Your Guide to Pizza Prep Tables for Your Pizzeria

Share

While the pizza oven usually gets all the glory, the real command center of any top-tier pizzeria is the pizza prep table. This one piece of equipment is the linchpin that dictates the speed, consistency, and profitability of your entire operation, making it one of the smartest investments you can make.

The Secret Ingredient to a High-Performing Pizzeria

It's easy to look at your kitchen layout and think the oven is the star player. But the actual hub that controls your pizzeria's success is the prep table. This isn't just a hunk of stainless steel; it's a strategic asset that streamlines your workflow, locks in food safety, and gives your team the power to build perfect pizzas under pressure.

A well-chosen table can be the difference between a kitchen that’s pure chaos and one that’s a smooth, money-making machine. This guide will unpack why the right pizza prep table is so mission-critical, exploring how it solves common pizzeria bottlenecks and sets you up for success.

Why Your Pizza Prep Table Matters More Than You Think

Stop thinking of a pizza prep table as furniture. It’s the engine of your assembly line. Every minute shaved off prep time translates directly into faster tickets and happier customers. When the dinner rush hits, an organized and efficient pizza prep station is what keeps the quality from slipping.

A poorly designed station, on the other hand, is a recipe for disaster. It creates immediate problems that snowball quickly:

- Slowed Production: Your crew wastes precious seconds reaching for ingredients across the kitchen or fumbling for the right tool.

- Food Safety Risks: Inconsistent refrigeration for toppings is a ticking time bomb, leading to spoiled ingredients and, even worse, health code violations.

- Inconsistent Pizzas: A disorganized workspace makes portion control nearly impossible, which hurts your food costs and gives customers a different pizza every time they order.

The right pizza prep table isn't just about holding ingredients; it's about creating a bulletproof system. It provides a dedicated, refrigerated, and organized space that ensures every single pizza is built quickly, safely, and identically—every single time.

Ultimately, this piece of equipment is foundational to your brand. It directly impacts your ability to handle a flood of orders, keep food costs in check, and build a reputation for consistent, high-quality pizzas that keeps people coming back. Your investment here is an investment in your pizzeria's future.

Breaking Down the Pizza Prep Table: What You Need to Know

Think of a pizza prep table as the command center of your kitchen. Every single component is designed for one thing: getting pizzas out the door faster and more efficiently. Understanding how all the pieces fit together is the first step in choosing a table that will turn kitchen chaos into a smooth, money-making operation.

Let's break down the essential anatomy of these specialized workhorses.

You're really looking at three core components: the cutting board, the refrigerated rail, and the refrigerated base. This trio works together to boost speed, ensure food safety, and keep your pizza line organized. Get a handle on how they interact, and you’re well on your way to building a high-performance pizzeria.

The Workspace: The Cutting Board

The cutting board is ground zero—it's the stage where every pizza starts its journey. The size and material of this board have a direct impact on how quickly your team can stretch dough, spread sauce, and build pies. The depth of the board is a huge deal; a deeper board gives you more real estate to work with, which means less flour and toppings ending up on the floor.

Choosing the right material is a big decision that comes down to durability, maintenance, and even tradition.

- Polyethylene: This is the industry standard for pizza shops, and for good reason. These tough plastic boards are non-porous, a breeze to clean, and they won't dull your knives. They resist stains and odors, making them a super practical choice for high-volume pizzerias focused on safety and speed.

- Marble: For that classic, artisan pizzeria vibe, nothing beats a marble surface. It's naturally cool, which is perfect for working with dough because it keeps it from getting sticky or overworked. The trade-off? Marble is porous, needs more TLC, and usually costs more.

Mission Control: The Refrigerated Rail

Sitting right above the cutting board is the refrigerated rail—this is your mission control for toppings. It’s where you keep your heavy hitters like pepperoni, mushrooms, cheese, and olives perfectly chilled and right at your fingertips. A well-designed rail is absolutely key to a fast, seamless pizza assembly line.

The way you arrange the pans in the rail dictates your topping capacity. Most tables use standard food pans (like 1/3-size or 1/6-size), so you can customize the layout to match your menu. Consistent temperature is non-negotiable here; the rail has to keep everything safely between 33°F and 41°F to stay on the right side of the health inspector and prevent spoilage.

