Refrigerated Drawers for Pizza Prep Tables

Share

In a packed pizzeria, every single second is a resource you can't get back, especially when the dinner rush hits. The secret to cranking out pies faster isn't just about a hotter oven; it's about building a smarter, more fluid workflow. This is where refrigerated drawers built right into a pizza prep table become an absolute game-changer. They act as the ultimate efficiency hack, putting perfectly chilled pizza ingredients exactly where your team needs them and cutting out all the wasted motion.

The Secret Ingredient for a Faster Pizza Line

Think about a high-end chef's kitchen, where the entire operation revolves around mise en place—the sacred principle of having every ingredient prepped and in its place before service begins. Now, imagine embedding that same level of military-grade organization directly into your pizza station. That's precisely what refrigerated drawers bring to the table in a pizzeria. They take a potentially chaotic prep line and turn it into a streamlined production machine.

Instead of chefs constantly turning and walking to a reach-in cooler, every single critical topping is within arm's reach. The mozzarella, pepperoni, mushrooms, and peppers are all kept at the ideal temperature right below the prep surface. It’s a simple concept with a massive impact.

Unlocking Peak Hour Performance

This one change fundamentally alters the rhythm of your pizzeria. By killing off all those unnecessary steps, you can shave precious seconds off the assembly time for every single pizza. Cutting just 15-20 seconds from each order adds up incredibly fast, letting your crew handle a higher volume of tickets during those crucial peak hours without ever compromising on quality. That boost in output goes straight to your bottom line.

This integrated setup is the key to unlocking a faster, smoother, and more profitable workflow in any high-volume pizzeria. It’s less about simple storage and more about strategic access to perfectly chilled pizza ingredients.

The shift toward smarter, space-saving kitchen gear is a huge driver in the market right now. The global drawer refrigerator market was already valued at around $1.2 billion in 2023 and is on track to hit nearly $2.1 billion by 2032. This isn't just a niche trend; it's a reflection of a broader industry move toward more integrated and efficient kitchen designs, especially in fast-paced environments like pizza restaurants.

More Than Just Speed

But it's not just about raw speed. This kind of setup also drives up consistency and cuts down on staff fatigue. With ingredients always in the same place, every pizza gets made the same way, every time. You can learn more about crafting the perfect setup in our guide on the secret sauce behind efficient pizza prep stations.

This highly organized approach also creates a much less stressful work environment. It allows your team to focus their energy on the craft of making perfect pizzas instead of wasting it hunting for ingredients. At the end of the day, these drawers are an investment in operational excellence.

Why Your Pizza Prep Table Needs Drawer Refrigeration

Let’s be honest, adding refrigerated drawers to your pizza prep table isn't about getting a new appliance. It’s about completely rethinking how your kitchen works. This move goes way beyond simple convenience—it directly impacts your speed, the quality of every pizza you send out, how you manage your space, and even food safety. These are the four pillars that support a smarter, more profitable pizzeria.

Think about it. Every single step a pizza maker takes to grab an ingredient from a separate cooler is a tiny delay that adds up. With integrated drawers, those steps just disappear. Getting instant access to toppings, cheese, and sauces can shave critical seconds off every single order, which is a massive win during a chaotic dinner rush.

Speed and Consistency Working Together

The most immediate benefit you'll see is raw speed. When every cold ingredient is within arm's reach, all that wasted motion of walking back and forth to a reach-in cooler is gone. This means you can assemble more pizzas per hour, which directly translates to a higher service capacity and more money in your pocket.

But speed without consistency is just chaos. Refrigerated drawers maintain a steady, precise temperature, making sure your pizza ingredients are always held in their sweet spot.

By keeping toppings like shredded mozzarella and sliced pepperoni at a consistent 33°F to 38°F, you guarantee every pizza starts with ingredients at their absolute peak. This completely eliminates the quality drop-off that happens when toppings sit out on the line for too long.

