Replacement Freezer Shelves Guide for Pizzerias

Share

A broken freezer shelf during a dinner rush is more than just an annoyance—it's a direct hit to your pizzeria's workflow and your bottom line. When shelves in your pizza prep table start to sag, crack, or rust, the whole operation can grind to a halt. Finding the right replacement freezer shelves isn't just a repair; it's a critical investment in your kitchen's performance.

Why Your Pizza Prep Table Shelves Matter More Than You Think

In the controlled chaos of a busy pizzeria, the freezer shelves inside your pizza prep table are the unsung heroes. They’re constantly bearing the weight of heavy dough boxes, bulk cheese, and pans of toppings. A failing shelf isn't a minor hiccup; it’s a critical breakdown in your operational chain that can send ripples through your entire service.

The moment a shelf cracks or warps, it throws your prep line's organization out the window. Ingredients get jumbled, making it harder for your crew to grab what they need on the fly. That slowdown, even if it’s just a few seconds per pizza, adds up fast during peak hours and can directly impact ticket times and customer satisfaction.

The Hidden Costs of a Bad Shelf

The trouble goes way beyond simple disorganization. A damaged shelf can introduce serious food safety risks that could jeopardize your reputation and lead to costly health code violations.

- Cross-Contamination Risk: Cracked or rusted shelving creates tiny crevices where bacteria can thrive. These spots are nearly impossible to sanitize properly, creating a high-risk zone for contaminating fresh ingredients.

- Poor Air Circulation: Overloaded or sagging shelves can easily block air vents, leading to inconsistent temperatures inside the unit. This can create warm spots where food spoils faster or cold spots that cause freezer burn on your expensive products.

- Ingredient Loss and Waste: A total shelf collapse is the stuff of nightmares, resulting in the immediate loss of hundreds of dollars in cheese, dough, and prepped toppings. Even a slight sag can cause containers to tip and spill, adding to your daily food waste.

The integrity of your prep table's interior is directly tied to your kitchen's output and safety standards. You have to see replacement freezer shelves not as a simple fix, but as an essential upgrade to keep your operation smooth and profitable.

Ultimately, the state of your shelving system reflects your kitchen's overall efficiency. Proactively replacing weak or damaged shelves ensures your team can work safely and effectively, keeping the pizza line moving and your customers happy. I'll walk you through everything you need to know about choosing, sourcing, and installing the perfect replacement freezer shelves for your specific setup.

How to Measure and Identify Your Freezer Shelves

Ordering the wrong replacement freezer shelves for your pizza prep table is one of those mistakes that costs way more than just money—it costs precious time. I’ve seen it happen: a missized shelf sits in the back room while the kitchen team struggles through another dinner rush. It’s a scenario every pizzeria owner wants to avoid.

Getting the measurements right the first time is everything. It’s a straightforward process, but it demands a bit of precision. Grab a simple measuring tape; it’s your best friend here. Start by carefully pulling the damaged shelf out of the unit.

First, measure the width from one side to the other. Then, measure the depth from front to back. It’s a smart move to jot these numbers down immediately, maybe even on a sticky note you slap right onto your order sheet. When you're trying to find the right replacement, there's no room for guessing. For some general advice on getting it right, check out these tips for precise furniture measurement.