A well-organized refrigerated rail is more than just cold storage; it’s an ergonomic tool. By placing your most popular pizza toppings in the most accessible spots, you can shave valuable seconds off every single pizza order, which adds up to significant gains during a busy service.

The Powerhouse: The Refrigerated Base

Underneath your workspace is the refrigerated base. This is the powerhouse that stores all your backup ingredients and, most importantly, your pizza dough. The setup of this base—whether it has doors, drawers, or a mix of both—needs to align perfectly with your kitchen’s flow.

Deciding between doors and drawers isn't just about looks; it's a strategic choice for your pizzeria.

- Doors: These are great for flexible, bulk storage. They're perfect for stashing big buckets of pizza sauce, boxes of cheese, and other oversized items that just won't fit in a drawer.

- Drawers: When it comes to organization and quick access, drawers are king. They are the ideal solution for storing pre-portioned dough balls in their own trays, letting pizzaiolos grab exactly what they need without having to dig through a packed cabinet.

For a lot of pizzerias, a hybrid model with both doors and drawers offers the best of both worlds, giving you a nice blend of organized access and bulk storage capacity.

Choosing the Right Type of Pizza Prep Table

Not all pizzerias are built the same, and your prep table should be a perfect fit for your unique kitchen. Picking the right model is a bit like choosing an engine for a vehicle; what works for a small cafe won't power a high-volume delivery operation. Let's break down the different types of pizza prep tables to help you find the ideal match for your workflow.

The decision can feel a little overwhelming, especially with the market for specialized pizza prep tables growing so fast. This segment, currently valued at USD 1.75 billion, is expected to skyrocket to USD 4.92 billion by 2033. This growth tells you one thing: these units are absolutely critical, driven by the expansion of pizza chains and customers who want customized pies delivered quickly.

Countertop and Worktop Models

For smaller operations like cafes that serve pizza, food trucks, or any pizzeria where space is at a premium, compact models are the only way to go. Countertop prep units are the ultimate space-savers. Think of them as just the refrigerated rail, designed to sit on top of an existing counter or work surface. They give you instant, easy access to chilled toppings without needing a whole new appliance.

A step up from that is the worktop refrigerator. This is a fantastic all-in-one solution that combines a smaller prep area and refrigerated rail with a refrigerated cabinet underneath. It’s a great middle-ground option, giving you both prep space and storage while still conserving that precious kitchen real estate.

Mega-Top and High-Capacity Tables

When volume is the name of the game, you need a pizza prep table built for speed and endurance. Mega-top tables are the heavy hitters in this category. They’re designed with an extra-deep refrigerated rail that often holds three rows of food pans instead of the usual two. For a busy pizzeria with a complex menu and a ton of toppings, this extra capacity is a total game-changer.

A mega-top table can increase your topping capacity by as much as 50% over standard models. This lets your team work faster without constantly stopping to restock the rail, which translates directly to more pizzas flying out the door during your busiest hours.

So, how do you choose? It comes down to taking a practical look at your business.

- Assess Your Menu: A simple menu with a few core toppings? A worktop model will probably do the trick. A gourmet pizzeria with dozens of specialty ingredients will get a huge boost from a mega-top.

- Analyze Order Volume: Look at your average and peak hourly pizza output. Your table has to keep up without becoming the bottleneck in your production line.

- Measure Your Footprint: Before you fall in love with a model, get out the tape measure. Know exactly how much space you can dedicate to your new equipment.

By thinking through these factors, you can pick a table that not only supports your current operation but also has the room to scale as you grow. For a deeper dive, check out our complete guide to commercial pizza prep tables.

Sizing Your Prep Table for Maximum Kitchen Efficiency

Picking the right size for your pizza prep table isn't like buying furniture. It's more like designing the perfect workflow for an assembly line. Your goal isn't just to make it fit; it's to create a smooth, frictionless path that prevents kitchen traffic jams right when you're slammed.

Get this wrong, and you’ll have pizzaiolos bumping elbows and tripping over each other during the Friday night dinner rush. It’s a recipe for slow ticket times and chaos.

A simple three-step process will help you nail the perfect size. First, get out the measuring tape and figure out your actual footprint. Don't forget to account for door swings and how much room your staff needs to walk by without creating a bottleneck.

