The Pizzeria's Guide to a Small Under The Counter Refrigerator

Share

In the heat of a dinner rush, every second is precious. For a high-speed pizza line, a small under the counter refrigerator isn't just a piece of equipment—it's your secret weapon. It transforms a scattered, chaotic prep station into a powerhouse of efficiency, keeping every topping perfectly chilled and literally within arm's reach. Think of it as a strategic investment in speed, consistency, and food safety, all built around your pizza prep table.

The Secret Ingredient to a Faster Pizza Line

Picture your pizzeria on a slammed Friday night. Your team is crisscrossing the kitchen, grabbing cheese from one cooler and pepperoni from another. Each extra step adds seconds to an order, creating bottlenecks at the pizza prep table that frustrate your crew and, even worse, your hungry customers. That disjointed workflow doesn't just kill your ticket times; it also increases the risk of ingredients sitting in the temperature danger zone for too long.

Now, imagine a different scene. A sleek, stainless steel small under the counter refrigerator is tucked neatly beneath your pizza prep table. Every essential topping—shredded mozzarella, sliced mushrooms, fresh basil—is organized and held at the perfect temperature, just inches from where the pizza is being built. Suddenly, all that wasted motion disappears.

From Chaos to Cohesion

This isn't just about saving a little space; it's about creating a powerful, ergonomic pizza prep station. When your equipment works in harmony, your entire operation flows. The journey from a freshly pressed dough to a fully topped pizza becomes one smooth, seamless process right at the prep table. That cohesion has a direct impact on your bottom line.

A well-organized station empowers your pizzaiolos to work faster and with greater precision. The benefits pile up quickly:

- Increased Order Throughput: Faster assembly at the pizza prep table means more pies fly out the door every hour.

- Enhanced Food Safety: Ingredients stay safely chilled right up until the moment they're used.

- Improved Consistency: Easy access to toppings ensures every single pizza is made to your exact standards.

- Reduced Staff Fatigue: Eliminating unnecessary steps around the kitchen keeps your team focused and energized.

This strategic placement of refrigeration is a cornerstone of an efficient pizzeria. It turns your pizza prep table from a simple counter into a high-performance production hub, directly impacting speed and profitability.

Ultimately, this essential tool is far more than just another appliance. It's a fundamental piece of a successful pizzeria's puzzle. To see how top shops design their layouts for maximum output, you can explore the secret sauce behind efficient pizza prep stations.

Figuring Out Your Undercounter Refrigerator Options

Diving into commercial refrigeration can feel like a lot, but for a pizzeria, it really just boils down to a few key choices. Think of your small under the counter refrigerator as the foundation of your pizza prep table's mise en place—that perfectly organized station that sets you up for a smooth, fast-paced service. We're going to skip the generic spec sheets and focus on what actually matters for making great pizza.

One of the biggest details is understanding how your refrigerator breathes. It's a surprisingly critical point that decides where you can put the unit and how well it will hold up under pressure. Get this wrong, and you're looking at an overheated compressor, expensive repair bills, and worst of all, spoiled pizza toppings.

Front-Breathing vs. Rear-Breathing: What's the Big Deal?

The most important thing to get right is the ventilation style. Imagine your refrigerator has to exhale the hot air it pulls from inside, just like you’d let out a breath. Where it exhales from determines its home under your pizza prep table.

- Front-Breathing Models: These units have their vents right on the front grille, usually just below the door. They pull in cool air and push out hot air from the front, which means you can slide them right between other pieces of equipment or build them in flush against a back wall. For tight pizzeria layouts where every inch under the prep table is prime real estate, these are the way to go.

- Rear-Breathing Models: These guys have their condenser coils and vents on the back. This means they need a few inches of breathing room on the back and sides to get proper airflow. They're often a bit friendlier on the wallet, but you lose a ton of placement flexibility. You absolutely can't build them in under a counter without leaving that crucial gap for air.

For any pizzeria planning to tuck a fridge directly under a pizza prep table, a front-breathing model is the non-negotiable choice. It’s the only way to ensure the compressor doesn’t burn itself out from working overtime in a stuffy, unventilated space.

