Choosing the Right Refrigerated Prep Table for Your Pizzeria

Share

Sure, a standard refrigerated sandwich prep table is a useful workstation. It’s got the cold base and the cutting board top, keeping things fresh and handy. But for a pizzeria? That standard model just won't cut it.

You need a specialized pizza prep table. This isn't just a minor upgrade; it's a completely different beast designed for the fast-paced art of pizza making. With a deeper cutting board and raised rails built for speed, it's the central hub where perfect pies are born.

The Heart of Your Pizzeria's Workflow

During a chaotic dinner rush, the success of your pizzeria really boils down to one key piece of equipment: the pizza prep table. This isn't just a fancy cooler for your toppings. It's the command center where speed, quality, and consistency all come together. Getting this choice right is a foundational decision that will dictate the entire rhythm of your kitchen.

A well-designed refrigerated prep table that’s actually built for making pizzas does a lot more than just hold pepperoni and mushrooms. It creates an ergonomic and streamlined hub where every single movement is optimized. This setup slashes ticket times by getting rid of unnecessary steps, like your crew having to constantly walk back and forth to a separate fridge.

Boosting Efficiency and Reducing Strain

Picture this: your staff smoothly sliding a pizza base across a deep cutting board, effortlessly grabbing perfectly chilled toppings from raised, angled pans, and sending it to the oven in one fluid motion. That’s the dream. This kind of streamlined process minimizes physical strain and fatigue, keeping your team sharp and productive through those long, grueling shifts.

An efficient layout isn't just a "nice to have"—it translates directly to faster service and happier, paying customers.

The right prep table is also a direct investment in the quality of every single pizza that leaves your kitchen. By holding every ingredient at consistent, food-safe temperatures, it guarantees freshness from the first slice to the last. This commitment to quality is what turns first-time visitors into loyal regulars.

A classic mistake I see pizzeria operators make is underestimating the importance of workflow. The wrong prep table creates bottlenecks, driving up labor costs through wasted time and movement. The right one becomes the engine of your entire production line.

More Than Just Pizza Preparation

The versatility of these tables is something that often gets overlooked. While their main job is pizza assembly, they also make fantastic stations for prepping other menu items like salads, strombolis, or sandwiches. This multi-functionality is a huge win, especially in pizzerias where every square foot of space is precious. The organized layout with refrigerated pans lets you manage a diverse menu from a single, compact workstation.

The growing demand for this specialized gear really highlights its importance. The global market for food prep tables, including these refrigerated models, was valued at around USD 1.18 billion in 2023 and is expected to keep climbing. This growth reflects a wider industry understanding of just how critical optimized prep stations are for success. You can dive deeper into the growing food prep tables market on Arizton.com.

Ultimately, the right unit transforms a potentially chaotic service into a smooth, profitable operation.

Selecting the Right Size and Configuration for Your Pizzeria

Your pizza prep table's footprint directly impacts your kitchen's entire flow. Choosing the right one goes way beyond just measuring an empty spot on the floor; it’s about matching the equipment's capacity to your pizzeria's real-world production needs—both now and in the future. Get this right, and you prevent bottlenecks during a rush. Get it wrong, and you're just wasting energy on an oversized, underused unit.

Guesswork is your worst enemy here. A table that’s too small will constantly need restocking, pulling staff off the line and slowing down ticket times. On the flip side, a unit that's too large eats up unnecessary electricity and hogs valuable floor space that could be used for other essential gear. The goal is to find that perfect balance for your pizza operation.

Sizing Your Pizza Prep Table for Peak Performance

Let's start with the most basic measurement: width. Pizza prep tables commonly range from compact 48-inch models to massive 93-inch workstations. A small café that just offers a limited pizza menu might find a 48-inch or 60-inch unit is plenty. This size gives you enough space for a handful of core toppings and a manageable refrigerated base for dough and backup ingredients.

However, a high-volume pizzeria needs to think bigger. A 72-inch or even a 93-inch refrigerated sandwich prep table becomes essential. These larger units can hold a huge array of toppings, let multiple pizza makers work side-by-side, and offer serious refrigerated storage below. You have to forecast your busiest hours to figure out if the investment in a bigger table is justified.

The most common mistake I see pizzeria operators make is buying for their current slow Tuesday, not their future busy Saturday. Always size your prep station for your peak demand, or you will create a permanent bottleneck in your production line.

