Choosing Your 67 Inch Pizza Prep Table

Share

For a busy pizzeria, the 67-inch pizza prep table is more than just a hunk of stainless steel—it's the heart of your operation, the place where speed and consistency are born. This specific size really hits the sweet spot, giving you a generous workspace for knocking out complex pizza orders without hogging your kitchen's precious floor space.

Why the 67-Inch Prep Table Is Your Pizzeria's Command Center

Picture your pizzeria during the Friday night dinner rush. Tickets are flying, dough is being stretched, and toppings are being slung left and right. In that chaotic dance, your pizza prep table is the command center where you either win or lose the battle for efficiency.

It’s the cockpit where your pizza maker has every essential ingredient right at their fingertips. A 67-inch table provides exactly that.

It's large enough to handle multiple pies at once without feeling like you're working in a closet, yet it’s still compact enough to slide into most pizzeria layouts. This size prevents the workflow bottleneck that happens when a prep area is too small, forcing your team into cramped, inefficient corners. The right unit directly shaves minutes off ticket times, bolsters food safety, and smoothes out the entire pizza-making process.

The Sweet Spot for Workflow and Space

The real genius of the 67-inch model is that it’s the perfect middle ground. Smaller tables will choke a growing pizzeria, while those massive 93-inch behemoths can be overkill for many independent pizzerias, eating up space you could use for another oven or a dough sheeter.

Think of it this way: The 67-inch table gives your pizza makers enough "runway" to assemble multiple orders at the same time. This is absolutely critical for juggling big takeout orders or a full dining room without your quality or speed taking a nosedive.

This balanced design creates an organized and efficient workflow. I’ve seen it firsthand in dozens of pizzerias. Key benefits include:

- Optimized Staff Movement: It comfortably allows two pizza makers to work side-by-side during peak hours without constantly bumping elbows, effectively doubling your output potential.

- Sufficient Ingredient Storage: The refrigerated rail can hold a wide variety of toppings, keeping everything from pepperoni to pineapple fresh and within arm's length to cut down on wasted steps.

- Enhanced Food Safety: A dedicated, spacious prep area makes it much easier to follow strict hygiene rules and dramatically lowers the risk of cross-contamination between different pizzas.

The rising popularity of these tables isn't just a coincidence; it reflects a major industry trend. The global market for pizza prep tables was valued at around $1.5 billion in 2023 and is projected to hit $2.3 billion by 2032. This jump shows the growing demand for smart kitchen solutions that help pizzerias keep up with today's customers. You can explore more about these market dynamics to get a feel for the industry's growth.

Breaking Down the Pizza Prep Table: What Really Matters

To get why a 67-inch pizza prep table is such a workhorse, you have to look past the shiny stainless steel and see what’s going on inside. Every single part is engineered to solve a real-world problem in a busy pizzeria. Once you understand the components, you can look at a spec sheet and instantly picture how that unit will perform during a chaotic Friday night rush.

At its heart, any pizza prep table is really three critical systems working in concert: the refrigerated top rail, the main work surface, and the refrigerated base. Each one has a direct impact on your pizza maker's speed, your food's quality, and the overall flow of your kitchen.

The Refrigerated Topping Rail

Think of the refrigerated topping rail as mission control for your ingredients. This is the chilled, open-top area that holds all your pans of pepperoni, mushrooms, olives, and cheese. Its one job is to keep those toppings in the food-safe sweet spot—typically between 33°F and 41°F—while still letting your crew grab what they need in a split second.

A powerful, well-designed rail system is what stands between fresh, delicious toppings and spoiled ingredients. It's a non-negotiable for quality and for keeping the health inspector happy.