Why You Can't Skip the NSF Certification

Another detail you absolutely have to look for is the NSF certification mark. NSF International is an independent group that puts commercial equipment through the wringer to make sure it meets strict public health and safety standards. In a commercial pizzeria, this isn't just a "nice to have"—it's a must.

An NSF-certified refrigerator is built for the chaos of a pizzeria. It’s made with food-safe materials, designed for easy cleaning and sanitizing, and has been proven to hold consistent, safe temperatures. In short, it has all the things a health inspector will be looking for.

Choosing a unit without that little blue stamp puts your pizzeria at risk of failing inspections. More importantly, it gambles with the safety of your ingredients and your customers. That certification is your seal of approval, telling you the unit is a quality piece of equipment that's compliant and ready for your pizza line.

The demand for these specialized compact units is a big deal in the restaurant industry. Small under-the-counter refrigerators have become a cornerstone of kitchen efficiency, with the global market projected to hit USD 16.19 million by 2035. That growth is all about pizzerias and other foodservice spots trying to maximize their workflow in cramped spaces. You can dive into more data on this commercial refrigeration market growth to see the bigger picture. It just goes to show that investing in the right unit for your pizza prep table isn't just an expense; it's a smart, forward-thinking move for your business.

Choosing the Right Size and Capacity for Your Pizzeria

Picking the right small under the counter refrigerator for your pizzeria is about way more than just plugging a hole in your pizza prep table line. It's a strategic move that has to sync up with your kitchen's rhythm, your daily output, and how your team actually works. Go too small, and you're setting yourself up for constant restocking nightmares during a dinner rush. Go too big, and you're just throwing money away on electricity and wasting precious real estate under your prep table.

The first step is always the most practical one: grab a tape measure. Get the exact height, width, and depth of the spot under your pizza prep table. But don't stop there. Remember what we said about ventilation? You have to leave room for the unit to breathe, especially if you're looking at a rear-breathing model.

From External Dimensions to Internal Volume

Once you've got your tape measure numbers, the next job is figuring out the internal capacity you need. This is measured in cubic feet, and it’s the real number that tells you how much cheese, sauce, pepperoni, and fresh veggies you can actually store. Think of it as the refrigerator's fuel tank for your busiest pizza-making shifts.

To nail this, you have to be honest about your ingredient usage on a slammed Saturday night. How many pans of mozzarella do you burn through? How many tubs of mushrooms or olives? That calculation directly tells you the cubic footage you need at your pizza prep table to get through a rush without sending someone on a frantic run to the walk-in. For a deeper look at common measurements and layouts, our guide on under counter refrigerator dimensions has detailed schematics and real-world examples.

Sizing for Your Pizzeria’s Scale

The perfect refrigerator size is directly tied to how many pizzas you're slinging every day. A cozy neighborhood joint has completely different needs than a high-volume spot pumping out hundreds of pies a night.

Let's break it down with some real-world pizzeria scenarios:

- The Cozy Neighborhood Pizzeria (Up to 75 pizzas/day): A single, compact 24-inch or 27-inch unit with around 5-7 cubic feet of space is usually plenty. This will comfortably hold all your prepped toppings for the day, keeping the essentials chilled and ready at the pizza prep table.

- The Busy Town Favorite (75-150 pizzas/day): Now we're talking more volume. You'll want to step up to a 36-inch or 48-inch model that gives you 10-13 cubic feet. This can handle the bigger ingredient load and stop your line cooks from having to restock the prep table mid-shift.

- The High-Volume Powerhouse (150+ pizzas/day): At this scale, one unit just won't cut it. The best play is often two or more 48-inch or even 60-inch units lined up under a long pizza prep table. This setup creates a true assembly line, where each fridge can be dedicated to specific ingredient groups like meats or veggies.

To help you visualize the right size for your operation, here’s a quick guide.