Next, you need to map out the "golden triangle" of your pizzeria: the path between your prep station, the oven, and the walk-in cooler. The table has to support this flow, not obstruct it.

Calculating Your Required Topping Capacity

The final and most important step is figuring out your topping capacity based on your absolute busiest hours. A smaller 48-inch table might seem perfect for a slow Tuesday, but it would completely cripple a pizzeria pumping out a hundred pies an hour on a weekend.

You have to match the refrigerated rail's pan capacity to the number of pizzas you make at your peak. This is where you stop guessing and start making a decision based on real data. Your table's width directly translates to how many toppings you can hold, which in turn dictates how many pizzas you can actually produce per hour.

Let's break down how table size relates to real-world output.

Pizza Prep Table Size and Capacity Guide

The table below gives you a solid starting point for matching a prep table's width to your pizzeria's volume. Think of it as a cheat sheet for turning physical dimensions into production power.

| Table Width (Inches) | Refrigerated Pan Capacity (1/3 Size Pans) | Under-Counter Storage (Cubic Ft.) | Ideal For (Pizzas Per Hour) |

|---|---|---|---|

| 44" - 48" | 6 - 8 Pans | 10 - 15 cu. ft. | Small cafes or startups (< 25) |

| 60" - 72" | 8 - 10 Pans | 15 - 25 cu. ft. | Mid-volume pizzerias (25 - 50) |

| 93" - 119" | 12+ Pans | 25 - 40+ cu. ft. | High-volume operations (50+) |

Remember, these are just guidelines. If your menu is extra complex with lots of unique toppings, you might need to size up to get the pan capacity you need, even if your hourly pizza count is on the lower end.

Material Durability and Your Investment

While you're zeroed in on size and capacity, don't overlook the material of your pizza prep table. This single choice plays a massive role in its long-term value and how much you'll end up spending over the years.

