Pizza Restaurant Health Inspection Checklist: Mastering Food Safety

Share

For any pizzeria, a health inspection can feel like a high-stakes final exam. More than just a letter grade posted on the door, it represents a public declaration of your commitment to quality, safety, and the trust your customers place in every slice you serve. Acing this inspection is crucial for protecting your hard-earned reputation, avoiding steep fines, and guaranteeing that your delicious pizzas are as safe as they are satisfying. This guide moves beyond generic advice to offer a comprehensive restaurant health inspection checklist specifically designed for the fast-paced, unique environment of a pizza-making operation.

We will dive deep into the eight critical areas that inspectors meticulously examine, from maintaining precise temperatures for your mozzarella and pepperoni to ensuring impeccable sanitation at every station. A significant focus will be placed on the heart of your kitchen: the pizza prep table. This central hub, where every masterpiece is assembled, is a major hotspot for potential violations related to cross-contamination, temperature control, and proper food handling.

This step-by-step listicle provides actionable strategies, practical examples, and expert insights to help you prepare effectively. We will transform inspection-day anxiety into a confident showcase of your pizzeria's operational excellence, ensuring you are not just compliant, but setting the standard for safety and quality in your community. Let's get your kitchen ready to earn that perfect score.

1. Flawless Temperature Control: From the Walk-In to the Pizza Prep Table

Of all the items on a restaurant health inspection checklist, none carry more weight than temperature control. For a pizzeria, this is the cornerstone of food safety, extending from your bulk cheese and sauce in the walk-in cooler to the individual toppings in your pizza prep table's refrigerated rail. The goal is to keep Time/Temperature Control for Safety (TCS) foods out of the "Temperature Danger Zone" (41°F to 135°F), where bacteria multiply rapidly.

A health inspector will meticulously check every refrigerated and heated point in your workflow. They'll probe your low-boy refrigerators, your walk-in, and most critically, the pan rail on your pizza prep station. This station is your frontline defense; it must consistently hold toppings like pepperoni, mushrooms, and fresh mozzarella at or below 41°F, even during the busiest dinner rush.

Implementation and Best Practices

Successful temperature management relies on consistent monitoring and reliable equipment.

- Systematic Logging: Implement a strict schedule for temperature checks. Create laminated log charts and post them directly on each piece of equipment, from the walk-in to the pizza prep table. Staff should record temperatures at the start of their shift, mid-day, and before closing.

- Digital Tools: Upgrade from paper logs to a more efficient system. Many pizzerias now use QR code-based digital logs that staff can scan and update via a tablet. This creates an easily accessible and time-stamped record, impressing inspectors and reducing paperwork.

- Thermometer Calibration: A thermometer is useless if it's inaccurate. Train all staff, especially managers, on how to calibrate thermometers using the ice-bath method. Demonstrate this during pre-shift meetings to reinforce its importance.