Undercounter Refrigerator Sizing Guide for Pizzerias

This table breaks down recommended refrigerator sizes based on your daily pizza output, making it easier to match your equipment to your business volume.

| Pizzas Per Day | Recommended Width | Estimated Capacity (Cu. Ft.) | Best For |

|---|---|---|---|

| Up to 75 | 24" - 27" | 5 - 7 | Small neighborhood shops, limited menus |

| 75 - 150 | 36" - 48" | 10 - 13 | Mid-volume pizzerias, growing businesses |

| 150+ | Two or more 48"+ | 20+ (total) | High-volume operations, extensive pizza menus |

This guide provides a solid starting point, but always factor in your specific menu and ingredient storage needs. A pizzeria with 30 specialty toppings will need more space at the prep table than one focused on the classics.

The goal is to match your refrigerator's capacity to your pizzeria's peak demand. This ensures your pizza prep table is a model of efficiency, with every ingredient perfectly chilled and always within arm's reach, never a bottleneck.

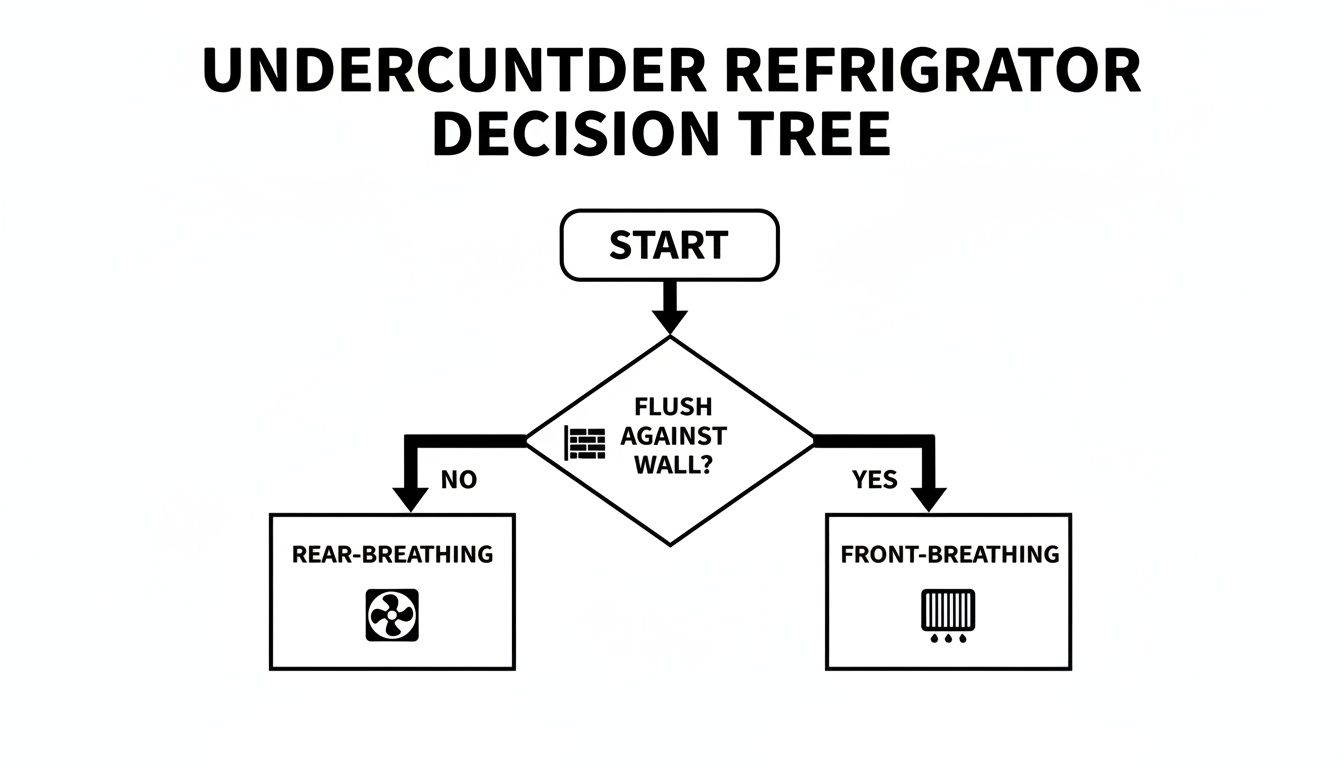

This simple decision tree helps visualize whether a front-breathing or rear-breathing model is right for your space.

