Don't Lose Your Cool – Where to Find Pizza Prep Table Parts

Share

The Heartbeat of Your Pizzeria: Essential Pizza Prep Table Parts

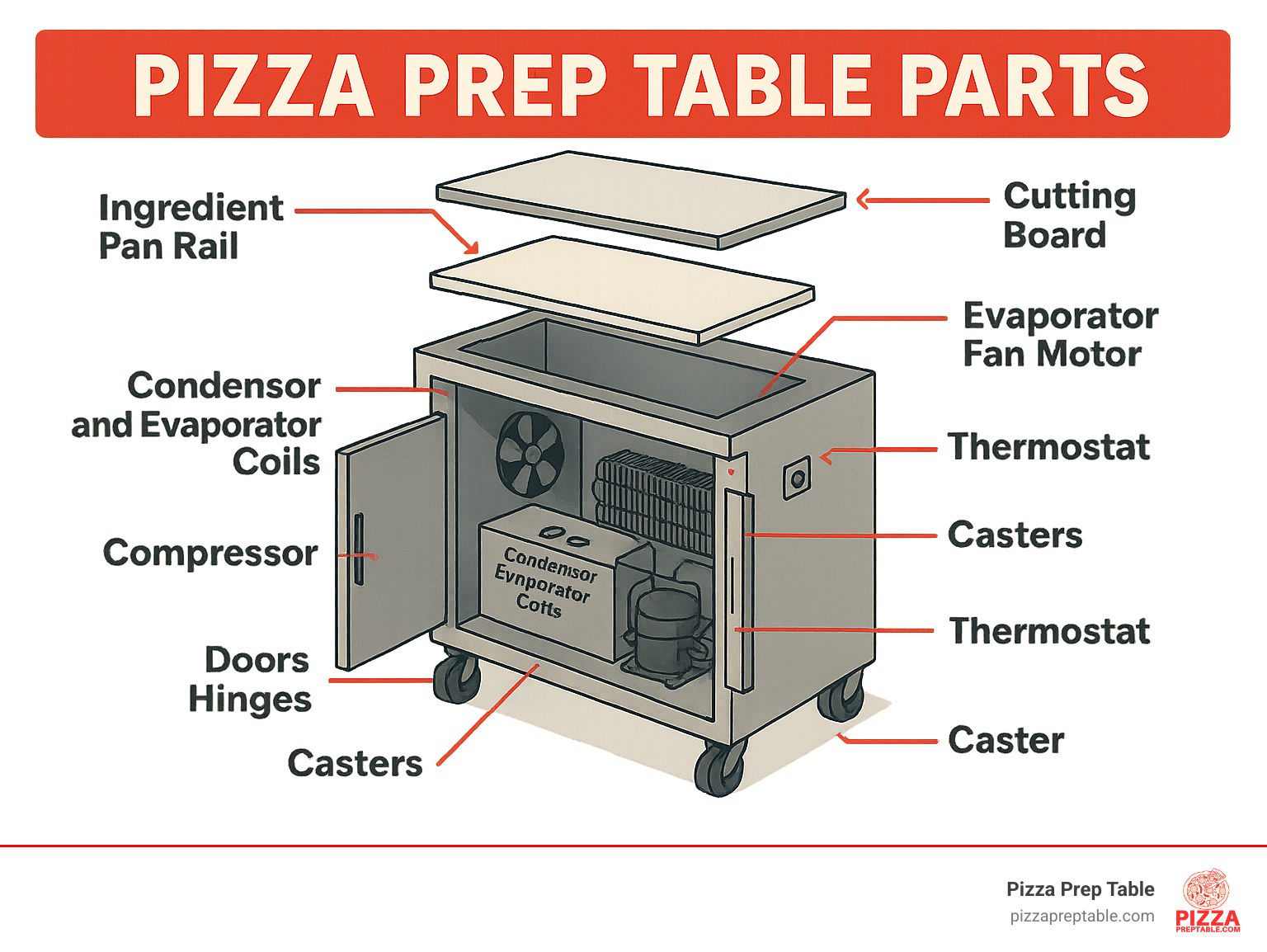

For quick reference, the essential pizza prep table parts include:

- Compressor

- Condenser and Evaporator Coils

- Evaporator Fan Motor

- Cutting Board

- Ingredient Pan Rail

- Doors and Hinges

- Gaskets

- Thermostat

- Casters

In a busy pizza kitchen, your prep table is the unsung hero. It keeps fresh ingredients at hand and cold, ready for every order. Selecting the right refrigeration is essential for efficiency, food safety, and workflow in a busy pizzeria.