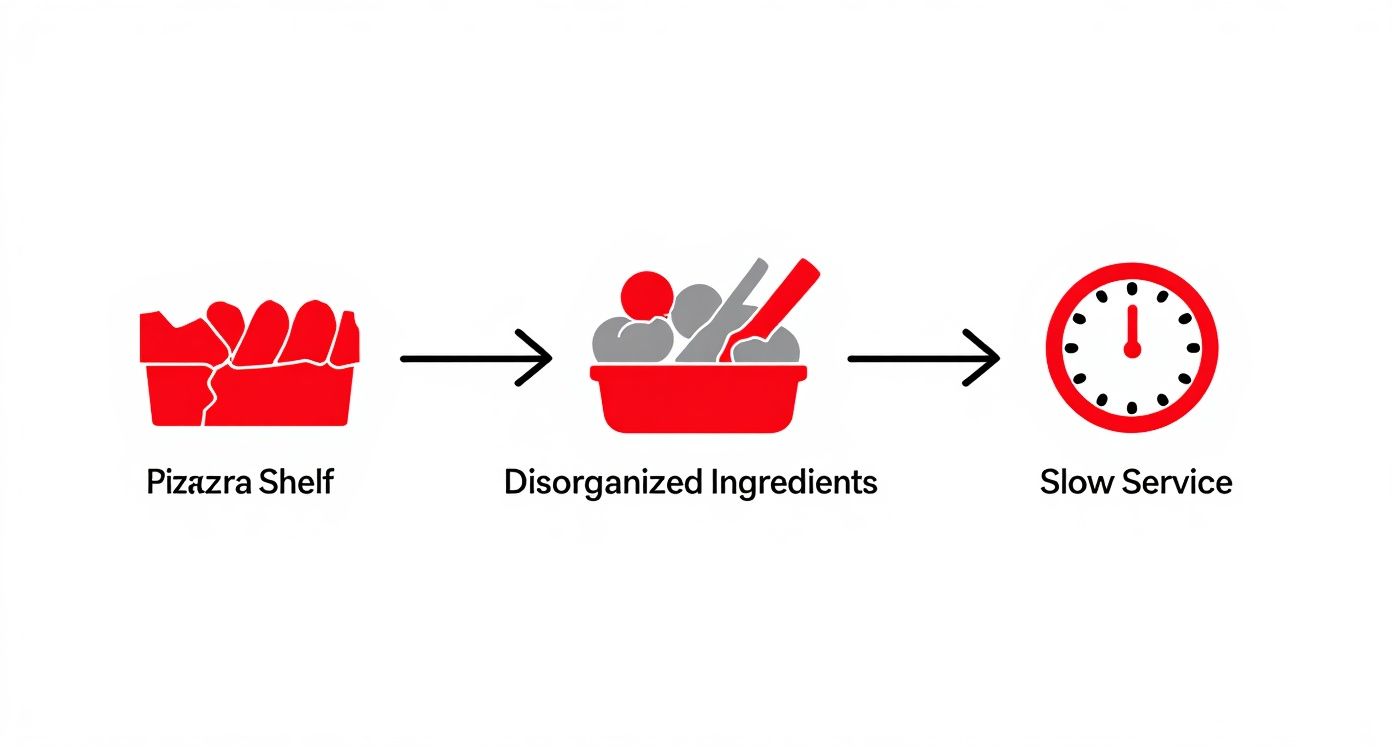

This infographic really drives home the ripple effect a single broken shelf can have in a pizzeria, snowballing from simple disorganization into slower service.

As you can see, the entire workflow gets thrown off, which is why a quick and accurate replacement is so critical to keeping the kitchen humming.

Locating Your Prep Table's Model Number

Beyond the shelf's physical dimensions, your pizza prep table's model and serial number are your golden ticket. This info is the most reliable way to find an exact Original Equipment Manufacturer (OEM) replacement, which guarantees a perfect fit.

So, where do you find it? This crucial ID tag is usually tucked away in one of a few key places:

- Inside the Door Jamb: Open the main refrigerator door and scan the interior frame, often near the top hinge.

- On the Exterior Back Panel: You might need to pull the unit away from the wall to find a metal plate on the back.

- On the Side of the Unit: Check the exterior side panels, especially near the bottom where the compressor housing is.

Once you find it, snap a clear photo with your phone. Having a digital copy prevents typos and makes it easy to reference when you're placing an order. Knowing your equipment’s specs is also key for optimizing your space; take a look at our guide on under-counter refrigerator dimensions to get a better handle on your kitchen layout.