As you can see, if the unit has to be pushed flush against a wall or built into your pizza prep table line, a front-breathing model is your only option. It’s the only way to guarantee proper airflow and keep the compressor from burning out. Getting the breathing configuration right is just as critical as getting the size right for your pizzeria's layout.

What to Look for in a High-Performance Pizza Station Refrigerator

Not all under-counter refrigerators are built to survive the heat and chaos of a real pizzeria. To keep your pizza line humming and your ingredients safe, you need a unit that’s basically built for battle. Choosing a small under the counter refrigerator with the right features is just as critical as picking the right oven—it has a direct impact on your pizza prep table’s speed, consistency, and profit margin.

Let's break down the specific features that actually make a difference in your day-to-day operations. This isn't about marketing fluff; it's about investing in a true workhorse for your pizza prep table. From the type of door you choose to the guts of the compressor, these details matter when you’re slammed during a dinner service.

Solid Doors vs. Glass Doors

One of the first decisions you'll make is between solid and glass doors. This is more than just a cosmetic choice; it’s a strategic one that affects both your utility bills and the workflow at your pizza prep table.

- Solid Doors: These are the undisputed champions of insulation. In a hot, hectic pizzeria kitchen where that fridge door gets yanked open dozens of times an hour, a solid door is far better at keeping the cold air inside. Better insulation means the compressor doesn't have to work as hard, which saves you money on electricity and reduces wear and tear on the unit itself.

- Glass Doors: The obvious win here is visibility. Your crew can see what’s running low at a glance without opening the door, which is handy for quick topping inventory checks at the prep table. The downside? Glass just isn't a great insulator. The unit will burn more energy to hold its temperature, especially if it's being opened constantly.

For the vast majority of high-volume pizzerias, solid doors are the smarter, more practical choice for a refrigerator under the pizza prep table. The energy savings and superior temperature stability they provide will almost always outweigh the convenience of seeing inside.

The Powerhouse Behind the Scenes: The Compressor

Think of the compressor as the heart of your refrigerator. Its job is to circulate refrigerant to pull heat out and keep everything chilled. In a pizzeria, you need a beast—a commercial-grade compressor that can take the constant abuse of a busy service.

A standard residential compressor would give up and die in this environment. Commercial compressors are engineered for rapid temperature recovery, which is the ability to get the internal temperature back down to a safe level right after the door has been opened. During a dinner rush, when your team is grabbing toppings nonstop from under the prep table, this feature is absolutely critical for food safety.

A powerful compressor ensures that even when the door is opened every 30 seconds, your cheese, pepperoni, and veggies stay safely below the 40°F (4°C) danger zone. It's your number one defense against foodborne illness and spoilage at the pizza prep table.

Flexible Shelving and Precise Temperature Control

The inside of your fridge needs to be as adaptable as your menu. Always look for a small under the counter refrigerator that comes with adjustable shelving. This flexibility is key to organizing your pizza prep table's workspace for maximum speed.

You have to fit all sorts of containers, from deep third-pans of mozzarella to shallow trays of proofed dough balls. Heavy-duty, adjustable shelves let you configure the space to perfectly match your inventory, which cuts down on wasted space and keeps everything organized for faster access.

Finally, precise temperature management is a must-have. Forget about those old analog dials with a vague "colder" setting. Any modern commercial unit worth its salt needs a digital thermostat and an external temperature display. This gives you an exact reading at a glance, allowing you to monitor and confirm your pizza toppings are held at a safe, consistent temperature. This isn't just for convenience; it's a vital tool for passing health inspections and maintaining quality control.

Seamlessly Integrating Your Refrigerator and Prep Table

A small under the counter refrigerator truly proves its worth when it stops being just another appliance and becomes a seamless extension of your pizza prep table. This isn't just about cramming more equipment into a tight space; it's a strategic move that can completely rewire your pizzeria's speed and rhythm. A properly integrated refrigerator is the bedrock of a high-octane pizza line.

The real goal here is to create an ergonomic ballet where every single movement is deliberate and productive. When you place the unit directly beneath your pizza prep table, you eliminate those wasted trips to a reach-in cooler, shaving precious seconds off every single pizza build. This setup also keeps your ingredients perfectly chilled right up until the moment they land on the dough, which is crucial for minimizing their time in the temperature danger zone.