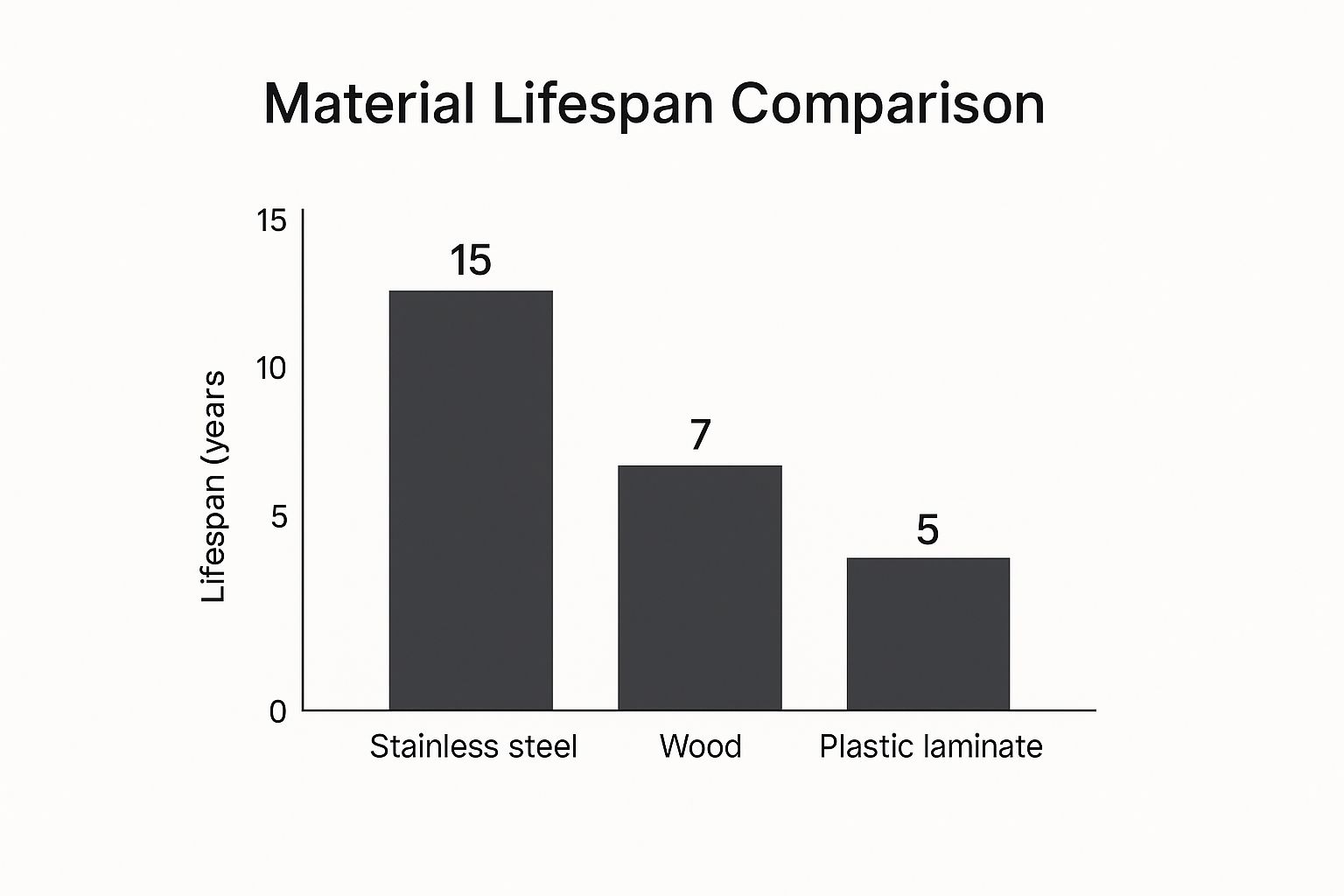

This image breaks down the average lifespan of common prep surface materials.

The data tells a clear story. Stainless steel offers a lifespan up to three times longer than something like plastic laminate, making it a much more durable and cost-effective choice for a busy pizzeria in the long run.

Thinking about sizing isn't just about what fits today. It’s about picturing your kitchen at its most hectic and giving your team the right tool to handle that pressure. A correctly sized table optimizes every square inch, turning potential chaos into a streamlined, profitable operation. When you align the physical table with the real-world demands of your pizzeria, you create an environment where your team can truly shine.

Getting Started: Installation and Upkeep

Think of your pizza prep table as a long-term investment. Just like any high-performance machine, its lifespan and reliability depend entirely on how you treat it. Getting the installation right from day one and sticking to a simple maintenance routine are the two pillars that will keep it running smoothly for years, saving you from the headache of costly downtime.

The process kicks off the second that new unit rolls off the delivery truck. Proper installation is way more than just plugging it in—it's about setting the table up for success. This means making sure you have the right electrical hookups and, crucially, giving the compressor enough space to breathe. Cramming it against a wall is a recipe for an overworked, overheated unit.

Another step people often overlook is leveling the unit perfectly. An unbalanced table can cause the doors to sag just enough to break their seal, leading to wasted energy and dangerous temperature swings.

Putting Together a Simple Maintenance Plan

Once your table is set up and humming along, a straightforward preventative maintenance schedule is your best defense against surprise repair bills. These aren't complicated chores; they're small, consistent habits that keep your equipment in peak condition.

- Daily Wipe-Down: At the end of every single shift, wipe down all stainless steel surfaces, the cutting board, and the door gaskets with a food-safe sanitizer. This simple act prevents bacteria from building up and protects the steel's finish.

- Weekly Temp Check: Grab an external thermometer and verify the temperatures in both the refrigerated rail and the base cabinet. You want to see everything holding steady in that food-safe sweet spot of 33°F to 41°F.

- Quarterly Coil Cleaning: Every 90 days, unplug the unit. Use a stiff brush or a vacuum to get all the dust, flour, and grease off the condenser coils. Honestly, this is the single most important thing you can do to maintain cooling power.

A clean condenser coil can boost a refrigerator's efficiency by as much as 30%. When you ignore this task, you're forcing the compressor to work overtime, which means higher energy bills and a much shorter life for your equipment.

While you're focused on keeping the table itself in top shape, don't forget that a healthy pizzeria depends on the whole ecosystem. This includes solid infrastructure, like reliable commercial plumbing solutions.

Maintaining your kitchen's core systems is key to preventing bigger problems that could halt your entire operation. By spending just a few minutes each day and a bit more every quarter, you're not just cleaning—you're protecting your investment and making sure your pizza line never skips a beat. If you're curious about other key pieces of gear, take a look at our overview of commercial food prep equipment.