Smarter Space and Safer Food

In any pizzeria, floor space is gold. A prep table with built-in drawers makes every square inch pull double duty, combining two critical functions—prep space and cold storage—into a single, compact footprint. This is a game-changer for smaller kitchens or food trucks where every inch is accounted for.

This setup also gives your food safety a serious boost. Perishable toppings are kept out of the temperature "danger zone" (40°F to 140°F) right up until the moment they hit the dough. This dramatically cuts down on risk and makes sailing through health inspections a lot easier.

To see the real-world impact, let's compare the old way with the new, integrated approach.

Standard Prep Table vs Integrated Drawer System

| Operational Metric | Standard Pizza Prep Table | Prep Table with Integrated Drawers |

|---|---|---|

| Ingredient Access | Frequent walks to a separate reach-in | Immediate, arm's-length access |

| Pizza Assembly Time | Higher due to wasted motion | Reduced by 15-20 seconds per pizza |

| Temperature Control | Inconsistent for ingredients on the line | Stable, precise chilling below 40°F |

| Kitchen Footprint | Separate prep and refrigeration units | Combined, space-saving footprint |

At the end of the day, this integrated system transforms your prep station from a simple workbench into the high-performance heart of your pizzeria. It’s a strategic move that pays off every single shift by enabling faster service, delivering a more consistent product, optimizing your kitchen layout, and locking down your food safety standards.

Choosing the Right Refrigerated Drawers for Your Pizzeria

Picking the right refrigerated drawers for your pizza prep table is a lot more than just finding a unit that fits and plugging it in. This is a strategic move that hits your kitchen's speed, efficiency, and the quality of every pizza that goes out the door. For a pizzeria running at full tilt, generic features just won't cut it—you need a workhorse built for the relentless pace of service.

The first thing you need to ignore is the simple cubic footage number. Instead, start thinking in terms of food pan capacity. A well-designed drawer system should easily hold the standard third-size or sixth-size pans you're already using for toppings. This lets you prep ingredients in the pans, slide them into storage, and pull them right onto the line. No extra steps, no wasted motion.

Prioritizing Durability and Temperature Precision

In a pizzeria, equipment gets abused. It’s just a fact of life. That’s why you should be looking for 100% stainless steel construction—not just on the outside, but on the inside, too. This makes the unit tougher and a whole lot easier to sanitize when things get messy. And don't forget to check the drawer slides. They need to be heavy-duty enough to handle the weight of cheese and meats being yanked open and slammed shut all day.

Temperature is the one thing you can't compromise on. You need a system that can lock in a temperature between 33°F and 38°F without breaking a sweat. Go any warmer, and you’re playing with fire when it comes to food safety. Any colder, and you risk ruining the texture of your cheese. A unit with a clear, external digital thermostat is a must-have so your team can see the temp at a glance.