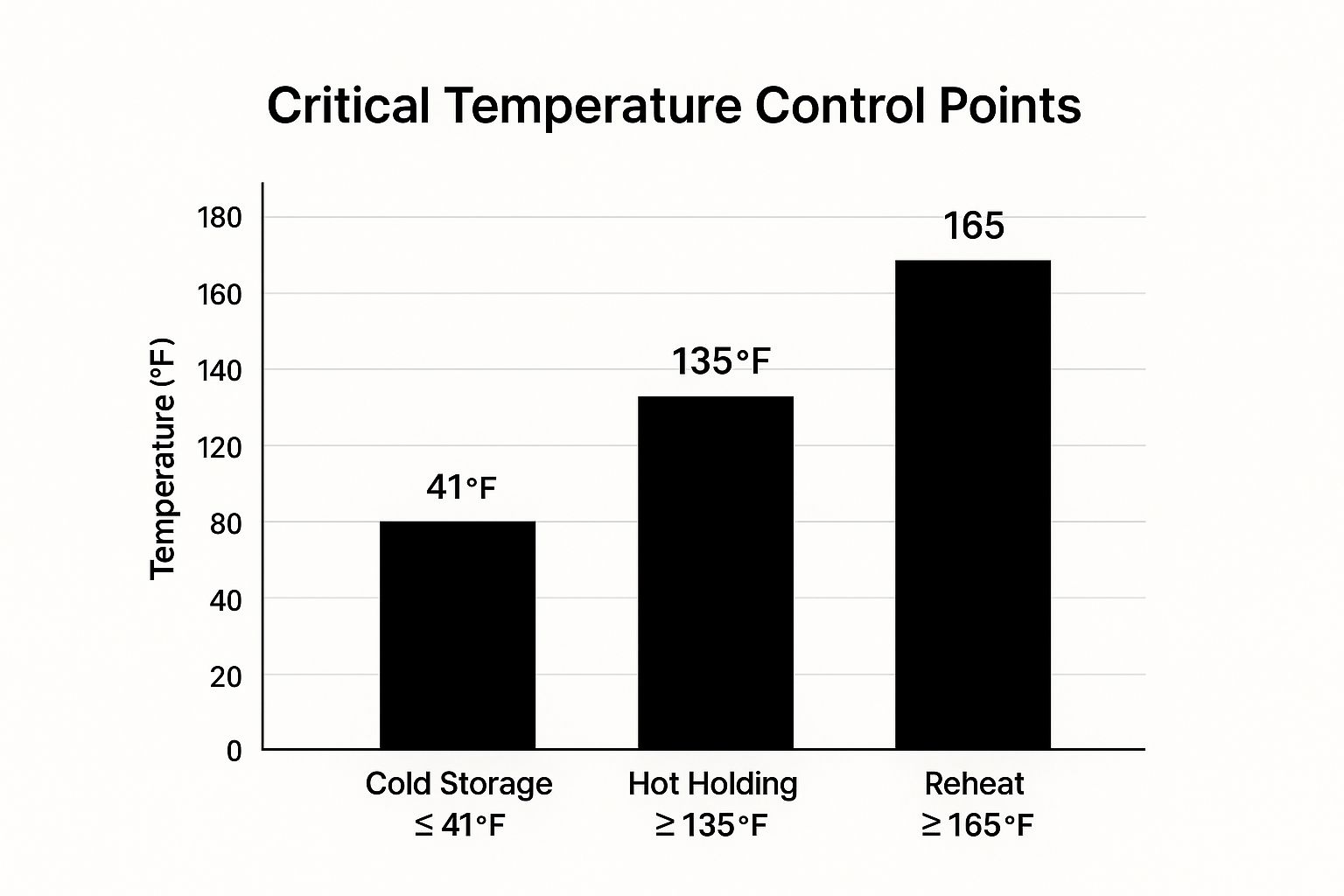

Critical Temperature Points for Pizzerias

The following bar chart visualizes the three non-negotiable temperature thresholds that every pizzeria must maintain to ensure food safety and pass a health inspection.

This chart clearly illustrates the safe zones for your ingredients and prepared foods, from cold storage in your prep table to hot-holding wings or pasta, and finally, reheating a slice of pizza for service.

Pro Tip: Invest in high-quality pizza prep tables, like those from True or Atosa, that feature integrated digital thermometers and alarms. These units provide constant, accurate readouts and alert your staff immediately if temperatures rise to unsafe levels. Proper equipment is just as crucial in a mobile setup; find out more about the top picks for food truck fridges to maintain compliance on the go.

2. Impeccable Personal Hygiene and Handwashing Practices

Beyond temperature control, the personal hygiene of your staff is the most scrutinized element on a restaurant health inspection checklist. An inspector sees your employees as the primary vehicle for cross-contamination. For a pizzeria, where hands are constantly in contact with dough, cheese, and toppings, this means flawless execution of hygiene protocols is non-negotiable. The goal is to create an unbreakable barrier between potential pathogens on an employee and the food they serve.

An inspector will observe your team's behavior from the moment they walk in. They’ll check for proper handwashing technique, correct glove usage, effective hair restraints like hats or hairnets, and clean uniforms. They will also verify that dedicated handwashing sinks are fully stocked and used only for their intended purpose, never for dumping drinks or rinsing pizza cutters. Every action, from answering a phone to stretching pizza dough, must be preceded by the correct hygiene step.

Implementation and Best Practices

Establishing a culture of hygiene requires clear policies, constant training, and visible reinforcement.