How the Right Prep Table Shapes Your Pizzeria's Future

Choosing the right pizza prep table is way more than just another box to check on your equipment list. Think of it as a strategic investment in the future of your pizzeria. This single piece of equipment is the true cornerstone of your kitchen, and it has a direct impact on your bottom line through better efficiency, consistent food quality, and happier staff.

When your team has an organized, reliable workspace, they can assemble perfect pizzas faster, even during the most chaotic dinner rush. This isn't just about buying a piece of steel; it's about building a more resilient and profitable pizzeria that's ready for whatever comes next.

Embracing Future Trends in Kitchen Equipment

The world of kitchen equipment is always moving forward, and pizza prep tables are right there in the mix. Smart pizzeria owners are looking for models that do more than just keep toppings cold. Two major trends are really shaping the next generation of these essential units.

- Energy Efficiency: Modern prep tables are built with eco-friendly refrigerants and high-efficiency compressors. These models don't just reduce your pizzeria's carbon footprint—they can actually lower your monthly utility bills, giving you a tangible return on your investment.

- Smart Technology: Newer "smart" tables are rolling out with digital temperature monitoring and alert systems. This tech takes the guesswork out of food safety by giving you precise, real-time data, helping you dodge costly spoilage and potential health code violations.

Viewing your equipment purchase through this strategic lens ensures you are prepared for evolving customer demands and stricter regulations. A forward-thinking choice today builds a stronger foundation for growth tomorrow.

The growing emphasis on efficient, hygienic kitchen equipment is driving some serious market growth. The global market for food prep tables, currently valued at USD 1.18 billion, is projected to rocket to USD 1.62 billion by 2029. This boom highlights a worldwide trend toward optimizing kitchen operations—a movement that savvy pizzeria owners are smart to join. You can read more about this expanding market for food prep equipment on Arizton.com.

Ultimately, the right pizza prep table gives your business the power to thrive in a competitive world. To make a smart decision, you can explore a ton of options in our detailed guide on prep tables for any restaurant.

Your Top Questions About Pizza Prep Tables, Answered

Picking out and taking care of the right pizza prep tables can feel like a lot, but getting straight answers to the usual questions makes it all much simpler. This section is all about giving you quick, useful insights so you can make the best call for your pizzeria.

Here are the answers to the questions we hear most from pizzeria owners.

What's the Right Temperature for a Pizza Prep Table Rail?

You want the refrigerated rail holding all your toppings to stay between 33°F and 41°F (that’s 0.5°C to 5°C). Keeping it in this sweet spot is non-negotiable for food safety. It keeps perishable ingredients like cheese, meats, and veggies out of the temperature "danger zone" where nasty bacteria can thrive.

I always tell my clients to use a separate thermometer to double-check the rail's temperature every single day. Make it a habit, especially before the dinner rush, to ensure everything is safely chilled and ready to pass any surprise health inspection.

Should I Get Drawers or Doors for the Base?

The classic drawers vs. doors debate! The best choice really boils down to your pizzeria's rhythm and what you plan on storing down below.

- Drawers are fantastic for organization and lightning-fast access. They're perfect for stashing pre-portioned dough balls or specific types of cheese because they pull all the way out, letting your team see everything at a glance. Those saved seconds add up during a rush.

- Doors give you more flexible, open space for bulkier items. They’re the better option if you need to store big containers of pizza sauce, backup bags of cheese, or other oversized items that just won’t squeeze into a drawer.

Honestly, a lot of high-volume pizzerias find that a combination unit—one with both doors and drawers—gives them the perfect mix of grab-and-go organization and bulk storage.

A clean condenser coil is one of the most effective preventative maintenance tasks you can perform. Clogged coils force the compressor to work harder, leading to higher energy bills and a greater risk of equipment failure.

Finally, regular cleaning is the secret to a long-lasting unit. You absolutely must clean the condenser coils at least once every 90 days. If your pizzeria kitchen is constantly full of airborne flour and grease, doing it monthly is even better. It’s a simple task that keeps your prep table running like a champ.

Ready to build a more efficient and profitable pizzeria? The experts at Pizza Prep Table can help you find the perfect unit to streamline your workflow and master the dinner rush. Explore our collection of high-performance pizza prep tables today!