But what happens when that essential equipment breaks down? A sudden breakdown during a dinner rush is every owner's nightmare. It can stop your operation cold, costing you money and customers.

Understanding the components of your pizza prep table means you can fix issues quickly. It helps you keep ingredients safe, reduce downtime, and maintain a smooth workflow. This guide will walk you through the common parts, how to identify problems, and where to find reliable replacements.

Sean Kearney brings a unique blend of sales expertise and industry knowledge to pizza prep table parts. His passion lies in helping restaurant owners keep their kitchens running smoothly by understanding the critical role that high-quality equipment plays.

Anatomy of a Pizza Prep Table: Understanding the Essential Components

A pizza prep table is a specialized workstation where every component is crucial. Understanding its key systems helps with troubleshooting and maintenance. This section breaks down the anatomy of your prep table.

The Workstation: Where the Magic Happens

The workstation is the surface-level area where staff assemble pizzas, and its components are crucial for speed and organization.

Your Cutting Boards are the primary work surface. Pizza prep tables feature deep boards (14-19 inches) for large pies, unlike shallower sandwich prep boards. Made from materials like polyethylene or composite, they are removable for easy cleaning and replacement and sit on replaceable brackets.

Above the cutting board, Pan Rails hold your fresh ingredients in food pans, kept at food-safe temperatures by the refrigeration system. Advanced designs may feature an independently cooled rail with a "cold-wall" to keep ingredients extra fresh.

To maintain temperature, prep tables have Lids & Covers. Insulated lids offer the best temperature retention, while clear lids allow for quick visual inventory checks.

The refrigerated base provides bulk storage. Doors offer more organizational space and often have self-closing and stay-open features for easy loading. Drawers provide quick access to frequently used ingredients. Some models offer a combination of both.

Inside the base, adjustable wire epoxy Shelving provides organized storage, typically holding up to 155 lbs per shelf.

Finally, heavy-duty Casters (wheels) allow you to easily move the unit for cleaning or reconfiguring your kitchen layout.

For more insights into optimizing your prep area, check out our guide on Table Manners: Picking the Perfect Kitchen Prepping Table.

The Refrigeration System: Keeping Your Ingredients Fresh

This system is the heart of your unit, responsible for maintaining food-safe temperatures (NSF-7 standard of 41°F or below).

The Compressor is the powerhouse that circulates refrigerant. Brands like Embraco are common, chosen for reliability and energy efficiency.

The Condenser Coil dissipates heat from the refrigerant, assisted by a condenser fan. Inside the cabinet, the Evaporator Coil absorbs heat, cooling the interior.

An Evaporator Fan Motor circulates cold air throughout the cabinet, ensuring consistent temperatures and preventing "hot spots."

The Thermostat or a digital controller (like Dixell) is the brain, regulating the internal temperature to keep ingredients safe.

Gaskets are the flexible seals around doors and lids, vital for maintaining temperature. A compromised gasket forces the system to work harder, increasing energy costs.

Modern prep tables use environmentally friendly Refrigerant like R290 (hydrocarbon), replacing older types like R134a.

Different units use various Cooling Methods:

- Single-Cavity Cooling: A single system cools the entire unit.

- Cold-Wall Cooling: Refrigerant lines in the walls provide consistent temperatures and can sometimes be shut down independently for energy savings.

- Forced-Air Cooling: Fans circulate cold air for rapid and uniform temperature pull-down.

- Liquid Cooling: A less common but highly efficient method using propylene glycol or eutectic liquid to chill pans.

For a deeper dive into commercial refrigeration, don't miss our article: Doughn't Settle for Less: Choosing the Perfect Pizza Preparation Refrigerator.