- Strategic Sink Placement: Ensure dedicated handwashing sinks are conveniently located at the pizza prep station, dishwashing area, and restrooms. Sinks must be stocked at all times with hot water, soap, and single-use paper towels. Make them easily accessible so there's no excuse for skipping a wash.

- Glove and Utensil Protocols: Mandate strict glove-changing rules, especially after handling raw ingredients, touching a face, or handling money. Train staff to use tongs and scoops for ready-to-eat toppings on the pizza prep table to minimize direct hand contact, even with gloves on.

- Visible Reminders: Post clear, graphical handwashing posters in multiple languages above every sink. These visuals serve as a constant, silent reminder of the proper 20-second washing procedure, reinforcing training during busy shifts.

- Illness Policy: Implement and enforce a strict policy requiring employees to report illness and stay home when sick, especially with symptoms like vomiting, diarrhea, or fever. This is a critical control point inspectors will ask about.

Critical Hygiene Actions for Pizzerias

A health inspector will be looking for specific actions that demonstrate a commitment to hygiene. Staff must wash hands after touching their face or hair, after using the restroom, before putting on new gloves, and after handling raw meats. This routine prevents the transfer of germs from employees to your fresh mozzarella, pepperoni, and perfectly proofed pizza dough, ensuring every pie is as safe as it is delicious.

Pro Tip: Use pre-shift huddles to run quick hygiene drills. Have a manager demonstrate the correct glove-changing procedure or ask a team member to list the critical times for handwashing. This "micro-training" keeps food safety top-of-mind and shows an inspector you have an active, engaged food safety culture.

3. Impeccable Cross-Contamination Prevention: From Raw Sausage to Ready-to-Eat Veggies

Cross-contamination is a silent threat in any kitchen, but for a pizzeria juggling raw meats like sausage and pepperoni alongside fresh, ready-to-eat vegetables, it's a critical point on any restaurant health inspection checklist. This is the transfer of harmful bacteria or allergens from one surface, food, or piece of equipment to another. An inspector will scrutinize your entire process, from how you store raw chicken wings in the walk-in to the specific cutting board used for slicing onions on your pizza prep table.

The goal is to create distinct, impenetrable barriers between raw and ready-to-eat (RTE) foods. This involves physical separation, dedicated utensils, and rigorous sanitation protocols. An inspector will observe your staff's workflow, checking for handwashing practices after handling raw ingredients and ensuring that the same tongs aren't used for raw sausage and cooked mushrooms.

Implementation and Best Practices

A systematic approach to workflow and sanitation is the key to preventing dangerous cross-contamination and satisfying inspectors.

- Color-Coded System: Implement a universal color-coded system for cutting boards, knives, and storage containers. A common setup is red for raw meats, green for vegetables and fruits, yellow for raw poultry, and white for RTE foods like cheese and cooked items. This visual cue system is easy for staff to follow, even during a high-pressure service.

- Pizza Prep Table Design: Structure your pizza prep table logically to minimize risk. Store raw meat toppings on one end of the refrigerated rail and RTE vegetable toppings on the opposite end. This physical separation prevents accidental drips or utensil mix-ups.

- Dedicated Equipment & Storage: Never store raw meat above ready-to-eat foods in your walk-in or low-boy coolers. A single drop of raw chicken juice can contaminate an entire container of fresh basil below. Ensure separate, clearly labeled containers and designated storage areas.

A Pizza-Specific Workflow Example

Think of your pizza-making process as a one-way street. A pizza should move from the dough station, to the sauce and cheese area, then to the veggie station, and finally to the raw meat topping station just before entering the oven. This linear flow prevents a pizza topped with raw sausage from ever coming back into contact with the station where fresh mushrooms are being prepped.

Pro Tip: Train your team to "clean as you go." This means sanitizing surfaces, changing gloves, and washing hands immediately after handling a potential contaminant. Reinforce this during every shift meeting. For a deeper dive into creating a food-safe kitchen, explore these comprehensive food safety guidelines for restaurants and make them a core part of your training manual.