Identifying the Shelf Support Style

The final piece of the puzzle is figuring out how the shelf is held in place. This is a common oversight that leads to ordering the wrong part. Even if two shelves have the exact same dimensions, they won't be interchangeable if their support systems are different.

You’ll typically run into one of three primary support styles in commercial pizza prep tables:

- Clip-On Shelves: These are the most common. The shelf rests on individual clips that you insert into vertical tracks (pilasters) running up the inside walls of the freezer.

- Slide-In Shelves: These shelves have built-in runners or slide into pre-formed grooves molded directly into the freezer's interior walls.

- Cantilever Shelves: These are supported by brackets that hook into the back wall of the unit, creating a "floating" look with no front supports.

Pro Tip: Before you even start searching online, take a couple of clear pictures of the shelf itself and a close-up of the support clips or grooves. Trust me, these images will be invaluable for visually confirming you're ordering the right part.

To make sure you don't miss anything, use this simple checklist to record all your details in one place. It will save you a headache later.

Freezer Shelf Measurement Checklist

| Measurement/Detail | Your Measurement (Inches/mm) | Notes (e.g., support type, material) |

|---|---|---|

| Shelf Width | ||

| Shelf Depth | ||

| Prep Table Model Number | ||

| Prep Table Serial Number | ||

| Shelf Support Style | e.g., Clip-On, Slide-In | |

| Number of Shelves Needed | ||

| Existing Shelf Material | e.g., Coated Wire, Stainless Steel |

Having this table filled out before you start shopping turns a potentially frustrating task into a quick and easy one, ensuring you get the right part on the first try.

Choosing the Right Shelf Material and Load Capacity

Let's be honest: the shelves that come standard with a pizza prep table are rarely built for the brutal reality of a high-volume pizzeria. When it's time to find replacement freezer shelves, the material you choose directly impacts your kitchen’s efficiency, food safety, and long-term costs. It’s not just about finding a shelf that fits; it’s about matching the material to the job it will do day in and day out.

In the world of pizzerias, two materials dominate the landscape: epoxy-coated wire and stainless steel. Each has its own strengths and weaknesses, especially when you're talking about holding precious pizza ingredients. Your choice should be a strategic one, based entirely on what you plan to store on that specific shelf.

Epoxy-Coated Wire Shelves: The Airflow Champion

Epoxy-coated wire shelves are what you'll find in most pizza prep tables, and for good reason. The open-wire design is their superpower, letting cold air circulate freely and evenly throughout the freezer. This is absolutely critical for maintaining consistent temperatures, preventing spoilage, and keeping your ingredients in the food-safe zone.

This fantastic airflow makes them perfect for storing things that need to cool down fast or benefit from constant cold exposure. Think open pans of sliced veggies, containers of house-made sauce, or portions of pepperoni.

But the epoxy coating is also their Achilles' heel. While it’s great at resisting moisture and rust, it's not invincible. A dropped pan or the sharp corner of a food box can chip the coating, exposing the metal underneath. Once that happens, rust is inevitable, creating a food safety hazard that health inspectors will spot from a mile away.

Stainless Steel Shelves: The Heavy-Duty Workhorse

When durability is the name of the game, nothing beats stainless steel. These solid or wire-grid shelves are the undisputed champions of strength and sanitation in a busy pizzeria. Their non-porous surface is incredibly easy to clean and sanitize, leaving absolutely no place for bacteria to hide.

This makes them the only real choice for your heavy, high-stakes items. A stainless steel shelf won't even flinch under the weight of a 50-pound block of mozzarella or a stack of dough boxes. If a shelf is going to hold your most expensive or heaviest ingredients, stainless steel provides a peace of mind that epoxy-coated wire simply can't offer.

The main trade-off is airflow. A solid stainless steel shelf can block air circulation, potentially creating warmer spots in your freezer. But for sheer load-bearing muscle and a surface that can take the daily abuse of sliding heavy containers, they are the clear winner. You can dig deeper into your options in our comprehensive guide to commercial kitchen shelving.