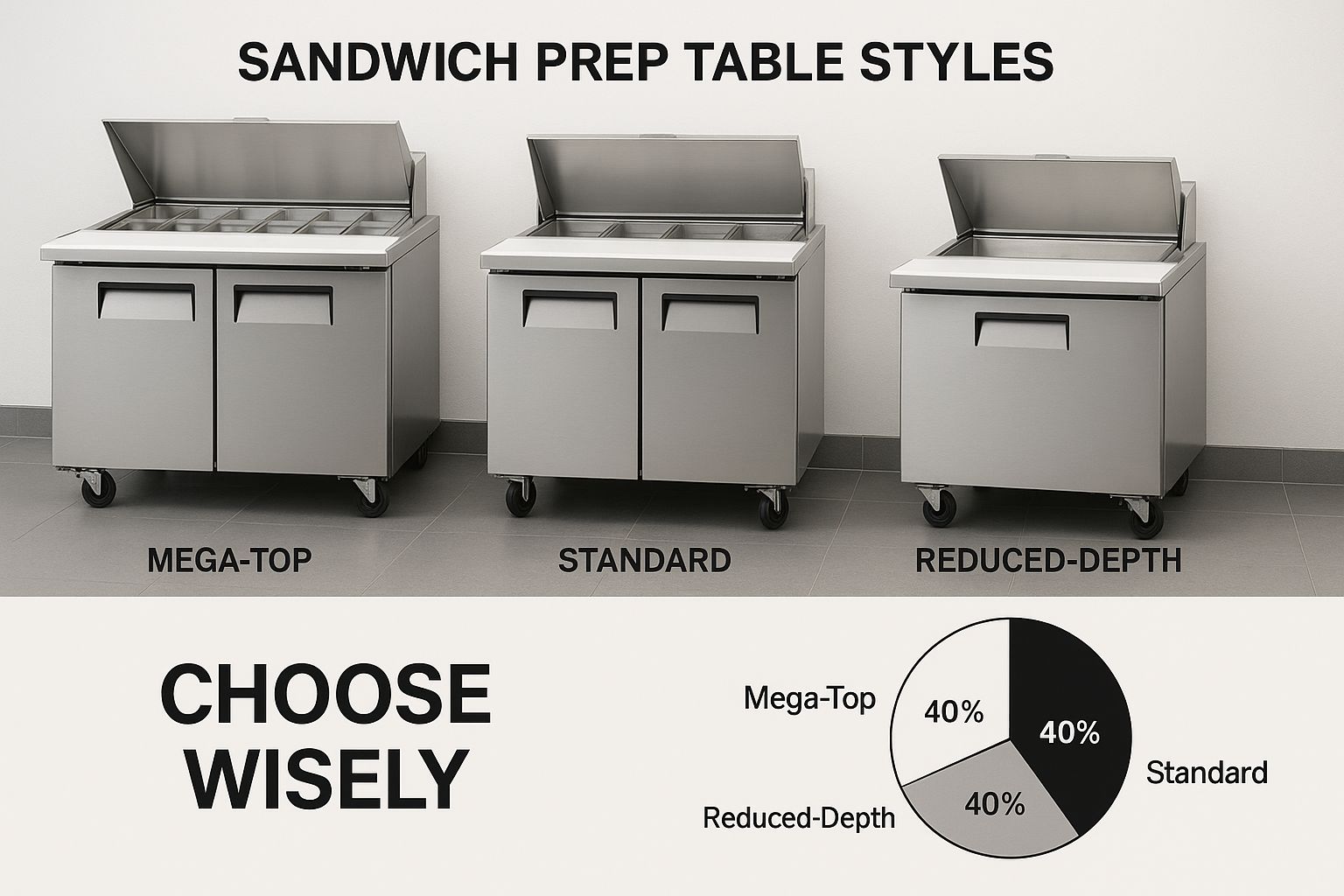

This infographic shows several different styles of refrigerated prep tables, which can help you visualize how each configuration might fit into a commercial pizza kitchen setting.

The image really drives home that your choice in prep table style—from standard tops to mega tops with drawers or doors—is a critical decision that defines your pizzeria's efficiency.

To help you visualize the options, I've put together a quick guide that breaks down the common sizes and what they're best suited for in a pizza-focused environment.