4. Cleaning and Sanitizing Procedures

Beyond temperature, the most scrutinized aspect of a restaurant health inspection checklist is the rigor of your cleaning and sanitizing protocols. For a pizzeria, where flour dust, stray cheese, and sauce splatters are constant, this means maintaining a state of pristine cleanliness on every surface. Proper procedure involves a two-step process: cleaning to remove food debris and grime, followed by sanitizing to reduce pathogens to a safe level. This applies to everything from the pizza peel to the dough sheeter and the door handle of your pizza prep table's reach-in.

A health inspector will evaluate your entire sanitation workflow, paying close attention to food-contact surfaces. They will observe your three-compartment sink setup, test the concentration of your sanitizer solution, and check for any cross-contamination risks, like using the same cloth to wipe down a prep table and then a non-food-contact surface. They expect to see evidence of a systematic, documented cleaning schedule that leaves no room for error.

Implementation and Best Practices

A successful sanitation program is built on clear procedures, consistent execution, and proper training.

- Establish a Master Cleaning Schedule: Create a detailed chart that outlines what needs to be cleaned, who is responsible, how often it should be done (e.g., hourly, daily, weekly), and what chemicals and equipment to use. Post this in a visible location like the dish pit or manager's office.

- Three-Compartment Sink Mastery: Train all staff on the correct wash-rinse-sanitize sequence for pizza pans, cutters, and prep utensils. Label each sink clearly and post a visual guide. Ensure test strips for your chosen sanitizer (chlorine or quaternary ammonium) are readily available and used frequently to verify proper concentration levels.

- Color-Coded System: Implement a color-coded system for cleaning tools to prevent cross-contamination. For example, use red cloths for raw meat areas, green for vegetable prep stations like the pizza prep table, and blue for front-of-house surfaces.

- Material Safety Data Sheets (MSDS): Keep an organized binder of MSDS for every chemical used in the restaurant. Ensure managers and key staff know where it is and understand the safety information it contains.

Pro Tip: Properly cleaned and sanitized environments are less attractive to pests, a major red flag for inspectors. To proactively manage potential threats, refer to a comprehensive pest control inspection checklist to ensure your pizzeria remains a fortress against unwanted visitors. Combining sanitation with prevention is key to a flawless inspection.

5. Pest Control and Prevention

The sight of a single pest can ruin a restaurant's reputation and lead to an immediate failed health inspection. An effective pest control program goes far beyond simply setting traps; it involves an Integrated Pest Management (IPM) system designed to prevent, monitor, and eliminate pests. For a pizzeria, this means securing every potential entry point, from the back delivery door to gaps around plumbing, and eliminating food sources that attract rodents and insects.

A health inspector will scrutinize your establishment for any evidence of pest activity. They will look for droppings under equipment, check for gnaw marks on food packaging in the dry storage area, and inspect floor drains and corners for signs of insects. They are not just looking for live pests but also for the conditions that welcome them, such as spilled flour behind the mixer or standing water near the dish pit.

Implementation and Best Practices

A proactive, multi-layered approach is the only way to ensure your pizzeria remains pest-free.

- Seal All Entry Points: Regularly inspect your building's exterior and interior for cracks, holes, or gaps. Install tight-fitting door sweeps on all external doors and ensure window and vent screens are intact and without tears. Pay close attention to utility line entry points.

- Eliminate Food and Water Sources: Maintain a rigorous cleaning schedule. This includes cleaning under and behind heavy equipment like your pizza ovens and mixers, regularly emptying and cleaning trash receptacles, and immediately cleaning up spills. Ensure all food, especially bulk ingredients like flour and sugar, is stored in sealed, rodent-proof containers off the floor.

- Professional Partnerships: Establish a contract with a reputable commercial pest control company like Orkin or Rentokil. They will provide regular inspections, maintain bait stations and traps, and provide detailed reports. This professional documentation is a key part of your restaurant health inspection checklist and demonstrates due diligence to an inspector.

Key Focus Areas for Pizzerias

Pizzerias have unique vulnerabilities that require special attention to prevent pest infestations.

- Dry Storage: Bags of flour and cornmeal are highly attractive to rodents and weevils. Store them on shelves at least six inches off the ground and in tightly sealed containers after opening.

- Dough Preparation Areas: Spilled yeast, sugar, and flour create a feast for pests. Ensure these areas are meticulously cleaned after every shift, including under prep tables.