Think of it like this: an epoxy-coated wire shelf is perfect for organizing lighter, prepped ingredients that need consistent cold air. A stainless steel shelf is the foundation for your bulk storage—the heavy hitters like cheese and dough.

Understanding Shelf Load Capacity

Beyond the material, the load capacity is a critical number you cannot afford to ignore. This rating, provided by the manufacturer, tells you the absolute maximum weight a shelf can safely hold when the load is evenly distributed. Pushing this limit is the number one reason shelves sag, warp, and sometimes fail spectacularly.

Imagine loading a new shelf with three heavy dough trays, only to walk in the next morning and find it bowed in the middle. That’s a classic sign the load rating was too low for the job.

- Standard-Duty Shelves: These are typically rated for 200-250 pounds. They're fine for lighter items like bags of shredded cheese, topping containers, or small sauce pans.

- Heavy-Duty Shelves: Built to hold 400-600 pounds or even more. These are essential for storing dense, heavy items like solid blocks of cheese, stacked dough boxes, or cases of tomato sauce.

When choosing replacement shelves, always overestimate your needs. A busy pizzeria is a dynamic environment where shelves are loaded and unloaded constantly, often unevenly. Opting for a higher load rating gives you a crucial safety margin, ensuring your new shelf will stand up to the rigors of your pizza line for years to come.

Finding Your Replacement: OEM vs. Aftermarket Shelves

Alright, you’ve got the measurements and you know what kind of shelf you need. Now comes the real challenge: actually getting your hands on the part. For a busy pizzeria, this isn't just a quick online order; it’s about getting your prep line back to 100% capacity, fast. You've really got two main paths here: sticking with the Original Equipment Manufacturer (OEM) or diving into the world of aftermarket and custom solutions.

The Case for Sticking with OEM

The most straightforward and bulletproof route is always to start with the Original Equipment Manufacturer (OEM). These are the shelves made by the same company that built your pizza prep table. Using that model and serial number you found earlier, you can order a replacement that's guaranteed to be a perfect match—down to the exact dimensions, the specific coating, and the way the support clips are designed.

Going with an OEM part just removes all the guesswork. There’s no crossing your fingers hoping it fits, no questioning if the load capacity is right, and no worrying if the material is actually food-safe. It's the plug-and-play fix that keeps your equipment up to the manufacturer's original specs.

Here's a critical point many people overlook: using genuine OEM parts is often a requirement to keep your equipment's warranty valid. If you install a non-certified part and something else goes wrong, you could void your coverage and be on the hook for a much bigger repair bill down the road.

When to Go Rogue with Aftermarket or Custom Shelves

But what if your trusty pizza prep table has been in the trenches for years and is now an older or discontinued model? Sometimes, the manufacturer simply doesn't make the parts anymore. This is where aftermarket parts and custom fabrication become absolute lifelines for your pizzeria.

Aftermarket suppliers make replacement shelves designed to fit a wide variety of models. They're often cheaper, but the quality can be all over the map. It's absolutely crucial to buy from a reputable commercial kitchen parts supplier who can confirm the shelf is compatible with your specific pizza prep table.

- Verify Compatibility: Always double-check that your model number is listed. Never, ever rely on a visual match alone.

- Check the Specs: Make sure the aftermarket shelf meets the same food-safety and durability standards as the original. Look for NSF certification.

- Read the Reviews: See what other pizzeria owners are saying. Real-world feedback will tell you a lot about the part's quality and how long it actually lasts.

If you strike out with both OEM and aftermarket options, custom fabrication is your final and most flexible move. A local metal fabricator can build you a brand-new shelf from scratch, using your exact measurements. This is a fantastic solution for unique or vintage units. You get to call the shots on the material—like upgrading to heavy-duty stainless steel—and can even ask them to reinforce the design for a higher load capacity.