Pizza Prep Table Sizing Guide

| Table Size (Width) | Pan Capacity (1/6 size) | Typical Storage (Cu. Ft.) | Best For |

|---|---|---|---|

| 48 inches | 12 pans | 12 - 14 | Small cafes, food trucks, or pizzerias with a limited, focused menu. |

| 60 inches | 16 pans | 16 - 18 | Growing pizzerias, mid-volume restaurants needing more topping variety. |

| 72 inches | 20 pans | 19 - 22 | Busy pizzerias where multiple staff work the line during peak hours. |

| 93 inches | 24 pans | 27 - 30 | High-volume pizza operations, large chains, or kitchens with extensive menus. |

As you can see, jumping from a 48-inch to a 72-inch unit doesn't just give you more workspace; it nearly doubles your topping capacity. This is the kind of detail that can make or break your service on a packed Friday night.

Standard Top vs Mega Top Units for Pizza Toppings

Once you've settled on a width, the next major decision is the top rail configuration. This choice directly impacts how many pizza ingredients you can keep chilled and ready to go.

- Standard Top: These are the classic models. They feature a single row of food pans, which is often more than enough for pizzerias with a straightforward, traditional menu.

- Mega Top: This design is a game-changer for pizzerias with complex or customizable menus. Mega-top tables feature an extra row of food pans, providing about 50% more topping capacity than a standard unit of the same width. This is a lifesaver for kitchens offering dozens of toppings, as it drastically cuts down on restocking the line during service.

Imagine you offer a "build-your-own" pizza special with 20+ topping options. A mega-top table lets you have everything on the line at once, organized and perfectly chilled. A standard top would force your staff to constantly swap out pans, creating delays and potential mix-ups.

Choosing Between Doors and Drawers for Dough and Supplies

The final piece of the configuration puzzle is the refrigerated base. You have two primary options: doors or drawers, or a combination of both. Your choice should be based entirely on your specific workflow and what you need to store for your pizza-making process.

Doors Offer Flexibility for Bulk Items

Doors are ideal for bulk storage. They can easily accommodate large, awkwardly shaped items like boxes of produce, big containers of sauce, or stacks of cheese blocks. If you need flexible space for a variety of items, a door-based setup is a great choice for a pizzeria.

Drawers Provide Organization for Pizza Ingredients

Drawers, on the other hand, are perfect for organization and getting quick access to portioned items. They are exceptionally useful for:

- Dough Balls: Keeping pre-portioned dough balls in dedicated drawers makes grabbing the next one in the sequence fast and efficient.

- Portioned Cheese: Drawers can hold multiple pans of shredded mozzarella or other cheeses, keeping them neatly organized.

- Sliced Meats: Pepperoni, sausage, and other popular pizza toppings can be stored in pans within the drawers for easy grabbing.

Many pizzeria owners find that a combination unit provides the best of both worlds. For example, a three-section table might have two drawer sections for dough and high-volume toppings, and one door section for bulkier backup supplies. The best way to decide is to map out your ingredient flow from storage to the pizza assembly line—that will tell you the ideal mix for your operation.

Essential Features for a Pizza Kitchen

When you're looking at a spec sheet for a refrigerated prep table, you're really reading a story about how it will perform under pressure. For a pizzeria owner, learning to translate that technical jargon is the secret to choosing a unit that helps your operation, not holds it back.

Every detail, from the compressor type to the interior material, directly impacts your daily workflow, your utility bills, and the safety of the food you serve. When you understand these features, you can glance at a product description and instantly see its real-world benefits for a pizza kitchen.

Suddenly, you’ll know why one unit can be pushed flush against a wall while another needs six inches of breathing room—a small detail that can completely change a tight kitchen layout. This knowledge turns a confusing shopping trip into a strategic business decision for your pizzeria.

The Compressor: Heart of Your Operation

The compressor is the engine of your prep table. Its design is one of the most important—and most overlooked—features, dictating exactly where and how you can install the unit. Get this wrong, and you’re looking at overheating, equipment failure, and costly emergency repairs.

You'll mainly run into two types:

- Front-Breathing Compressors: These units pull air in and push it out from the front, usually through a grille. This is a massive advantage in cramped pizza kitchens. It means you can install the prep table right up against a wall or next to other equipment without worrying about suffocating the compressor.

- Rear-Breathing Compressors: These are the more traditional models that need several inches of clearance at the back for proper airflow. While they work just fine, they demand careful placement and can eat up valuable floor space. Forgetting this clearance requirement is a classic installation mistake that will drastically shorten the equipment's lifespan.