- Exterior and Dumpster Area: Keep the area around your dumpster clean and free of debris. Lids should always be kept closed to deny pests an easy food source.

Pro Tip: Schedule your professional pest control service for off-hours or on a day you are closed. This allows the technician to perform a thorough inspection and treatment without disrupting your operations or creating potential contamination risks during service hours. Having a consistent, documented service record is invaluable during a health inspection.

6. Water Safety and Plumbing Systems

A restaurant's plumbing is its circulatory system, and any failure can bring operations to a halt and result in an immediate health code violation. An inspector on your restaurant health inspection checklist will verify that you have a safe, potable water supply, adequate hot water, and a properly functioning drainage and sewage system. For a pizzeria, this means ensuring the three-compartment sink has sufficient hot water for sanitizing pizza pans and that the handwashing stations near your dough prep areas are fully functional.

The inspection will scrutinize every aspect of your water systems. This includes checking for the required air gap between a faucet and a sink basin to prevent backflow, ensuring floor drains are clear and not backing up, and confirming that hot water reaches the required temperature (typically at least 100°F) at all handwashing sinks. A single clogged floor drain near the pizza prep table or an ice machine with improper drainage can lead to cross-contamination and a failed inspection.

Implementation and Best Practices

Maintaining a compliant and safe plumbing system requires diligent upkeep and adherence to specific standards.

- Routine Drain Maintenance: Implement a weekly schedule for cleaning all floor drains, especially in high-grease areas like near the dish pit or fryer. Use enzymatic drain cleaners to break down organic buildup that can cause clogs and attract pests.

- Backflow Prevention: Ensure all necessary plumbing connections, such as the water line to your dough mixer or the ice machine, are fitted with approved backflow prevention devices. These are non-negotiable for preventing contaminated water from re-entering your clean supply.

- Water Heater Checks: Regularly check the temperature settings on your commercial water heater. The goal is to consistently deliver water at a minimum of 100°F to handwashing sinks and sufficiently hot water (often 110°F or higher) to your three-compartment sink for proper sanitizing.

Pro Tip: Don't wait for a leak or a clog to become an emergency. Beyond simply reacting to issues, establishing a routine of proactive commercial plumbing maintenance is crucial for continuous adherence to health codes and preventing costly operational disruptions. A professional can identify potential failures before they happen.

7. Food Handler Certification and Training

Beyond equipment and procedures, your staff is the most critical element in your food safety program. A health inspector sees your team's knowledge as a direct indicator of your commitment to public health. Proper food handler certification and ongoing training ensure every employee, from the dishwasher to the lead pizza maker, understands the "why" behind food safety rules, turning your checklist from a set of tasks into a shared culture of responsibility.

An inspector will verify that all required staff hold valid food handler cards and that a manager on duty has a higher-level food safety manager certification, like ServSafe. They may also quiz employees on key principles, such as proper handwashing techniques, the symptoms of foodborne illness that require them to stay home, and how to prevent cross-contamination between raw sausage and ready-to-eat vegetables at the pizza prep station.

Implementation and Best Practices

A well-trained team is your best defense against common health code violations. Building a robust training program is a continuous process.

- Standardize Onboarding: Make food handler certification a mandatory part of the new-hire process. Schedule their training and exam within the first week of employment, and cover the cost to remove any barriers. Incorporate a review of your pizzeria's specific policies, like your temperature logging and pizza prep table sanitation schedules, into their orientation.

- Visual and Interactive Training: Supplement certification programs with in-house training. Use visual aids, like posters from the health department showing correct handwashing steps, above every sink. During pre-shift meetings, conduct quick, hands-on demonstrations, such as how to properly calibrate a food thermometer or assemble the pizza prep table to avoid cross-contact.

- Continuous Reinforcement: Food safety is not a one-time course. Provide ongoing coaching and regular refreshers. Acknowledge and reward employees who consistently demonstrate excellent food safety practices, making it a celebrated part of your pizzeria's culture.

Pro Tip: Post copies of all employee food handler certificates and manager certifications in a binder or on a designated board in the back-of-house. This makes them immediately accessible for an inspector, showing you are organized and compliant. Programs like the National Restaurant Association's ServSafe and the National Registry of Food Safety Professionals offer nationally recognized certifications that are the gold standard in the industry.