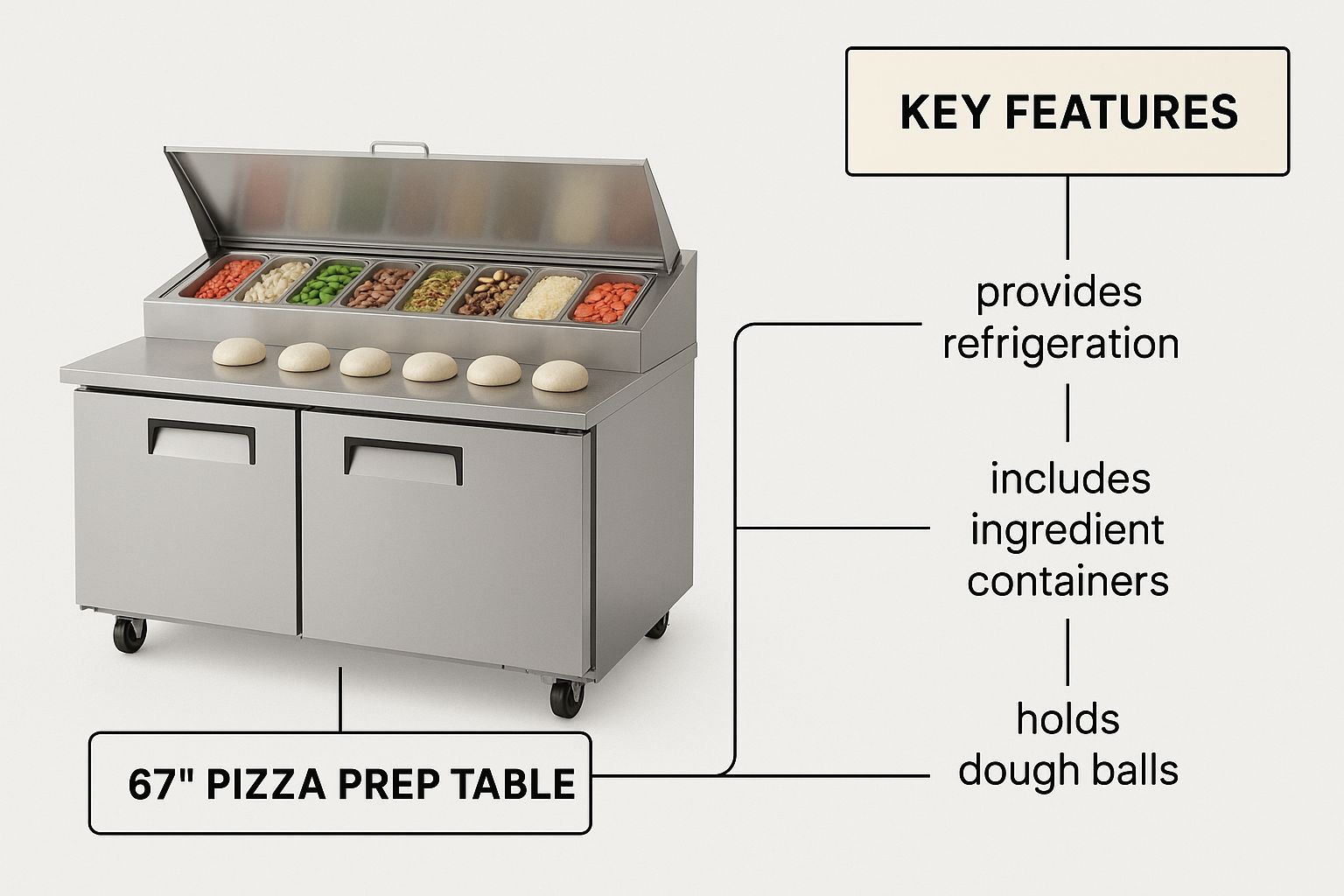

This infographic really puts into perspective how these key features come together to create such a valuable piece of equipment in a commercial pizzeria.

As you can see, a 67-inch pizza prep table isn't just a table; it's a fully integrated system that combines refrigeration, workspace, and storage into one efficient unit.

The Cutting Board Work Surface

That big cutting board running the length of the table is where the real magic happens. This is your main assembly line for building pizzas, and the material it’s made from matters more than you’d think. Most modern tables come with a high-density polyethylene board.