Materials Matter: Durability and Hygiene in a Pizzeria

The materials used to build a pizza prep table are a dead giveaway of its durability and how easy it will be to maintain. In a pizzeria, where you’re constantly dealing with acidic tomato sauce, grease, and flour, choosing the right materials is non-negotiable for longevity and food safety.

High-quality stainless steel is the industry standard for exteriors and work surfaces, and for good reason. It’s tough, resists corrosion, and is a breeze to sanitize.

For the interior, you might also find ABS plastic liners. These are often designed with coved corners that prevent food particles from getting trapped, which makes your daily sanitation routine that much simpler.

A critical feature for any pizza kitchen is a raised pan rail. This design lifts the ingredient pans and often angles them toward the user, creating a blanket of cold air that keeps toppings safely chilled below 41°F. It's a non-negotiable feature for maintaining food safety and quality.

Smart Designs for Energy Savings

Utility bills are a huge operational cost in any pizzeria. Modern refrigerated prep tables have smart design features aimed at cutting down energy use without sacrificing performance. One of the simplest, yet most effective, is the self-closing door.

Think about a chaotic Friday night. Your crew is moving fast, grabbing dough, cheese, and backup sauces. In the rush, refrigerator doors are easily left ajar. Self-closing doors gently pull themselves shut, preventing cold air from escaping and stopping the compressor from working overtime.

This one small feature can lead to real savings on your monthly electric bill. Similarly, magnetic door gaskets create a tight seal, which is another crucial element in preventing energy waste. You'll want to check these for cracks or wear as part of your regular maintenance routine. You can find more details on how to select refrigerators that keep your ingredients fresh while managing costs in our dedicated guide: https://pizzapreptable.com/blogs/pizza/prep-sandwich-refrigerators-that-keep-your-ingredients-fresh-and-your-customers-happy.

The demand for efficient, well-designed equipment like this is surging. The global market for refrigerated prep tables was valued at about USD 3.2 billion in 2024 and is expected to keep growing. This growth is driven by the foodservice industry's need for reliable, energy-saving solutions that improve workflow and food safety. You can find more details in this market report on refrigerated prep tables.

By focusing on these key features, you ensure your investment in a refrigerated sandwich prep table pays off through efficiency, durability, and long-term savings for your pizza business.

Comparing Top Brands for Pizza Prep Tables

Picking a brand for your pizzeria's refrigerated sandwich prep table is a bigger deal than just choosing a logo for a stainless steel box. You're putting your trust in a piece of equipment that will be the heart of your kitchen's daily grind. So, instead of just rattling off a list of names, let's get into what makes these top brands tick and why pizzeria owners swear by them.

You’re not just buying a machine. You're investing in the reliability and efficiency that keeps your pizza line moving smoothly. The right brand can be the difference between a calm, predictable service and a night full of equipment-related headaches.

True Manufacturing The Industry Benchmark

When you talk to seasoned restaurant pros about commercial refrigeration, True Manufacturing is almost always the first name that comes up. And for good reason. They’ve built an unshakable reputation on equipment that just keeps running, year after year. A True pizza prep table is seen as a long-term investment, not a short-term fix.

Their units are built like tanks, designed to handle the non-stop punishment of a high-volume pizzeria. Sure, they often come with a higher price tag upfront, but you get that back in superior energy efficiency and components that are made to last. For an established pizza business looking for premium performance and lower utility bills, True is the benchmark everyone else is measured against.

Investing in a reputable brand isn't just about dodging repair bills; it's about peace of mind. Knowing your pizza prep table will hold its temperature during the Saturday night dinner rush is priceless for food safety and consistency.

Avantco A Smart Choice for New Pizzerias

For a new pizzeria just getting off the ground or any shop working with a tighter budget, Avantco hits that sweet spot between performance and value. Their prep tables give you all the essential features a busy pizza kitchen needs without the premium cost of the legacy brands. This has made them a go-to choice for startups and independent owners.

Avantco is all about practical, no-nonsense functionality. Their units are designed to help your team work fast, with reliable cooling and generous cutting boards built for quick pizza assembly. They provide a solid foundation for a new kitchen, freeing up capital you can put toward other critical parts of your business.