The need for tailored storage solutions like this is growing. The global market for shelving is projected to hit an estimated USD 41.07 billion, a trend driven by the need for efficient, customized storage in commercial kitchens just like yours. You can learn more about this trend in this shelving units and shelves market report.

Finding a Reputable Supplier

Knowing where to look is half the battle. Your first call should always be to the equipment dealer where you bought the pizza prep table. They usually have a direct line to the manufacturer's parts department and can make the whole process a lot smoother.

Beyond your dealer, there are tons of online restaurant supply stores that specialize in commercial kitchen parts. These websites let you search directly by model number, which makes it easy to compare OEM and aftermarket prices side-by-side. For a deeper dive into hunting down components, check out our guide on where to find pizza prep table parts.

No matter which path you take, having a reliable source for parts is key to minimizing downtime and keeping your pizzeria humming.

Installing Your New Shelf and Maintenance Best Practices

Once your new freezer shelves land on your doorstep, the final step is getting them installed correctly to bring order back to your pizza prep line. This isn't just about making it fit; a wobbly or unlevel shelf is a disaster waiting to happen during a busy dinner service.

First things first, empty the unit completely. This is the perfect chance to give the interior of your pizza prep table a thorough cleaning, wiping down the walls and getting rid of any gunk that’s built up over time. Now, carefully remove the busted shelf and its support clips, making sure not to scrape or damage the freezer's interior lining.

Getting the Fit Just Right

Grab your new shelf clips and position them in the vertical tracks (the pros call them pilasters) inside the freezer. Here’s a tip from the field: use a small torpedo level to make sure the clips on both sides are perfectly aligned. An unlevel shelf is bad news—it causes ingredients to slide around and puts uneven stress on the supports.

A level shelf is a stable shelf. Taking an extra 30 seconds with a level can prevent a catastrophic failure down the road, saving you from lost product and potential injuries. It's a small step with a huge payoff in a busy pizzeria.

With the clips locked in, slide your new shelf into place. It should sit snugly on the clips with zero rocking or movement. Give it a gentle but firm press to confirm it’s stable before you start loading it up with heavy boxes of cheese and dough.

A Simple Cleaning Routine That Actually Works

Installation is just the start. The real secret to making your replacement freezer shelves last and acing every health inspection is a consistent cleaning routine. A simple, non-negotiable schedule is your best defense against rust and cross-contamination in your pizzeria.

On a daily basis, spot-clean any spills immediately. For the weekly deep clean, pull everything off the shelves so you can wash them properly in a three-compartment sink using a food-safe detergent and sanitizer.

- Epoxy-Coated Shelves: Stick with a soft cloth or a non-abrasive sponge. Anything harsher, like a steel scrubber, will chip that protective coating, and that’s the first step toward rust.

- Stainless Steel Shelves: These guys are tougher and can handle more aggressive scrubbing, but you should still steer clear of steel wool. It can leave behind tiny particles that will eventually lead to rust spots. A nylon brush works great for any stuck-on food.

Always let the shelves air dry completely before putting them back. Reinstalling a wet shelf in a sub-zero freezer is a recipe for trapped moisture and accelerated corrosion, which totally defeats the purpose of cleaning.

Proactive Checks for Long-Term Durability

Beyond the weekly scrub-down, a little proactive attention will go a long way in extending the life of your shelves and the efficiency of your whole pizza prep table. Small checks now prevent massive headaches later.

Depending on your unit's design, you might explore different concealed shelf support systems to get a clean and sturdy fit during installation.

Build these quick habits into your team's workflow:

- Inspect the Clips: Once a month, give the support clips a quick visual check. Look for any signs of cracking, bending, or stress. These little pieces hold all the weight and are often the first point of failure.

- Mind the Airflow: Constantly remind your staff not to cram product against the air vents inside the freezer. Blocked vents make the compressor work overtime and can create warm spots—which is exactly why wire shelves are so great for circulation in the first place.