- Polyethylene: This is the industry standard for a good reason. It's tough as nails, non-porous (so bacteria can't find a place to hide), and it won't dull your pizza cutters. Best of all, it’s easy to pop off for deep cleaning and sanitizing.

- Marble or Granite: While they look great, stone surfaces are more at home in a bakery that makes delicate pastries. They stay naturally cool, which is a dream for pastry dough, but they’re hard on pizza cutters and can crack. For the rough-and-tumble world of pizza making, polyethylene is almost always the smarter, more practical pick.

Refrigerated Base: Doors vs. Drawers

Underneath the work surface lies the refrigerated base, which is your bulk storage for dough boxes, backup cheese, and tubs of sauce. This is where you face a classic pizzeria dilemma: doors or drawers?

Before we dive into a comparison, it's helpful to understand the core trade-off you're making. Doors offer maximum flexibility for storing bulky, odd-shaped items like blocks of cheese, while drawers provide unparalleled organization and quick access for standardized pans of prepped toppings or dough balls.

| Feature | Common Options | Best For... | Key Consideration |

|---|---|---|---|

| Access Style | Full-height doors with adjustable shelves or pull-out drawers (often stacked) | Doors are great for large, bulky items like boxes of cheese or large sauce containers. | How easy is it for pizza makers to bend down and retrieve items during a rush? Doors require more bending than top drawers. |

| Organization | Shelves inside doors offer open space; drawers offer compartmentalization. | Drawers excel at organizing pre-portioned dough, different types of cheese, or backup topping pans. | Can you fit your standard dough boxes or cheese blocks in the drawers? Check internal dimensions carefully. |

| Speed | Doors can be slower to access specific items; drawers offer quick pull-out. | High-volume pizzerias that need to restock the line quickly often prefer drawers for grab-and-go efficiency. | Do drawers slide smoothly under heavy loads? Poor quality slides can become a major frustration. |

| Cost & Config | Door models are often less expensive. Combination units are also available. | Pizzerias with a varied inventory (some bulk, some portioned) benefit from combination door/drawer units. | A combo unit often provides the best of both worlds, giving you a dedicated space for both bulk storage and quick-access organized items. |

Ultimately, the choice comes down to your specific menu and workflow. Many pizzeria owners I've worked with land on a combination unit—maybe one door section next to two or three drawer sections—to get the perfect mix of storage styles. For a deeper look at how different setups can support your kitchen, you might be interested in our guide to the commercial pizza prep table.

The Compressor: Engine of Your Prep Table

Finally, you have the compressor—the engine that powers the entire cooling system. Where it’s located will dictate where you can place the unit and how you’ll maintain it.

- Rear-Breathing: These units pull air in and push it out from the back. You absolutely have to leave several inches of clearance between the wall and the unit to keep it from overheating.

- Front-Breathing: These compressors are at the front, pulling air from the front and venting it out the side or front. This design is a game-changer for pizzerias because it lets you place the table flush against a wall, saving precious floor space.

This might seem like a small detail, but it's critical for planning your pizzeria's layout. In fact, the pizza prep tables market is booming—projected to hit $1.8 billion by 2033—precisely because of functional innovations like these. The huge demand for versatile models like the 67-inch size just goes to show how much pizzerias need equipment that maximizes every square inch of workspace. You can read the full research about these market trends to see exactly how the industry is evolving.

Choosing the Right Brand for Your Pizzeria

Walking into the market for commercial pizza equipment can feel overwhelming. When you're dropping serious money on a 67 inch pizza prep table, you're not just buying a hunk of stainless steel; you're picking a partner for the daily grind. This piece of equipment will either be your most reliable employee or your biggest headache.

You’ll see names like True, Avantco, and Turbo Air everywhere. But just comparing feature lists doesn't give you the full picture. What really separates the good from the great for a busy pizzeria is how they hold up over time, how solid their warranty support is, and what they actually cost to run every month—including energy bills.