Common Failures: The Most Frequently Replaced Pizza Prep Table Parts

In a high-volume pizzeria, your pizza prep table works hard, and some parts will wear out faster than others. Knowing what to look for can prevent costly downtime and is your best defense against a kitchen crisis.

Even with the best care, wear and tear are inevitable. Let's look at the common culprits.

High-Traffic Wear: Cutting Boards and Gaskets

These parts endure constant use and are prone to wear.

Your cutting boards are the stage for constant slicing and prep. Over time, deep knife grooves, warping, or cracks can appear. These grooves can harbor bacteria, and a warped surface slows down prep. Replacing a worn board is vital for food safety and efficiency.

Door and lid gaskets are critical for sealing in cold air. Constant use can cause them to crack, tear, or become brittle. To check the seal, close the door on a dollar bill. If you can pull it out easily, the seal is compromised. A bad seal makes your refrigeration system work overtime, increasing energy bills and risking compressor failure.

Mechanical Movers: Fan Motors and Relays

These components keep the refrigeration system running.

Evaporator and condenser fan motors move air to cool the unit and dissipate heat. Signs of a failing fan motor include grinding or buzzing noises, a lack of cooling even when the compressor is running, or no fan sound at all. Overheating near the condenser is another red flag.

Compressor relays are electrical switches that start the compressor. If your compressor fails to start or clicks on and off frequently, a faulty relay could be the issue. This can prevent your unit from maintaining a safe temperature.

The Unsung Heroes: Thermostats and Door Hardware

These parts are often overlooked but are vital for safety and operation.

The thermostat senses the internal temperature and signals the compressor. A faulty thermostat can lead to unsafe food temperatures—either too warm or too cold. Inconsistent temperatures are a major warning sign.

Door hinges, handles, and latches see constant use. Worn hinges can cause doors to sag and not seal properly, wasting energy. Broken handles or latches are an inconvenience and a potential safety hazard in a kitchen.

The DIY vs. Pro Decision: Identifying and Replacing Key Parts

When your prep table needs a repair, you must decide whether to DIY or call a pro. Some pizza prep table parts are easy to replace, while others require professional expertise. Knowing the difference saves time and money.

Simple Swaps: How to Replace Your Cutting Board

Replacing a cutting board is one of the easiest repairs. First, measure the length, width, and depth of your current board, noting any special cutouts.

Next, choose your material. Polyethylene is affordable but can get deep grooves, while composite materials are more durable and sanitary but cost more.

| Material | Durability | Sanitation | Cost |

|---|---|---|---|

| Polyethylene | Good, but prone to deep knife grooves | Easy to clean, but grooves can harbor bacteria | Lower |

| Composite | Excellent, highly resistant to knife cuts | Less porous, harder for bacteria to penetrate | Higher |

Installation is simple: most boards just lift out. Clean the area, then slide the new board into place, ensuring it's secure.

Finding the right size for your model is key. Our guide on the 67-inch Pizza Prep Table offers helpful sizing insights.

Intermediate Repairs: Servicing common pizza prep table parts

Door gaskets and thermostats are manageable DIY repairs that require basic tools and patience.

To replace door gaskets, first identify the type (snap-in, screw-in, etc.). Most pull out from a channel in the door. Clean the channel thoroughly before pressing the new gasket firmly into place.

Test your work with the dollar bill trick: a proper seal should grip the bill firmly when the door is closed. This simple test can save you money on energy costs.

Thermostat replacement requires some electrical care. Always disconnect the power first. Take a photo of the wiring before removing the old unit. Connect the new thermostat following the diagram or your photo, and double-check all connections before restoring power. Accuracy is crucial for food safety.

When to Call a Pro: Complex pizza prep table parts

Some pizza prep table parts are off-limits for DIY repairs because they involve the sealed refrigeration system and require specialized tools and certifications.

Compressor replacement is a job for a professional. It is the heart of the system and replacing it involves handling refrigerants and complex procedures.

Replacing evaporator and condenser coils also requires breaking into the sealed system, which is professional territory.

Refrigerant leaks are critical issues that require a certified technician. Handling modern refrigerants is strictly regulated by the EPA under the Clean Air Act. Only certified technicians can legally work on these systems. Attempting these repairs yourself can be dangerous, void warranties, and lead to more expensive damage.