Atosa High Quality Materials and Reliable Components

Atosa has carved out a nice niche for itself by focusing on high-quality materials and dependable parts. Their pizza prep tables are known for premium stainless steel construction that holds up to heavy use and makes daily cleaning and maintenance much easier.

What I really like about Atosa is their commitment to putting reliable tech into their units at an accessible price. You'll often find features like:

- Digital Temperature Controllers for dead-simple, precise temperature management.

- Heavy-Duty Compressors built to ensure your ingredients stay perfectly chilled, even when the doors are constantly opening.

- Durable Construction that resists the dents and dings that are just a part of life in a busy pizza kitchen.

This focus on solid engineering makes Atosa a serious contender for any pizzeria owner who values both modern features and long-term durability. To see how different models compare and figure out the best fit for your kitchen, check out our guide on the top pizza prep tables for restaurant success.

Making the Final Brand Decision for Your Pizzeria

At the end of the day, the "best" brand for your pizzeria really depends on your situation. An established, high-volume spot might find the long-term energy savings and proven reliability of a brand like True is the smartest play. But a new venture might see the immediate value and solid performance of Avantco or Atosa as the wiser financial move.

Your choice should be a careful balance of your budget, your daily pizza volume, and your long-term goals. Don't forget to look at warranty coverage and the availability of local service and parts as you weigh your options. Any of these brands can be a winner, but the perfect fit is the one that lines up with the unique demands of your pizzeria.

Installation and Maintenance That Prevents Downtime in Your Pizzeria

Your pizza prep table's real performance—and how long it lasts—is decided long after it rolls off the delivery truck. Getting proactive about installation and sticking to a simple maintenance routine is your best defense against those dreaded emergency repair bills and the lost sales that come with downtime. It's all about protecting your investment, and that starts before you even plug it in.

So many day-one problems trace back to simple oversights. Before the unit even arrives, double-check that your kitchen's electrical setup can handle it. These compressors need juice, and a dedicated circuit is often required. Trying to run it off an extension cord is not just a fire hazard; it's a great way to void your warranty instantly.

Ventilation is just as critical. The most common mistake I see is a new unit getting shoved flush against a wall without anyone checking how it breathes. A rear-breathing model needs several inches of clear space for airflow. Without it, the compressor will overheat and burn out, sometimes in just a few months. That one simple check can save you from a catastrophic failure.

Setting Up a Simple Maintenance Schedule

Once your refrigerated sandwich prep table is in place and humming along, the key is a maintenance routine you can actually stick to. Let's be honest, complicated schedules get ignored during a busy week. The goal is to focus on small, consistent actions that have a huge impact. A well-maintained unit doesn't just last longer; it uses less energy, saving your pizzeria money every month.

You don't need a complex chart. Just break it down into daily, weekly, and monthly tasks so it becomes second nature for your team.

- Daily Habits: At the end of every single shift, wipe down all surfaces, including the cutting board and stainless steel. The most important part? Clean the door gaskets with warm, soapy water. Food gunk and grease will dry them out, causing them to crack and ruin the seal. That's just wasted electricity.

- Weekly Tasks: Set aside a few minutes each week for a slightly deeper clean. Pull out the ingredient pans and storage shelves and get them properly sanitized. This is also the perfect time to glance at the condensate drain pan and make sure it’s clear of any blockages—you don’t want a surprise puddle on your floor.

- Monthly Checks: Here's the big one: clean the condenser coils. In a pizzeria, airborne flour and grease are coil magnets. When they get clogged, the compressor has to work overtime, jacking up your utility bills. A quick once-over with a brush or vacuum restores efficiency and prevents overheating. You should also check your temperature calibration to make sure it's holding true.

A clogged condenser coil is the number one cause of premature compressor failure in pizzerias. Spending just ten minutes cleaning it once a month can save you from a repair bill that could easily top $1,000. It's the highest-return maintenance task you can perform.

Troubleshooting Common Pizzeria Prep Table Headaches

Even with perfect maintenance, things can go wrong. Knowing the difference between a quick fix and a "call the technician now" problem will save you a ton of time and money.

If you're noticing the temperature is fluctuating, the first things to check are the door seals and the condenser coil. Are the doors closing tightly? Is the coil clean? If you see condensation forming on the outside of the unit, that's another big clue you've got a bad gasket seal.