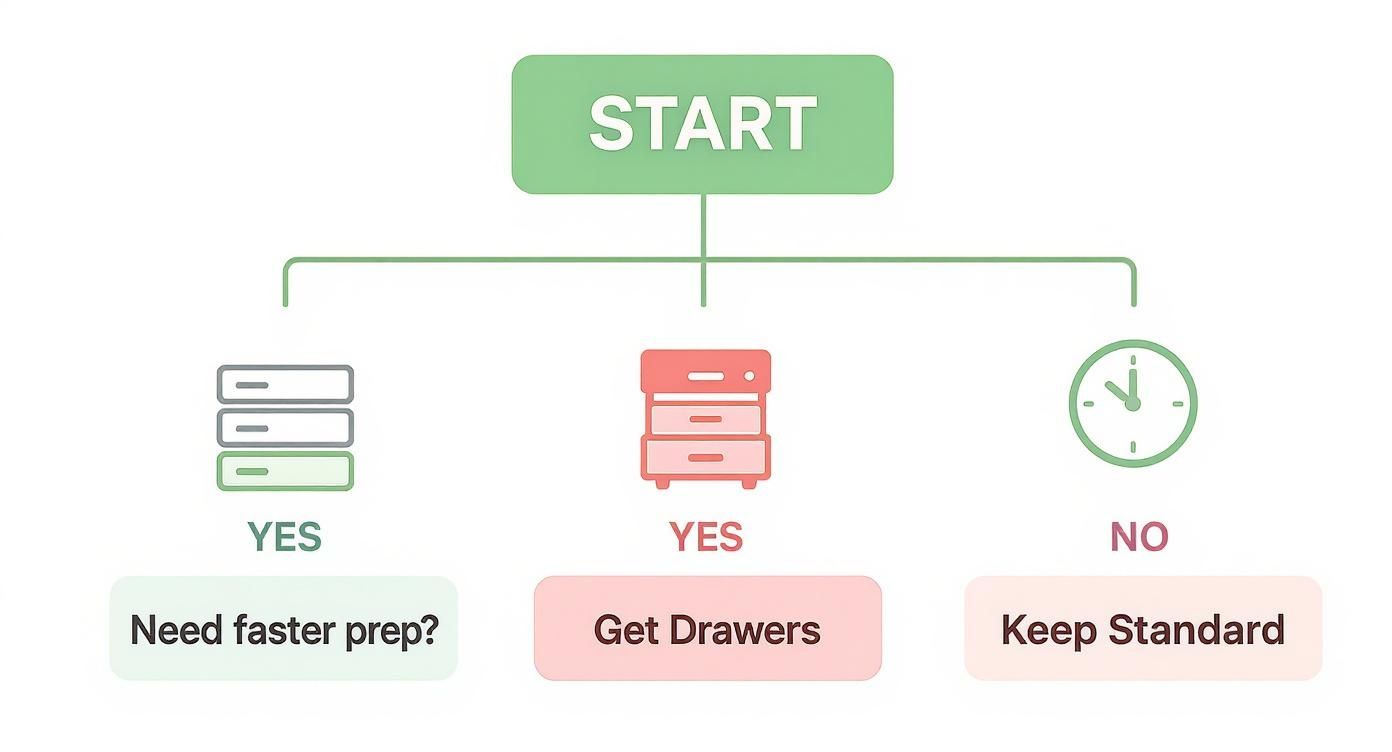

This simple infographic breaks down the decision perfectly. If you need to speed up your pizza prep line, the answer is pretty clear.

As you can see, for any pizzeria serious about cranking out more pies and making the line more efficient, refrigerated drawers are the next logical step.

Smart Design for Practical Kitchens

The practical features are what really separate a good unit from a great one. If your kitchen layout is tight—and whose isn't?—a front-breathing ventilation system is non-negotiable. This design pulls air in and pushes it out from the front, meaning you can slide the unit right up against a wall without worrying about it overheating.

Cleaning is another one of those things that saves a ton of time and labor. Make sure the drawer gaskets are easy to remove. This lets your staff pop them off for a deep clean, preventing grime buildup and keeping that energy-efficient seal nice and tight. For some unique layouts, looking into a shallow beverage refrigerator can also be a clever space-saving move. You can dive deeper into that idea by checking out our guide on shallow beverage refrigerator options.

The demand for units like these is part of a bigger shift in the industry. The global beverage refrigeration market is projected to jump from $5.1 billion in 2025 to $7.6 billion by 2035, all because kitchens like yours need smarter, more efficient cooling solutions. To see the data behind this trend, you can read the full research on the beverage refrigeration market.

At the end of the day, choosing the right refrigerated drawers is an investment in your pizzeria's workflow for the long haul—not a quick fix that ends up creating more problems than it solves.

Integrating Drawers Into Your Pizza Prep Workflow

Dropping refrigerated drawers into your pizza prep line is a smart move, but you won't get the full benefit without a bit of planning. It’s like setting up a new workstation for an artist; the right layout and tools make all the difference. Before that shiny new pizza prep table even arrives, a few quick checks can save you from major headaches and help you build a smarter, faster pizza line from day one.

This all starts with the boring but essential stuff. Get out the tape measure and check the space—width, height, and depth—to make sure it’s a perfect fit. Next, look at your electrical outlet. You need to be certain it’s compatible and can handle the load, because a tripped breaker during the dinner rush is the last thing you want.