High-Volume Heroes vs. Artisan Workhorses

The "best" brand for you completely hinges on what kind of pizzeria you're running. A shop cranking out 500 pizzas a night has a totally different set of needs than a small, artisan spot that focuses on gourmet, low-volume pies.

If your pizzeria is a 24/7 warzone, you need a tank. For these kinds of operations, brands like True Manufacturing are often the go-to. They’ve built their reputation on bomb-proof construction and rock-solid reliability, designed to take the relentless beating of a non-stop kitchen.

On the flip side, a smaller shop or a startup pizzeria might be more focused on getting the best bang for their buck upfront. This is where a brand like Avantco really shines, offering a great set of features at a price that won't break the bank. They might not have the legendary build quality of the premium brands, but they deliver fantastic performance for pizzerias that aren't pushing their gear to the absolute limit day in and day out.

The decision really boils down to one simple question: Is this thing a daily workhorse or a supportive tool? Answering that honestly will point you straight to the right balance of price, performance, and toughness for your pizzeria.

Beyond the Brand Name: Certifications and Support

Those little stickers on your equipment are more than just decoration; they're your proof of quality and safety. Two of the most important ones you need to look for on a pizza prep table are:

- NSF (National Sanitation Foundation): This seal is non-negotiable. It certifies that the prep table is designed and built to promote food safety, meaning surfaces are smooth, easy to scrub down, and won't harbor bacteria.

- ENERGY STAR: An ENERGY STAR-rated 67 inch pizza prep table can literally save you hundreds of dollars a year on your power bill. These units use better compressors, insulation, and smarter designs to cut energy use by up to 30% compared to standard models.

But even the most well-built machine will need a tune-up eventually. This is where having good local support becomes absolutely critical. Before you buy, find out who in your area is certified to service the brand you're considering and how easy it is to get parts.

A fantastic warranty means nothing if you have to wait two weeks for a technician while your cheese and pepperoni spoil. The premium brands usually have huge service networks, making sure that if something goes wrong, your downtime is kept to a bare minimum.

A Closer Look at Leading Brands

Let’s break down what you can generally expect from some of the top names in the pizza prep table world. Think of this as a cheat sheet to help you frame your decision around what truly matters for your pizzeria.

| Brand | Primary Strength | Ideal Pizzeria Model | Key Consideration |

|---|---|---|---|

| True | Unmatched Durability & Reliability | High-volume, 24/7 pizzerias where downtime is not an option. | Highest upfront investment, but often lowest long-term cost of ownership. |

| Avantco | Excellent Value & Accessibility | Startup pizzerias, smaller shops, or businesses with moderate daily volume. | A great balance of features and price, making it a strong budget-conscious choice. |

| Turbo Air | Innovative Features & Energy Efficiency | Tech-forward pizzerias focused on reducing utility costs and smart design. | Often pioneers features like self-cleaning condensers, which reduce maintenance. |

This table is a great starting point, but you'll still need to do your homework. For a much deeper dive into different models and what to watch out for, you might want to check out our guide on the commercial pizza prep table. It’s packed with extra insights that can help you lock in your choice.

At the end of the day, the right brand is the one that fits your budget, matches your pizzeria's intensity, and becomes a silent, reliable partner in making your business a success.

Strategic Installation and Pizzeria Workflow

Buying the perfect 67-inch pizza prep table is a huge win for your pizzeria, but its true value is only unlocked when you put it in the right spot. Think of it like buying a high-performance deck oven; if you don't have an efficient line feeding it, you'll never hit its full capacity. Smart installation turns your prep table from a simple appliance into the engine of an efficient pizzeria.

The goal is to create a seamless, logical path for your pizza makers. This journey starts with grabbing a dough ball, moving to the prep table to sauce and top it, and ends with a smooth slide into the pizza oven. A well-planned layout kills wasted steps, reduces physical strain on your team, and absolutely demolishes ticket times.