Sourcing Your Parts and Making the Right Call: Repair or Replace?

Once you've diagnosed the problem, the next step is finding the right pizza prep table parts and deciding whether to repair your current unit or replace it.

The Cost-Benefit Analysis: Repairing vs. Buying New

This is a classic dilemma. While a simple fix like a gasket is a no-brainer, a major breakdown requires more thought.

First, get a quote for the repair costs (parts and labor) and compare it to the price of a new unit. Factor in downtime and the cost of lost business during the repair.

Consider the age of your prep table. Commercial refrigeration units typically last 7-10 years. Investing heavily in an older unit may not be wise if other parts are likely to fail soon. Always check your warranty, as some components like the compressor may have a longer warranty period (e.g., 5 years).

Finally, consider energy efficiency. Newer models with modern refrigerants like R290 are often far more efficient. A new prep table could save you money on electricity bills, helping to offset the initial cost. If a major component fails on an older unit, investing in a new, efficient Commercial Pizza Prep Table is often the smarter long-term decision.

Finding Reliable OEM and Aftermarket Parts

If you decide to repair, finding quality, compatible pizza prep table parts is crucial.

OEM (Original Equipment Manufacturer) Parts are made by the company that built your unit (e.g., True, Turbo Air, Atosa). They guarantee a perfect fit and performance but may cost more. Aftermarket Parts are made by third-party companies and can be more budget-friendly, but quality and fit can vary. Stick to trusted suppliers if you choose this route.

Where can you find parts? Start with manufacturer websites (like True Manufacturing), which often have dedicated parts sections. Large restaurant supply stores and specialized online retailers also carry a wide range of components. Authorized service centers are another excellent source.

No matter where you buy, always have your unit's model and serial number ready. This information is essential for getting the correct part for your specific brand, whether it's an Atosa Pizza Prep Table or another make. You can find these numbers on a metal data plate, usually inside the cabinet or on the back of the unit.

Frequently Asked Questions about Pizza Prep Table Parts

Here are answers to some of the most common questions we receive about pizza prep table parts to help you keep your kitchen running smoothly.

How do I find the model and serial number on my prep table?

This is the most important information for ordering any pizza prep table parts. Look for a small metal data plate or sticker. Check these common locations: the interior wall of the refrigerated section, the exterior back of the unit, or on the side of the compressor housing (you may need to remove a panel).

Can I use a sandwich prep table cutting board on my pizza prep table?

No, this is not recommended. Pizza prep tables require a much deeper cutting board, typically 14 to 19 inches deep, to provide enough space for stretching dough and assembling large pies. A sandwich prep board is much shallower, usually only 8 to 10 inches deep. Using the wrong size will disrupt your workflow and make prep messy and inefficient.

How often should I clean my condenser coil?

Clean the condenser coil at least every 90 days, or more frequently in busy kitchens with a lot of airborne grease and flour. The coil releases heat from the refrigeration system, and when it gets clogged with dust and grime, it can't work efficiently. This forces the compressor to work harder, leading to higher energy bills and a greater risk of premature failure. Regular cleaning with a stiff brush or vacuum is a simple preventative measure that can save you significant money on future repairs.

Conclusion: Keep Your Pizzeria Running Smoothly

Your pizza prep table is the heart of your operation. Understanding its essential pizza prep table parts, performing regular maintenance, and knowing where to source components are key to maximizing its lifespan and your pizzeria's profitability. A broken part during a dinner rush is a disaster you can avoid.

From the workstation to the refrigeration system, every component plays a vital role. By regularly checking high-traffic parts like cutting boards and gaskets, listening for unusual noises from fan motors, and ensuring your thermostat is accurate, you can catch small issues before they become major problems.

Whether it’s a simple DIY swap or a complex repair requiring a certified technician, being informed helps you make the best decision for your business. When you need new pizza prep table parts, having your unit's model and serial number ready is the key to finding the perfect fit.

By following this guide, you can confidently handle repairs and keep the heart of your kitchen beating strong. For a wide selection of new units and expert advice, explore the best pizza tables for sale to slice your prep time at PizzaPrepTable.com. We're here to help you maintain your cool, even during the busiest rushes!