Crafting the Pizzaiolo's Golden Triangle

In the world of professional kitchens, efficiency is often built around a "work triangle" that connects key stations to cut down on wasted steps. For a pizzeria, we call this the "Pizzaiolo's Golden Triangle"—an ergonomic layout linking the three most critical points: dough, toppings, and the oven. Your under-counter refrigerator sits at the very heart of this system, right under the pizza prep table.

Think of your pizzaiolo as a pilot in a cockpit. Everything they need should be within a quick pivot or a single step.

- Station 1 Dough: The spot where dough is stretched and sauced.

- Station 2 Toppings: Your pizza prep table, with all the refrigerated ingredients directly underneath.

- Station 3 Oven: The final destination for the fully built pizza.

When these three stations are just a step or two apart, your pizzaiolo can crank out orders with incredible speed and very little physical effort. The under-counter refrigerator becomes their chilled pantry at the prep table, ensuring the whole process flows without a single hitch. This smooth, uninterrupted system is what leads to faster ticket times and happier customers during your busiest rushes.

Designing the Ultimate Pizza Prep Station

Getting to this level of efficiency doesn’t happen by accident; it takes careful planning. To really squeeze every bit of performance out of your pizza station, it helps to understand the fundamental principles of effective space planning. This is about more than just placing equipment—it's about choreographing your team's movements around the pizza prep table for peak performance.

Think about how your staff will actually use the space. The idea is to create a self-contained station where they can build a pizza from start to finish without ever needing to walk away for ingredients. This means your under-counter fridge should be organized to mirror the pizza-making process. For example, your most popular items like cheese and pepperoni should be in the most accessible drawers or shelves.

When you design your pizza prep table station with workflow in mind, you stop thinking about individual pieces of equipment and start seeing a single, high-speed production system. This is where your investment in a quality refrigerator really pays dividends in both speed and consistency.

Beyond Refrigeration: The Role of a Chef Base

For kitchens that demand even tighter integration, a refrigerated chef base is the next logical step. These heavy-duty units combine the cooling power of a small under the counter refrigerator with a reinforced, heat-resistant top designed to hold countertop cooking equipment like griddles or salamanders.

While less common for a standard pizza topping station, they are an absolute game-changer for sauté stations where hot and cold prep needs to happen in the exact same spot. If you want to dive deeper into how these specialized units work, check out our guide on the versatility of a refrigerated chef base. This approach is the ultimate expression of kitchen efficiency, putting cold storage directly under the heat of the action.

Getting Set Up and Keeping It Running for the Long Haul

Think of your new small under the counter refrigerator as a key player on your pizzeria team. A proper setup and a little routine care will ensure it works hard for you for years. Rushing the installation or ignoring maintenance is a surefire way to burn out a compressor, spoil expensive ingredients, and face a costly emergency repair right in the middle of a dinner rush.

Getting it right from day one is everything. Placement isn't just about making it fit under your pizza prep table; it's about giving the unit the breathing room it needs to, well, breathe. Choking off the airflow is the single fastest way to kill a commercial refrigerator.

Setting Up for Success

Before you even think about plugging it in, take a few minutes to run through a quick setup checklist. This small step can save you thousands of dollars in repairs and lost product down the line, ensuring your unit stays cool and efficient even when the pizzeria is chaotic.

- Give It Some Space: Check the manufacturer's spec sheet. A rear-breathing model needs a few inches of clearance at the back and sides for air to circulate. A front-breathing unit needs its front grille to be completely clear of obstructions—no boxes, no trash cans, nothing blocking the airflow under your prep table.

- Keep It Level: An off-kilter fridge can prevent the doors from sealing correctly. This tiny gap forces the compressor to work overtime just to keep things cold. Use a level and adjust the feet until it’s rock solid.

- Use a Dedicated Circuit: Commercial fridges are power-hungry. Always plug your unit into its own dedicated circuit to avoid tripping breakers or, worse, creating a fire hazard.

You’d be surprised how often we see a rear-breathing unit shoved flush against a wall to save a few inches of floor space. This traps hot air, forcing the compressor to run non-stop until it gives out. It's a simple mistake that can literally cut the life of your refrigerator in half.