Finally, think about breathing room. Most commercial units need at least a couple of inches of clearance around them for proper ventilation. If you skip this, you risk overheating the compressor, leading to poor cooling and higher energy bills.

Designing a Smarter Prep Station

Once you’ve got the technical checks out of the way, the real fun begins: optimizing your workflow. The goal here is to set up a system so intuitive that your pizza makers can build pies almost on autopilot, with every single motion having a purpose. This means getting strategic about how you organize ingredients in those drawers.

Think of your drawers like real estate—some spots are more valuable than others. The top drawer is prime property, reserved for the ingredients your team grabs for nearly every single pizza.

- Top Drawers: This is where your highest-volume items live. Think shredded mozzarella, pepperoni, and your house pizza sauce. Putting them here minimizes bending and keeps the most-used ingredients right at your fingertips.

- Bottom Drawers: These are for your secondary toppings. Things like mushrooms, onions, peppers, or specialty meats belong here. They’re still super accessible, just perfectly placed for items you don't need quite as often.

This simple layout strategy turns your pizza prep table into a high-efficiency command center where every ingredient has a logical home.

Ergonomics aren't a luxury in a busy pizzeria; they're a necessity. A well-designed workstation reduces physical strain, which helps prevent fatigue and keeps your team performing at their best throughout a long and demanding shift.

The Ergonomic Advantage

Getting the placement right is about more than just speed; it directly impacts the well-being of your staff. When you position the unit correctly and organize your ingredients with care, you cut down on the physical demands on your crew. Less bending, reaching, and twisting means less fatigue and a much lower risk of repetitive motion injuries over time.

This focus on ergonomics creates a more comfortable and sustainable work environment. And let's be honest, a happy, less-tired team is a more productive and consistent team. Taking the time to integrate your refrigerated drawers correctly is an investment that pays you back not just in faster service, but in the long-term performance and satisfaction of your people.

Maintaining Your Drawers for Peak Performance

Your refrigerated drawers are a serious investment in your pizzeria's efficiency. Protecting them with a solid maintenance plan isn't just a good idea—it's non-negotiable.

A consistent care routine is your best defense against costly downtime and spoiled ingredients. Think of it as a simple insurance policy that prevents a complete meltdown during your Friday night rush.

Regular maintenance doesn't have to be a huge chore. By breaking it down into simple daily, weekly, and monthly tasks, you can build a plan that your whole team can stick to. This is how you keep your refrigerated drawers in prime condition for years.

Building a Simple Maintenance Schedule

A little bit of attention every day goes a long, long way. These quick checks are the bedrock of a healthy refrigeration system and take just a few minutes at the end of a shift.

- Daily Tasks: Wipe down all stainless steel surfaces, inside and out, to stop grime from building up. Most importantly, give the drawer gaskets (those rubber seals) a quick look for any cracks or gaps that could be letting precious cold air escape.

- Weekly Tasks: Time for a deeper clean. Pull out all the food pans, wipe the interior down with a food-safe sanitizer, and make sure the drawer slides are clear of debris so they operate smoothly.

This kind of consistency not only keeps your unit sparkling clean but also helps you spot small issues before they blow up into big, expensive problems.

The single most important monthly task is cleaning the condenser coils. Seriously, if you do nothing else, do this. It's like an oil change for your refrigerator—the most effective way to maintain cooling power and energy efficiency.

Cleaning Condenser Coils The Right Way

Dust, grease, and airborne flour are the enemies of your condenser coils. When these vital parts get clogged, they force the compressor to work overtime, burning through electricity and struggling to keep things cool.

Proper maintenance, especially cleaning these components, is key to making sure your refrigerated drawers hold their temperature and don't inflate your utility bills. The same core principles apply to other cooling systems, and you can find some great tips on cleaning HVAC coils for peak system performance that are surprisingly relevant here.