However, if the unit is running constantly but not getting cold, or you hear grinding or clanking from the compressor, that’s your cue to call a professional. Don't wait. Pushing a struggling compressor often turns a manageable repair into a complete replacement. If you want to learn more about how a refrigerated sandwich prep table can be optimized for your pizza kitchen, take a look at our detailed guide on the prep table sandwich station.

Regular cleaning is about more than just preventing breakdowns; it’s about food safety. For a broader look at keeping your whole operation safe, check out these tips for food safety and mold prevention in commercial kitchens. A little bit of prevention goes a long way in keeping your equipment running and your customers safe.

Your Top Questions About Pizza Prep Tables, Answered

When you're equipping a pizzeria, a lot of questions come up. And when it comes to the heart of your operation—the prep station—you need straight, honest answers. Picking out the right refrigerated sandwich prep table built for pizza is a big decision, and you want to be sure you're getting it right.

To help you out, I’ve put together the most common questions I hear from pizzeria owners. These answers will cut through the confusion and give you the practical advice you need to find the perfect unit for your kitchen.

Pizza Prep Table vs. Sandwich Prep Table

"What's the real difference between a pizza prep table and a regular sandwich table?" I get this one all the time. The answer is all about workflow—the little design details that make a huge difference during a busy pizza rush.

A true pizza prep table is built with a much deeper cutting board, often 19 inches or more. That extra real estate is non-negotiable for handling big pizza doughs without making a mess or feeling cramped. A standard sandwich table, on the other hand, usually has a shallow 8-12 inch board. Trying to assemble a 16-inch pie on that is a recipe for frustration.

Another key difference is the refrigerated rail. Pizza prep tables almost always have a raised, angled rail. This design doesn't just make it easier to grab toppings; it creates a pocket of cold air that keeps your ingredients consistently chilled and safe. A typical sandwich table has a flat rail, which just isn't as ergonomic for the scooping and spreading motions of a pizza maker.

Cleaning the Condenser Coil

"How often should I clean the condenser coil in my pizzeria?" In a normal commercial kitchen, the standard advice is every 90 days. But a pizzeria is anything but normal.

With flour, cornmeal, and grease constantly in the air, the condenser coil in a pizzeria gets clogged way faster. Because of this, you absolutely need to clean the coil at least once a month. A clogged coil forces the compressor to work overtime, jacking up your energy bills and dramatically increasing the risk of a catastrophic failure. A simple calendar reminder can save you from an expensive emergency repair call. For really high-volume shops, checking it every two weeks is even smarter.

I can't stress this enough: The number one cause of expensive, avoidable refrigeration repairs in pizzerias is a neglected condenser coil. A ten-minute cleaning each month is the single best thing you can do for the longevity of your equipment.

Doors or Drawers for the Base

"Should I go with doors or drawers for my pizza prep table's base?" The best choice here really depends on your menu and how your crew works. There's no single right answer for every pizzeria.

- Drawers are for organization. They're fantastic for portioned items. Think pans of pre-portioned dough balls, shredded cheese, and high-volume meats like pepperoni. This setup allows for lightning-fast, assembly-line access during the dinner rush.

- Doors are for bulk storage. Doors give you flexible, open space for bigger or awkwardly shaped items. They're perfect for holding bulk containers of sauce, boxes of produce, or backup ingredient bins that you don't need to access every five minutes.

Honestly, many pizzeria owners I've worked with find that a combination unit—one with both doors and drawers—offers the best of both worlds. You can use the drawers for your everyday, high-volume ingredients and keep the door section for your bulkier backup supplies.

Understanding Mega-Top Units

"What's a mega-top, and is it worth it for a pizzeria?" A mega-top prep table is all about maximizing your ingredient capacity without taking up more floor space. It’s a pretty clever design.

Compared to a standard table of the same width, a mega-top unit has an extra row of food pans in the refrigerated rail. This simple change gives you about 50% more topping capacity. It's an amazing solution if your menu features a ton of specialty pizzas or if you run a popular "build-your-own" concept. By cutting down on how often you need to restock the line during a busy service, a mega-top can be a true game-changer for high-volume pizzerias.

At Pizza Prep Table, we provide the specialized equipment your pizzeria needs to thrive. From compact workstations to high-capacity units, our selection from top brands like Atosa and True ensures you find the perfect fit for your kitchen's workflow and budget. Explore our complete collection of refrigerated pizza prep tables and upgrade your operation today at https://pizzapreptable.com.