8. Equipment Maintenance and Calibration

Properly functioning equipment is the backbone of a safe and efficient pizzeria, a fact that health inspectors know all too well. Beyond just temperature control, the operational integrity of every piece of equipment, from the pizza oven to the dish machine, is a key component of a restaurant health inspection checklist. Neglected maintenance can lead to food contamination, inaccurate cooking temperatures, and critical violations.

An inspector will scrutinize your equipment for signs of disrepair, dirt, and grime. They’ll check the seals on your walk-in cooler, look for grease buildup in your oven's ventilation hood, and test the sanitizer concentration in your dishwasher. For a pizzeria, the pizza prep table is a focal point; they will check that gaskets are intact, condenser coils are clean, and that the unit is not leaking or over-icing, all of which impact its ability to hold safe temperatures.

Implementation and Best Practices

A proactive approach to maintenance prevents costly breakdowns and ensures you pass your inspection with flying colors.

- Create Detailed Maintenance Logs: Go beyond simple temperature checks. Develop a comprehensive logbook for each major piece of equipment. This schedule should include daily cleaning tasks (e.g., wiping down the pizza prep table's cutting board), weekly checks (e.g., cleaning condenser coils), and monthly or quarterly professional servicing.

- Staff Training on Daily Checks: Empower your team to be the first line of defense. Train them to perform basic daily checks, like ensuring oven doors seal properly or that the pizza prep table's gaskets are clean and free of tears. This prevents minor issues from becoming major violations.

- Build Vendor Relationships: Don't wait for an emergency. Establish a relationship with a reliable and certified equipment repair service before you need them. Having a trusted technician on call can mean the difference between a quick fix and a prolonged shutdown.

Key Maintenance Focus Areas for Pizzerias

A pizzeria's success hinges on specialized equipment, each with unique maintenance needs. Neglecting any one of these can lead to a failed inspection.

- Refrigeration Units: Regularly clean condenser coils on all units, especially your pizza prep table, to ensure efficient cooling. Check and clean door gaskets weekly to maintain a tight seal and prevent cold air loss.

- Pizza Ovens: Calibrate your oven's thermostat quarterly to guarantee accurate cooking temperatures. Schedule professional cleaning of the ventilation and hood system to prevent grease buildup, a major fire hazard and health code violation.

- Dishmachine: Test sanitizer and detergent levels before every shift. De-lime the machine regularly according to manufacturer specifications to ensure it effectively sanitizes pizza pans and utensils.

Pro Tip: Keep a small inventory of common spare parts for your most critical equipment, like replacement gaskets for your pizza prep table or a spare thermostat for your oven. This simple step can turn a potential multi-day shutdown into a quick, in-house repair, keeping your operation running smoothly and in compliance.

8-Point Restaurant Health Inspection Comparison

| Item | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Food Temperature Control and Storage | Moderate: requires ongoing monitoring and documentation | Medium: thermometers, storage containers, calibrated equipment | Prevents foodborne illness; reduces spoilage | Restaurants needing strict food safety compliance | Prevents outbreaks; reduces waste; regulatory compliance |

| Personal Hygiene and Handwashing Practices | Low to Moderate: staff training and reinforcement needed | Low: hygiene supplies, sinks, gloves | Reduces pathogen transmission; builds customer trust | All food service establishments | Low cost; high impact on contamination control |

| Cross-Contamination Prevention | Moderate to High: requires workflow changes and extra equipment | Medium to High: color-coded tools, prep areas | Prevents contamination and allergen exposure | Kitchens with varied food types and allergy concerns | Protects customers; reduces liability |

| Cleaning and Sanitizing Procedures | Moderate: time-intensive protocols and schedules | Medium: cleaning chemicals, test strips | Eliminates bacteria and viruses; meets regulations | All kitchens requiring sanitation | Prevents biofilms; extends equipment life |

| Pest Control and Prevention | Moderate: ongoing monitoring and facility adjustments | Medium to High: professional services, exclusion devices | Prevents contamination and infestations | Facilities with pest risk or history of issues | Maintains hygiene; prevents regulatory violations |