Keeping up with this isn't just about your one unit; it's part of a bigger trend. The refrigerator drawer market is on track to hit about $2.5 billion by 2025, and it's expected to grow at a rate of roughly 7% annually through 2033. This boom shows just how much modern commercial kitchens, especially pizzerias, rely on this kind of specialized equipment.

Making sure your coils are clean is also a cornerstone of any strategy for running an energy-efficient commercial refrigeration system. A clean unit simply uses less power to do its job, which you'll see reflected in your monthly bills. By following this simple plan, you ensure your drawers remain a high-performing asset, not a ticking time bomb.

Got Questions About Refrigerated Drawers? We've Got Answers.

When you're thinking about adding refrigerated drawers to a pizza prep table, a lot of real-world, practical questions come up. This piece of equipment is a serious investment in your kitchen’s rhythm, so getting straight answers is everything. We’ll tackle the most common questions we hear from pizzeria owners, with no fluff—just practical info for a busy commercial kitchen.

Our goal is to cut through the sales jargon and give you the details you need to make a smart, confident choice for your pizzeria.

Can Refrigerated Drawers Hold Standard Food Pans?

Yes, they absolutely can. In fact, that's one of their most important jobs in a high-volume pizzeria. Commercial-grade refrigerated drawers are built specifically to handle standard foodservice pans—think 1/3, 1/6, and 1/9 sizes—which are the building blocks of any well-organized pizza prep line.

This means you can prep ingredients like diced onions or sliced pepperoni right in the pans you'll use on the line. Just be sure to check the unit's spec sheet before you buy to confirm its exact pan capacity and how the drawers are set up. This little bit of homework ensures it’ll work perfectly with the pans you already own, so you don't have to waste money on new containers.

Are These Drawers More Energy Efficient Than a Reach-In Cooler?

When you’re using them right on the pizza prep line, they almost always are. Picture this: every time a cook swings open a big reach-in door, a huge wave of cold air rushes out into the hot kitchen. The compressor has to roar back to life to cool everything down again. This happens hundreds of times during a busy shift.

With refrigerated drawers, you’re only opening one small, self-contained section at a time. That simple change dramatically cuts down on cold air loss and gives your compressor a much-needed break.

To get the biggest bang for your buck on your utility bill, always look for ENERGY STAR certified models. These units are built with better gaskets and use modern, efficient refrigerants like R290, which will lower your energy costs while holding rock-solid temperatures.

This focused approach to cooling doesn't just save you money on electricity; it also keeps your pizza toppings at a more consistent temperature because they aren't getting blasted with warm kitchen air all day.

How Do You Clean Under a Prep Table with Drawers?

This is a make-or-break question for keeping your pizzeria spotless and passing health inspections. Luckily, manufacturers have already thought this through. The vast majority of commercial pizza prep tables with integrated drawers are built on a set of heavy-duty casters (wheels), with front-locking brakes to keep them stable during service.

That mobility is the key. Your crew can simply unlock the brakes and roll the entire prep table away from the wall. Just like that, you have full access to the floor and walls behind it, making deep cleaning a quick and painless job. It gets rid of those hard-to-reach spots where crumbs and grease love to hide, keeping your whole kitchen truly sanitary.

What Is the Ideal Temperature for Storing Pizza Toppings?

For both food safety and quality, you need to keep all your perishable pizza toppings—cheese, meats like sausage, and prepped veggies—at or below 40°F (4°C). This is a hard-and-fast rule from the health department to stop nasty bacteria from growing.

The sweet spot for most commercial refrigerated drawers is between 33°F and 38°F (0.5°C to 3.3°C). This range keeps everything safely chilled and tasting great without any risk of freezing. Pro tip: always choose a unit with an external digital thermostat. It lets your team check temperatures with a quick glance, giving you peace of mind and making daily food safety logs a breeze.

Ready to upgrade your pizzeria's efficiency and consistency? At Pizza Prep Table, we specialize in high-quality refrigerated prep tables designed for the demands of a busy kitchen. Explore our wide selection of equipment to find the perfect fit for your operation at https://pizzapreptable.com.