A Simple Maintenance Routine That Actually Works

Once it’s installed, a consistent maintenance schedule is your best defense against unexpected breakdowns. This isn't about complicated, time-consuming tasks. It's about a simple, repeatable routine that keeps your unit running like a champ, lowers your energy bills, and protects your precious pizza toppings. A few simple fridge maintenance tips can go a long way in ensuring its longevity.

A proactive approach breaks down into daily, weekly, and monthly tasks your whole team can easily manage.

Your Pizzeria's Maintenance Checklist

| Frequency | Task | Why It Matters |

|---|---|---|

| Daily | Wipe Down Door Gaskets | Prevents sticky grime from building up, ensuring a tight seal that keeps cold air in. |

| Weekly | Clean Interior Shelves and Surfaces | Gets rid of spills and crumbs, preventing cross-contamination and keeping your toppings sanitary. |

| Monthly | Clean Condenser Coils | Flour and grease dust are magnets for these coils. Cleaning them helps the unit shed heat efficiently. |

| Monthly | Check and Calibrate Thermostat | Verifies your cheese, pepperoni, and sauces are held safely at or below that critical 40°F (4°C) mark. |

Following this schedule turns maintenance from a chore into a powerful habit. Just keeping the condenser coil clean can boost your unit's energy efficiency by up to 30%. This simple upkeep doesn't just extend the life of your small under the counter refrigerator—it directly helps you run a safer, more profitable pizzeria.

Your Questions, Answered

Jumping into commercial refrigeration can feel like learning a new language. Let's cut through the noise and get straight to the real-world answers pizzeria owners like you are looking for when it comes to picking the right small under the counter refrigerator for their pizza prep tables.

Can I Use a Residential Refrigerator in My Pizzeria?

Absolutely not. I know it's tempting to try and save a few bucks upfront, but putting a home fridge in a commercial pizzeria kitchen is a guaranteed recipe for failure. They simply aren't built to keep up with the constant door openings and high heat of a busy pizza line.

A commercial small under the counter refrigerator has a powerhouse compressor designed to bounce back to a safe temperature in seconds. More importantly, they are NSF-certified, which is a non-negotiable for most health departments. It’s your proof that the unit is safe, built to last, and easy to keep sanitary for your pizza prep.

How Much Clearance Does It Need?

This all boils down to one thing: how the unit breathes. A front-breathing model is the hero of tight spaces. It pulls in and pushes out air right through the front grille, which means you can build it in flush with zero clearance needed on the sides or back. It's the perfect choice to slide right into a custom pizza prep table line.

A rear-breathing unit, on the other hand, needs room to exhale. You have to leave several inches of open space at the back and on the sides for air to circulate properly. Choking off that airflow will fry the compressor, and that's a costly mistake.

Always, always check the manufacturer’s spec sheet before you install anything. Forgetting to leave proper clearance for a rear-breathing model is one of the most common—and expensive—rookie mistakes I see pizzeria owners make.

What Is the Ideal Temperature for Pizza Toppings?

For food safety, there's no wiggle room here: all your refrigerated toppings—cheese, meats, prepped veggies—have to be held at or below 40°F (4°C). This is the magic number that stops harmful bacteria from growing.

A good commercial unit with a digital thermostat and an easy-to-read external display makes this a piece of cake. You can see the temperature at your pizza prep table at a glance, keeping your food safe and ensuring you’ll always ace your health inspections.

How Often Should I Clean the Condenser Coils?

In a real-world pizzeria, with flour dust and grease in the air, you need to be cleaning your condenser coils at least once a month. Think of these coils like the radiator in your car; they get rid of the heat.

When they get clogged with grime, the compressor has to work overtime, which drives up your energy bill and dramatically increases the risk of a breakdown. A quick monthly cleaning with a stiff brush is probably the single best piece of preventative maintenance you can do for the refrigerator under your pizza prep table.

At Pizza Prep Table, we live and breathe the high-performance refrigeration that pizzerias need to succeed. Take a look at our full lineup of NSF-certified undercounter refrigerators and complete pizza prep tables, all designed for the real-world demands of a busy kitchen.