When this workflow is clunky, you see it immediately. Pizza makers cross paths, tickets get backed up, and the kitchen descends into chaos during a rush. A properly installed prep table is your best defense against that logjam.

Mapping the Ideal Pizzeria Flow

The best pizzeria layouts follow a simple, linear progression. This workflow should be built around your 67-inch pizza prep table as the main event.

- Dough Station First: Your dough press, sheeter, or stretching area should be right next to the prep table. This allows a cook to form a pizza skin and immediately place it on the cutting board without taking more than a step or two.

- Prep Table in the Middle: This is your assembly line. With the dough ready, all the toppings, cheeses, and sauces in the refrigerated rail are within arm's reach. The generous width of a 67-inch table gives your crew plenty of room to build multiple pizzas without feeling cramped.

- Oven Last: The pizza oven should be the final stop. Ideally, it’s positioned directly across from or right next to the prep table, letting a finished pizza slide onto a peel and into the oven with a simple turn.

This assembly-line approach keeps your staff moving in one direction, preventing the kinds of bottlenecks that destroy productivity.

Critical Installation Details You Cannot Ignore

Once you've mapped out the workflow, you have to nail the technical details of the installation. Getting these wrong can lead to expensive repairs, voided warranties, and even dangerous situations in your pizzeria.

Poor ventilation is the silent killer of refrigeration equipment. A compressor that can't breathe is a compressor that's working itself to death, driving up your energy bills before it fails completely.

Proper clearance isn't just a suggestion; it’s a non-negotiable requirement for the health of your equipment. For a rear-breathing unit, this means leaving at least 3-5 inches of open space between the back of the table and the wall. This gap allows the compressor to pull in cool air and push out hot air. Blocking this airflow is like forcing an athlete to run a marathon while holding their breath. It's not going to end well.

Electrical and Ergonomic Considerations

Beyond airflow, smart electrical and ergonomic planning is crucial for a smooth, safe operation. A 67-inch pizza prep table runs a powerful refrigeration system that needs its own dedicated circuit. Plugging it into an overloaded circuit with other power-hungry appliances like a dough mixer or convection oven is a recipe for tripped breakers right in the middle of a dinner rush. Always bring in an electrician to make sure your wiring can handle the load.

Ergonomics also plays a massive part in your team's performance and morale.

- Reduce Physical Strain: Position the table at a comfortable height. While most are standard, make sure it works for your crew to prevent unnecessary bending and reaching all shift long.

- Avoid Heat Sources: This is an absolute rule. Never, ever install your refrigerated prep table next to a deep fryer, charbroiler, or especially the pizza oven. The constant radiant heat forces the compressor to work overtime just to keep toppings safe, which drastically shortens its lifespan and puts your food quality at risk.

By focusing on these strategic installation points—workflow, clearance, electrical, and placement—you ensure your 67-inch pizza prep table performs at its peak, protecting your investment and empowering your team to make great pizza, fast.

Mastering Your Prep Station Workflow

A top-tier 67 inch pizza prep table is packed with potential for incredible speed and consistency, but it's your workflow that actually unlocks it. Just having great equipment isn't enough; you need a system. This is where the classic culinary principle of mise en place, or "everything in its place," becomes your pizzeria's secret weapon.

When you apply this philosophy to your prep station, you transform it from a simple countertop into a high-output pizza machine. It’s about more than just having ingredients nearby. It's about arranging them with intention to shave off wasted movement, slash errors, and make the whole process feel smooth, even during a chaotic dinner rush.

Think about it: every second your pizza maker saves by not having to hunt for an ingredient or take an extra step adds up. Over a shift, that allows your pizzeria to handle more orders with a whole lot less stress.

The Art of Mise en Place for Pizza

For any pizzeria, mise en place begins at the refrigerated rail. This isn't just a cold holding area; it's a strategic map designed for speed. The real trick is to organize your toppings in a logical sequence that mirrors the physical motion of building a pizza.