- Load Smarter, Not Harder: Train your team to spread the weight evenly across the entire shelf. Piling heavy items like blocks of cheese or stacks of dough boxes right in the middle is a surefire way to cause sagging.

Combine a solid installation with a smart maintenance plan, and your new freezer shelves will provide a reliable and hygienic foundation for your pizza ingredients for years to come.

Questions from the Pizzeria Floor

Even the most seasoned pizzeria owner runs into questions when it comes to the nitty-gritty details of their equipment. When a freezer shelf in your pizza prep table gives out, you need answers fast. A broken shelf can throw a wrench in your entire service. We've pulled together the most common questions we hear from pizzeria operators to help you sidestep common issues and costly mistakes.

Can I Use a Shelf From a Different Brand if It Fits?

It's a tempting thought, especially when you spot a cheaper option online that seems to have the right dimensions. But take it from me, this is a gamble you don't want to take with your pizza prep table. I strongly advise against it.

Even if the width and depth are a perfect match, the mounting system—those unique clips, grooves, or brackets—is almost always specific to the manufacturer. A shelf that isn't seated perfectly becomes unstable. You might not notice it at first, but the constant hum and vibration from the compressor, combined with the shifting weight of your ingredients, will eventually cause it to fail.

A collapsed shelf means lost product, a mess to clean up, and a serious safety risk for your team. The only way to guarantee a secure, stable, and safe fit is to stick with the OEM replacement freezer shelves made for your exact model.

My Epoxy-Coated Shelf Is Rusting. Can I Fix It?

Once you see rust on an epoxy-coated shelf, its career in your pizzeria is officially over. That rust is a clear sign the protective coating has failed, letting moisture attack the metal underneath. Worse, rust particles can flake off and contaminate your pizza ingredients, leading to a major health code violation no one can afford.

You might come across epoxy repair kits, but they are not a reliable or food-safe solution for a commercial pizza prep table. That patch will fail under the daily stress of loading and unloading heavy ingredients.

The only professional and safe move is to replace any shelf showing signs of rust immediately. Consider it a non-negotiable investment in your pizzeria's reputation, your food safety, and your customers' trust.

What's the Best Way to Clean My Freezer Shelves?

Keeping your shelves clean is non-negotiable for both longevity and food safety in a pizzeria. For your epoxy-coated or polymer shelves, stick to a soft cloth with a mild, food-safe detergent and sanitizer. Abrasive scrubbers or harsh chemicals will scratch the coating, creating weak spots that lead to rust and breakdown.

Stainless steel shelves are tougher and can handle more aggressive cleaning, but always rinse them thoroughly to get rid of any chemical residue. The best practice is a weekly deep clean: empty the shelves, let them come to room temperature (this prevents cracking from thermal shock), and then wash them properly in a three-compartment sink. Making this a non-negotiable part of your weekly cleaning schedule is the key to staying compliant and serving safe pizza.

How Do I Stop My New Shelves From Sagging or Breaking?

Prevention here is all about making smart choices from the start and building good habits with your pizzeria team. It begins with choosing a shelf with a load capacity that can actually handle the demands of your kitchen. Don't just aim for what you think you need; go for a higher rating to give yourself a safety buffer.

Once the shelf is in, train your staff on proper loading techniques. Heavy items like blocks of cheese or stacks of dough boxes should be distributed evenly across the shelf, not piled up in the middle. This simple habit dramatically reduces the stress on the shelf and its support clips.

Finally, make quick visual inspections part of your routine. A quick glance at the support clips and brackets for any signs of bending, stress, or damage can save you a huge headache. If you see something wrong, replace those small parts right away. Smart loading and regular checks are the most effective ways to make sure your replacement freezer shelves last for years.

At Pizza Prep Table, we know that every single component in your kitchen is vital to your success. Find the perfect, durable replacement freezer shelves and other essential equipment by visiting us at https://pizzapreptable.com.