| Water Safety and Plumbing Systems | High: requires technical expertise, regulatory compliance | High: plumbing systems, backflow devices | Prevents waterborne illness; ensures sanitation | Facilities needing reliable water and drainage | Prevents contamination; ensures operational continuity |

| Food Handler Certification and Training | Low to Moderate: requires scheduling and training delivery | Low to Medium: training programs, materials | Reduces violations; builds knowledgeable staff | All food service operations | Reduces incidents; demonstrates safety commitment |

| Equipment Maintenance and Calibration | Moderate to High: scheduled upkeep and technical tasks | Medium to High: service contracts, spare parts | Ensures equipment reliability and safety | Operations with extensive equipment use | Prevents breakdowns; maintains food safety temps |

Beyond the Checklist: Cultivating a Culture of Food Safety

Passing your health inspection is a critical milestone, but it's not the finish line. The true objective is to build an unwavering culture of food safety that becomes the foundation of your pizzeria's daily operations. The comprehensive restaurant health inspection checklist detailed in this guide is more than a list of tasks to complete before the inspector arrives; it's a blueprint for embedding excellence into every slice you serve.

This journey from preparation to perfection transforms a reactive, last-minute scramble into a proactive, consistent commitment. It's about moving beyond simply avoiding violations and actively championing the health and safety of every customer who walks through your door. When food safety is ingrained in your team's mindset, the inspection grade becomes a natural reflection of your everyday high standards.

From Checklist Items to Cultural Cornerstones

Let's distill the core principles from our checklist into foundational pillars for your pizzeria. These are the takeaways that should resonate long after the inspector leaves, shaping your operational philosophy.

- Temperature as a Non-Negotiable: Precise temperature control isn't just a rule; it's the guardian of your ingredients. From the walk-in cooler holding your bulk mozzarella to the low-boy refrigerator in your pizza prep table keeping pepperoni and mushrooms at the perfect temperature, every degree matters. Consistent logging and immediate action on deviations are non-negotiable.

- Hygiene as a Habit: Proper handwashing and personal hygiene are the first line of defense against foodborne illness. This must be a deeply ingrained habit, reinforced through training, accessible handwashing stations, and a culture where team members hold each other accountable.

- Sanitation as a System: A clean kitchen is a safe kitchen. Your cleaning and sanitizing procedures, from dough mixers to deck ovens, must be systematic, scheduled, and verified. Cross-contamination prevention, especially between raw and ready-to-eat ingredients on your pizza prep table, is paramount to this system's success.

- Training as an Investment: Your staff is your greatest asset and your most critical food safety control point. Investing in ongoing training and certifications empowers them to be proactive problem-solvers. An employee who understands why they must swap out the pizza cutter and board after handling an allergen-topped pizza is far more effective than one who is just following a rule.

Actionable Next Steps: Embedding Safety into Your DNA

Mastering your restaurant health inspection checklist requires turning knowledge into action. Here are your immediate next steps to build that unshakable culture of safety:

- Conduct a Self-Audit: Use this article as your guide. Walk through your pizzeria with the critical eye of an inspector, from the back delivery door to the pizza prep table. Document every observation, no matter how small, and create a prioritized action plan.

- Empower Your Team: Hold a team meeting dedicated to food safety. Review the key areas of the checklist and assign "ownership" of different sections to specific team members. This fosters accountability and turns passive employees into active safety advocates.

- Upgrade Your Equipment: Evaluate your critical equipment, especially your pizza prep table. Is it holding temperature consistently? Is it easy to clean and sanitize? Investing in reliable, NSF-certified equipment is an investment in compliance, efficiency, and peace of mind.

Ultimately, your commitment to these principles does more than just secure a passing grade. It builds trust with your community, enhances your brand's reputation, and ensures the longevity of your business. Every perfectly baked, safely prepared pizza becomes a testament to your dedication, turning first-time customers into loyal patrons who know they can trust the quality and care you put into your food.

Ready to ensure your prep line is an asset, not a liability, in your next health inspection? A high-quality pizza prep table with reliable refrigeration and an easy-to-clean design is a cornerstone of food safety. Explore our NSF-certified models at Pizza Prep Table to find the perfect solution for your kitchen's needs.