A proven strategy is to arrange ingredients based on your most popular pies. If "The Works" is your bestseller, group all its toppings—pepperoni, sausage, onions, peppers, mushrooms—together in one section of the rail. This lets your pizza maker move down the line in a smooth, practiced motion instead of playing whack-a-mole, hunting for individual items.

Here’s another simple but brilliant tactic: consider your pizza maker’s dominant hand. A right-handed cook will naturally work from left to right. By placing the most common ingredients (like cheese and pepperoni) on the left, you create a workflow that feels more natural and is automatically faster. For a deeper dive into arranging your workspace, check out our guide on how to prep like a pizza pro with these topping stations, which is full of layout ideas.

FIFO Your Way to Freshness

One of the most critical systems in any pizzeria is FIFO (First-In, First-Out). This simple rule dictates that older inventory must be used before newer inventory, and it's non-negotiable for your refrigerated rail.

Implementing a strict FIFO system isn't just about cutting down on food waste; it's a guarantee of quality you make to your customers. It ensures that every single topping you put on a pizza is as fresh as possible, protecting both flavor and food safety.

To make FIFO a reality, train your team to always place new pans of toppings behind the existing ones in the rail. When it's time to restock, the old pan gets pulled forward and the new one slots in the back. This simple habit stops older ingredients from getting lost and forgotten, ensuring you serve consistent quality and slash costly spoilage.

Keeping Your Workspace Clean and Consistent

During a chaotic service, the cutting board on your 67 inch pizza prep table can quickly turn into a disaster zone of spilled sauce, stray toppings, and flour. Keeping that work surface clean isn't just about looks—it's absolutely critical for consistency and sanitation.

Here are a few practical techniques to keep your station pristine during peak hours:

- Dedicated Scrapers: Keep a bench scraper or a small squeegee right at the station. After every few pizzas, a quick scrape of the board into a waste bin takes just seconds but prevents flavor transfer between a meat lover's and a veggie pie.

- Sanitizer on Standby: Have a spray bottle with an approved food-safe sanitizer and a dedicated cloth nearby. This makes quick wipe-downs between orders a breeze, especially after you've handled potential allergens.

- Contain the Mess: Use the right size pans in your rail. Overfilled pans are one of the biggest reasons for toppings spilling all over the cutting board.

By combining a smart layout with disciplined habits like FIFO and constant cleaning, you turn your pizza prep table into a true command center. These are the operational secrets that let you ramp up speed, reduce errors, and boost your pizzeria's overall output—starting tonight.

Keeping Your Investment Running Like New

A 67 inch pizza prep table isn't just another piece of equipment; it's the heart of your pizzeria. This is the workhorse that powers your entire assembly line. And like any high-performance machine, it needs consistent, smart care to keep pumping out pizzas day after day.

Protecting this investment is about more than just wiping it down. It’s about building a solid preventative maintenance routine that guarantees food safety, stops expensive breakdowns before they happen, and adds years to the life of your unit.

Think of it this way: a few minutes of daily care is the cheapest insurance policy you can buy. It's what stands between you and the nightmare of a dead compressor on a Friday night—a disaster that can cost you thousands in lost sales and emergency repair bills. Neglecting your prep table doesn't just risk breakdowns; it quietly jacks up your energy bill, too.

Your Prep Table Maintenance Playbook

Building a smart maintenance schedule is easy when you break it down. The real secret is consistency. You have to make these checks a non-negotiable part of your pizzeria's opening and closing routine until they become second nature.

Daily Checks (5-10 Minutes):

- Wipe Down Everything: At the end of each shift, grab a food-safe cleaner and wipe down all the stainless steel surfaces, door handles, and especially the gaskets.

- Scrub the Cutting Board: Pull the polyethylene cutting board off, give it a good wash with hot, soapy water, and sanitize it exactly how your local health department wants it done.

- Empty and Sanitize Bins: Pull every single topping pan from the refrigerated rail. Consolidate your product, then wash and sanitize all the empty containers.

