energy bills and a much shorter lifespan for the unit. Always leave as much breathing room as possible between your refrigeration and cooking equipment. For a deeper dive into picking the perfect unit, check out this comprehensive guide on prep tables for a restaurant.

At Pizza Prep Table, we get that the right equipment is the foundation of a great pizzeria. We're here to help you find the perfect 60-inch prep table to streamline your workflow and perfect your pies.

Explore our full selection of Pizza Prep Tables and elevate your kitchen's efficiency