Weekly Checks (15-20 Minutes):

- Deep Clean the Interior: Empty out the refrigerated base completely. Wipe down all the interior walls and shelving to catch any spills you might have missed during the week.

- Check the Drain Lines: Find the condensation drain line and make sure it's clear of any gunk or debris. A simple clog can cause water to back up inside the unit, creating a huge mess and a serious safety hazard.

The One Task You Absolutely Cannot Skip

If you only do one thing on this list, make it this: clean the condenser coils. These coils are literally the lungs of your prep table's refrigeration system. Their job is to release all the heat that the system has pulled out from inside the cabinet.

Over time, these coils get caked in a nasty blanket of grease, flour, and dust from the pizzeria air. This buildup acts like an insulator, trapping heat and forcing the compressor to work way harder and run much longer just to hold the right temperature.

A dirty condenser coil is the #1 cause of premature compressor failure in commercial refrigeration. That extra strain doesn't just make your electricity meter spin faster; it puts a ton of wear and tear on the single most expensive part of your prep table.

Monthly Task (15-30 Minutes):

- Kill the Power: Before you do anything else, unplug the unit from the wall. Safety first, always.

- Find the Coils: Locate the condenser coils. They're usually hiding behind a removable grille on the front or back of the unit.

- Brush and Vacuum: Use a stiff-bristle brush (gently!) to loosen all the caked-on dust and grime. Follow up with a shop vacuum and a brush attachment to suck up all that debris. Be thorough.

- Power Up: Once the coils are spotless, put the grille back on and plug the unit back in.

By committing to this simple playbook, you’ll make sure your 67 inch pizza prep table stays the reliable, efficient, and food-safe cornerstone of your pizzeria for years.

Got a few more questions rattling around in your head? It’s completely normal. Picking out a core piece of equipment like a 67-inch pizza prep table is a major decision for any pizzeria, and you want to get it right. Let's tackle some of the most common questions I hear from pizzeria owners.

Think of this as the final check-in before you pull the trigger. Making the right choice isn't just about buying a great product; it's about knowing exactly how it will slot into your daily grind.

How Many Topping Pans Can a 67-Inch Table Hold?

A standard 67-inch pizza prep table is typically built to hold (9) 1/3-size food pans along its refrigerated rail. This setup gives you a fantastic spread of your most popular toppings right where you need them.

But here’s the pro tip: you aren’t locked into that configuration. If your menu is loaded with specialty toppings for gourmet pizzas, you can easily swap in smaller 1/6-size or 1/9-size pans to hold more individual ingredients. It’s all about tailoring the setup to your menu.

What Is the Ideal Temperature for the Refrigerated Rail?

For both food safety and quality, that refrigerated rail needs to live between 33°F and 41°F (0.5°C to 5°C). This is the non-negotiable "safe zone" that stops bacteria in its tracks while keeping your cheese, meats, and veggies perfectly fresh and crisp.

Thankfully, most modern pizza prep tables have digital thermostats that make setting and monitoring these temperatures a breeze. You set it and forget it—almost.

Keeping your toppings within this specific temperature range isn't just a suggestion—it's a core requirement for passing health inspections and keeping your customers safe. I tell every pizzeria operator: make checking that rail temperature a non-negotiable part of your daily opening and closing duties.

Can I Put Hot Pans on the Stainless Steel Surface?

I get this question a lot. My advice? Don't do it. You should avoid slamming a scorching hot pizza pan straight from the oven onto the stainless steel surface of your prep table.

While stainless steel is tough, that kind of extreme and sudden temperature shock can cause the metal to warp over time. It's much smarter to use trivets or have a designated landing spot for hot items. This simple habit will protect the finish and structural integrity of your table for years to come.

Ready to find the perfect command center for your pizzeria? At Pizza Prep Table, we live and breathe this stuff. We specialize in connecting pizzeria owners with high-quality equipment that drives efficiency and quality. Explore our extensive selection of 67-inch pizza prep tables and find the ideal fit for your kitchen by visiting Pizza Prep Table.